The Basics of X-Ray Inspection in Food Manufacturing

X-ray food inspection offers non-invasive quality control, identifying contaminants by analyzing density differences in a product. This technology addresses a significant risk, as foreign objects caused 11.4% of US food recalls between 2020 and 2024. Consequently, the global market for x ray inspection for food industry reached an estimated $2.3 billion in 2023, reflecting its essential role.

How X-Ray Inspection Works and What It Detects

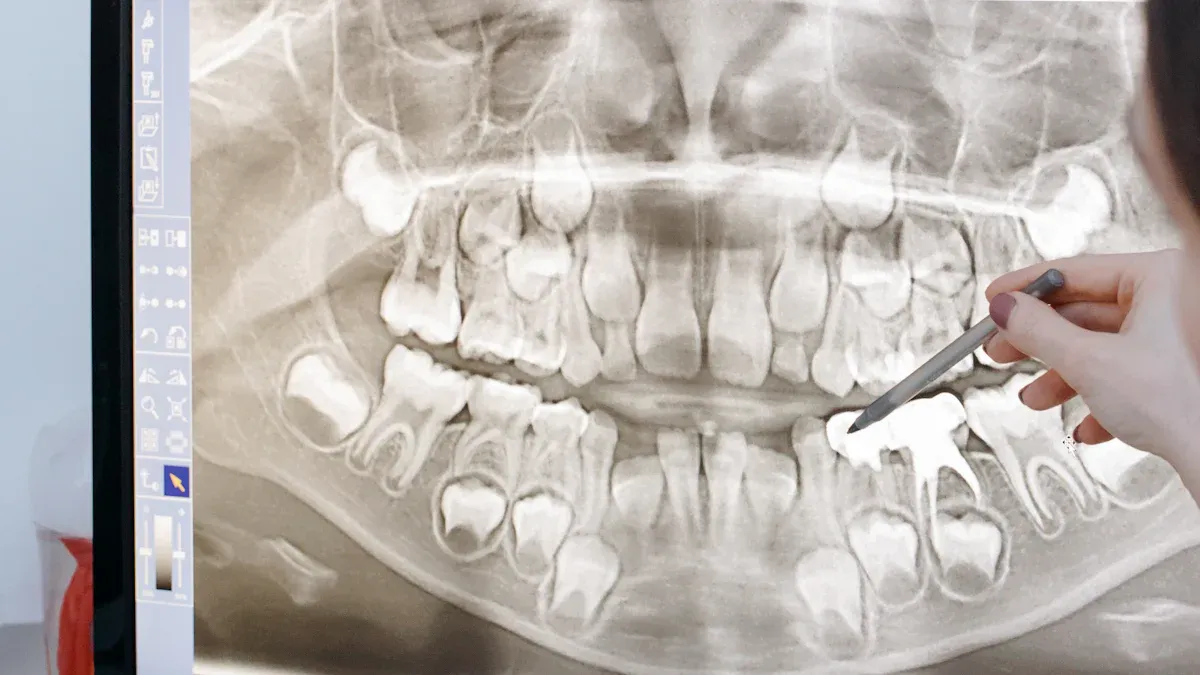

An X-ray inspection system functions by passing a product through a low-energy X-ray beam. A detector on the opposite side captures the X-rays that pass through, generating a grayscale image. The system's software then analyzes this image to identify anomalies, providing a powerful tool for quality assurance.

The Core Principle of Density Detection

X-ray inspection operates on a simple principle: density. Every material absorbs a certain amount of X-ray energy. Denser materials absorb more energy, while less dense materials allow more to pass through. This difference creates contrast in the X-ray image. Contaminants like metal or glass are much denser than most food products. They appear as darker spots on the image, making them easy to identify.

Food products themselves have varying densities. Understanding these values is key to calibrating an inspection system effectively.

| Food Product Category | Example Foods | Density (g/cm³) |

|---|---|---|

| Whole grains | Whole grain bread | 0.65 |

| Refined grains and baked goods | White bread | 0.62 |

The system uses these density differences to distinguish a potential foreign object from the product it is inspecting.

From Image Analysis to Automated Rejection

Creating an image is only the first step. Advanced software algorithms interpret the image in milliseconds to make a decision.

- Grayscale Contrast algorithms differentiate materials based on their density, visualizing internal structures and highlighting foreign objects like bone fragments in fish.

- Edge Detection & Pattern Recognition analyze a product's shape and contours. These algorithms can spot irregular shapes, find missing components, and compare a product against a pre-programmed standard.

- Deep Learning & AI Integration represent the cutting edge of analysis. Convolutional Neural Network (CNN) algorithms like YOLO, Inception, and Xception enable near real-time assessment. These AI-powered systems learn from vast datasets to recognize complex patterns, adapt to product variations, and reduce false rejections over time.

When the software detects a contaminant or defect, it sends a signal to an automated rejection mechanism. This system physically removes the non-conforming product from the production line. High-speed systems are remarkably efficient. Some machines, like those for cheese blocks, can operate at 150 items per minute, while other high-speed food inspection systems scan thousands of items per minute, ensuring contaminated products never reach the consumer.

Contaminants X-Rays Can Find

The effectiveness of an x ray inspection for food industry depends on the contaminant's density relative to the food product. Denser contaminants are easier to find. Systems can reliably detect:

- Metal: All types of metal, including ferrous, non-ferrous, and stainless steel, are easily detected due to their high density.

- Glass: Glass is significantly denser than most foods. Soda-lime glass, which accounts for 90% of glass in regular use, is particularly detectable. Manufacturers often use Type P or Type M soda-lime glass for challenge testing to ensure their systems can find real-world glass shards.

- Calcified Bone: Dense, calcified bone fragments are readily identifiable. Systems can detect chicken bone fragments as small as 1 mm. The detectability varies based on the bone's calcification level.

| Bone Type | Calcification Level (HU) |

|---|---|

| Chicken (average) | 400-450 HU |

| Chicken (soft-bone/cartilage) | 100-250 HU |

| Chicken (larger, more calcified) | Up to 1000 HU |

| Pork | 600-1000 HU or beyond |

- High-Density Plastics and Rubber: While many plastics are problematic, some can be found.

Certain plastics and rubbers with inorganic filler or other compounds which are reactive to x-rays such as chlorine, bromine or fluorine will have a higher probability of detection.

Contaminants X-Rays Cannot Find

X-ray inspection is not a silver bullet. Its reliance on density means it cannot detect everything.

- Low-Density Plastics: Materials like polyethylene (PET, LDPE) have densities very close to water (1.00 g/cm³). Since many food products are also water-based, there is not enough density difference for the system to create sufficient image contrast. This makes reliable detection of thin plastic films or soft plastics very difficult.

- Organic Contaminants: Low-density organic materials often blend in with the food product. Common examples include:

- Wood, paper, and cardboard

- Hair and insects

- Soft bones or cartilage

For these low-density contaminants, manufacturers often use complementary technologies. Optical sorters use cameras and lights to detect foreign material based on color and shape, while metal detectors specialize in finding metallic objects.

Beyond Contaminants: Advanced Quality Checks

Modern X-ray systems do more than just find foreign objects. They serve as multi-functional quality control stations. The comprehensive nature of x ray inspection for food industry allows manufacturers to perform several other critical checks simultaneously.

- Mass Measurement: The system can analyze the total X-ray absorption to calculate the product's overall mass, flagging overweight or underweight items.

- Fill Level Verification: For bottled or canned goods, X-rays can "see" through the container to verify the fill level. Companies like The Absolut Company and Unilever Canada use X-ray machines to ensure every bottle of vodka or jar of mayonnaise is filled correctly, preventing underfills that disappoint customers and overfills that waste product.

- Component Verification: In multi-pack products, an X-ray system confirms all components are present. It can spot a missing sausage in a pack, verify the correct number of items in a snack bag, or ensure a promotional item is included in a package.

Safety in X Ray Inspection for the Food Industry

While X-ray technology is powerful, its use in food production raises important safety questions for both the product and the people operating the equipment. Manufacturers address these concerns through rigorous standards and advanced machine design.

Ensuring Food Safety and Quality

A primary question is whether X-rayed food is safe for consumption. Extensive research confirms that it is. Systematic reviews of current studies, including one from a researcher affiliated with Iran's FDA, show that the low energy levels used in inspection do not harm the nutritional value or safety of food. The food does not become radioactive and is completely safe to eat.

Furthermore, the use of x ray inspection for food industry is a key component of modern food safety plans. Global standards require robust hazard control systems.

- BRCGS (British Retail Consortium Global Standards)

- SQF (Safe Quality Food)

- IFS (International Featured Standards)

These programs, benchmarked by the Global Food Safety Initiative (GFSI), recognize X-ray systems as a critical preventive measure for detecting physical contaminants.

Guaranteeing Operator Safety

Protecting machine operators is paramount. Modern X-ray systems are fully enclosed cabinets with multiple safety features.

These systems include lead-lined curtains to contain emissions, safety interlocks that shut down the X-ray generator if a panel is opened, and clearly accessible emergency stops.

Employers must also comply with government regulations, such as OSHA's standard for ionizing radiation (29 CFR 1910.1096). This requires them to monitor exposure levels, post clear caution signs, and provide comprehensive training. Specialized courses, like Radiation Safety Officer (RSO) training, ensure personnel understand all safety procedures and regulatory requirements, creating a secure work environment.

X-ray inspection is a fundamental technology for modern food safety, protecting consumers and safeguarding brand reputation, a strategy proven by companies like St. Clair Foods. The x ray inspection for food industry enhances quality control with checks for mass and fill levels. Implementation is a critical investment for manufacturers.

Financial Insight: Most operations see a full return on investment within a 12-36 month payback period.

FAQ

What is the difference between an X-ray system and a metal detector?

X-ray systems and metal detectors serve different functions.

- X-Ray Systems: Detect contaminants based on density, finding metal, glass, and bone.

- Metal Detectors: Identify only metallic objects using electromagnetic fields.

Are X-ray inspection systems a good investment?

Yes, they provide a strong return on investment.

Most operations see a full return within 12 to 36 months. They prevent costly recalls, reduce product waste, and protect brand reputation.

What types of food can X-ray systems inspect?

X-ray technology is highly versatile. Systems inspect a wide range of products, including raw ingredients, bulk solids, liquids, and fully packaged retail goods.

See Also

Discovering Premier Chinese Suppliers for Advanced X-Ray Inspection Technology

Essential Industrial Checkweighers: A Trio for Optimal Food Production

Understanding Pharmaceutical Checkweighers: Key Features and Core Functions

Hygienic Design: Comparing EHEDG Guidelines with 3A SSI Standards

Ensuring Safety: Best Practices for Storing Nitric Acid Securely