Why Your Extrusion Line Needs the X-10 Vacuum Pump

The X-10 Single Stage Rotary Vane Vacuum Pump provides the definitive solution to costly extrusion defects like voids and bubbles. It delivers consistent, powerful vacuum for superior degassing. This directly improves product quality and profitability. Businesses can finally stop wasting material and losing money on rejects caused by poor vacuum performance.

How Inefficient Vacuum Sabotages Your Extrusion Quality

Poor vacuum performance directly harms your final product and your profits. An unstable or weak vacuum fails to properly degas the molten polymer. This failure leaves behind trapped air, moisture, and other volatile materials. These contaminants expand during extrusion, creating flaws that ruin product quality and compromise structural integrity. The result is a production line that consistently generates unacceptable parts, undermining operational efficiency and profitability.

The High Cost of Common Defects

Defects caused by inadequate vacuum are not just cosmetic issues; they represent significant financial losses for a business. Every flawed product translates into direct and indirect costs that impact the bottom line. These costs include:

- Increased material scrap and waste from rejected parts.

- Lost production time due to line stoppages and re-runs.

- Higher labor costs for sorting and handling defective products.

- Potential damage to the company's reputation for quality.

- Reduced product strength, leading to field failures and warranty claims.

Why Standard Vacuum Systems Fail

Many extrusion lines operate with standard vacuum systems that are ill-equipped for the demanding environment. These pumps often struggle to deliver the consistent, deep vacuum necessary for complete degassing. Their performance can fluctuate, especially during continuous, high-temperature operation.

Note: When a vacuum pump's performance is inconsistent, it cannot reliably remove all trapped gases. This partial degassing is the root cause of bubbles and voids. The system may seem to be working, but it is actively allowing defects to form in the final product.

Standard systems often cannot handle the vapor loads generated during extrusion. This limitation causes them to lose suction power over time. Manufacturers are left with a system that fails precisely when peak performance is most critical.

The X-10 Single Stage Rotary Vane Vacuum Pump: Engineered for Peak Performance

Where standard systems falter, the X-10 excels. Joysun Machinery engineered this pump specifically to overcome the challenges of modern extrusion. Its design provides the power, consistency, and durability needed to eliminate vacuum-related defects. The pump delivers a definitive solution for manufacturers seeking higher quality and greater operational efficiency.

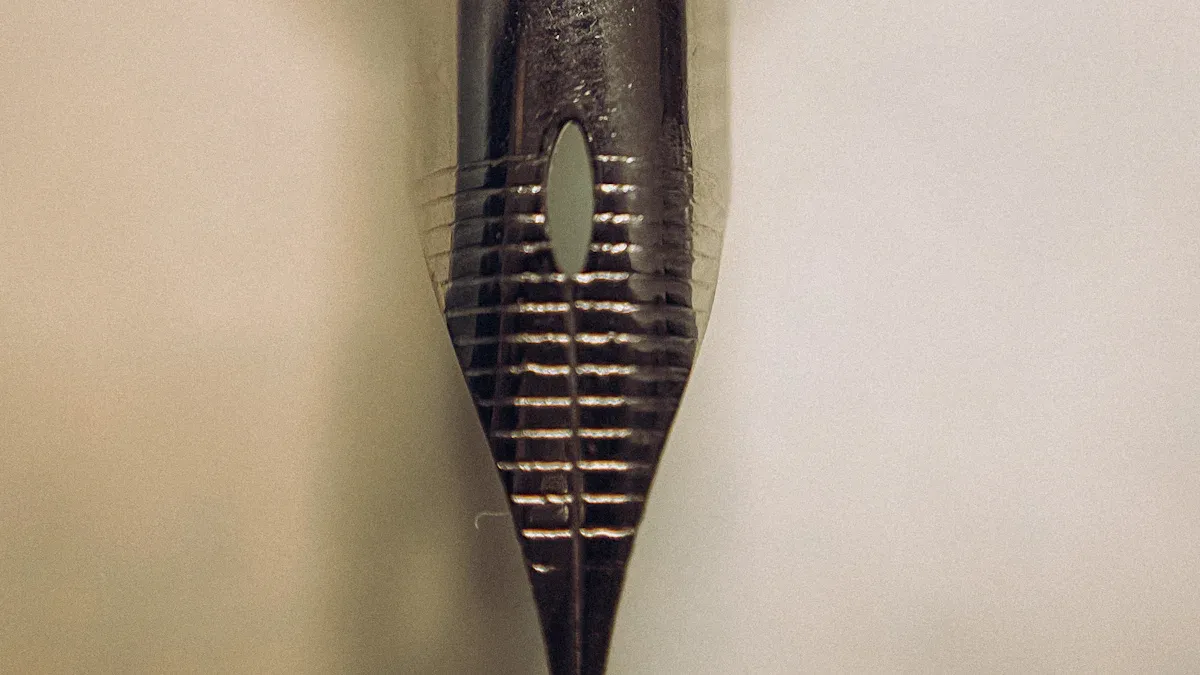

Achieve Flawless Products with Consistent Vacuum

The X-10 Single Stage Rotary Vane Vacuum Pump provides the deep, stable vacuum required for complete polymer degassing. It achieves an impressive utmost pressure between 0.1 and 0.5 mbar. This powerful suction removes trapped moisture, air, and other volatiles from the melt before they can form defects. The result is a consistently flawless product, free from voids and surface imperfections.

How Deep Vacuum Creates Quality: A deep and consistent vacuum ensures that all volatile contaminants are boiled off and evacuated from the polymer melt. The X-10's powerful performance guarantees this process is thorough, leaving behind pure material ready for extrusion. This directly prevents the formation of bubbles and structural weaknesses.

With a rated speed of 10 cubic meters per hour, the pump evacuates the degassing chamber quickly and maintains vacuum levels without fluctuation. This reliability translates directly to a smoother, more uniform product finish and superior structural integrity, run after run.

Built for Tough Extrusion Environments

Extrusion lines are demanding environments with high heat and long operational hours. The X-10 is built to thrive under these conditions. It is designed for continuous operation and maintains a stable work temperature of 81℃, ensuring it performs reliably without overheating.

A key advantage is its ability to manage process byproducts. The pump effectively handles vapor loads with a permitted pressure up to 40 mbar. This capability prevents the loss of suction that plagues lesser systems, guaranteeing consistent degassing performance over extended periods. Its robust engineering ensures long-term durability and minimal downtime.

- Continuous Operation: Designed to run nonstop without performance degradation.

- Temperature Stability: Maintains a consistent internal temperature for reliable function.

- Vapor Tolerance: Expertly manages vapors generated during extrusion, protecting vacuum performance.

- Low Maintenance: An oil consumption rate of just 0.5 liters reduces upkeep requirements and costs.

Boost Your Bottom Line with the X-10

Upgrading to the X-10 Single Stage Rotary Vane Vacuum Pump delivers a direct and measurable return on investment. By eliminating the root cause of vacuum-related defects, it tackles major sources of financial loss. The pump transforms a problematic process into a highly efficient and profitable operation.

| Common Problem | The X-10 Solution |

|---|---|

| High Material Scrap | 📉 Drastically reduces rejected parts, saving material costs. |

| Lost Production Time | ⏱️ Increases line uptime with reliable, continuous performance. |

| High Labor Costs | 🧑🔧 Minimizes the need for sorting defects and handling waste. |

| Product Failures | ✅ Improves product strength and eliminates structural voids. |

Furthermore, the pump operates with an energy-efficient 0.37 kW motor. This low power consumption, combined with its minimal maintenance needs, lowers overall operating expenses. The X-10 is not just a piece of equipment; it is a strategic tool for reducing waste, improving quality, and increasing profitability.

The X-10 Single Stage Rotary Vane Vacuum Pump is a necessity for extrusion lines aiming for higher quality and greater profitability. Upgrading eliminates the root cause of common defects. This change reduces waste and boosts operational efficiency.

Contact our specialists at Joysun Machinery today to request a quote and permanently solve your extrusion vacuum issues.

FAQ

How does the X-10 integrate with an existing extrusion line?

The X-10 features a standard Rp3/4” inlet for easy connection. Its compact, lightweight design allows for flexible placement, making integration into current setups simple and efficient.

What is the operational noise level of the X-10 pump?

The pump operates at a low noise level of just 61 dB(A). This feature helps create a quieter and more comfortable production environment for operators.

Is the X-10 compatible with different power supplies?

Yes. Joysun Machinery offers the X-10 in both three-phase and single-phase models. This ensures the pump meets the specific power requirements of your facility.

See Also

Unlock Optimal Performance: 5 Key Uses for Rotary Vane Vacuum Pumps

Understanding Rotary Vane Vacuum Pumps: Functionality and Operational Principles Explained

Automatic UV Coaters: Indispensable for Achieving High-Speed Printing Excellence

Evaluating Automated Virus Sampling Tube Assembly Lines: A Smart Investment?

Top 6 Industrial Vacuum Cleaners: Essential Equipment for Every Business