WT20 thoriated tungsten electrode facts that make TIG welding better

You want better TIG welding results. The WT20 thoriated tungsten electrode helps you achieve cleaner welds and longer tool life. Check out the main benefits:

| Feature | Advantage |

|---|---|

| Lifespan | Long, low burn-off |

| Contamination | High resistance |

| Load Handling | Handles excessive currents easily |

WT20 thoriated tungsten electrode benefits and selection

Unique properties and advantages

You get several unique benefits when you use a WT20 thoriated tungsten electrode for TIG welding. This electrode stands out because it contains 2% thorium oxide. The addition of thorium gives you a stronger, more reliable arc and a longer-lasting electrode. You will notice that the WT20 thoriated tungsten electrode carries about 20% more current than pure tungsten. This means you can weld thicker materials or use higher amperage without damaging the electrode.

- You start the arc easily and keep it stable during welding.

- You see less contamination in your welds, which leads to cleaner results.

- The electrode keeps a sharp tip, which helps you make precise welds on steel.

Tip: If you want a steady arc and less downtime for electrode changes, choose WT20 thoriated tungsten electrodes.

Here is a quick look at how thorium oxide improves performance:

| Characteristic | Description |

|---|---|

| Arc Initiation | Easy arc initiation |

| Arc Stability | Stable arc |

| Service Life | Long service life |

| Conductivity | Better conductivity |

| Current Load | High current load |

| Mechanical Performance | Good mechanical cutting performance |

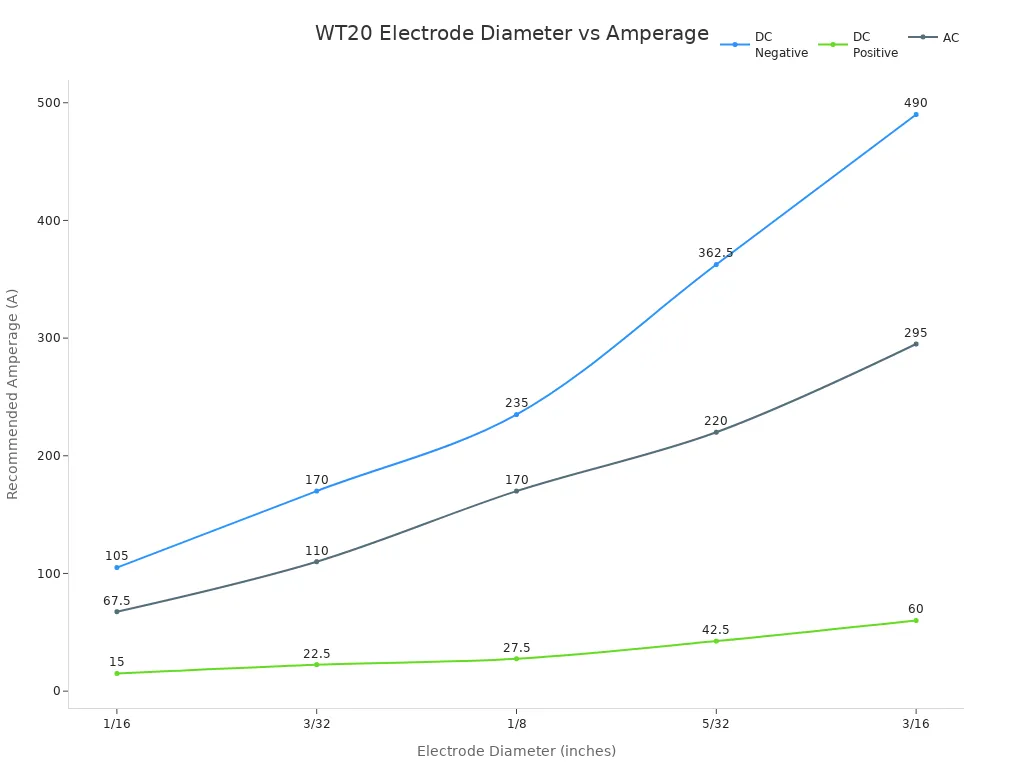

Choosing the right diameter and amperage

Selecting the correct diameter for your WT20 thoriated tungsten electrode is important. The right size helps you match the electrode to your welding current and the thickness of the metal. If you use an electrode that is too small, it may overheat or melt. If you use one that is too large, you may have trouble starting the arc or making a neat weld bead.

Here is a table to help you choose the right diameter for your amperage range:

| Electrode Diameter (Inches) | Amperage Range (DC Negative) | Amperage Range (DC Positive) | Amperage Range (AC) |

|---|---|---|---|

| 1/16 | 60 - 150 | 10 - 20 | 45 - 90 |

| 3/32 | 120 - 220 | 15 - 30 | 80 - 140 |

| 1/8 | 160 - 310 | 20 - 35 | 150 - 190 |

| 5/32 | 275 - 450 | 35 - 50 | 180 - 260 |

| 3/16 | 380 - 600 | 50 - 70 | 240 - 350 |

Note: Use a 1/16 inch electrode for low currents and thin materials. Use a 1/8 inch electrode for high currents and thicker metals. The right match gives you better weld penetration and a smoother bead.

Best applications and compatible metals

You get the best results with a WT20 thoriated tungsten electrode when you use it for DC welding, especially on stainless steel. This electrode works well for carbon steel and nickel alloys too. You should avoid using it for AC welding on aluminum, because it does not perform as well as other types.

- WT20 thoriated tungsten electrodes are effective for DC welding of stainless steel.

- You get poor results if you use them for AC welding, which is needed for aluminum.

- Choose these electrodes for jobs that need a sharp tip and a stable arc, like welding steel pipes or making precise welds on thin stainless sheets.

Alert: Always match your electrode type to the metal and welding current. This helps you get strong, clean welds every time.

How to use WT20 thoriated tungsten electrode safely and effectively

Grinding and shaping the electrode tip

You need to prepare the tip of your WT20 thoriated tungsten electrode before you start welding. A sharp and properly shaped tip helps you get a stable arc and clean welds. Use a dedicated tungsten grinder or a fine-grit grinding wheel. Always grind the electrode lengthwise, not sideways. This method keeps the grain structure straight and helps the arc stay focused.

When you grind the electrode, avoid touching it with your hands or other metals. This step prevents contamination. WT20 thoriated tungsten electrodes resist contamination better than other types, but you still want to keep the tip as clean as possible.

- You get a sharper arc and less wandering when you shape the tip to a point for DC welding.

- For AC welding, a slightly rounded tip works better, but WT20 thoriated tungsten electrodes are not the best choice for aluminum.

Tip: Always use a separate grinding wheel for tungsten electrodes. This habit keeps your electrode free from unwanted materials.

Installation and machine settings

After you shape the tip, install the WT20 thoriated tungsten electrode into your TIG torch. Make sure the electrode sticks out about 1/8 to 1/4 inch from the cup. Tighten the collet to hold the electrode firmly in place.

You must set your TIG welder to the right amperage and voltage for the metal and thickness you plan to weld. The table below shows recommended machine settings for different materials and thicknesses:

| Metal | Thickness (mm) | Amperage (A) | Voltage (V) | Weld Speed (cm/min) |

|---|---|---|---|---|

| Aluminum | 0.8 - 1.6 | 20 - 40 | 10 - 14 | 50 - 80 |

| Aluminum | 1.6 - 3.2 | 40 - 80 | 14 - 18 | 30 - 50 |

| Aluminum | 3.2 - 6.4 | 60 - 100 | 14 - 18 | 20 - 30 |

| Stainless Steel | 0.8 - 1.6 | 20 - 40 | 10 - 14 | 50 - 80 |

| Stainless Steel | 1.6 - 3.2 | 40 - 60 | 14 - 18 | 30 - 50 |

| Stainless Steel | 3.2 - 6.4 | 60 - 80 | 14 - 18 | 20 - 30 |

| Steel | 0.8 - 1.6 | 20 - 40 | 10 - 14 | 50 - 80 |

| Steel | 1.6 - 3.2 | 40 - 60 | 14 - 18 | 30 - 50 |

| Steel | 3.2 - 6.4 | 60 - 80 | 14 - 18 | 20 - 30 |

You should always check your machine’s manual for more details. Adjust the settings based on your welding position and the type of joint.

Note: Using the correct settings helps you get a smooth weld bead and prevents the electrode from overheating.

Safety precautions and proper disposal

You must protect yourself when working with WT20 thoriated tungsten electrodes. Grinding these electrodes creates dust that contains thorium oxide. Inhaling this dust is dangerous because thorium is radioactive. Exposure can harm your lungs and increase health risks.

Follow these safety steps every time you grind or handle the electrode:

- Wear a dust mask or respirator.

- Use gloves to avoid direct contact.

- Work in a well-ventilated area or use a local exhaust system.

- Clean up dust with a vacuum that has a HEPA filter.

When you finish using a WT20 thoriated tungsten electrode, dispose of it properly. You do not need special registration or authorization to buy or throw away these electrodes. However, you must follow your workplace rules and the Ionising Radiations Regulations. Always ask your employer for permission before using or disposing of thoriated electrodes.

⚠️ Alert: Never grind WT20 thoriated tungsten electrodes in open areas. Always use safety gear and follow local guidelines for handling radioactive materials.

You can achieve cleaner welds and longer electrode life with WT20 thoriated tungsten electrodes. Many welders praise their durability and arc stability:

| Reviewer | Feedback |

|---|---|

| Bob Hughes | The tungsten stays sharp longer than expected and is excellent for daily use. |

| Lou Gray | Stable arc with each use! Good for high-current tasks. |

Apply these tips to improve your TIG welding results.

See Also

Assessing Molybdenum Plugs in Steel Pipe Manufacturing for 2025

Unexpected Methods for Diagnosing Sulfur Recovery Catalysts

Do TDC Residential Door Hinges Provide Good Value?