Why a 2025 rice seeds optical sorter is a smart investment

An investment in a 2025 rice seeds optical sorter directly boosts profitability. It increases premium-grade rice yield. The technology also minimizes costly product loss. It significantly cuts operational expenses like manual labor. This modern equipment leads to a rapid and substantial return on investment for any rice mill.

Global Rice Market Outlook The global rice market demonstrates steady growth, underscoring the need for competitive technology.

Metric Value Market Size in 2024 US$ 305.14 billion Projected Market Size in 2033 US$ 378.41 billion CAGR (2025-2033) 2.42%

How a Rice Seeds Optical Sorter Maximizes Revenue and Yield

A 2025 optical sorter is an engine for revenue generation. It achieves this by elevating product quality to command premium prices and by maximizing the amount of sellable product from every batch. This dual approach directly enhances a rice mill's top-line financial performance.

Command Higher Prices with Superior Quality

Modern consumers and B2B buyers associate rice quality with specific intrinsic attributes. These include grain color, cleanliness, purity, and uniformity. A product free from imperfections signals higher value, allowing mills to access premium markets and increase profit margins. A 2025 rice seeds optical sorter uses advanced technology to achieve this level of purity with unmatched precision.

The latest sorters integrate artificial intelligence and machine learning to identify and remove a wide range of defects.

- Discolored grains (e.g., extremely light yellow)

- Chalky, broken, or black-tipped grains

- Foreign materials like glass and stone

- Diseased or mildewy rice

Note: Meeting Global Standards By removing contaminants and imperfect grains, mills can more easily comply with international food safety standards like ISO 22000 and FSSC 22000. This certification signals reliability to buyers, reduces the risk of sourcing inferior products, and justifies premium pricing in a competitive global market.

The technological leap in 2025 models is significant. Advanced imaging sensors, including hyperspectral and near-infrared (NIR) scanners, analyze attributes beyond what the human eye can see. These systems achieve rejection accuracies exceeding 99.9% and can spot imperfections as small as 0.05mm. This capability ensures that every bag of rice consistently meets the highest quality expectations, building brand reputation and consumer trust.

Increase Sellable Yield from Every Ton

Maximizing revenue is not just about price; it is also about volume. Every grain of rice that is unnecessarily discarded represents lost profit. A modern rice seeds optical sorter is engineered to minimize this loss, thereby increasing the total sellable yield from each ton of raw product.

The exceptional accuracy of AI-driven sorting prevents good grains from being mistakenly ejected along with defects. Older systems often had a higher "false positive" rate, leading to significant good-in-bad waste. With sub-10 millisecond decision latency, 2025 sorters make faster, more precise choices, ensuring only true defects are removed. This precision directly translates to more finished product ready for sale.

Case studies confirm the financial impact. For example, XYZ Rice Mill saw a 30% increase in throughput after adopting advanced sorting technology. This efficiency, combined with a superior quality product, allowed them to capture a premium market position and boost revenue. Furthermore, early adopters of cloud-based analytics integrated with optical sorters report a 12% improvement in yield accuracy, demonstrating a clear and measurable return. By recovering more high-quality rice from the initial input, mills convert potential waste into tangible profit.

Driving Down Costs for Long-Term Profitability

An investment in modern technology is not just about increasing revenue; it is also a powerful strategy for reducing operational costs. A 2025 rice seeds optical sorter streamlines production, minimizes financial losses, and builds a foundation for sustainable profitability. By optimizing resource allocation and reducing inefficiencies, mills can significantly improve their bottom line.

Cut Expenses by Automating Manual Sorting

Manual sorting is a major operational expense for rice mills. It is labor-intensive, inconsistent, and slow. Labor costs, including salaries, benefits, and training, represent a significant portion of a mill's budget. For instance, skilled operator salaries can range from $35,000 to $50,000 annually, with additional investments required for training and performance incentives. Automating this process with an optical sorter provides immediate and long-term financial relief.

An automated system operates 24/7 without fatigue, breaks, or human error. This consistency drastically reduces the need for a large manual sorting workforce, cutting direct labor expenses. Automation also addresses labor shortages and allows employees to shift from repetitive tasks to higher-value roles, improving worker retention. The operational costs of a modern sorter are predictable and manageable. For example, a 5 kW optical sorter running for an eight-hour shift with electricity at $0.15/kWh would only incur a daily energy cost of $6. This efficiency contrasts sharply with the variable and ever-increasing costs of manual labor.

Operational Cost Breakdown in Rice Milling 💰 Labor is a primary cost driver in rice milling, often accounting for 30-40% of total operational expenses. Other significant costs include:

- Equipment Depreciation: Can consume up to 15% of the annual business investment.

- Fuel and Logistics: Represents roughly 20-25% of operating budgets for mobile units.

- Administrative Fees: Includes insurance, permits, and compliance, costing thousands annually.

By replacing manual inspection with a high-speed, precise machine, mills can reallocate their financial resources toward growth initiatives instead of payroll.

Reduce Financial Loss from Waste and Rejects

Product waste and recalls are silent profit killers. Every rejected batch or recalled shipment represents lost revenue, disposal costs, and potential brand damage. A modern optical sorter acts as a powerful risk mitigation tool, protecting a mill from these significant financial threats.

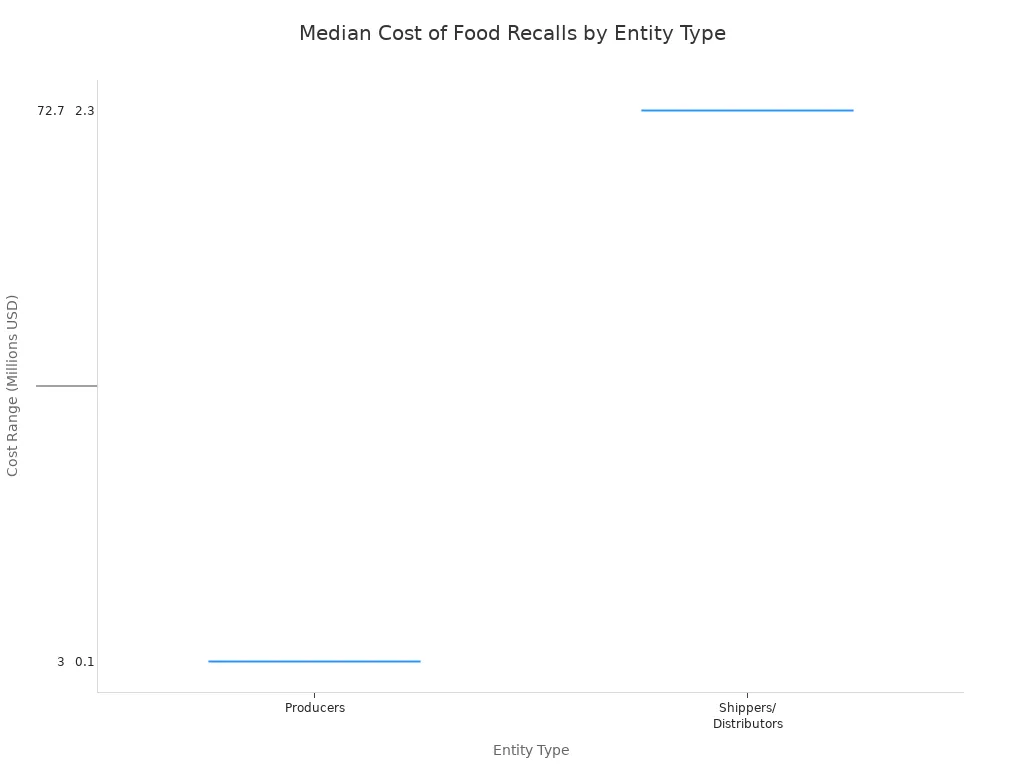

The primary cause of costly recalls in the food industry is foreign material contamination. The financial impact of such an event can be devastating, especially for producers.

| Entity Type | Median Cost Range (Millions USD) |

|---|---|

| Producers | $3.0 to $72.7 |

| Shippers/Distributors | $0.1 to $2.3 |

| Restaurants | $0.04 to $1.1 |

| Nonrestaurant Retailers | $0.1 to $3.1 |

A 2025 optical sorter’s ability to detect and remove glass, stone, and other contaminants with over 99.9% accuracy virtually eliminates this risk. This precision prevents contaminated products from ever reaching the market, safeguarding the mill from recall costs that average between 8 and 10 million Euros. Furthermore, by minimizing the rejection of good grains, the sorter reduces good-in-bad waste, directly converting what would have been lost product into sellable inventory. This efficiency helps maintain a healthy gross profit margin, with industry benchmarks ranging from 20% to 35%.

Secure Future Profits with a Competitive Edge

In today's rapidly evolving agribusiness sector, technology adoption is no longer optional—it is essential for survival and growth. Investing in a 2025 rice seeds optical sorter provides a distinct competitive advantage that secures a mill's market position for years to come. The global agriculture technology (agri-tech) market is expanding quickly, with innovations like precision farming and IoT-enabled solutions transforming traditional practices.

Automation enables mills to scale operations efficiently. It streamlines processes, increases throughput, and ensures consistent quality, which are all critical for entering new, more demanding markets. Automated systems allow a business to adapt quickly to changing consumer preferences and regulatory updates without incurring massive retraining costs. This flexibility is key to staying competitive.

The Future is Automated Market trend analyses confirm that organizations prioritizing resilience and advanced capabilities will lead the industry. Key competitive strategies include:

- Implementing automation and digital tools.

- Investing in research and development.

- Forming strategic partnerships to enhance market integration.

By embracing this technology, rice mills can improve efficiency, reduce waste, and meet the highest international quality standards. This positions them as reliable, forward-thinking suppliers in a global market that increasingly values sustainability and technological sophistication. Adopting advanced sorting technology is a strategic move to future-proof the business against market shifts and rising operational pressures.

Investing in a 2025 rice seeds optical sorter is a direct strategy for financial growth, not just an equipment upgrade. It boosts revenue through premium pricing and higher yields while simultaneously cutting labor and waste costs. Mills like Phung Hoang Rice Mill see significant quality improvements, with many achieving a return on investment within 2-3 years. Adopting this technology secures a stronger, more profitable market position for the future.

FAQ

What is the typical ROI for a 2025 optical sorter?

Rice mills typically see a full return on investment within 2 to 3 years. This results from increased revenue and significant cost savings in labor and waste.

How does a new sorter integrate with existing mill equipment?

Modern sorters feature modular designs for seamless integration. They fit into existing production lines with minimal downtime, ensuring mills maintain continuous operation and productivity.

What makes 2025 models better than older sorters?

The 2025 models integrate AI and hyperspectral sensors. This technology provides superior accuracy in defect detection, minimizes good grain loss, and maximizes overall processing efficiency.

See Also

Essential Capsule Checkweighers For Buyers To Evaluate In The Coming Year

Is Investing In Automated Virus Sampling Tube Assembly Lines A Smart Move?

The Three Best Industrial Checkweighers Crucial For Every Food Facility

Key Folder Gluer Innovations Expected In Carton Production Lines By 2025

How Capsule Sorters Function And Their Vital Role In Eliminating Defects