2026 Fabrication Trends Welding and Forming SS 321 Flanges

Fabricating Stainless Steel 321 Flanges demands specific techniques due to their titanium stabilization, which provides excellent high-temperature resistance. Successful fabrication hinges on controlling heat and mechanical stress.

Key Fabrication Principles:

- Welding: Welders utilize low heat input processes like Gas Tungsten Arc Welding (GTAW) with ER347 filler metal to prevent weld decay.

- Forming: Fabricators employ cold working methods with robust tooling. This approach manages the material's high work-hardening rate and avoids cracking.

Key Takeaways

- SS 321 flanges need special care when welding and forming. This is because they have titanium, which helps them handle high heat.

- When welding SS 321, use low heat and ER347 filler metal. This stops the metal from breaking down and keeps it strong.

- When shaping SS 321, use strong tools and cold methods. This helps with the metal's tendency to get harder as you work with it.

- New tools like robots and computer simulations make welding and shaping SS 321 better. They help make parts more exact and save materials.

Understanding SS 321's Unique Properties

To fabricate SS 321 effectively, fabricators must first understand its distinct material characteristics. The grade’s performance in high-temperature environments stems directly from its unique chemical composition and resulting mechanical strengths.

The Role of Titanium Stabilization

The defining feature of SS 321 is its titanium stabilization. Titanium has a stronger affinity for carbon than chromium. During high-temperature exposure or welding, titanium forms stable titanium carbides. This process prevents the formation of chromium carbides at the grain boundaries, which is a common issue in other stainless steels. As a result, the material maintains excellent resistance to intergranular corrosion, especially after operating within the critical temperature range of 800–1500°F (427–816°C).

Key Applications Driven by Titanium Stabilization: This superior high-temperature performance makes SS 321 ideal for demanding applications such as aircraft exhaust systems, chemical processing equipment, refinery units, and thermal expansion joints.

Comparing Grade 321 vs. 321H

Fabricators often encounter two variants: 321 and 321H. The primary difference lies in their carbon content. Grade 321H contains a higher carbon percentage, which directly enhances its performance in extreme heat. This elevated carbon content gives 321H superior high-temperature strength and creep resistance, making it the preferred choice for the most demanding service conditions.

| Feature | Grade 321 | Grade 321H |

|---|---|---|

| Carbon Content | Max 0.08% | 0.04% – 0.10% |

| Primary Benefit | Excellent general high-temp use | Enhanced creep strength |

| Best For | Intermittent high-heat cycles | Sustained high-temp service |

Key Mechanical and Thermal Strengths

The combination of titanium stabilization and a robust austenitic structure gives Stainless Steel 321 Flanges a powerful set of performance attributes. Fabricators can rely on this material for its durability and resilience in harsh operating environments.

- High Oxidation Resistance: It performs reliably in continuous service up to 1700°F (925°C) and in intermittent service up to 1650°F (900°C).

- Excellent Creep Strength: The material resists deformation under long-term mechanical stress at high temperatures.

- Good Weldability: Titanium stabilization prevents carbide precipitation during welding, simplifying fabrication.

- Good Formability: The grade can be readily formed into complex shapes, offering versatility in manufacturing.

Best Practices for Welding Stainless Steel 321 Flanges

Successful welding of SS 321 hinges on precise control over the welding process. Because the material is designed for high-temperature service, welders must use techniques that preserve its unique corrosion-resistant properties. The primary goal is to minimize heat input, which prevents undesirable changes in the metal's microstructure.

Optimal Welding Process Selection

Choosing the right welding process is the first step toward a high-integrity weld. Fabricators select methods that offer excellent control over heat and weld bead profile.

- Gas Tungsten Arc Welding (GTAW/TIG): This process is the preferred method for welding Stainless Steel 321 Flanges. GTAW provides exceptional control over heat input, produces clean, high-quality welds, and minimizes the risk of defects. It is ideal for root passes and applications requiring superior finish and structural integrity.

- Gas Metal Arc Welding (GMAW/MIG): GMAW offers higher deposition rates and faster travel speeds, making it efficient for thicker sections. Welders must use a short-circuiting or pulsed spray transfer mode to keep heat input low and prevent distortion or burn-through.

- Shielded Metal Arc Welding (SMAW/Stick): SMAW is a versatile process suitable for field repairs and fabrication. It requires a high level of operator skill to maintain a consistent arc length and travel speed, ensuring minimal heat exposure to the heat-affected zone (HAZ).

ER347 Filler Metal and Alternatives

The selection of an appropriate filler metal is critical for creating a strong, corrosion-resistant weld that matches the performance of the base material.

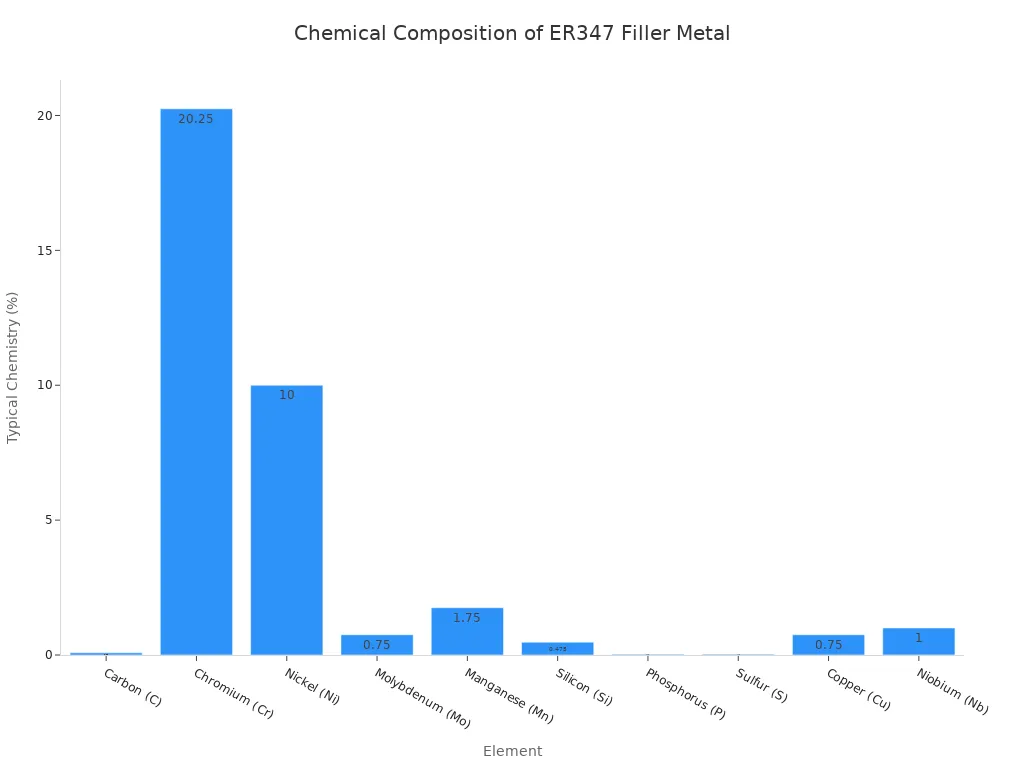

For SS 321, the industry standard is ER347 filler metal. This wire contains a Niobium (Nb) addition, also known as Columbium (Cb). Niobium acts as a stabilizer, binding with any free carbon in the weld pool to form stable niobium carbides. This action prevents the formation of chromium carbides, thereby protecting the weld from intergranular corrosion, especially in high-temperature service above 750°F (400°C). The chemical composition of ER347 is specifically designed to complement the properties of SS 321.

| Element | AWS Chemical Composition Requirements (max/range) |

|---|---|

| Carbon (C) | 0.08 max |

| Chromium (Cr) | 19.0 – 21.5 |

| Nickel (Ni) | 9.0 – 11.0 |

| Manganese (Mn) | 1.0 – 2.5 |

| Silicon (Si) | 0.30 – 0.65 |

| Niobium (Nb) | 10 x C (min) – 1.0 (max) |

While ER321 filler metal also exists, ER347 is more commonly used because the Niobium stabilizer transfers more effectively across the welding arc than the Titanium in ER321.

Preventing Common Welding Defects

Proactive measures are essential to avoid common welding defects like weld decay and hot cracking. A disciplined approach ensures long-term performance.

Weld Decay (Sensitization)

Weld decay occurs when chromium carbides form in the HAZ, depleting the area of chromium and reducing its corrosion resistance. Although SS 321's titanium stabilization minimizes this risk, improper procedures can still cause issues.

Key Preventive Strategies:

- Employ Controlled Welding: Welders use low heat input techniques and maintain appropriate travel speeds. This minimizes the time the material spends in the sensitization temperature range of 800–1500°F (427–816°C).

- Perform Solution Annealing: For critical applications, a post-weld heat treatment (PWHT) can be performed. This process involves heating the flange to a high temperature and then cooling it rapidly to redissolve any harmful carbides.

- Ensure Post-Weld Cleaning: Fabricators must thoroughly clean the weld area to remove any heat tint or oxides. A final passivation treatment restores the protective chromium-oxide layer on the surface.

Hot Cracking

Hot cracking can occur during weld solidification, especially in thick sections or highly restrained joints. It is caused by a combination of material properties and mechanical stress. Fabricators prevent this defect through careful planning and execution.

| Common Causes of Hot Cracking | Effective Remedies |

|---|---|

| High concentration of impurities like sulfur and phosphorus. | Select high-purity base materials and filler metals. |

| Poor joint design or fit-up leading to a wide, concave bead. | Ensure proper joint preparation and a strong design. |

| Excessive heat input from high voltage settings. | Use controlled welding parameters with appropriate voltage. |

| Shallow craters or abrupt stops at the end of a weld pass. | Backfill craters at the end of each weld to add thickness. |

By understanding these causes and implementing the correct remedies, welders produce sound, crack-free welds that ensure the reliability of the final assembly.

Advanced Forming Techniques for SS 321

Forming Stainless Steel 321 Flanges requires a deep understanding of the material's response to mechanical stress. Fabricators choose between cold and hot forming methods based on the final component's design complexity, dimensional requirements, and mechanical properties. Each technique offers distinct advantages and presents unique challenges.

Cold Forming vs. Hot Forming

The choice between cold and hot forming fundamentally alters the fabrication process and the final properties of the flange.

Hot forming involves shaping the steel at an elevated temperature. For SS 321, fabricators heat the material to a range between 1149 and 1260 degrees Celsius (2100–2300°F). This high temperature significantly increases the material's malleability, allowing for the creation of complex shapes with less force. However, it results in a rough, scaled surface that requires additional finishing processes.

Cold forming, performed at or near room temperature, is the preferred method for parts demanding high precision. Cold working methods like cold drawing and rolling are highly suitable for SS 321 components that require superior dimensional accuracy and surface quality. This process delivers several key benefits:

- It produces a smooth, bright surface finish suitable for visible or critical components.

- It achieves high dimensional precision, ensuring the part meets exact specifications.

- It allows for various finishes, such as brushed or polished, to enhance appearance.

The table below compares the outcomes of cold-drawn versus hot-rolled SS 321, highlighting the clear advantages of cold working for precision applications.

| Feature | Cold Drawn SS 321 | Hot Rolled SS 321 |

|---|---|---|

| Surface Finish | Bright, smooth finish | Rough, scaled surface |

| Dimensional Accuracy | Tolerances within ±0.002" | Tolerances of ±0.030" or wider |

| Machining Efficiency | Reduces machining time by 25-40% | Requires significant material removal |

| Waste Reduction | Minimal scrap due to tight tolerances | Higher scrap rates |

Managing Work Hardening and Springback

SS 321 has a high work hardening rate, a critical factor in any forming operation. The material's work hardening exponent (n-value) is approximately 5.442, meaning it strengthens and hardens rapidly as it is bent, pressed, or drawn. While this presents a challenge, it also significantly increases the final part's tensile properties and contributes to excellent dimensional accuracy.

This high work hardening rate requires fabricators to use powerful, robust equipment and hardened tooling to shape the material effectively. It also leads to another phenomenon: springback. After the forming pressure is released, the material has a tendency to partially return to its original shape.

Strategies for Managing Springback:

- Over-bending: Fabricators intentionally bend the material slightly beyond the target angle to compensate for springback.

- Coining: Applying localized pressure at the bend radius helps "set" the material and reduce its tendency to spring back.

- Stress Relief: A low-temperature heat treatment can be applied after forming to reduce internal stresses without affecting the material's core properties.

The Role of Intermediate Annealing

For complex shapes or parts requiring significant deformation, the effects of work hardening can limit formability and lead to cracking. To overcome this, fabricators use a process called intermediate annealing. This heat treatment restores the material's ductility, allowing for further forming operations.

Intermediate annealing involves heating the workpiece to a specific temperature, holding it there, and then cooling it. This process reverses the effects of work hardening.

Pro Tip: Restoring Ductility with Precision 💡 For SS 321, the recommended annealing temperature range to achieve maximum ductility is 1800 to 2000°F (928 to 1093°C). The soaking time is just as critical. Ductility reaches its peak after approximately 60 minutes at temperature. This step is essential for multi-stage forming processes, as it enables cumulative strains that would otherwise be impossible.

By strategically applying intermediate annealing between forming stages, fabricators can produce highly complex components from SS 321 without sacrificing material integrity. This technique is fundamental to unlocking the full manufacturing potential of this high-performance alloy.

Future-Ready Fabrication in 2026

As 2026 approaches, the fabrication industry is embracing advanced technologies to enhance precision, efficiency, and sustainability. Fabricators of specialized components like Stainless Steel 321 Flanges are leveraging automation, digital simulation, and green practices to stay competitive and meet modern demands.

Automation in Welding and Finishing

Automation is transforming welding and finishing operations. Robotic systems now deliver unparalleled consistency and speed, directly improving quality and return on investment.

- Precision Welding: Modern robotic arms equipped with fiber laser systems achieve repeatability within 0.02mm. Hybrid TIG-MIG configurations combine deep penetration with high deposition rates, cutting cycle times by up to 60%.

- Quality Assurance: Integrated monitoring systems are becoming standard. Vision-based seam tracking, thermal sensors, and data logging ensure every weld meets exact parameters, preventing defects before they occur.

- Predictive Maintenance: Cloud-based analytics platforms monitor equipment health, enabling predictive maintenance that can reduce downtime by 30%.

Simulation for Forming Optimization

Digital simulation is eliminating the guesswork from complex forming processes. Engineers use advanced software to design and validate tooling virtually, saving significant time and resources.

Digital Prototyping: A Game Changer Simulation software allows fabricators to bypass expensive physical tryouts. It accurately predicts material behavior, helping to prevent common forming defects like wrinkling, thinning, and tearing. This digital-first approach optimizes blank size for maximum material utilization and uncovers design flaws early in development.

Sustainable Fabrication Practices

Sustainability is no longer an option but a core business strategy. Fabricators are adopting cleaner technologies and smarter manufacturing processes to reduce their environmental impact.

- Energy Efficiency: Shops are integrating renewable energy sources like solar and wind power. They also use smart sensors and AI to ensure machines consume only the necessary power for a given task.

- Waste Reduction: Precision methods like laser cutting and automated welding minimize material waste. Advanced techniques such as powder metallurgy can reduce scrap rates to as low as 3%, a massive improvement over traditional machining.

Mastering the fabrication of Stainless Steel 321 Flanges in 2026 requires a focus on precision and advanced methods. Fabricators achieve success by adhering to core principles.

Key Takeaways for Success: 🚀

- Welders use controlled, low-heat input processes with ER347 filler metal to ensure weld integrity.

- Operators manage the material's high work-hardening rate during cold forming with robust tooling and strategic annealing.

- Shops embrace automation and digital simulation to boost precision, consistency, and overall efficiency in modern projects.

FAQ

Why is ER347 filler metal recommended for welding SS 321?

Fabricators choose ER347 filler metal because its Niobium (Nb) stabilizer effectively prevents weld decay. Niobium binds with carbon during welding. This action protects the weld's corrosion resistance in high-temperature service, ensuring a durable and reliable joint that matches the base material's performance.

What is the main difference between SS 321 and SS 321H?

The primary distinction is carbon content. Grade 321H contains more carbon (0.04%–0.10%). This higher carbon level gives SS 321H superior strength and creep resistance at elevated temperatures. Fabricators select it for the most demanding, sustained high-heat applications.

How do fabricators manage SS 321's high work hardening rate?

Operators manage the high work hardening rate with specific strategies. They use powerful equipment and hardened tooling to overcome the material's resistance. For complex parts, they perform intermediate annealing to restore ductility, which allows for additional forming stages without causing cracks.

Can you weld SS 321 without a post-weld heat treatment?

Yes, welding without post-weld heat treatment (PWHT) is common. The material's titanium stabilization minimizes the risk of sensitization. However, for critical applications requiring maximum corrosion resistance, fabricators may perform a solution anneal to dissolve any potential chromium carbides in the heat-affected zone.

See Also

Mastering Pass Partition Plate Welding: Expert Strategies for 2025 Success

Innovative Materials: Transforming the Future of Heat Exchanger Supply Chains

Optimized Steel Processing: Consistently Achieving Superior Heat Exchange Performance

Assessing Molybdenum Plugs: Enhancing Seamless Steel Pipe Manufacturing by 2025

Essential 2025 Guide: Semi-welded Plate Heat Exchangers for Industrial Efficiency