Best Places to Buy X-Ray Inspection Machines in China

China’s top sources for x-ray inspection machine purchases include Unicomp Technology, Dandong NDT Equipment, Dingsheng Technology, and major platforms like Alibaba. These suppliers lead the market, which is projected to reach USD 115,734.45 thousand by 2030 with a 9.3% growth rate.

| Certification | Description |

|---|---|

| ROHS, FCC, IP Ratings | Ensure safety, environmental compliance, and reliable performance |

Choosing certified suppliers guarantees compliance and product quality.

Top X-Ray Inspection Machine Manufacturers in China

Unicomp Technology

Unicomp Technology stands as a leader in the x-ray inspection machine market. The company operates several R&D and manufacturing centers and holds more than 432 patents. Unicomp collaborates with top institutions such as The Chinese Academy of Sciences and Tsinghua University. Their product range covers non-destructive testing, real-time inspection, benchtop models, BGA inspection, casting inspection, SMT/EMS, flaw detection, chip counting, food and beverage inspection, security scanning, lithium battery inspection, and microfocus sources.

| Product Line Category | Examples / Details |

|---|---|

| NDT X Ray Equipment | Non-destructive testing X-ray machines |

| Real Time X Ray Equipment | Real-time inspection systems |

| Benchtop X Ray Machines | Compact benchtop models |

| BGA X Ray Inspection Machines | Ball Grid Array component inspection |

| Casting NDT X Ray Machines | Casting inspection equipment |

| SMT / EMS X Ray Machines | Electronics manufacturing inspection |

| X Ray Flaw Detectors | Flaw detection devices |

| X Ray Chip Counters | Chip counting via X-ray |

| Food and Beverage X Ray Machines | Food and beverage inspection |

| X Ray Security Scanners | Security scanning equipment |

| Lithium Battery X Ray Machines | Lithium battery inspection |

| Microfocus X Ray Sources | Specialized microfocus X-ray sources |

Unicomp’s demo center in Shenzhen highlights their technical strengths and innovation. Their machines use AI-based intelligent inspection and serve industries such as public security, electric vehicles, semiconductors, automotive casting, and food processing. Unicomp holds certifications like ISO 9001, ISO 14001, OHSAS18001, and ISO27001.

Dandong NDT Equipment

Dandong NDT Equipment specializes in non-destructive testing solutions. Their x-ray inspection machines help manufacturers detect flaws in materials and components. The company focuses on reliability and precision, supporting sectors such as electronics, automotive, and aerospace.

Dingsheng Technology

Dingsheng Technology provides advanced x-ray inspection machine solutions for industrial applications. Their systems offer high-resolution imaging and automated defect detection. Dingsheng’s products support electronics manufacturing, casting inspection, and quality control in various industries.

Shanghai Fanchi-tech Machinery

Shanghai Fanchi-tech Machinery supplies x-ray inspection machines mainly to the food, packaging, and pharmaceutical industries. Their equipment identifies contaminants and product defects, helping companies maintain safety and quality standards. Fanchi-tech’s machines are designed for easy integration into production lines.

Tip: Companies in the food and pharmaceutical sectors often choose Fanchi-tech for its specialized inspection systems.

Minfound Medical Systems

Minfound Medical Systems focuses on medical imaging technology. Their x-ray inspection machines support hospitals and clinics with diagnostic imaging. Minfound’s products feature advanced imaging software and ergonomic designs, making them suitable for healthcare environments.

Juzheng

Juzheng manufactures x-ray inspection machines for industrial and laboratory use. Their systems provide accurate detection of defects in electronics, automotive parts, and materials. Juzheng emphasizes user-friendly interfaces and robust construction.

Safeway Inspection System Limited

Safeway Inspection System Limited offers x-ray inspection machines with multiple international certifications. Their products, such as the SAFEWAY SYSTEM AT100100D, hold ISO, CE, ROHS, FCC, and FDA certifications. These certifications ensure compliance with global safety and quality standards. Safeway’s machines are widely used in security screening and industrial inspection.

MeCan Medical

MeCan Medical delivers x-ray inspection machines for medical and industrial applications. The company provides strong after-sales support, including:

- One-year warranty covering quality issues.

- Comprehensive repair services.

- Technical support and prompt assistance.

- Local engineers in the Philippines for on-site installation and inspection.

- Remote one-to-one installation guidance.

- Multi-language customer service.

- Safe transportation with logistics updates.

MeCan’s commitment to customer service ensures smooth operation and maintenance for users worldwide.

CHAOQIANG

CHAOQIANG specializes in food inspection systems that combine x-ray and metal detection technologies. Their x-ray inspection machines detect foreign objects such as metal, stone, glass, and ceramic in products like bread, coffee, and potato chips. The company supports food safety and quality control in manufacturing.

| Application Sector | Description |

|---|---|

| Biscuit Snacks | Food processing and packing lines ensuring product integrity |

| Chemical or Cosmetic | Inspection for contaminants and product safety |

| Vegetable | Hygienic design for fresh produce inspection |

| Pharmaceutical & Nutraceutical | Ensuring safety and quality in health-related products |

| Other / General Industries | Broad industrial applications beyond food |

CHAOQIANG’s machines help companies maintain high standards in food safety and product integrity.

Seamark ZM

Seamark ZM produces x-ray inspection machines for electronics, semiconductors, and industrial applications. Their systems offer high-precision imaging and automated analysis. Seamark ZM supports manufacturers with reliable inspection solutions.

SunzonTech

SunzonTech develops x-ray inspection machines for electronics manufacturing and quality control. Their products feature advanced imaging technology and user-friendly operation. SunzonTech’s machines help companies detect defects and improve production efficiency.

Leading Online Platforms for Sourcing X-Ray Inspection Machines

Alibaba

Alibaba stands as one of the largest global marketplaces for industrial equipment. Buyers can find thousands of suppliers offering a wide range of x-ray inspection machines. The platform provides advanced search filters, allowing users to sort by certification, price, and supplier location. Many suppliers on Alibaba display verified badges, which indicate a higher level of trust and reliability.

Note: Buyers should always check supplier profiles for trade assurance and customer reviews before making a purchase.

Alibaba supports secure payment methods and offers logistics solutions for international shipping. The platform also features live chat and inquiry forms, making it easy for buyers to communicate directly with manufacturers. Many suppliers provide detailed product catalogs, technical specifications, and videos to help buyers make informed decisions.

Made-in-China.com

Made-in-China.com specializes in connecting global buyers with Chinese manufacturers. The platform lists a broad selection of x-ray inspection machines from certified suppliers. Users can compare products by features, certifications, and minimum order quantities. Made-in-China.com verifies supplier credentials and provides a transparent rating system.

A unique feature of this platform is the "Request for Quotation" (RFQ) service. Buyers can submit their requirements and receive multiple quotes from different suppliers. This process saves time and helps buyers find the best deal. The website also offers industry news, trade shows, and product trends to keep buyers updated.

| Platform Feature | Description |

|---|---|

| Supplier Verification | Ensures only qualified suppliers are listed |

| RFQ Service | Collects multiple quotes for easy comparison |

| Product Videos | Demonstrates machine operation and features |

Global Sources

Global Sources serves as a trusted B2B platform for sourcing industrial equipment. The website features a curated list of suppliers who specialize in x-ray inspection machines. Each supplier profile includes company background, certifications, and export history. Global Sources conducts supplier audits to ensure product quality and compliance.

Buyers can attend virtual trade shows and webinars hosted by Global Sources. These events provide opportunities to see new products and connect with suppliers in real time. The platform also offers sourcing guides and industry reports, helping buyers stay informed about the latest technology and market trends.

Tip: Global Sources is ideal for buyers seeking suppliers with export experience and international certifications.

Each of these platforms offers unique advantages for sourcing x-ray inspection machines. Buyers should compare features, supplier credentials, and support services to find the best fit for their needs.

Company Overview and Reputation

History and Experience

Leading x-ray inspection machine manufacturers in China have built strong reputations through years of dedicated service. Many companies started as small workshops and grew into major industry players. They invested in research and development, which helped them create advanced inspection technologies.

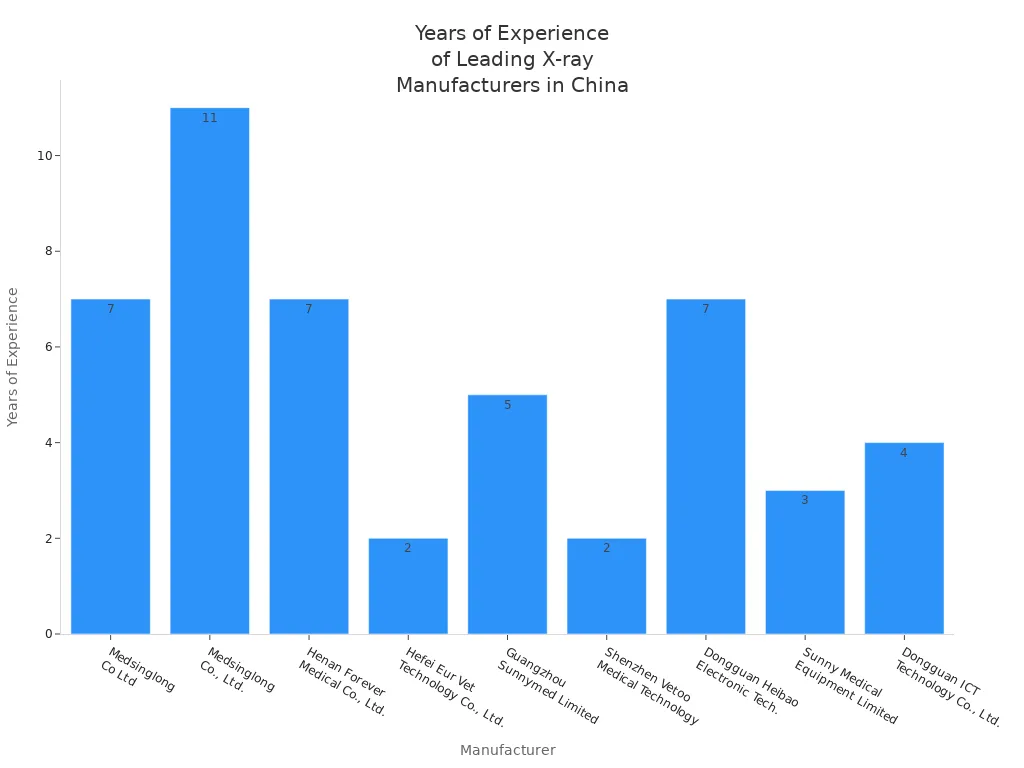

The average manufacturer in this sector has about 5.8 years of experience. Some companies, such as Medsinglong Co., Ltd., have operated for over a decade. Others, like Hefei Eur Vet Technology Co., Ltd., entered the market more recently. This mix of established and emerging companies drives innovation and competition.

| Manufacturer | Years of Experience |

|---|---|

| Medsinglong Co Ltd | 7 |

| Medsinglong Co., Ltd. | 11 |

| Henan Forever Medical Co., Ltd. | 7 |

| Hefei Eur Vet Technology Co., Ltd. | 2 |

| Guangzhou Sunnymed Limited | 5 |

| Shenzhen Vetoo Medical Technology | 2 |

| Dongguan Heibao Electronic Tech. | 7 |

| Sunny Medical Equipment Limited | 3 |

| Dongguan ICT Technology Co., Ltd. | 4 |

Companies with longer histories often provide more reliable products and better support.

Industry Recognition

Chinese x-ray inspection machine manufacturers have earned respect in global markets. Many companies hold certifications such as ISO, CE, and FDA. These certifications show their commitment to safety and quality.

Industry awards and positive customer feedback also highlight their achievements. Manufacturers often participate in international trade shows, which helps them showcase new technologies. Buyers recognize these companies for their innovation and service.

- Many suppliers receive high ratings from customers.

- Leading brands appear in industry publications and reports.

- Trade organizations often invite these companies to speak at events.

Manufacturers with strong reputations attract more buyers and build lasting partnerships.

Key Products and Technologies of X-Ray Inspection Machines

Types of X-Ray Inspection Machines Offered

Chinese manufacturers produce a wide range of x-ray inspection machines to meet industry needs. Each type serves a specific application, from food safety to industrial quality control. The table below summarizes the main categories and their uses:

| Type of X-ray Inspection Machine | Description / Application | Example Manufacturers / Models |

|---|---|---|

| Food X-ray Inspection Machines | Detect bones and foreign matter in food products | Foodman Optoelectronic (Fxr-Yc6017, Fxr-Yc4017) |

| Security X-ray Scanners | Baggage, luggage, cargo, vehicle scanning for security | Safeway Inspection System Limited (Baggage Scanner, Vehicle Scanning System) |

| Industrial X-ray Inspection Systems | Electronics and semiconductor inspection | Dongguan Juzheng Electronic Technology Co., Ltd. (Jzxr Xr-500d) |

| Non-Destructive Testing (NDT) X-ray Flaw Detectors | Flaw detection in materials without damage | Huangshi Shangfang Inspection Equipment Co., Ltd. |

| Combined Systems (Metal Detectors, Check Weighers) | Used in food and industrial inspection | Baoji Toptech Industrial Co., Ltd., Guangdong Shanan Technology Co., Ltd. |

Manufacturers like Zhejiang Yingxing also offer specialized microfocus models. The X5 model inspects small parts for R&D and quality control. The X6 model handles large boards in semiconductor and electronics manufacturing.

Advanced Features and Innovations

Modern x-ray inspection machines from China include advanced technologies that improve accuracy and efficiency. Many systems use modular digital radiography and computed tomography. Some machines feature automated robotic X-ray CT scanning for batch processing and part manipulation.

| Feature/Parameter | Description/Value |

|---|---|

| Loading platform rotation | 360º |

| Image detector tilt | 60º |

| Geometric magnification | Up to 300 times |

| Spatial resolution | 5.8 line pairs per millimeter |

| Pixel matrix | 1536 × 1536 pixels |

| Voltage range | 90KV - 130KV |

| Focus size | 5 micrometers |

| Effective imaging area | 130 × 130 mm |

| Cooling method | Air cooling |

| Radiation tolerance | 10,000 Gy |

Many machines now use AI deep learning for defect recognition. TDI technology delivers ultra-high-resolution imaging. Dual energy detectors help find low-density and calcified contaminants. Intelligent algorithms enable real-time defect detection. These features support industries such as automotive, electronics, and food safety.

- Seamless integration into production lines

- Automated robotic loading and unloading

- 24/7 support for continuous operation

These innovations help companies detect cracks, voids, and counterfeit parts, ensuring reliable quality control.

Industry Applications and Certifications for X-Ray Inspection Machines

Electronics Manufacturing

X-ray inspection machines play a vital role in electronics manufacturing across China. Manufacturers use these systems for several key tasks:

- Solder joint inspection on printed circuit boards (PCBs)

- Component placement verification

- Detection of defects such as voids, cracks, misalignments, and foreign object debris

These machines provide non-destructive testing, allowing engineers to see inside PCBs and components. Real-time feedback during production helps optimize processes and improve product reliability. Advanced features like AI-powered analytics and 2D/3D CT scanning increase defect detection rates, especially for hidden features in BGAs and QFPs. The technology supports zero-defect manufacturing and meets the strict quality demands of the semiconductor, automotive electronics, and medical device sectors.

Food and Pharmaceutical

Food and pharmaceutical companies in China rely on x-ray inspection machines to ensure product safety and regulatory compliance. These systems detect contaminants such as metal, glass, stone, and bone fragments in both bulk and packaged products. Manufacturers use compact economical models, bulk food inspection systems, and dynamic inline machines to maintain hygiene and quality standards.

| X-ray System Type | Application |

|---|---|

| Compact Economical X-ray | Food, pharmaceuticals, beverages |

| Bulk Product X-ray | Bulk food foreign material detection |

| Dynamic Foodgrade X-ray | Inline hygiene and safety inspection |

| Single Beam X-ray for Canned Food | Canned product contaminant detection |

These machines operate at high speeds and provide automatic, real-time quality control.

Automotive and Aerospace

Automotive and aerospace manufacturers depend on x-ray inspection for non-destructive testing. These systems detect internal defects and contaminants without damaging components. High-resolution imaging, 3D CT, and AI-powered recognition help ensure structural integrity and safety. X-ray inspection supports compliance with international standards and enables smart factory initiatives, reducing downtime and improving operational efficiency.

Certifications and Compliance

Manufacturers must meet strict certification requirements to ensure safety and quality. Key certifications include ISO 13485 for medical devices, IEC 60601 for electrical safety, and ISO 9001 and ISO 14001 for quality management. CE certification demonstrates compliance with European safety standards, while RoHS ensures environmental safety for accessory components. These certifications guarantee that x-ray inspection machines operate reliably and meet global regulatory demands.

Customer Service and After-Sales Support for X-Ray Inspection Machines

Technical Support and Training

Chinese suppliers of x-ray inspection machines provide strong technical support and training to help buyers use their equipment effectively. Many companies offer professional installation instructions and detailed videos. Experienced engineers lead online training sessions that cover installation, operation, and daily maintenance. Buyers receive manuals and video guides for every step, from setup to repair. Some suppliers pre-install software on computers, making the process easier. If clients choose to install software themselves, online meetings are available for guidance. Suppliers also recommend suitable laptop configurations to ensure smooth operation. Remote support is common, with engineers using remote control apps, video calls, and email to solve problems quickly. Overseas buyers benefit from after-sales branches in select countries and ongoing expansion of support networks.

| Support Aspect | Description |

|---|---|

| Installation Guidance | Professional instructions and videos; online training by engineers. |

| Software Setup | Pre-installed software; online meetings for guidance. |

| Hardware Requirements | Recommendations for laptop specs. |

| After-sales Service | 12-month warranty; rapid response team. |

| Technical Resources | Manuals and videos for all procedures. |

| Remote Support | Remote control, video, and email troubleshooting. |

| Customer Complaint Process | Video inspections, engineer communication, spare parts sent if needed. |

| Overseas Support | After-sales branches in some countries; expanding partnerships. |

Warranty and Maintenance

Warranty and maintenance services give buyers peace of mind. Leading manufacturers, such as Shanghai Fanchi-tech Machinery, provide comprehensive warranties with each machine. YSN Medical Equipment stands out by offering a 3-year warranty. Their after-sales service includes emergency response, remote technical support, and on-site visits. Regular maintenance keeps machines running smoothly. Key recommendations include:

- Calibrating the filament regularly

- Performing template calibration of ball tubes

- Calibrating detectors as needed

These services ensure that x-ray inspection machines remain reliable and efficient throughout their lifespan.

How to Purchase X-Ray Inspection Machines in China

Direct Contact Information

Buyers often achieve the best results by contacting manufacturers directly. Leading companies like Shanghai Fanchi-tech Machinery Co., Ltd. recommend reaching out via phone or email. This approach allows buyers to ask detailed questions about product features, quality control, and technical support. Direct communication also helps buyers receive accurate quotes and understand warranty terms. Many manufacturers list their contact details on their official websites, making it easy to start a conversation with a sales representative.

Online Ordering Process

Purchasing an x-ray inspection machine online involves several important steps. Buyers should first research and identify vendors that meet industry audit requirements. Seeking advice from other processors or retailers can provide valuable insights. Testing equipment from multiple vendors ensures the machine meets contaminant detection standards at actual production speeds. Buyers should evaluate performance by asking about contaminant goals, false reject rates, and test sample consistency. Considering the total cost of ownership, including maintenance and energy consumption, helps avoid unexpected expenses. Reviewing warranty terms and the availability of spare parts is also essential.

Tip: Always check if the supplier offers 24/7 technical support and timely on-site service.

International Shipping and Payment Options

Most Chinese manufacturers offer international shipping for their x-ray inspection machines. Buyers can choose from air, sea, or express courier services based on urgency and budget. Payment options usually include bank transfers, letters of credit, and secure online payment platforms. Reliable suppliers provide tracking information and assist with customs documentation. Clear communication about shipping timelines and costs ensures a smooth purchasing experience.

Comparison Table of Top X-Ray Inspection Machine Suppliers

Choosing the right x-ray inspection machine supplier in China requires careful comparison. Buyers should look at product range, certifications, support, warranty, and ordering methods. The table below summarizes key differences among leading suppliers:

| Supplier | Product Range | Certifications | Support & Warranty | Ordering Methods |

|---|---|---|---|---|

| Unicomp Technology | Industrial, Food, Security, Medical | ISO, CE, RoHS, FCC | 12-month warranty, global support | Direct, Online |

| Dandong NDT Equipment | NDT, Industrial | ISO, CE | Technical training, warranty | Direct, Online |

| Shanghai Fanchi-tech | Food, Pharma, Packaging | ISO, CE, FDA | 1-year warranty, remote support | Direct, Online |

| Safeway Inspection | Security, Industrial | ISO, CE, RoHS, FCC, FDA | 1-year warranty, 24/7 support | Direct, Online |

| MeCan Medical | Medical, Industrial | ISO, CE | 1-year warranty, local engineers | Direct, Online |

Product Range

Top suppliers offer a wide selection of x-ray inspection machines. Some focus on industrial and electronics applications. Others specialize in food safety or medical imaging. Buyers should match their needs to the supplier’s strengths. Companies like Unicomp Technology and Safeway Inspection provide machines for multiple industries, while Fanchi-tech targets food and pharmaceutical sectors.

Certifications

Certifications show a supplier’s commitment to safety and quality. Leading companies hold ISO, CE, RoHS, and FCC certifications. Some, like Safeway Inspection, also have FDA approval. These certifications ensure machines meet international standards and operate safely in different environments.

Support and Warranty

Strong customer service sets top suppliers apart. Many offer 12-month warranties and global technical support. Some provide local engineers for installation and training. Quick responses and detailed manuals help buyers integrate machines smoothly. After-sales support includes remote troubleshooting and spare parts delivery.

Tip: Look for suppliers who invest in research, innovation, and timely customer service.

Ordering Methods

Buyers can order directly from manufacturers or through online platforms. Direct contact allows for detailed discussions about requirements. Online ordering offers convenience and access to verified supplier profiles. Most suppliers support secure payment and international shipping.

- Quality and reliability

- Advanced technology

- Responsive customer service

These factors help buyers choose the best partner for their x-ray inspection needs.

China offers many trusted sources for purchasing an x-ray inspection machine. Buyers should select certified suppliers to ensure quality and compliance. Reliable manufacturers and online platforms provide strong support. Readers can contact companies or visit sourcing websites to request quotes and product details.

FAQ

What certifications should buyers look for when purchasing x-ray inspection machines in China?

Buyers should check for ISO, CE, RoHS, and FCC certifications. These ensure product safety, quality, and compliance with international standards.

How can buyers verify the reliability of Chinese suppliers?

Buyers can review supplier profiles, check customer ratings, and request references. Verified badges on platforms like Alibaba indicate trustworthy suppliers.

What after-sales support do leading manufacturers provide?

Manufacturers offer technical training, warranty coverage, and remote troubleshooting. Some companies provide local engineers for installation and maintenance.

See Also

Why Automatic UV Coating Machines Are Vital For Fast Printing

Top Six Industrial Vacuum Cleaners Businesses Must Evaluate

Key Folder Gluer Innovations Shaping 2025 Carton Production

Comparing Leading Ampoule Filling Line Manufacturers Today

Essential Insights On Aminoguanidine Bicarbonate Supplier Costs 2024