Top 7 Canola Seed Optical Sorters for 2026

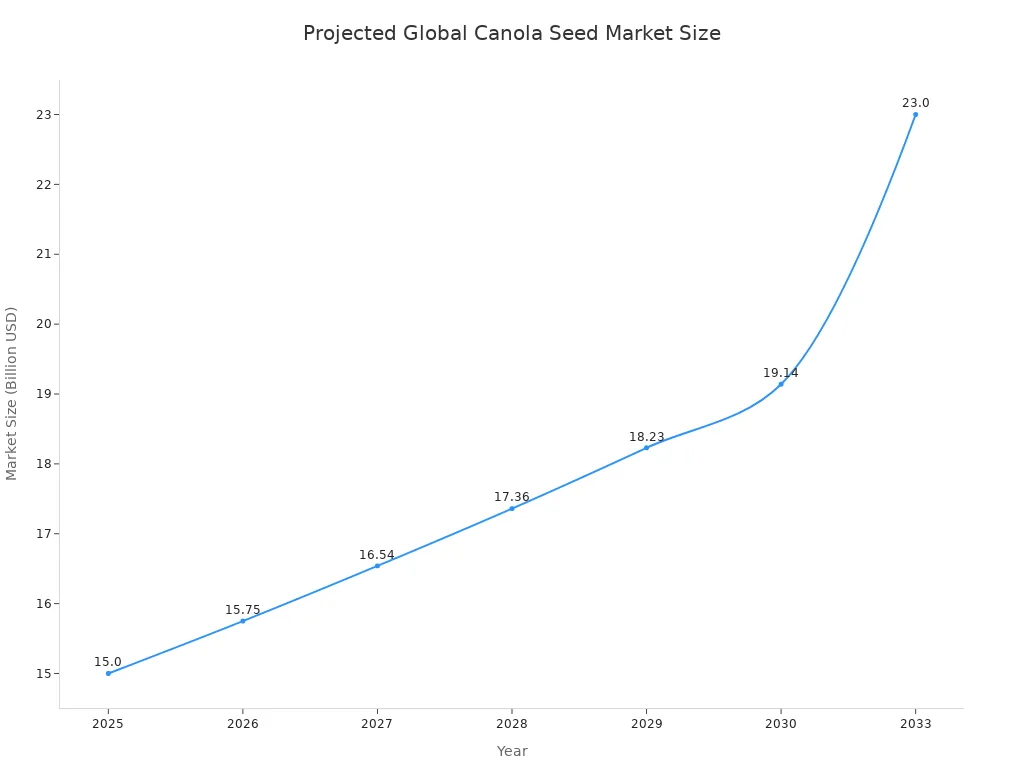

The global canola seed market is projected to reach USD 3.09 billion by 2032. This expansion drives demand for superior processing technology.

Processors require advanced equipment to meet purity standards and production volumes. This guide reviews the top canola seeds optical sorter models for 2026.

- Buhler SORTEX H SpectraVision

- Tomra 5C ProScan

- Key Technology VERYX C140

- Satake FMS-IR

- Cimbria SEA.CX Vision

- Hefei Meyer AI-Pro Series

- Anysort SC7

Detailed Reviews of the Top 7 Sorters

This section provides an in-depth look at each leading sorter. We analyze their core technologies, key features, and ideal applications for canola seed processing in 2026.

1. Buhler SORTEX H SpectraVision: The High-Throughput Leader

The Buhler SORTEX H SpectraVision stands out for large-scale operations. It prioritizes maximum throughput without compromising sorting quality. This machine is engineered for processors who handle immense volumes of canola seed daily. Its primary advantage is its ability to process product at exceptional speeds, making it a cornerstone for industrial-grade facilities.

The sorter's advanced detection system is central to its performance. It uses a combination of powerful technologies to identify even the most challenging defects.

- SpectraVision Technology: This proprietary feature excels at identifying subtle color defects and foreign materials.

- Full-Colour Cameras: High-resolution cameras provide detailed visual analysis of each seed.

- Enhanced LED Lighting: The system uses LEDs that produce triple the light of many competitors. This intense illumination improves the visibility of defects, ensuring a higher sorting accuracy.

Note: The SORTEX H SpectraVision is the go-to choice for processors needing to maximize volume. Its robust build and high-speed ejectors minimize downtime and keep production lines moving efficiently.

2. Tomra 5C ProScan: The Purity Champion

The Tomra 5C ProScan earns its title as the purity champion. It is designed for processors who demand the highest quality output with near-zero product loss. This machine combines advanced imaging with intelligent ejection to remove sclerotia, weed seeds, and discolored canola. Its focus is on delivering a premium final product suitable for export or specialty markets.

The sorter's precision comes from its surround-view technology and biometric signature identification. It analyzes each seed from multiple angles, leaving no defect hidden. The result is an exceptionally clean product stream with minimal rejection of good seeds.

3. Key Technology VERYX C140: The User-Friendly Innovator

The Key Technology VERYX C140 redefines ease of use in optical sorting. It merges powerful technology with an exceptionally intuitive operator experience. This design allows facilities to achieve expert-level sorting performance with minimal staff training. Operators can become proficient users in less than one hour.

The machine's user-friendliness is built on several smart features:

- Intuitive User Interface: The software offers different views for various user skill levels.

- Recipe-Driven Operation: Operators can switch between pre-set sorting parameters with a single touch. This ensures consistent performance across different batches.

- Smart Features: The system includes auto-learning, self-adjustment algorithms, and predictive diagnostics. It adapts to product variations automatically.

At its core is Key's groundbreaking Pixel Fusion™ technology. This system combines data from multiple sensors at the pixel level for unmatched detection.

- It integrates next-generation 4-channel cameras and high-resolution laser sensors.

- Cameras recognize color, size, and shape, while lasers detect structural properties.

- This fusion creates higher contrast, enabling the sorter to find difficult foreign materials and defects with minimal false rejects.

4. Satake FMS-IR: The Best Value Performer

The Satake FMS-IR offers an excellent balance of performance, reliability, and affordability. It is an ideal choice for small to medium-sized processors seeking to upgrade their sorting capabilities without a massive capital investment. This machine provides consistent, high-quality sorting for common canola defects like sclerotia and damaged seeds.

Its combination of full-color RGB cameras and optional Infrared (IR) sensors gives it flexibility. The FMS-IR is known for its straightforward operation and low maintenance requirements, which contribute to a lower total cost of ownership over the machine's lifespan.

5. Cimbria SEA.CX Vision: The Durability Workhorse

The Cimbria SEA.CX Vision is built for continuous, demanding operation. Its reputation rests on its robust construction and long-term reliability. This canola seeds optical sorter is designed to withstand the harsh conditions of a 24/7 processing environment. Processors value its durable components and consistent performance year after year.

The SEA.CX Vision uses high-resolution cameras and a stable software platform to ensure reliable defect removal. Its heavy-duty frame and sealed optics protect sensitive components from dust and vibration, minimizing maintenance needs and maximizing uptime.

6. Hefei Meyer AI-Pro Series: The Specialty Seed Specialist

The Hefei Meyer AI-Pro Series leverages artificial intelligence to master complex sorting challenges. It is particularly effective for specialty canola varieties or for processors targeting niche markets with unique quality specifications. The machine's deep-learning algorithms can be trained to identify and remove defects that conventional sorters might miss.

This sorter excels at distinguishing between subtle color variations and shape abnormalities. Its AI engine continuously improves its sorting logic, adapting to new defect patterns over time. This makes it a powerful tool for achieving specific, high-value product grades.

7. Anysort SC7: The Future-Proof Modular System

The Anysort SC7 is designed with scalability and future needs in mind. Its modular architecture allows processors to expand their sorting capacity as their business grows. This flexibility makes it an intelligent long-term investment. A facility can start with a smaller configuration and add more sorting channels later.

A key feature of the SC7 is its advanced connectivity.

- The sorter uses a cloud-based monitoring system for real-time oversight.

- This platform allows managers to control the equipment remotely.

- It provides critical data on machine performance and flags potential issues.

- Users can access this information from any location, enabling flexible and proactive management.

This remote capability helps optimize sorting efficiency and facilitates timely maintenance, ensuring the system operates at peak performance.

Comparative Analysis of Top Canola Seeds Optical Sorter Models

This analysis compares the top models across key performance metrics. It helps you align a machine’s strengths with your specific operational needs.

Throughput and Capacity

Throughput is a critical factor for large-scale processors. The Buhler SORTEX H SpectraVision leads this category, designed for maximum volume. Its capacity is essential for facilities that must process significant tonnage daily. For context, some pre-cleaning systems can handle canola at 20 tons/hour. High-throughput sorters must match or exceed these rates to prevent bottlenecks. In contrast, models like the Tomra 5C ProScan may prioritize purity over sheer speed, offering a more moderate throughput.

Sorting Accuracy and Defect Removal

Sorting accuracy directly impacts final product quality and profitability. The Tomra 5C ProScan and Key Technology VERYX C140 excel at delivering exceptional purity. These machines use advanced sensor fusion to identify and remove challenging foreign materials and subtle seed defects. Intelligent sorting algorithms are key to this process. They enhance defect removal while simultaneously increasing the overall product yield by minimizing the rejection of good seeds.

Core Technology and AI Integration

Artificial intelligence is transforming sorting capabilities. The Buhler SORTEX H features an AI engine for self-adjustment, which reduces the need for operator intervention. Hefei Meyer shows its commitment to innovation by investing around 6% of its annual revenue in R&D, focusing heavily on AI-based sorters. These smart systems continuously learn and adapt, ensuring consistent high performance and improving the removal of diseased or damaged seeds.

Target User and Ideal Application

The ideal canola seeds optical sorter depends on the scale and focus of your operation. Large industrial processors and smaller specialty producers have different needs. The table below outlines which sorter types best suit each user.

| Producer Type | Sorter Models/Types | Key Characteristics |

|---|---|---|

| Large-Scale Processors | Buhler SORTEX H, Tomra 5C | High throughput, unparalleled precision, and reliability for bulk processing. |

| Specialty Producers | Hefei Meyer AI-Pro, Anysort SC7 | Customized sorting, modular platforms, and adaptability for niche seed varieties. |

Estimated Price and Ownership Cost

Initial investment varies significantly. Models like the Satake FMS-IR offer a strong value proposition with a lower upfront cost. High-end, multi-sensor sorters from brands like Buhler and Tomra carry a higher price tag. However, their superior performance often reduces product loss and commands premium prices for the final product. This can offset the initial investment over the machine's lifespan.

Key Selection Criteria for Your 2026 Canola Sorter

Selecting the right equipment requires a careful evaluation of your specific needs. This guide outlines the essential criteria for choosing the best canola seeds optical sorter for your operation in 2026.

Define Your Sorting Priorities

Processors must first identify their primary goal. Is the objective maximum purity for a premium market or high throughput for bulk processing? A facility targeting export-grade canola will prioritize a machine with superior defect removal. An operation focused on volume will need a sorter that minimizes bottlenecks. Clearly defining this priority narrows down the suitable models.

Evaluate Throughput vs. Footprint

A sorter's capacity must align with your production line's speed. High-throughput machines require more physical space. Facilities should measure their available floor area before committing to a large-scale system. Smaller operations might find a compact, lower-capacity model offers a better balance of performance and space efficiency.

Assess Technology and Software

Modern sorters rely on advanced software for optimal performance. A user-friendly interface is crucial for quick staff adoption and consistent operation. Some systems offer a straightforward design that helps operators understand sorting data at a glance. Processors should evaluate the software's simplicity and the power of its underlying AI and sensor technologies.

Calculate Total Cost of Ownership

The initial purchase price is only one part of the total investment. A comprehensive calculation provides a more accurate financial picture.

A true cost analysis should include:

- Initial Investment: The machine price plus installation and facility retrofitting costs.

- Operational Expenses: Energy consumption per ton and other running costs.

- Labor and Training: Costs to train staff and any changes to staffing needs.

- Maintenance: The expense of service contracts and spare parts.

Consider Maintenance and Support

Reliable post-purchase support is essential for maximizing uptime. A quality canola seeds optical sorter should come with a strong warranty and accessible customer service. Processors should inquire about the manufacturer's maintenance protocols and the availability of technicians. Regular, manufacturer-supported maintenance reduces the risk of unexpected breakdowns and extends the machine's lifespan.

Selecting the right equipment depends on specific operational priorities. This guide provides clear recommendations for 2026.

- For Purity: The Tomra 5C ProScan is the clear winner, delivering maximum purity with minimal product loss.

- For Value: The Satake FMS-IR provides the best balance of performance and affordability.

- For Throughput: The Buhler SORTEX H SpectraVision remains the top choice for high-speed, large-scale operations.

Use this guide to select the optimal canola seeds optical sorter that aligns with your processing goals and budget.

FAQ

What are the primary defects optical sorters remove from canola?

Sorters primarily target sclerotia, a major grading factor. They also remove foreign materials, weed seeds, damaged seeds, and discolored kernels to improve overall product quality and value.

Is an IR or full-color sorter better for canola seeds?

Full-color cameras are essential for identifying color defects. Infrared (IR) sensors add value by detecting foreign materials that have a similar color but different structure, improving overall sorting precision.

See Also

Essential Industrial Checkweighers: A Must-Have for Modern Food Processing Facilities

Leading Capsule Checkweighers: Smart Investments for Buyers in the Coming Year

Capsule Sorters Explained: Crucial Technology for Effective Defect Elimination

Premier Precoating Materials: Enhancing Filtration System Performance for the Future

Innovations in Folder Gluer Features: Shaping 2025's Carton Production Lines