The Ultimate List of Top 5 Poppy Seed Sorters

The global poppy seeds market is projected to grow from USD 220.65 million in 2025 to USD 266.33 million by 2033. This expansion increases the need for efficient processing. A modern poppy seeds optical sorter ensures product purity. Leading machines include the Buhler SORTEX A, TOMRA 3C, Satake Pikasen Alpha, Key Technology VERYX, and NAGE Seven Channel Sorter.

1. Buhler SORTEX A

The Buhler SORTEX A stands as a benchmark for high-capacity, precision sorting in the food processing industry. Its advanced technology suite makes it a formidable tool for achieving superior product quality. This machine combines robust engineering with sophisticated detection systems to meet the most stringent purity standards.

Key Specifications

The SORTEX A features a powerful set of technical capabilities designed for maximum efficiency. Key specifications include:

- Throughput: Processes up to 40 metric tons per hour.

- Color Detection: High-resolution ColorVision cameras identify up to five color defects simultaneously across its five chutes.

- Advanced Sensing: It utilizes InGaAs technology to spot foreign materials that are difficult to detect. PROfile technology analyzes product shape and size.

- Compliance: The machine is fully ATEX-compliant for safe operation in potentially explosive environments.

Benefits for Poppy Seed Sorting

This machine provides exceptional benefits for poppy seed processors. Its InGaAs technology excels at identifying and removing subtle foreign materials like stems, pods, and other organic matter. The PROfile shape recognition system precisely ejects clumps or misshapen seeds, ensuring a uniform final product. High-resolution cameras detect minute color variations, effectively separating discolored or immature seeds from the prime batch. This comprehensive approach guarantees a high level of purity and safety. The SORTEX A is a premier poppy seeds optical sorter for quality-focused producers.

Ideal Industrial Application

The Buhler SORTEX A is engineered for large-scale industrial processors. Its high throughput and multi-chute design are perfect for facilities that handle massive volumes of poppy seeds daily. Companies supplying international markets or major food manufacturers will find its performance and reliability essential for maintaining consistent output and meeting strict quality contracts.

2. TOMRA 3C

The TOMRA 3C offers a powerful and versatile sorting solution for a wide range of food products, including tiny seeds. It combines advanced sensor technologies to deliver high-efficiency sorting, making it a strong contender for processors who prioritize both purity and operational flexibility. The machine is engineered for reliability and precision across various capacity needs.

Key Specifications

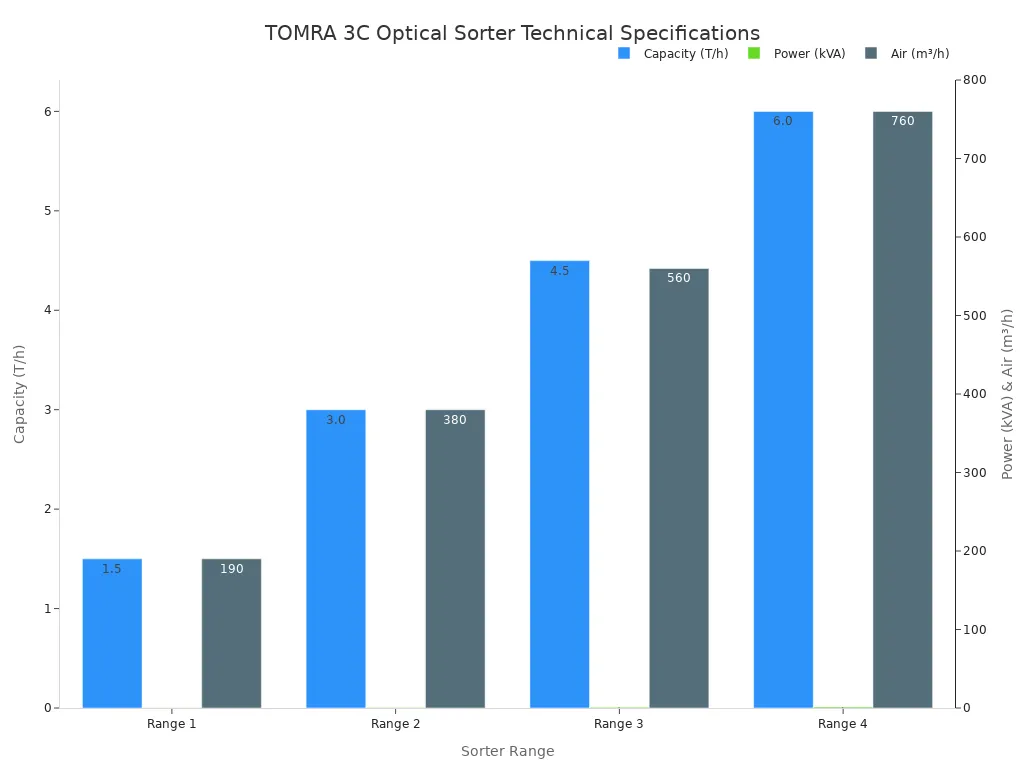

TOMRA provides several configurations for the 3C model, allowing businesses to scale operations effectively. Its specifications vary by range:

| Specification | Range 1 | Range 2 | Range 3 | Range 4 |

|---|---|---|---|---|

| Capacity (T/h*) | 1.2 - 1.8 | 2.4 - 3.6 | 3.6 - 5.4 | 4.8 - 7.2 |

| Power (kVA) | 0.4 | 0.7 | 1.1 | 1.4 |

| Air (m³/h) | < 190 | < 380 | < 560 | < 760 |

Note: The maximum flow rate depends on product type, input defect load (IDL), and specific sorting arrangements.

Benefits for Poppy Seed Sorting

The TOMRA 3C provides significant advantages for poppy seed processors. Its dual-sided, high-resolution cameras and laser technology work together to inspect each seed thoroughly. This combination is highly effective at detecting and ejecting foreign materials, discolored seeds, and even subtle structural defects. The machine’s intelligent ejection system minimizes the loss of good product, maximizing yield and profitability. Its robust design ensures consistent performance, which is critical for maintaining product quality batch after batch.

Ideal Industrial Application

The TOMRA 3C is an excellent choice for small to large-sized processors who require a scalable and adaptable sorting solution. Its multiple capacity ranges make it suitable for businesses planning for growth. Companies that process a variety of seeds or food products will benefit from its versatility and quick changeover capabilities, ensuring a high return on investment.

3. Satake Pikasen Alpha

The Satake Pikasen Alpha (FMS-2000) is a compact and highly efficient sorter known for its precision and user-friendly design. It offers an excellent balance of performance and value, making advanced sorting technology accessible to a broader range of producers. Its thoughtful engineering focuses on delivering high-purity results in a small footprint.

Key Specifications

The Pikasen Alpha packs impressive capabilities into a portable frame. Its specifications make it a versatile tool for quality control.

| Specification | Detail |

|---|---|

| Model | PIKASEN (FMS-2000) |

| Capacity | 1 LB to 4,000 LBS/H |

| Camera | Full Color RGB |

| Light Source | CCFL (20,000 HRS) |

| Chute Width | 240 MM |

| Control Panel | Full Color Touch Panel |

| Power Supply | Single Phase AC200-240 |

| Portability | Integrated Wheels |

Benefits for Poppy Seed Sorting

This machine delivers significant advantages for poppy seed processing. Its full-color RGB cameras accurately detect and remove off-color seeds, foreign grains, and other small contaminants. The patented raw material supply system ensures a consistent, stable flow of seeds, which is critical for effective inspection and ejection. Operators can easily manage sorting parameters using the full-color touch panel, allowing for quick adjustments. The Pikasen Alpha's precision minimizes the rejection of good seeds, maximizing product yield and profitability for processors.

Ideal Industrial Application

The Satake Pikasen Alpha is the perfect solution for small to medium-sized enterprises, specialty food processors, and pilot plants. Its wide capacity range and integrated wheels offer unmatched flexibility. Businesses that require high-purity sorting without the massive scale or capital investment of larger industrial machines will find this model provides an exceptional return on investment.

4. Key Technology VERYX

Key Technology's VERYX platform represents a leap forward in intelligent sorting. It is a highly modular system that fuses advanced sensor technology with powerful data analytics. This combination allows processors to not only remove defects but also to gather critical information about their product stream, driving process improvements.

Key Specifications

The VERYX sorter is configurable, with the VERYX BioPrint C140 model being particularly powerful. Its specifications showcase its advanced detection capabilities.

- Capacity: Processes up to 8 metric tons of product per hour.

- Sensor Fusion: It utilizes Multi-Sensor Pixel Fusion™ to combine pixel-level data from multiple sensors.

- Advanced Imaging: The system integrates high-resolution color cameras with BioPrint® hyperspectral imaging technology. This technology analyzes the unique biological and chemical properties of objects.

- Data Analytics: Key’s Information Analytics software collects and shares sorting data, enabling deep process analysis via an OPCUA-compliant infrastructure.

- Inspection: The machine performs complete in-air inspection of every object from all sides.

Benefits for Poppy Seed Sorting

The VERYX sorter offers unparalleled precision for poppy seed processors. Its Pixel Fusion™ technology is a key advantage. This system combines input from cameras and laser scanners to generate higher contrast, making it easier to find the most difficult-to-detect foreign materials. It creates a unique "signature" for each substance, allowing the machine to differentiate good seeds from tiny contaminants with extreme accuracy. This process ensures the consistent removal of defects without mistakenly ejecting good product, maximizing yield.

Ideal Industrial Application

The Key Technology VERYX is engineered for large-scale, data-driven food processors. Its ability to analyze product attributes in real-time makes it invaluable for operations that prioritize process optimization. Companies can use its Information Analytics to monitor incoming product quality, provide feedback to growers, and identify issues in upstream equipment. It is the ultimate tool for processors seeking to leverage big data for enhanced quality control and improved operational efficiency.

5. NAGE Seven Channel Sorter

The NAGE Seven Channel Sorter, originating from the manufacturing hub of Hefei City, provides a robust and accessible sorting solution. This machine is designed to deliver reliable performance with a focus on value and long-term operational support. It represents a practical choice for producers seeking modern sorting capabilities without a premium price tag.

Key Specifications

The NAGE 6SXZ-448 model showcases the brand's focus on high-density channel design for effective sorting. Key parameters highlight its industrial-grade construction.

| Parameter | Value |

|---|---|

| Model NO. | 6SXZ-448 |

| Channel Number | 448 |

| Structure | Waterfall |

| Light Source | LED |

| Sensor Type | CCD |

| Origin | Hefei City |

Benefits for Poppy Seed Sorting

This sorter offers excellent value for poppy seed processors. Its high-density channel configuration and CCD sensors, illuminated by a stable LED light source, effectively identify and eject foreign materials and discolored seeds. A significant advantage is the manufacturer's support package, which lowers the total cost of ownership. Key support benefits include:

- One year of free repair and maintenance.

- Lifelong software upgrade services at no cost.

- Guaranteed supply of spare parts. The machine's modest power requirement of 4 KW also helps manage operational expenses, making it an economically sound investment.

Ideal Industrial Application

The NAGE Seven Channel Sorter is an ideal fit for producers who prioritize a low initial investment and predictable long-term costs. It is particularly well-suited for new businesses entering the market or established companies in regions seeking cost-effective capacity expansion. Its straightforward design and strong post-sale support make it a reliable workhorse for operations focused on efficiency and budget control.

Key Factors for a Poppy Seeds Optical Sorter

Selecting the right machine requires a careful evaluation of several critical factors. Processors must balance production demands with technology to achieve the best return on investment. A thorough analysis of throughput, accuracy, and machine configuration will guide you to the ideal poppy seeds optical sorter for your operation.

Throughput and Capacity

Throughput measures the volume of product a sorter can process within a specific timeframe. This metric is crucial for aligning the machine's capabilities with your production goals. For poppy seeds, typical optical sorters handle between 800 and 1,200 kilograms per hour. Large-scale operations require high-capacity machines to meet output targets, while smaller businesses may find a lower-throughput model more cost-effective. Matching capacity correctly prevents bottlenecks and ensures efficient workflow.

Sorting Accuracy and Technology

The core function of a sorter is to remove defects with precision. Modern machines achieve remarkable accuracy, with some capable of detecting imperfections as small as 0.04 mm. This level of detail is essential for removing tiny foreign materials, discolored seeds, and other contaminants.

Advanced technologies like high-resolution CCD cameras, laser sensors, and hyperspectral imaging enable this precision. They identify subtle differences in color, shape, and even chemical composition, ensuring a final product of the highest purity.

Chute vs. Belt Configuration

Sorters move products past sensors using either a chute or a belt system. While chute sorters are common, belt-fed sorters offer distinct advantages for delicate products like poppy seeds.

- Gentle Handling: A belt provides a stable surface, minimizing bouncing and collisions that can damage fragile seeds.

- Superior Accuracy: The controlled movement on a belt allows for more precise imaging. This stability helps belt sorters achieve accuracy rates between 97% and 99.99%.

- Reduced Breakage: By preventing friction and impact, belt systems protect the value of the crop.

Processors prioritizing product integrity and maximum purity often prefer a belt configuration.

Comparative Analysis

Choosing the right sorter involves comparing their performance, technology, and intended applications. This analysis breaks down how each machine stacks up against the others, helping you identify the best fit for your specific poppy seed processing needs.

Performance Metrics

A direct comparison of key metrics reveals the distinct strengths of each model. Processors can evaluate these specifications to align a machine's capabilities with their production demands.

| Sorter Model | Max Capacity (Metric Tons/hr) | Key Technology | Ideal Scale |

|---|---|---|---|

| Buhler SORTEX A | 40 | InGaAs & PROfile Shape | Large Industrial |

| Key Technology VERYX | 8 | Hyperspectral Imaging | Large, Data-Driven |

| TOMRA 3C | ~7.2 | Laser & Dual-Side Cameras | Small to Large |

| Satake Pikasen Alpha | ~1.8 | Full Color RGB | Small to Medium |

| NAGE Sorter | Varies | CCD & LED | Budget-Focused |

Technology Showdown

Advanced camera technology is a critical differentiator. Buhler's sorters feature highly developed monochromatic and bi-chromatic cameras. These sensors offer an extremely high resolution, enabling the detection of the smallest defects. This system, combined with PROfile shape recognition, identifies a wide range of foreign materials and subtle color variations.

Other industry leaders also push technological boundaries. Competing systems from manufacturers like TOMRA Systems ASA and Key Technology, Inc. (A Duravant Company) utilize their own sophisticated sensor fusion and hyperspectral imaging to achieve remarkable sorting precision.

Best Use Case Summary

Each sorter excels in a specific operational context. Matching the machine to your business model ensures the best return on investment.

- Buhler SORTEX A: Best for maximum throughput and purity in large-scale industrial settings.

- Key Technology VERYX: Ideal for data-driven processors who want to optimize their entire production line.

- TOMRA 3C: A versatile choice for processors needing a scalable solution for various products.

- Satake Pikasen Alpha: Perfect for small-to-medium operations requiring flexibility and high precision.

- NAGE Sorter: Suited for new or budget-conscious businesses focused on reliable performance and low ownership costs.

Selecting the ideal machine depends on your operational scale and quality goals.

- The Buhler SORTEX A is the premier choice for large-scale processors demanding maximum purity and throughput.

- The Satake Pikasen Alpha offers exceptional value for small to medium-sized operations seeking a versatile, cost-effective solution.

Pro Tip: Always contact manufacturers for a product demo. This final step ensures you select the perfect poppy seeds optical sorter tailored to your specific requirements.

FAQ

What is the primary function of an optical sorter for poppy seeds?

An optical sorter uses cameras and sensors to inspect poppy seeds. It rapidly identifies and removes foreign materials, discolored seeds, and other defects to ensure product purity and safety.

How does a sorter improve poppy seed quality?

A sorter enhances quality by creating a uniform final product. It ejects misshapen seeds, clumps, and contaminants. This process guarantees a premium batch that meets strict industry standards.

See Also

Essential Industrial Checkweighers: Top 3 for Food Plant Operations

Capsule Sorters: Key to Efficient Defect Removal in Production

Best Capsule Checkweighers for Buyers to Evaluate in 2025

Five Optimal Uses for Single Stage Rotary Vane Vacuum Pumps

Tablet Sampling Machines: A Comprehensive Lab Selection Guide Explained