The Top 5 Sorters for Your Apple and Pear Line

Leading brands like TOMRA Food, GREEFA, Aweta, MAF RODA Agrobotic, and Unitec set the standard for an apples and pears optical sorter.

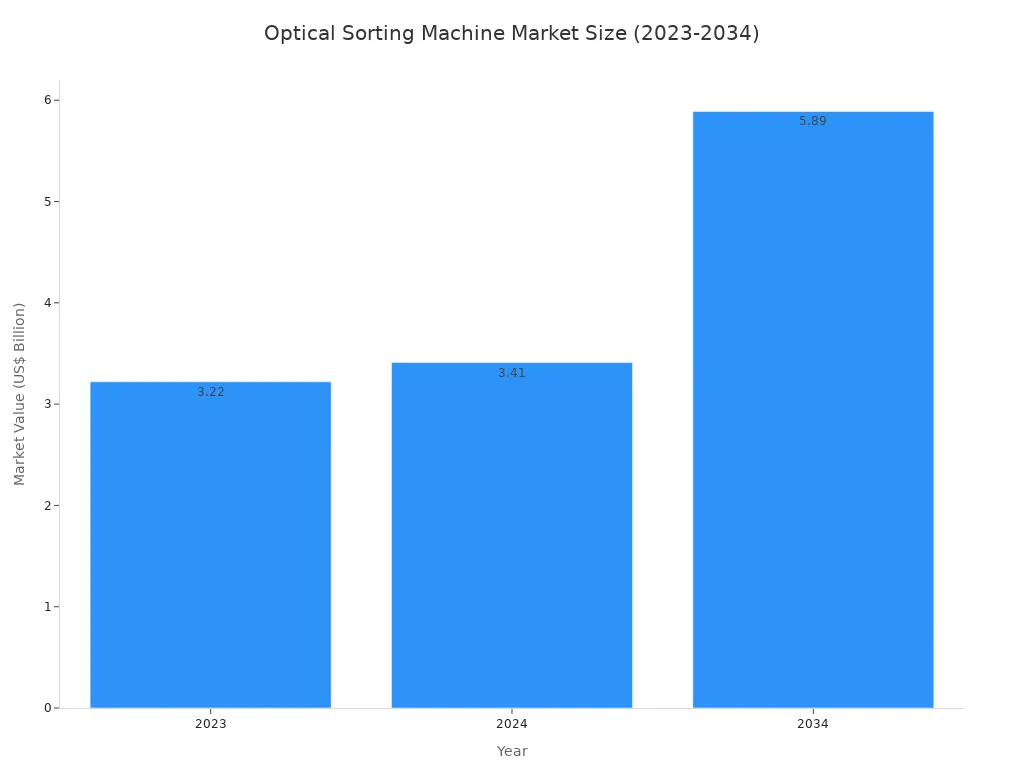

Optical sorting currently holds the largest share within the broader sorting machine market. This sector is projected for significant expansion.

These industry leaders provide advanced technology, proven reliability, and specialized features designed for the gentle handling of delicate pome fruits.

1. TOMRA Food: Precision at High Volumes

TOMRA Food establishes itself as a leader for packing houses that require accuracy at high speeds. The company engineers its sorting technology to handle large volumes of fruit without sacrificing quality control, making it a top choice for demanding apple and pear operations.

Spectrim and InVision2 Sorters

TOMRA offers two powerful platforms: the Spectrim and the InVision2. Each system provides distinct capabilities for modern packing lines. The primary differences revolve around their integrated technologies and upgrade paths.

- TOMRA Spectrim: This advanced system already integrates LUCAi™ Deep Learning AI. It assesses thousands of images per second and uses pre-trained models for precise grading.

- InVision2: This grading system is slated to receive a LUCAi™ upgrade. The initial focus for this AI enhancement is on cherries, with plans to expand to other fruits later.

Advanced Defect and Blemish Detection

The company's technology excels at identifying difficult-to-spot imperfections. The Spectrim sorter, powered by LUCAi™ AI, uses high-resolution imaging to detect complex defects like skin splits, punctures, and subtle blemishes. This capability makes it an exceptional apples and pears optical sorter. Operators can customize grading parameters, giving them full control over the final product quality and ensuring consistency across every batch.

Gentle Handling for Delicate Fruit

Note: TOMRA designs its equipment with the delicate nature of pome fruits in mind. The company prioritizes gentle handling to minimize bruising and preserve fruit value.

Systems like the TOMRA 5B belt sorter demonstrate this principle. They incorporate specialized mechanisms to move fruit smoothly through the inspection process. This careful design maintains the premium quality of apples and pears from the moment they enter the line until they are packed, protecting grower investment and delivering a superior product to consumers.

2. GREEFA: Excellence in Quality Grading

GREEFA distinguishes itself with a strong focus on comprehensive quality grading and system flexibility. The company provides sorting solutions that meticulously evaluate both the inside and outside of each fruit, ensuring only the best products reach the market.

GeoSort and SmartSort Models

GREEFA offers several models tailored to specific fruit types and operational needs. The GeoSort and SmartSort are two prominent examples, each designed for high performance and gentle handling. Their key differences cater to various packing house requirements.

| Feature/System | GREEFA GeoSort | GREEFA SmartSort |

|---|---|---|

| Primary Application | Delicate fruit like apples | Citrus and stone fruit |

| Speed | Up to 8 fruits/sec per lane | Up to 12 fruits/sec per lane |

| Key Features | Modular, fruit-friendly design | Special transfer for speed |

The GeoSort is particularly well-suited as an apples and pears optical sorter due to its gentle mechanics and precise weight measurement.

Measuring Internal and External Quality

GREEFA technology provides a complete picture of fruit health. High-definition cameras inspect the entire surface of each apple and pear, detecting external issues like discoloration and blemishes. The system also measures size and shape with exceptional accuracy. For internal quality, GREEFA’s non-invasive sensors can determine:

- Apples: Sugar content (Brix), ripeness, and internal defects.

- Pears: Brix levels and internal flaws such as brown spots or rot.

This dual capability ensures that product quality meets the highest standards, both visibly and internally.

Modular Design for Future Scalability

A key advantage of GREEFA systems is their modular construction. This design allows packing houses to start with a configuration that meets their current needs and add new capabilities later.

This approach provides excellent investment protection. As a business grows or market demands change, operators can easily integrate additional modules. Available upgrades include advanced measuring systems for internal quality (iFA), automated packers (SmartPackr), and enhanced data analysis tools. This scalability ensures the sorting line remains a valuable asset for years to come.

3. Aweta: Customizable Sorting Solutions

Aweta provides highly customizable sorting solutions for packing houses with specific operational demands. The company engineers its systems for flexibility, allowing growers to tailor the technology to their unique fruit types and processing environments.

Calistar and Megastar Sorters

Aweta offers the Calistar and Megastar sorters, each built for distinct applications. The Calistar is specifically designed as an 'Apple Pre-sizer' for handling wet products directly from water flumes. Its unique gripper design prevents water and dirt from affecting system performance. Key features include:

- Robust design for wet or dry conditions

- Extremely gentle fruit handling

- Perfect singulation and camera presentation

- Accurate weight measurements

- Quiet operation and low cost of ownership

The Megastar model offers another powerful solution, providing high-capacity sorting for various round and oblong fruits.

Advanced Camera and Sensor Technology

Aweta integrates advanced camera and sensor systems to ensure precise quality control. High-resolution cameras capture detailed images of each fruit's entire surface. This technology allows the system to accurately detect external defects, including blemishes, russeting, and shape or color inconsistencies. Operators can set specific grading parameters, ensuring the final pack meets exact market specifications and brand standards. This makes it a reliable apples and pears optical sorter for quality-focused operations.

Adapting to Diverse Fruit Varieties

A primary strength of Aweta systems is their adaptability. The technology is not limited to a single fruit type but can be configured to handle a wide range of apple and pear varieties.

This versatility is crucial for growers who cultivate multiple types of pome fruit, each with different sizes, shapes, and handling requirements. The system’s software and mechanical components can be adjusted to optimize performance for everything from small, delicate pears to large, robust apples. This ensures gentle handling and accurate grading across the entire crop portfolio.

4. MAF RODA Agrobotic: A Robust Apples and Pears Optical Sorter

MAF RODA Agrobotic delivers robust and reliable sorting solutions engineered for durability and precision. The company focuses on creating systems that provide consistent performance and serve as a key tool for operational decision-making in modern packing houses.

Globalscan 7 and Insight Quality Systems

MAF RODA's technology is centered around its advanced electronic grading platforms, Globalscan 7 and Insight. The Globalscan 7 system stands at the cutting edge of technology, offering real-time analysis to ensure high-precision quality grading. Its primary functions include:

- Controlling external fruit aspects like color, shape, and skin defects.

- Analyzing fruit in real-time to select only products with no external flaws.

- Integrating AI-based solutions for faster and more adaptive defect detection.

These systems provide operators with the data needed to make informed decisions and maintain strict quality control.

High-Resolution Imaging for Subtle Defects

MAF RODA utilizes a patented multispectral camera technology to achieve superior defect detection. This innovative approach sets its systems apart from conventional sorters.

Instead of using multiple cameras, the system employs a single camera per position to capture all necessary wavelengths simultaneously. This design produces exceptionally homogeneous and sharp images for the quality algorithms. It also eliminates the overlaps and alignment errors common with multi-camera setups. The result is greater precision in identifying subtle skin defects on apples and pears.

Comprehensive Support and Reliability

The design of the MAF RODA apples and pears optical sorter emphasizes system stability and profitability. By requiring fewer cameras—for example, three multispectral cameras versus up to twelve conventional ones—the system significantly reduces potential points of failure. This streamlined hardware leads to less downtime, fewer incidents, and lower maintenance costs. The increased robustness and stability ensure the sorting line operates efficiently, maximizing throughput and delivering a stronger return on investment for growers.

5. Unitec: Preserving Premium Fruit Quality

Unitec specializes in sorting technology that preserves the integrity and value of premium fruit. The company engineers its systems to combine high-speed processing with exceptionally gentle handling, ensuring that delicate apples and pears maintain their quality from entry to exit.

Apples Sort 3 and Pears Sort 3 Technology

Unitec provides dedicated solutions for pome fruits with its Apples Sort 3 and Pears Sort 3 technologies. The Pears Sort 3 system uses an innovative conveyor that allows high-resolution cameras to scan the entire surface of the fruit without rotating it. This unique design protects the delicate skin of pears. Similarly, the Apples Sort 3 platform utilizes advanced cameras to achieve precise and reliable classification for every apple variety.

Non-Invasive Internal Quality Sorting

Unitec technology delivers reliable quality selection by assessing fruit according to multiple criteria. This capability makes it an effective apples and pears optical sorter for meeting diverse market expectations.

This is all possible because this system can select the quality of apples with great reliability and according to multiple parameters: external quality, shape defects, size and color.

This precise grading allows packing houses to sort fruit for different distribution channels and consumer preferences, ensuring the final product consistently meets high standards.

Maximizing Speed While Minimizing Waste

Unitec systems are designed to increase operational efficiency while protecting fruit from damage. The gentle mechanics significantly reduce the risk of bruising, a critical factor for maintaining the value of premium pears.

A pear that starts with no skin damage its run on the UNITEC line will end up with no markings after being ran across the line.

This focus on gentle handling, combined with automation, leads to major operational benefits. The technology increases overall productivity and provides significant savings in labor costs. Unitec also offers advanced packing solutions:

- UNI INTELLIGENT PACK: This robotic system orients apples in trays based on color and stem direction, creating an aesthetically perfect final package.

Choosing the right apples and pears optical sorter depends on your specific needs. Each leading brand offers distinct advantages:

- TOMRA: High-volume precision

- GREEFA: Modular quality grading

- Aweta: Customization

- MAF RODA: Robust reliability

- Unitec: Premium fruit preservation

Contact our experts to discuss your operational goals and find the perfect fit.

FAQ

How does AI improve apple and pear sorting?

AI uses deep learning to analyze thousands of images per second. This technology identifies complex defects with superior precision, ensuring more consistent and accurate fruit grading.

Can one machine sort both apples and pears? ⚙️

Yes, most modern sorters handle both fruits. Systems from brands like Aweta offer adaptability. They adjust mechanical and software settings for different fruit shapes and sizes.

What is the most important factor when choosing a sorter?

The ideal sorter depends on key operational factors. A packing house must consider its processing volume, specific quality grading requirements, and overall budget to find the best fit.

See Also

Capsule Sorters: Essential Technology for Flawless Product Defect Elimination

Essential Industrial Checkweighers for Optimal Food Plant Efficiency

Advanced Folder Gluer Innovations Shaping 2025 Carton Production Lines

Crucial Revisions to Bearing Box Freight Classification Standards

Leading Ampoule Filling Line Manufacturers Compete for Industry Dominance