Optical Sorting for Squid A Guide to Better Quality

The global octopus market is projected to reach $5 billion by 2029. To meet this demand, over 15% of seafood facilities now use automated sorting. A squid and octopus optical sorter uses advanced cameras and sensors. It automatically removes defects and foreign materials, delivering superior speed and accuracy for a higher-value product.

Key Quality Upgrades with a Squid and Octopus Optical Sorter

Implementing an optical sorter provides immediate and significant upgrades to product quality. The technology enhances the final product by targeting three critical areas: removing imperfections, standardizing product size, and separating valuable components with unmatched precision. These improvements directly translate to higher market value and greater consumer confidence.

Superior Defect and Foreign Material Removal

A primary function of a squid and octopus optical sorter is the identification and ejection of defective products and foreign materials. Cephalopods present a unique challenge for processors. Their bodies undergo autolysis, or self-digestion, up to 10 times faster than other fish species. This rapid process shortens shelf life and can lead to quick spoilage, causing discoloration and off-odors that result in product rejection.

Advanced sorters use high-definition cameras to spot these subtle imperfections. The system can detect issues that are difficult for the human eye to catch consistently, especially at high speeds.

| Defect Type | Higher Quality Indicator | Lesser Quality Indicator |

|---|---|---|

| Flesh Color | White, slightly translucent | Darkens to a strong pink tinge |

| Skin Condition | Intact, with distinct iridescence | Some tears in the skin, some broken arms |

| Flesh Texture | Elastic, very firm, not slimy | Loss of elasticity, soft, slimy or gritty |

Beyond aesthetic defects, removing contaminants is essential for food safety.

Improperly stored or spoiled squid can harbor harmful bacteria like Vibrio. This poses a significant health risk, potentially causing food poisoning. Ensuring all compromised product is removed is crucial for protecting consumers and brand reputation.

The sorter instantly removes any item that fails to meet pre-set quality standards, ensuring only the best product continues down the processing line.

Precise Size and Weight Grading

Consistency is key to commanding a premium price. A squid and octopus optical sorter excels at grading products by size and dimension with remarkable accuracy. Using high-resolution cameras, the system performs multi-dimensional image processing to analyze the length, width, and shape of each individual piece, from whole octopus to calamari rings.

This capability allows processors to meet exact specifications for commercial packaging. Products are often sold in specific formats, such as 3lb boxes of cleaned squid rings or vacuum-packed trays of 8/10g tentacles. Automated grading ensures every package contains a uniform product, which is essential for both retail and food service clients.

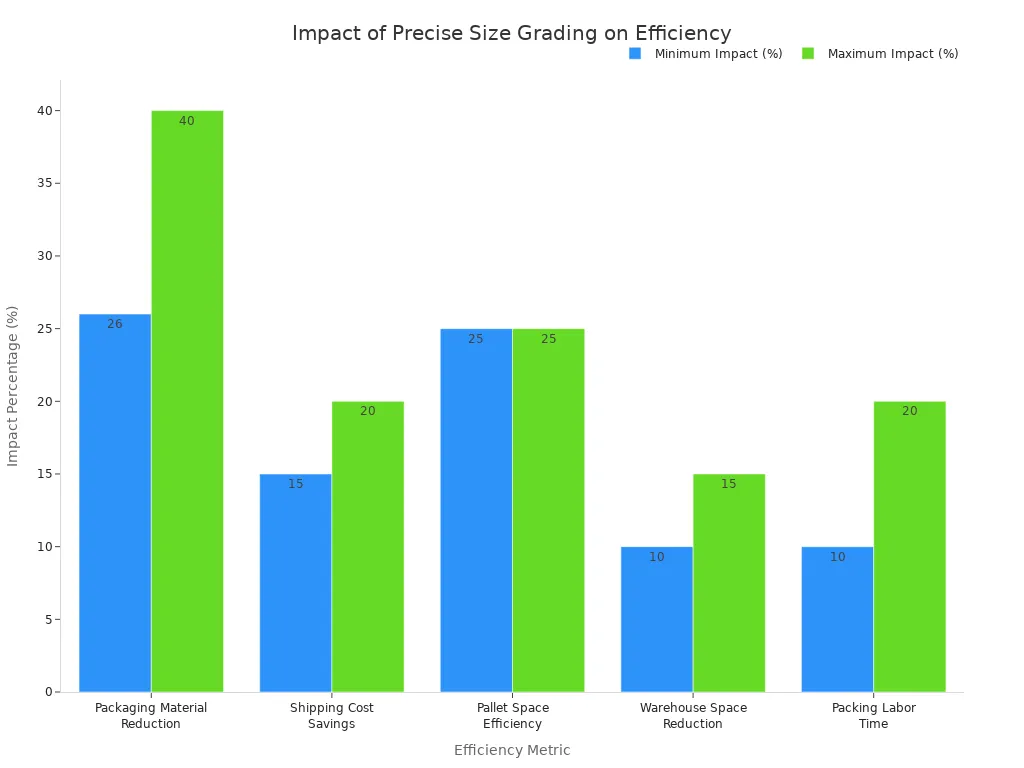

Precise grading enables "right-sized" packaging, a strategy that dramatically reduces operational costs and improves efficiency across the supply chain.

By sorting squid and octopus into uniform size groups, processors can achieve:

- Reduced Shipping Costs: Eliminating oversized boxes lowers dimensional weight charges.

- Less Material Waste: Tightly packed boxes require less cardboard and void fill.

- Improved Labor Efficiency: Uniform pieces are faster and easier for workers to pack.

- Greater Pallet Density: More boxes fit onto a single pallet, optimizing transport and storage.

This level of precision is nearly impossible to achieve with manual sorting, giving automated systems a clear advantage in creating a cost-effective and visually appealing final product.

Accurate Species and Part Separation

Different cephalopod species, and even different parts of the same animal, carry different market values. Optical sorting technology can distinguish between these variations, allowing processors to create separate, high-value product streams from a mixed batch.

The technology's effectiveness is proven in other industries. For example, optical sorters separate different types of legumes with near-perfect accuracy to create certified gluten-free products, which command a higher price. In recycling, sorters distinguish between PET and PVC plastics with over 99% accuracy, enabling the production of high-grade materials. The data below shows the typical accuracy of industrial sorters in separating a target product from contaminants.

| Dataset | % Correct Classification | % True Positive | % False Positive | % False Negative |

|---|---|---|---|---|

| Broad bean | 99.44 | 99.44 | 0.00 | 0.56 |

| Lentil | 99.67 | 99.67 | 0.00 | 0.33 |

| Chickpea | 99.36 | 99.36 | 0.00 | 0.64 |

This same principle applies to seafood. A sorter can be programmed to differentiate Loligo squid from Illex squid or to separate high-demand tentacles from tubes. This automated separation ensures product line purity and allows processors to market each component at its optimal price point, maximizing revenue from the total catch.

Operational Advantages Over Manual Inspection

Shifting from manual inspection to automated sorting delivers transformative operational benefits. Beyond enhancing product quality, a squid and octopus optical sorter streamlines the entire processing workflow. This technology provides a powerful solution to modern challenges like labor shortages, inconsistent quality control, and stringent food safety demands, giving processors a significant competitive edge.

Increased Throughput and Reduced Labor Costs

Seafood processing is a labor-intensive industry often facing significant workforce shortages. Optical sorters directly address this challenge by automating the demanding task of inspection. These systems operate at high speeds, processing tons of product per hour and dramatically increasing throughput. This automation reduces the facility's reliance on manual labor, allowing staff to be reassigned to other value-added tasks.

Automated systems work tirelessly without fatigue, identifying defects that are often imperceptible to the human eye. This leads to a substantial boost in overall efficiency.

| Method | Efficiency |

|---|---|

| Automated Detection | 80% to 90% |

| Manual Picking (Human) | 20% to 40% |

By adopting automation, seafood processors can maintain high productivity levels even during periods of labor scarcity, ensuring a stable and efficient operation.

Unmatched Consistency and Accuracy

Human inspection is inherently subjective and prone to error. Factors like fatigue, distraction, and varying skill levels cause accuracy to degrade over long shifts, leading to inconsistent product quality. Optical sorters eliminate this variability by applying objective, pre-defined standards to every single item.

| Feature | Optical Sorters | Human Inspectors |

|---|---|---|

| Consistency | Maintain consistent accuracy 24/7 | Accuracy degrades over time due to fatigue |

| Defect Detection | Near 100% detection of micro-cracks and discoloration | Prone to inconsistencies and human error |

| Speed | Processes thousands of items per hour | Creates production bottlenecks at high speeds |

This superior performance is driven by advanced technologies.

- Artificial Intelligence (AI): AI algorithms allow the system to learn from data, recognize complex patterns, and make sorting decisions with exceptional accuracy.

- Deep Learning: This technology enables the sorter to adapt its criteria over time, continuously improving its ability to identify new or subtle defects.

- High-Speed Processors: These components facilitate real-time analysis and decision-making, enabling the sorter to operate at maximum speed without sacrificing precision.

This technological advantage ensures that every batch meets the same high-quality standard, which is fundamental for building customer loyalty and protecting brand reputation.

Improved Food Safety and Traceability

Maintaining a hygienic processing environment is critical in the seafood industry. Optical sorting enhances food safety by minimizing human contact with the product. The non-contact sorting process significantly reduces the risk of cross-contamination.

How Non-Contact Sorting Works ⚙️

- A conveyor belt moves the squid or octopus under advanced sensors.

- The sensors identify each item based on its unique properties (color, shape, or chemical signature).

- Precisely aimed jets of compressed air eject any defective or foreign material.

- The accepted product continues on a separate conveyor, untouched.

This automated, non-contact method ensures that contaminants are removed efficiently and hygienically. Furthermore, the data generated by a squid and octopus optical sorter provides detailed records of sort criteria, defect rates, and batch quality. This information creates a robust digital trail, improving traceability and giving processors valuable insights for optimizing their operations.

A squid and octopus optical sorter directly elevates product quality through superior defect removal and precise grading. This technology offers a more efficient, reliable, and data-driven alternative to manual methods, boosting key metrics like throughput and accuracy to increase both product value and operational performance.

FAQ

Can one sorter handle both squid and octopus?

Yes. Processors program the system with specific parameters. It accurately sorts different species and product forms, from whole octopus to calamari rings, ensuring maximum operational flexibility.

Does optical sorting damage the delicate product?

No. The system uses a non-contact sorting method. It identifies defects with cameras and uses precise air jets for ejection, preserving the product's integrity and quality.

How quickly can a facility see a return on investment?

The ROI is typically rapid. Increased throughput, reduced labor costs, and higher product value from precise grading contribute to a fast payback period for most processing facilities.

See Also

Capsule Sorters: Essential Tools for Flawless Product Quality

Top Capsule Checkweighers for Smart Buyers in the Year 2025

Crucial Changes to Bearing Box Freight Classification You Need to Know

Tablet Samplers: A Comprehensive Guide for Laboratory Equipment Selection

Hygienic Design: EHEDG and 3A SSI Standards in Detailed Comparison