The Ultimate Comparison Optical Sorters and Manual Sorting in 2025

Producers of niche dietary products build their brands on superior quality and safety. The right sorting technology choice is therefore essential for profitability.

A specialty diets optical sorter delivers a higher return on investment, ensuring near-perfect accuracy that manual sorting cannot match.

This advanced technology drastically reduces labor costs and increases production throughput.

Cost Analysis: Initial Investment vs. Long-Term ROI

The decision between automation and manual labor often comes down to numbers. A detailed cost analysis reveals that while an optical sorter requires a significant initial investment, it delivers a far superior long-term return on investment (ROI) by eliminating unpredictable and ever-increasing labor expenses.

The True Upfront Cost of an Optical Sorter

An optical sorter represents a major capital expenditure (CapEx). The price tag includes not just the hardware but also several other critical components:

- Machine & Technology: The core cost is the sorter itself, equipped with high-resolution cameras, advanced sensors (like infrared or X-ray), and powerful processors.

- Installation & Integration: This covers the physical setup and integration of the machine into an existing production line.

- Software & Programming: Customizing the sorting parameters for specific products, such as gluten-free grains or allergen-free nuts, is essential.

- Team Training: Initial training ensures operators can manage, clean, and troubleshoot the equipment effectively.

This upfront cost is a one-time, predictable investment. It establishes a fixed asset on the balance sheet, unlike the variable and recurring nature of a manual workforce.

Viewing this expense as a strategic investment in infrastructure is the first step toward understanding its long-term value.

Quantifying Recurring Manual Labor Expenses

Manual sorting teams introduce significant and often volatile operational expenses (OpEx). The direct cost of wages, benefits, and payroll taxes is only the tip of the iceberg. The true financial drain comes from labor instability.

Warehouse turnover rates average between 40% and 49% annually. This means a producer might need to replace nearly half of their sorting team every year. This constant churn creates a cycle of hiring, training, and burnout that carries substantial hidden costs. Each departure forces a company to spend on recruiting, background checks, and onboarding. The full replacement cost per worker can reach an estimated $18,600.

These recurring expenses include:

- Lost Productivity: New hires operate at just 25-70% efficiency for their first 8 to 26 weeks.

- Training Investment Loss: All the time and resources spent training an employee are lost when they leave.

- Team Burnout: Experienced workers must cover for vacancies and train new staff, leading to fatigue, reduced accuracy, and a higher likelihood that they will also leave.

This reliance on manual labor creates an unsustainable model in a tight labor market. Automation eliminates these variables, providing consistent operational capacity without dependency on a fluctuating labor pool.

Calculating Your Break-Even Point

The break-even point is when the cumulative savings from automation equal the initial investment in the machine. A producer can calculate this to justify the purchase and forecast future profitability. The basic formula is straightforward:

Break-Even Point (Months) = Total Sorter Cost / (Monthly Manual Labor Savings - Monthly Sorter Operating Costs)

Let's analyze a hypothetical scenario for a medium-sized producer of specialty diet products.

| Cost Metric | Manual Sorting Team (10 Workers) | Specialty Diets Optical Sorter |

|---|---|---|

| Monthly Labor Cost | $45,000 | $4,500 (1 Supervisor) |

| Monthly Turnover Cost (Avg.) | $7,750 | $0 |

| Monthly Sorter OpEx | $0 | $1,500 (Energy, Maintenance) |

| Total Monthly Cost | $52,750 | $6,000 |

| Net Monthly Savings | $46,750 |

Assuming a total investment of $450,000 for the specialty diets optical sorter, the break-even point would be:

$450,000 / $46,750 per month ≈ 9.6 months

In this example, the machine pays for itself in under a year. After that, the business gains over $46,000 in pure profit every month—money that can be reinvested into growth, marketing, or product development. This calculation transforms the sorter from an expense into a powerful profit-generating asset.

Efficiency and Throughput: Scaling Your Production

Beyond cost savings, automation delivers a fundamental competitive advantage: the ability to scale production efficiently. A specialty diets optical sorter dramatically increases throughput, ensures consistent quality, and minimizes waste in ways manual labor simply cannot. This operational superiority allows a business to grow without the bottlenecks of a human workforce.

Processing Volume: Machine vs. Human Speed

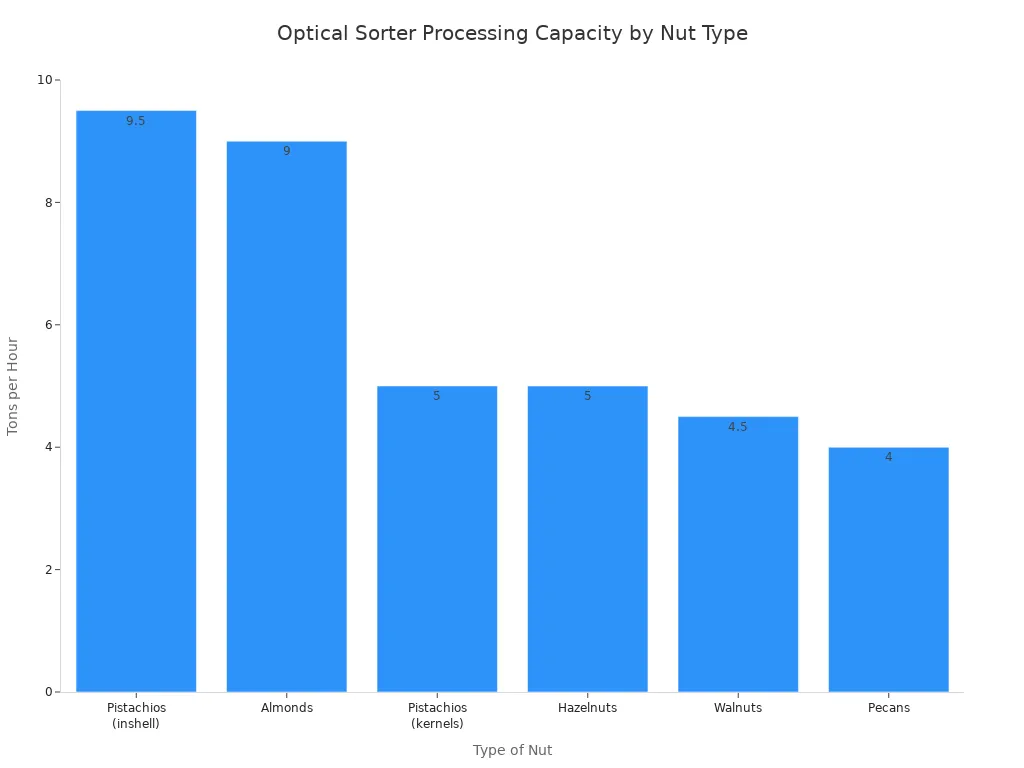

An optical sorter processes tons of product in the time it takes a manual team to sort pounds. This massive difference in speed directly impacts a company's ability to fulfill large orders and expand its market reach. The machine's processing capacity far exceeds human capability, with the exact volume depending on the product.

For grains, a basic color sorter handles 1–10 tons per hour. More advanced optical sorters can process up to 150 tons per hour. A manual team cannot compete with this industrial scale.

Achieving 24/7 Operational Consistency

Automation provides unmatched operational stability. An optical sorter operates continuously without fatigue, breaks, or shift changes.

Machines deliver the same peak performance in the first hour as they do in the twenty-fourth. This consistency ensures predictable output and helps businesses meet tight production deadlines.

Human sorters, in contrast, are prone to fatigue and distraction, which leads to inconsistent performance and variable output throughout the day.

Reducing Product Loss and Material Waste

Efficiency is not just about speed; it is also about maximizing yield. Optical sorters excel at minimizing the rejection of good products, a common and costly issue in manual sorting known as "good-in-bad" rejects.

- They use automated processes to compare items against precise, user-defined quality standards.

- Object-based recognition provides greater control, improving accuracy when ejecting only defective items.

This precision reduces material waste and increases the volume of sellable product, directly boosting revenue.

The Specialty Diets Optical Sorter: Accuracy and Quality

For producers of specialty dietary foods, quality is not a feature; it is the entire brand promise. A single contaminant or undeclared allergen can destroy consumer trust and trigger a catastrophic recall. A specialty diets optical sorter provides a level of precision that safeguards brand reputation by achieving unparalleled accuracy in defect, contaminant, and allergen control.

Detection Beyond Human Vision

The human eye is a remarkable tool, but it has significant limitations. It cannot see microscopic toxins, subtle color variations indicating spoilage, or internal defects. Optical sorters operate with superhuman vision, using advanced sensors to detect imperfections that are completely invisible to a manual inspection team.

A prime example is the detection of aflatoxin, a toxic and carcinogenic compound produced by mold on crops like peanuts and almonds. Aflatoxins are microscopic and cannot be seen, smelled, or tasted. An optical sorter equipped with AflaSort technology makes the invisible visible. It uses a combination of lasers and specialized optics to identify the unique fluorescent signature of aflatoxin.

The detection process is highly technical and precise:

- Fluorescence Detection: The system illuminates the product with ultraviolet (UV) light. Aflatoxin emits a specific fluorescent glow under this light.

- Real-Time Analysis: High-resolution sensors detect this fluorescence signal instantly, identifying the contaminated nut or grain.

- Automated Sorting: A high-speed air jet ejects only the contaminated particle with pinpoint accuracy, ensuring the rest of the product stream remains pure.

This technology removes a dangerous, invisible threat from the food supply, a task impossible for human sorters to perform reliably.

Comparing Error Rates and Recall Risks

Every sorting error introduces risk. While manual inspectors try their best, fatigue, distraction, and human limitations lead to inconsistent results. Automated systems, however, deliver objective and repeatable accuracy, drastically reducing the likelihood of a defective product reaching the consumer.

The data reveals a stark difference in performance. Manual inspectors correctly reject defective items around 85% of the time, meaning they can miss 20% to 30% of all defects. In contrast, modern automated inspection systems achieve accuracy rates between 90% and 99.86%.

| Factor | Manual Inspection | Automated Inspection |

|---|---|---|

| Defect Detection Accuracy | 85% | Up to 99.86% |

| Defects Missed | 20%–30% | As low as 0.14% |

| Consistency | Varies by worker and time of day | Consistent 24/7 |

This gap in accuracy has enormous financial implications. A single sorting failure can lead to a product recall, an event that carries devastating direct and hidden costs. The initial financial hit includes expenses for logistics, product disposal, retailer fees, and regulatory fines. However, the long-term damage is often far worse, encompassing lost sales, increased insurance premiums, and intense regulatory scrutiny.

In the long term, the biggest threat to your company could be intangible brand damage. How your organization responds to the recall can determine whether it becomes a major crisis and damages your brand in the eyes of your consumer and investors.

A well-managed recall may be forgotten, but a poorly handled one can become a case study in crisis mismanagement, permanently eroding brand loyalty and company value. Investing in near-perfect sorting accuracy is a direct investment in risk prevention.

Ensuring Allergen and Contaminant Control

Producers of "free-from" products operate under intense scrutiny. Preventing allergen cross-contact is a foundational requirement for consumer safety and brand integrity. Companies must adhere to rigorous industry standards, including Current Good Manufacturing Practices (cGMP) and comprehensive food safety certifications like SQF, BRCGS, and FSSC 22000. These frameworks mandate strict allergen management protocols.

An optical sorter is an essential tool for meeting these standards. It can be programmed to identify and remove unintended ingredients that may have entered the product stream. For example, in a gluten-free oat processing line, the sorter can detect and eject stray kernels of wheat, barley, or rye with exceptional precision. This protects consumers with celiac disease or severe gluten sensitivities.

By automating the removal of allergens and foreign material, a business demonstrates a commitment to the highest levels of safety. This technological validation helps build trust with consumers, retailers, and regulatory bodies, solidifying the brand's position as a safe and reliable choice in the competitive specialty diets market.

The Verdict: Which Method Fits Your Business Scale?

The right sorting method depends entirely on a company's operational scale and growth ambitions. While manual sorting has a place, automation offers a clear path to scalability and market leadership.

The High-Volume Producer

For large-scale producers, optical sorting is an operational necessity. Manual sorting creates bottlenecks, increases labor costs, and fails to meet the demands of high-speed production. The switch to automation yields transformative results.

- A tomato processing facility increased its yield by a remarkable 25% after implementing optical sorters.

- A major recycling plant improved material quality and profit margins by reducing contamination with automated systems.

These examples show that at a high volume, optical sorters are not just an improvement; they are a fundamental requirement for maintaining efficiency and profitability.

The Growth-Focused SME

Many small and medium-sized enterprises (SMEs) believe a specialty diets optical sorter is financially out of reach. However, a variety of accessible financing options makes this technology attainable. Growth-focused businesses can leverage these tools to invest in their future.

- Equipment Loans and Leasing: Banks and manufacturers offer direct financing, often using the machine as collateral. Leasing provides access to the latest technology without a large upfront purchase.

- SBA Loans and Vendor Financing: Government-backed loans provide favorable terms, while some vendors offer flexible payment plans.

These options allow an SME to acquire a profit-generating asset without depleting its cash reserves.

The Artisan Startup

Even artisan producers with small-batch operations can benefit from automation. The market now includes compact and modular optical sorters designed for smaller facilities. Companies like WECO and Cimbria offer machines with a smaller footprint that deliver high precision without requiring a massive production line. Models such as the Optica Mini are engineered for businesses that need scalable, high-performance sorting in a compact design, making advanced quality control accessible to everyone.

In 2025, the choice is clear. Manual sorting is a short-term fix, while optical sorting is a long-term investment in scalability, quality, and profitability. For niche dietary brands, an optical sorter's precision is a requirement to compete. The initial investment is quickly offset by massive savings and enhanced brand reputation.

An expert noted that manual sorters might prioritize efficiency over safety, making contamination "'mysteriously disappear.'" This highlights the long-term risk of relying on manual processes.

Optical technology is the definitive choice for any serious operator.

FAQ

How difficult is it to operate a specialty diets optical sorter?

Modern sorters feature user-friendly interfaces. Operators receive comprehensive training to manage sorting programs and perform routine maintenance. The systems are designed for straightforward daily use by trained staff.

Can one optical sorter handle multiple types of products?

Yes. A company can program and save multiple sorting profiles for different products.

Switching between profiles is quick. This offers excellent production flexibility for businesses with diverse product lines, maximizing the machine's utility and return on investment.

What does maintenance for an optical sorter involve?

Routine maintenance is simple and ensures optimal performance. Key tasks include:

- Daily cleaning of cameras and viewing areas.

- Periodic checks of the air ejector system.

- Following the manufacturer's recommended service schedule.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality Assurance

Top Capsule Checkweighers for Smart Investment Decisions in 2025

Innovative Folder Gluer Advancements Shaping 2025 Carton Production Lines

Three Methods PHE Plates Boost System Efficiency and Output in 2025

Essential Industrial Checkweighers for Optimal Performance in Food Processing Facilities