The Science Behind Inconel 625 Bar's Superior Strength

The superior strength of Inconel 625 bar stems directly from a solid-solution strengthening mechanism. This process provides the alloy inherent strength without complex heat treatments, a key difference from materials like Inconel 600 round bar.

At its core, large atoms of molybdenum and niobium integrate into the nickel-chromium crystal lattice. This creates atomic-level strain, which impedes dislocation movement and builds the exceptional material strength of the Inconel 625 bar.

Key Takeaways

- Inconel 625 gets its strength from special atoms like molybdenum and niobium. These atoms fit into the metal's structure and make it very hard to bend or break.

- This metal stays strong even when it gets very hot. It can handle high temperatures without losing its shape or breaking easily.

- Inconel 625 also fights off rust and damage from harsh chemicals. It forms a protective layer that can even fix itself if scratched.

- You can easily shape and weld Inconel 625. This makes it useful for many different products and industries.

The Science of Solid-Solution Strengthening

Solid-solution strengthening is the fundamental principle behind Inconel 625's impressive mechanical properties. Imagine trying to push a piece of furniture across a perfectly smooth, empty floor. It moves easily. Now, imagine that same floor is crowded with large, heavy obstacles. Pushing the furniture becomes much harder.

At the atomic level, this is exactly what happens inside Inconel 625 bar. The "floor" is the alloy's nickel-chromium crystal lattice, and the "furniture" is a potential deformation or slip, known as a dislocation. The "obstacles" are large alloying atoms that intentionally disrupt the smooth lattice structure.

The Role of Molybdenum and Niobium

The primary strengthening agents in Inconel 625 are molybdenum (Mo) and niobium (Nb). The alloy's chemistry, defined by standards like UNS N06625, specifies a significant amount of these elements.

| Element | Weight Percentage (%) |

|---|---|

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium (Nb) | 3.15 – 4.15 |

Molybdenum acts as a substitutional element. Its large atoms take the place of smaller nickel or chromium atoms within the crystal structure, contributing a powerful solid-solution hardening effect. Niobium atoms perform a similar function, integrating directly into the lattice. This integration makes it significantly more difficult for dislocations to move. The interaction between these large atoms and any potential slip plane effectively slows down dislocation mobility, which directly increases the material's overall strength and resistance to deformation.

Strength Without Precipitation Hardening

Many high-strength alloys rely on precipitation hardening, a process that requires specific heat treatments to form tiny, hard particles within the metal. Inconel 625 achieves its strength differently, deriving it directly from its atomic composition. This inherent strength provides excellent stability and predictability. The primary mechanisms of this solid-solution strengthening include:

- Lattice Distortion: The difference in atomic size between the large Mo and Nb atoms and the base nickel atoms causes the crystal lattice to stretch and distort. This distortion creates internal strain fields that impede the sliding of crystal layers, making the alloy more resistant to deformation.

- Atomic Interaction Changes: The presence of solute atoms alters the natural distances and forces between atoms in the lattice. Any force trying to displace atoms must now overcome these changed repulsive and attractive forces, requiring more energy and thus strengthening the material.

- Stacking Fault Formation: Solute atoms like molybdenum and niobium do not distribute perfectly evenly. They can gather in certain areas, creating localized defects known as stacking faults. A dislocation requires significantly more energy to move through these faulty regions, effectively pinning it in place and improving strength.

- Short-Range Order Interaction: In areas with a high concentration of solute atoms, a "short-range order" can occur where atoms form small, ordered clusters. Any dislocation attempting to pass through these clusters must overcome the combined force of the entire group, greatly increasing the difficulty of movement and macroscopically strengthening the alloy.

Key Takeaway: Inconel 625's strength is not a temporary state induced by heat treatment. It is a permanent, built-in feature of its chemical DNA, providing reliable and robust performance from the moment it is manufactured.

How Inconel 625 Bar Retains Strength Under Heat

The solid-solution strengthening that gives Inconel 625 its baseline power also makes it a formidable performer in high-temperature environments. Unlike many alloys that weaken significantly when heated, Inconel 625 bar maintains a remarkable portion of its mechanical integrity, making it ideal for applications like jet engine components and exhaust systems.

High-Temperature Strength Retention

The alloy's nickel-chromium matrix, reinforced by molybdenum and niobium, provides exceptional thermal stability. This robust atomic structure resists the weakening effects of thermal energy. The material shows only a moderate decrease in strength up to 850°C (1562°F). This allows it to outperform many other metals, including common stainless steels, which can experience rapid scaling and strength loss at much lower temperatures.

For example, an Inconel 625 bar retains an impressive percentage of its room-temperature strength even at elevated temperatures, as shown below.

| Temperature (°F / °C) | Tensile Strength (psi) | Strength Retention |

|---|---|---|

| 70 / 21 (Room Temp) | 144,000 | 100% |

| 1200 / 650 | 119,000 | ~83% |

This high retention rate is a direct result of its stable microstructure.

Resistance to Creep and Fatigue

Creep is a material's tendency to slowly deform under constant stress at high temperatures. The same mechanisms that provide Inconel 625's strength also give it outstanding creep resistance. The large molybdenum and niobium atoms anchor the crystal lattice, preventing the atomic slip that leads to creep.

Furthermore, prolonged exposure to heat can trigger the formation of strengthening precipitates.

- At temperatures around 600-700°C, a gamma double prime (γ'') phase can form, initially increasing hardness.

- At higher temperatures (e.g., 800°C), a hard delta (δ) phase precipitates, creating a "composite strengthening" effect that further boosts hardness and stability over long periods.

This microstructural evolution, combined with a highly stable dislocation network, allows the alloy to resist both creep and cyclic fatigue, ensuring long-term reliability in demanding thermal environments.

The Alloy's Strength in Corrosive Environments

Inconel 625's remarkable strength is not limited to mechanical stress and high temperatures. Its unique chemical composition also provides formidable resistance to aggressive corrosion, making it a premier choice for chemical processing and marine applications. This resilience comes from a multi-layered defense system built at the atomic level.

The Nickel-Chromium Protective Layer

The first line of defense for Inconel 625 is a passive, self-healing oxide film. The alloy's high chromium content, typically 20-23%, is the primary driver of this protection. In an oxidizing environment, chromium atoms at the surface react with oxygen in an electrochemical process. This reaction forms a thin, tough, and continuous layer of chromium oxide (Cr₂O₃).

This protective film acts as a durable shield, isolating the underlying metal from the corrosive environment. A key feature of this layer is its ability to self-repair. If the surface is scratched or damaged, the exposed chromium rapidly reacts with oxygen to reform the protective barrier, effectively preventing further degradation. This dynamic process ensures the alloy maintains its integrity even in harsh conditions.

Molybdenum's Role in Corrosion Resistance

While chromium provides general protection, molybdenum specifically enhances the alloy's defense against localized attacks like pitting and crevice corrosion, particularly in chloride-rich environments such as seawater. Molybdenum strengthens the passive film in several ways:

- It stabilizes the passive state, making the film more resistant to breakdown.

- It promotes rapid repassivation (self-repair) if the film is breached.

- It mitigates the damaging effects of chloride ions that try to attack the surface.

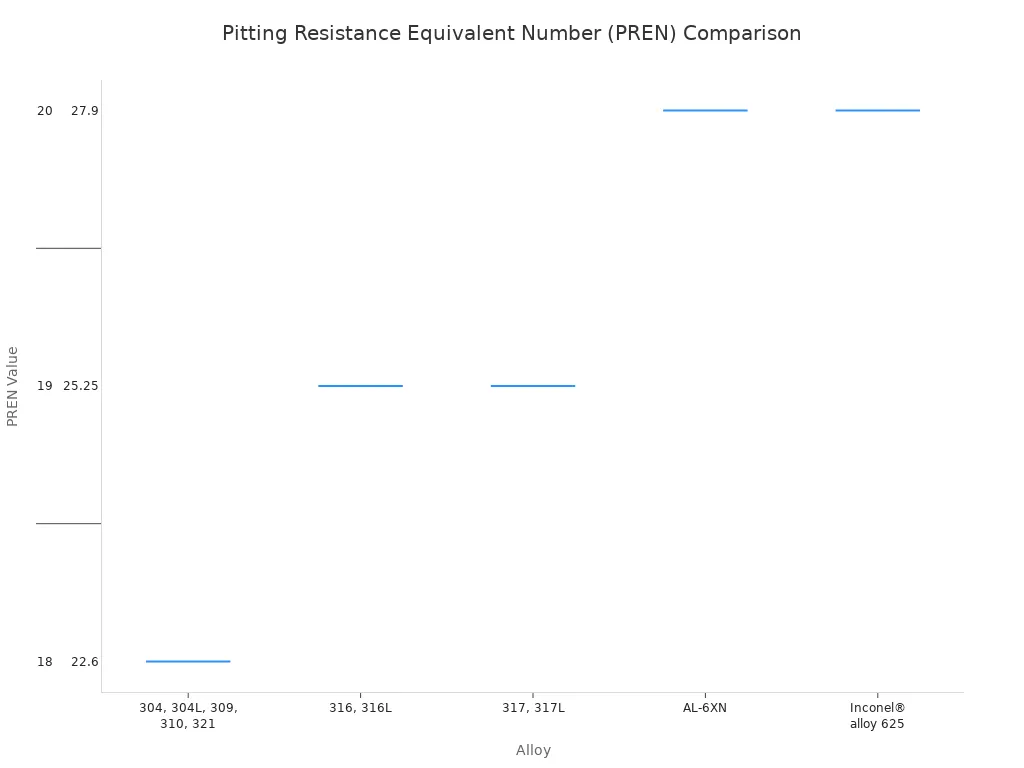

This superior resistance is often quantified using the Pitting Resistance Equivalent Number (PREN). A higher PREN value indicates greater resistance to pitting corrosion.

Inconel 625 possesses a PREN value that is more than double that of common 316L stainless steel, highlighting its exceptional performance. While alloys like Hastelloy® C-276 score higher, Inconel 625 occupies a critical performance tier for severe service applications.

The powerful combination of a stable nickel-chromium matrix and the targeted protection from molybdenum gives Inconel 625 bar its robust, all-around strength in corrosive environments.

Key Properties Defining Inconel 625 Bar

Beyond its fundamental strength, Inconel 625 possesses a combination of properties that make it exceptionally versatile. Its performance is defined not just by what it can withstand, but also by how easily engineers can shape and join it for critical applications.

Excellent Fabricability and Weldability

An alloy's strength is only useful if it can be formed into practical components. Inconel 625 excels in this area. It demonstrates excellent ductility, with an elongation value that can reach over 40%. This property allows the material to be readily formed through processes like bending, rolling, and deep drawing without fracturing.

This workability extends to its welding characteristics. The alloy is readily weldable using various techniques, with Tungsten Inert Gas (TIG) welding being highly recommended for its precision and control. Proper welding procedures are crucial for maintaining the material's integrity.

- Heat Control: Careful management of heat input prevents overheating and distortion.

- Preheating: For thicker sections, preheating the material to around 300°F (150°C) can reduce the risk of thermal shock and cracking.

- Filler Metal: Using an appropriate Inconel filler rod ensures the weld joint retains the desired strength and corrosion resistance.

Pro Tip: Precise control over the weld pool is essential. It prevents the formation of unwanted phases in the heat-affected zone, ensuring a strong and uniform joint.

Key Designations (UNS N06625)

To guarantee consistent quality and performance, the Inconel 625 bar is manufactured according to strict international standards. These designations ensure that every bar meets the precise chemical and mechanical requirements for high-stakes industries. The most common designations include:

| Standard | Designation |

|---|---|

| UNS | N06625 |

| Material No. | 2.4856 |

| EN | NiCr22Mo9Nb |

Certification to these standards is mandatory for applications where failure is not an option. Industries such as aerospace, chemical processing, marine engineering, and nuclear power rely on the UNS N06625 designation to procure material that delivers proven strength and reliability in the most demanding environments.

The superior strength of an Inconel 625 bar originates from its fundamental chemistry, not heat treatment. Its power comes from a solid-solution strengthening mechanism where molybdenum and niobium atoms stiffen the nickel-chromium matrix. This unique atomic structure provides exceptional strength and resists creep at high temperatures. The same elements also deliver outstanding resistance to pitting and crevice corrosion, making the Inconel 625 bar a uniquely versatile material for the most demanding industrial applications.

FAQ

What makes Inconel 625 so strong?

Inconel 625 derives its strength from solid-solution strengthening. Large molybdenum and niobium atoms disrupt the nickel-chromium crystal lattice. This atomic-level strain impedes deformation, providing inherent strength without requiring heat treatment.

Is Inconel 625 magnetic?

No, Inconel 625 is a non-magnetic alloy. Its nickel-based composition and austenitic microstructure prevent it from being attracted to a magnet. This property is critical for specialized electronic and sensing equipment applications.

What is the main difference between Inconel 625 and Inconel 600?

The key difference lies in their chemistry and strength. Inconel 625 contains significant molybdenum and niobium for superior solid-solution strength and corrosion resistance. Inconel 600 is a simpler nickel-chromium alloy without these additions, resulting in lower mechanical properties.

Can you weld Inconel 625?

Yes, Inconel 625 exhibits excellent weldability. Engineers can join it using various techniques, with TIG welding being a preferred method. Using a matching filler metal and controlling heat input ensures the weld joint retains the alloy's strength and corrosion resistance.

See Also

Optimized Steel Processing: Consistently Delivering Excellence in Heat Exchange Applications

Essential WT20 Thoriated Tungsten Electrode Insights for Superior TIG Welding

Mastering Pass Partition Plate Welding: Expert Guidance for 2025 Success

Revolutionary Heat Exchanger Production Advances Boosting Industrial Performance Significantly

Assessing Molybdenum Plugs' Role in Seamless Steel Pipe Manufacturing by 2025