Your Ultimate Rye Sorting Solution Bühler or Cimbria SEA?

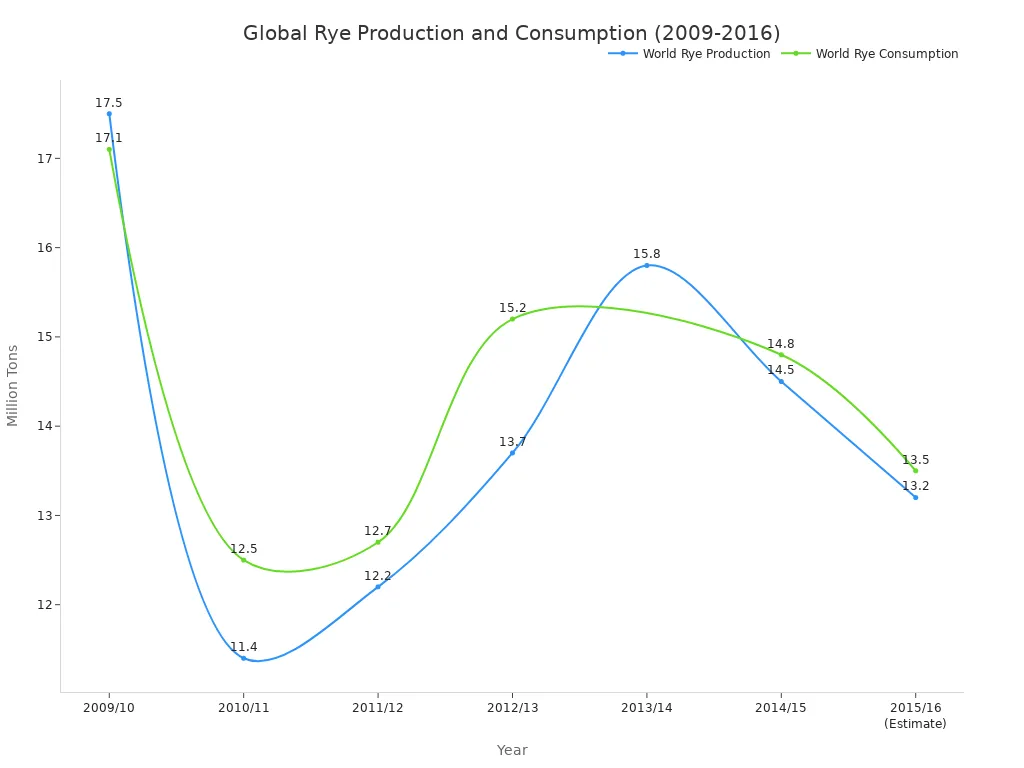

Global rye production and consumption trends highlight the need for efficient grain processing.

Bühler SORTEX offers the leading rye sorting solution for maximum purity in food-grade applications, where its advanced sensors excel at ergot removal. For feed-grade rye, Cimbria SEA presents a compelling, cost-effective alternative that balances performance with value.

Bühler vs. Cimbria: Core Sorting Performance for Rye

The effectiveness of any optical sorter hinges on its core performance capabilities. Processors must evaluate how each machine handles the primary contaminants and defects found in raw rye. Key performance indicators include the removal of toxic ergot, separation of other grains, and ejection of damaged kernels.

Ergot and Sclerotia Removal

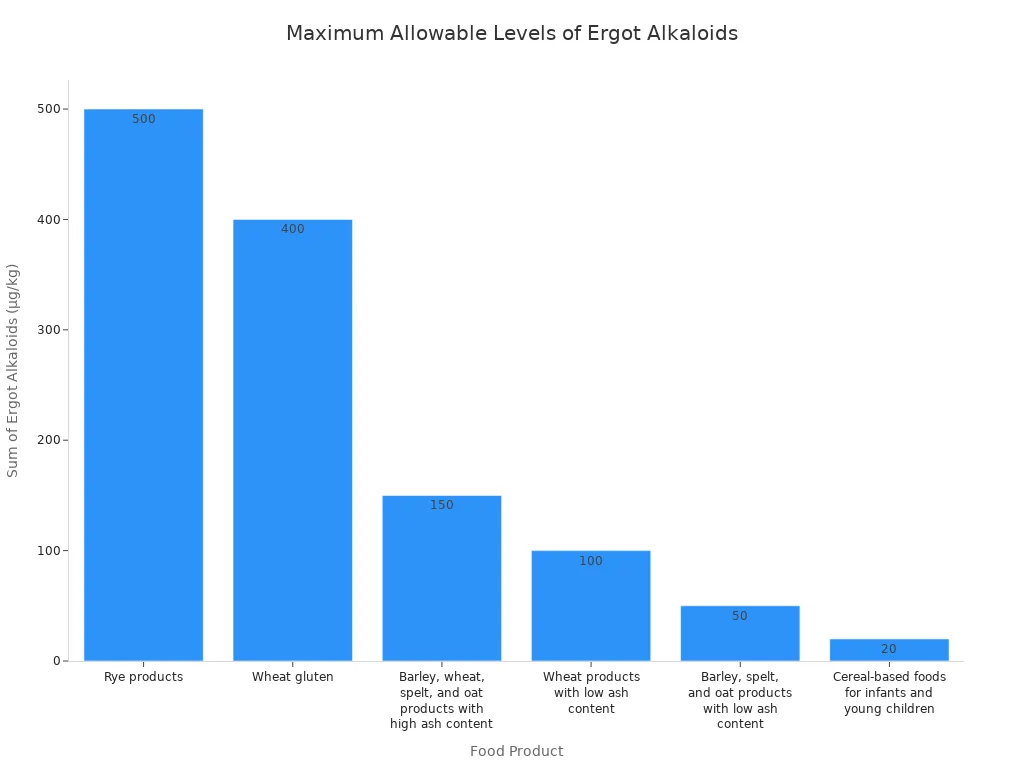

Ergot contamination is the most critical food safety challenge in rye processing. Ergot sclerotia contain toxic alkaloids. Regulatory bodies like the European Food Safety Authority (EFSA) have established strict maximum levels to protect consumers. The European Commission continues to tighten these standards for food products.

Note: The EU is reducing the maximum level for ergot sclerotia in unprocessed rye from 0.5 g/kg to 0.2 g/kg, effective July 1st, 2024. This change requires processors to adopt more precise sorting technologies to remain compliant.

Bühler SORTEX machines excel in this area. Their high-resolution cameras and advanced sensor technologies identify the subtle color and textural differences between healthy rye kernels and dangerous ergot sclerotia. This precision ensures processors can meet even the most stringent food safety regulations for premium, food-grade rye.

Cimbria SEA sorters also provide robust ergot removal. Models like the SEA.IQ PLUS are engineered to help operators comply with evolving EU regulations. While Bühler is often the choice for achieving the absolute lowest contamination levels, Cimbria offers a highly effective rye sorting solution that reliably meets established safety thresholds.

The maximum allowable levels for ergot alkaloids vary by product, with rye products facing some of the tightest controls after an initial adaptation period.

The table below details the EU's maximum levels for the sum of ergot alkaloids in various foodstuffs.

| Food product | Sum of ergot alkaloids (µg/kg) |

|---|---|

| Rye products | 500 |

| Wheat gluten | 400 |

| Barley, spelt, and oat products with high ash content | 150 |

| Wheat products with low ash content | 100 |

| Barley, spelt, and oat products with low ash content | 50 |

| Cereal-based foods for infants and young children | 20 |

Foreign Grain Separation

Rye historically co-evolved with wheat and barley. It often grew as an unintended crop within those fields. Consequently, harvested rye frequently contains other grains that must be removed to ensure product purity.

Bühler addresses this challenge with its SORTEX H SpectraVision technology.

- Full-Color Cameras: New cameras provide superior spectral purity. They detect the slightest color variations between rye and other grains like wheat or barley.

- InGaAs Technology: Advanced InGaAs cameras significantly improve the detection of foreign matter that is difficult to see in the visible spectrum.

- Intelligent Algorithms: The system uses machine learning to continuously refine its sorting parameters, ensuring precise removal of foreign grains and other materials like glass, plastic, or stones.

Cimbria also delivers powerful foreign grain separation with its SEA series sorters.

- High-Resolution Optics: The SEA.TN model boasts an optical resolution of 0.06 mm and performs 25,000 scans per second, enabling it to spot and eject unwanted grains with high accuracy.

- NIR and InGaAs Options: Cimbria utilizes Near-Infrared (NIR) technology to identify foreign bodies based on material composition. Optional InGaAs cameras are also available to enhance sorting capabilities for more complex separation tasks.

Both manufacturers provide the technology needed to separate grains effectively. Bühler's advantage lies in its integrated, multi-spectral approach for the most demanding applications, while Cimbria offers excellent performance with flexible, powerful options.

Discolored and Damaged Kernel Sorting

Product quality and visual appeal depend on removing discolored and damaged kernels. These defects can arise from disease, improper storage, or drying issues. Both Bühler and Cimbria sorters use their advanced camera systems to identify and remove these imperfections. Common defects include:

- Fusarium Damage: Kernels appear chalky and may have a fibrous growth.

- Heated Kernels: Grains turn red or orange due to deterioration in storage.

- Smudge: A disease-related discoloration that darkens the kernel.

- Fireburnt Kernels: Charred, low-weight kernels that crumble easily.

- Sclerotinia: Hard fungal masses that can be mistaken for stones or soil.

Bühler's full-color cameras and Cimbria's high-resolution optical systems are both adept at detecting these color and texture flaws. By ejecting these damaged kernels, processors can significantly improve the grade, safety, and market value of their final rye product. The choice between them often depends on the specific types and prevalence of defects in the incoming raw material.

Finding Your Optimal Rye Sorting Solution

Beyond core performance, a processor's operational realities heavily influence the choice of equipment. Factors like production scale, operator skill level, and long-term budget strategy are critical. Evaluating throughput, software usability, and the total cost of ownership helps determine which machine aligns best with a facility's goals.

Throughput and Capacity

A sorter's throughput, measured in tons per hour, directly impacts a plant's overall efficiency and ability to meet market demand. The right capacity ensures a smooth production flow without creating bottlenecks.

Bühler designs its systems for high-capacity industrial environments. Their equipment handles substantial volumes of grain, making it suitable for large-scale rye processors. For instance, components within their broader grain cleaning systems demonstrate this capability:

- Aspiration Channel: This machine can process up to 24 tons of grain per hour in a main cleaning line. It can pre-clean up to 100 tons per hour in silos.

- Bran Finisher MKLA: This unit is available in various models to match different throughput requirements.

Cimbria SEA offers a flexible approach to capacity. The company provides a wide range of sorter models, each designed for different production scales. This allows small, mid-sized, and large processors to find a machine that fits their specific volume needs and budget. Cimbria focuses on providing a scalable rye sorting solution that can grow with a business's operational demands.

Software and Ease of Use

Modern sorting performance depends heavily on the machine's software. An intuitive interface empowers operators to achieve consistent results, reduce setup times, and quickly adapt to changes in raw material quality.

Bühler prioritizes advanced automation and user-friendly design in its SORTEX ProSortX software. The platform comes with numerous features to simplify operation and maximize uptime.

- The software is pre-installed and can store up to 100 sorting modes.

- It uses machine learning to minimize setup and calibration needs.

- Industry 4.0 readiness and Sortex Connect provide connectivity to the Bühler Insights platform for advanced data analysis.

- The TrueColor™ user interface offers enhanced visualization for identifying defects.

Pro Tip: Bühler's TrueColor™ technology allows operators to see what the machine sees in real-time. They can highlight subtle defects on the screen and instantly adjust sorting parameters, ensuring maximum precision without lengthy trial-and-error processes.

Cimbria SEA equips its sorters with powerful and intuitive software focused on operator control. The user interface provides clear, real-time visualization of the product stream and sorting performance. Operators can easily define and save custom sorting programs for different rye batches or quality requirements. While it offers robust functionality, the design philosophy centers on giving experienced operators the tools they need for direct and precise manual control over the sorting process.

Total Cost of Ownership

The initial purchase price is only one part of the equation. The Total Cost of Ownership (TCO) provides a more complete financial picture, encompassing installation, training, maintenance, energy consumption, and spare parts over the machine's lifespan.

Bühler represents a premium investment. The initial capital outlay is higher, reflecting its advanced technology and robust build quality. This investment often translates to lower long-term operational costs through superior efficiency, reliability, and the ability to produce higher-grade products that command better prices. Part of this investment includes specialized training to ensure operators can maximize the machine's capabilities.

| Training Aspect | Detail |

|---|---|

| Duration | 1 week |

| Location | Milling Academy, Uzwil, Switzerland |

| Cost | CHF 2,000.00 per person |

| Target Audience | Seasoned millers and head millers with solid milling experience |

Cimbria SEA, in contrast, often presents a lower TCO, driven by a more accessible initial purchase price. This makes it an attractive option for processors focused on achieving a faster return on investment. The machines are engineered for durability and energy efficiency, helping to keep ongoing operational costs low. Training is typically streamlined and often conducted on-site, reducing associated travel and time expenses. This makes Cimbria a strong contender for operations where budget is a primary driver and good, reliable performance meets all commercial needs.

Technology and Long-Term Value

A sorter's long-term value extends beyond its immediate performance. The underlying technology, support infrastructure, and potential for future upgrades are crucial considerations for any capital investment. These factors determine a machine's relevance and effectiveness for years to come.

Camera and Sensor Technology

The "eyes" of the sorter—its cameras and sensors—define its ultimate sorting precision. Bühler leads with its advanced Multivision camera technology. This system uses a four-wavelength approach (visible and infrared) combined with PROfile (shape) detection to identify contaminants that standard RGB cameras miss. Its enhanced InGaAs cameras detect defects invisible to the human eye. This technology is crucial for finding foreign materials hidden in the near-infrared spectrum. For mycotoxin threats, Bühler's LumoVision system even uses hyperspectral imaging (HIS) to identify contamination at a chemical level.

Cimbria offers a versatile suite of technologies across its models, allowing processors to tailor the machine to their needs.

- The SEA.IQ PLUS model combines RGB, NIR, and SWIR cameras.

- Its AI-powered software, BRAIN™, helps detect contaminants as small as 0.08mm.

- Processors can choose from multiple vision packages, including SWIR/InGaAs or UV options, to target specific defects like unhulled grains or foreign materials with similar colors.

Maintenance and Support

Reliable support ensures maximum uptime and protects the initial investment. Bühler provides a global service network staffed by highly trained technicians, reflecting its status as a premium equipment provider. Cimbria offers a distinctly flexible and accessible after-sales service structure.

Cimbria's tiered maintenance programs provide tailored support:

- ONLINE-PRO: Remote service for quick troubleshooting.

- EASY-PRO: A standard preventive maintenance contract.

- TOP-PRO: An all-inclusive program for comprehensive care.

This approach, which includes 24/7 remote assistance and on-site visits, allows processors to select a support level that matches their operational needs and budget.

Future-Proofing and Upgradability

Technology evolves rapidly. A future-proof rye sorting solution must be ready for tomorrow's challenges. Bühler demonstrates its commitment to innovation with a massive investment in AI research and development. This focus ensures its platforms continuously integrate cutting-edge machine learning for enhanced classification. Cimbria integrates forward-thinking technology through its SmartSort platform, which features cloud-based AI optimization and remote monitoring. This shows a focus on creating an intelligent, connected, and adaptable rye sorting solution. Both companies are leveraging AI to ensure their machines remain valuable assets long into the future.

Bühler SORTEX is the definitive choice for achieving the highest purity in premium food-grade rye, justifying its investment. Cimbria SEA is the recommended rye sorting solution for operations prioritizing a faster return on investment and reliable performance for standard quality requirements. A processor's final decision balances the need for absolute purity against budget and operational goals.

FAQ

Which sorter is better for food-grade rye?

Bühler SORTEX excels at producing premium food-grade rye. Its advanced sensors meet the strictest purity and ergot removal standards, justifying the investment for top-tier products.

What if my budget is the main concern?

Cimbria SEA is the recommended choice for budget-conscious operations. It offers reliable performance and a faster return on investment, especially for feed-grade or standard-quality rye applications.

Can both machines handle new EU ergot regulations?

Yes, both manufacturers design their sorters to meet evolving EU regulations. Bühler provides maximum precision for compliance, while Cimbria offers a highly effective and reliable solution.

See Also

Essential Industrial Checkweighers: Top 3 for Modern Food Production Facilities

Future-Proofing Carton Lines: Trending Folder Gluer Innovations for 2025

Smart Investment: Capsule Checkweighers Buyers Must Evaluate for 2025

Laboratory Excellence: A Comprehensive Guide to Tablet Sampling Machine Selection

Optimizing Performance: Steel Processing for Effective Heat Exchange Applications