Maximizing Your Return with a Pumpkin Seed Optical Sorter

An optical sorter's return on investment (ROI) is a key consideration for pumpkin seed processors. The global pumpkin seed market is expanding rapidly, highlighting the need for efficient and high-quality production.

| Metric | Value |

|---|---|

| Global Market Size (2024) | USD 956.71 million |

| Projected Market Size (2032) | USD 2616.28 million |

| CAGR (2025-2032) | 13.4% |

A pumpkin seeds optical sorter directly addresses this demand. It boosts revenue by increasing product yield and enhancing seed quality for premium pricing. The technology also reduces operational expenses by minimizing manual labor costs. Processors typically see a positive ROI within 18-36 months. This investment turns potential waste into valuable revenue, secures higher market prices, and streamlines operations.

How a Pumpkin Seeds Optical Sorter Boosts Your Revenue

A pumpkin seeds optical sorter directly impacts a processor's top line by transforming production efficiency into tangible financial gains. This technology creates value by maximizing the volume of sellable product and elevating its market worth. Companies that adopt this equipment often see significant revenue growth.

Recovering Product to Increase Yield

Processors can substantially increase their saleable output by recovering valuable seeds from the reject stream. A pumpkin seeds optical sorter excels at identifying and separating good seeds from foreign material and defective products. This precision minimizes good product loss, a common issue in manual or mechanical sorting. The result is a direct increase in yield efficiency, often by as much as 10-12%.

Key benefits include:

- Reduced Waste: The sorter reclaims high-quality seeds that would otherwise be discarded.

- Increased Throughput: Automated sorting processes large volumes quickly, boosting overall production capacity.

- Consistent Output: It ensures every batch meets uniform quality standards, which builds customer loyalty.

Achieving Premium Pricing with Superior Quality

Superior product quality allows processors to command premium prices in the market. An optical sorter achieves this by meticulously removing a wide range of imperfections that downgrade the final product. This precision ensures the seeds meet strict standards for top-tier grading and regulatory certification.

A high-purity product is the foundation of a premium brand. By eliminating defects, processors can confidently market their pumpkin seeds to discerning buyers who pay more for guaranteed quality.

A pumpkin seeds optical sorter can accurately detect and eject undesirable items, including moldy grains, discolored seeds, damaged pieces, and even small stones. Delivering a cleaner, safer, and more visually appealing product strengthens a company's competitive advantage and unlocks access to higher-value markets.

How an Optical Sorter Cuts Your Operational Costs

Beyond increasing revenue, an optical sorter significantly reduces a processor's operational expenditures. These savings come from two main areas: decreased reliance on manual labor and the prevention of costly production errors. Automating the sorting process creates a more efficient and financially stable operation.

Quantifying Savings from Reduced Manual Labor

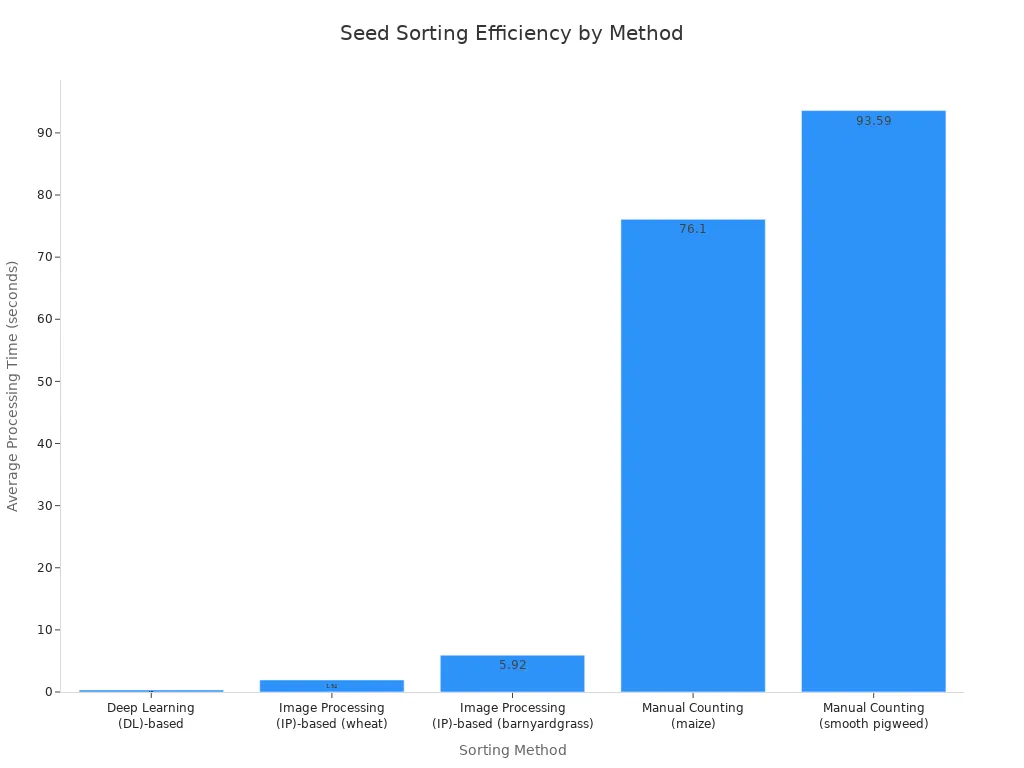

Automated sorting technology directly lowers labor costs by performing tasks faster and more accurately than human workers. Manual sorting is time-intensive and prone to inconsistency. In contrast, automated systems process vast quantities of seeds with remarkable speed. For example, manual seed counting can take over 90 seconds per 100 seeds, while automated systems perform the task in a fraction of a second.

This efficiency allows processors to reallocate staff to higher-value roles. Modern AI-enabled vision systems also achieve grading accuracy rates up to 98.5%, far surpassing traditional methods. This reduces the need for manual quality checks and minimizes human error.

Minimizing Risks of Recalls and Re-Processing

A pumpkin seeds optical sorter acts as a critical defense against food safety incidents. It excels at removing foreign materials and defective products that could trigger a product recall. The financial consequences of a recall are severe.

The average cost of a food recall for a manufacturing company is at least $10 million. This figure includes expenses for logistics, product destruction, and lost sales.

A single recall can damage a brand's reputation, erode consumer trust, and lead to significant legal costs. By ensuring a consistently clean and safe product, an optical sorter protects a company from these catastrophic financial and reputational losses. It minimizes the risk of re-processing batches, saving both time and resources while safeguarding the brand's market position.

A Framework for Calculating Your Specific ROI

Calculating the return on investment for a pumpkin seeds optical sorter is a data-driven process. It allows processors to move beyond general benefits and create a specific financial forecast. This framework provides a clear path to quantifying the value this technology brings to an operation.

The ROI Formula Explained

The food processing industry uses a standard formula to determine the profitability of a capital equipment purchase. This calculation measures the net financial gain relative to the total cost of the investment. It provides a clear percentage that represents the return.

The most common formula is:

ROI = (Profit / Cost of Investment) x 100

In this equation, "Profit" represents the net benefit generated by the new equipment. "Cost of Investment" includes the total expense required to acquire and implement the machine.

This straightforward formula empowers processors to make informed decisions. It transforms operational improvements into a clear, universally understood financial metric.

A positive ROI indicates that the investment generates more income than it costs. A higher percentage signifies a more profitable investment. Processors can use this calculation to project when the equipment will pay for itself and begin generating net profit.

Key Variables for Your Calculation

An accurate ROI calculation depends on gathering precise data for your specific operation. The key variables fall into two main categories: the total cost of the investment and the net financial benefit it produces.

1. Total Cost of Investment This figure extends beyond the initial purchase price. A comprehensive calculation includes all associated expenses.

- Initial Purchase Price: The base cost of the machine.

- Additional Fees: This includes shipping, installation, and commissioning costs.

- Renovation Costs: Any facility modifications needed to accommodate the new equipment.

- Training Costs: Expenses for training staff to operate and maintain the sorter.

The initial purchase price for optical sorters can vary based on capacity and features.

| Sorter Type | Price Range (USD) |

|---|---|

| Intelligent 3-Channel Sorter | $9,700 - $13,000 |

| Automatic Seed Sorting Machine | $13,800 - $14,800 |

| Advanced Color & Shape Sorter | $20,450 - $20,650 |

Finally, processors must consider the equipment's effective lifespan to understand the full investment period. Most electronic sorters have a functional life of 8 to 10 years, over which the return is realized.

2. Net Benefit (Profit) The net benefit is the sum of new revenue generated and operational costs saved.

Increased Revenue:

- Higher Yield: Calculate the value of recovered seeds that were previously lost. A 10-12% increase in yield from a machine processing 3.0 to 6.0 tons per hour quickly adds up.

- Premium Pricing: Determine the price increase achievable by selling a higher-purity product.

Reduced Operational Costs:

- Labor Savings: Quantify the reduction in wages and benefits from reallocating manual sorting staff.

- Maintenance Costs: While sorters have maintenance needs, they are often predictable. Annual costs can range from $3,000 for smaller units to over $10,000 for large, continuously operating machines. Key expenses include:

- Belts: $200 - $500

- Sensors: $300 - $1,000

- Motors: $500 - $2,000

- Energy Consumption: Modern sorters are designed for efficiency. Lower energy consumption is a key pillar of ROI. Features like intelligent power management and positive-pressure air jets (which use less compressed air than vacuum systems) directly reduce monthly utility bills.

By carefully inputting these variables, a processor can build a detailed and accurate ROI projection, justifying the investment with a clear financial case.

The return on investment from this technology is a calculated outcome. It is based on measurable gains in revenue and reductions in operational costs. This investment directly boosts profitability and long-term viability.

- Austrian processor Schalk Mühle achieved 99.9% accept quality.

- Their sorter provided a seal of quality assurance for partners.

FAQ

What defects can an optical sorter remove?

The sorter removes discolored seeds, mold, foreign materials like stones, and damaged pieces. This precision ensures a high-purity final product that meets top-tier grading standards.

How does an optical sorter fit into an existing production line?

Processors typically install the sorter after initial cleaning and before packaging. Its compact design allows for straightforward integration into most existing pumpkin seed processing layouts.

What is the typical maintenance schedule for these sorters?

Maintenance involves daily cleaning and periodic checks on components like belts and sensors. Manufacturers provide specific schedules to ensure optimal performance and longevity for the equipment.

See Also

Capsule Sorters: Essential Technology for Flawless Pharmaceutical Product Quality

Boosting Pharma Efficiency: Modern Capsule Decapsulation Machine Innovations Revealed

Top Capsule Checkweighers for 2025: A Buyer's Essential Guide

Ampoule Filling Lines: Comparing Leading Manufacturers for Optimal Production

Tablet Sampling Machines: The Definitive Lab Selection Guide for Excellence