Beyond the Hype Real Ways AI Is Improving Our Food Supply Chain

Artificial intelligence delivers tangible improvements across the food supply chain. It increases farm yields with precision farming and cuts restaurant waste using smart analytics. The application of ai for food industry enhances demand forecasting, optimizes logistics, and bolsters food safety. This technology makes our food system more efficient, sustainable, and resilient at every stage.

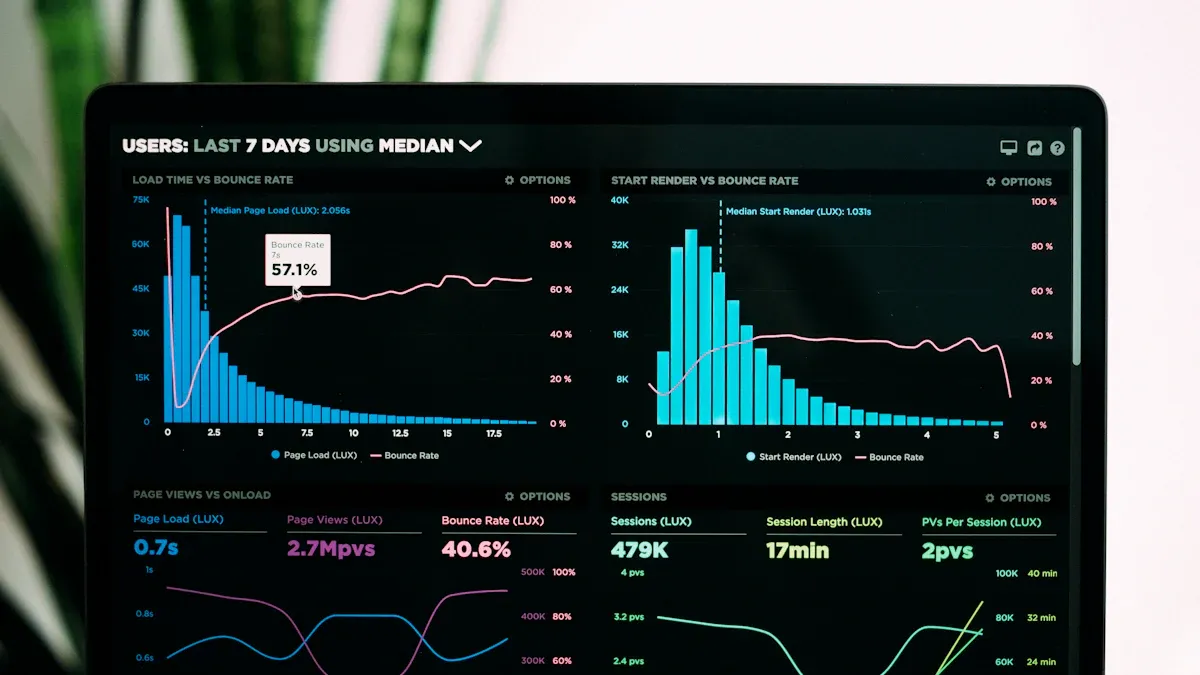

Note: Early adopters of AI are already seeing significant gains.

| Efficiency Metric | Improvement/Reduction |

|---|---|

| Logistics Costs | 15% reduction |

| Inventory Levels | 35% improvement |

| Service Levels | 65% enhancement |

| Machine Downtime | 30-50% decrease |

This technology builds a more robust foundation for our global food future.

Smarter Farming: AI for Cultivation and Harvesting

AI is transforming agriculture from the ground up. It empowers farmers with data-driven tools for smarter cultivation and more efficient harvesting. This technology moves farming beyond traditional methods into an era of precision and predictability.

Precision Farming and Resource Management

Precision farming uses AI to optimize the use of essential resources like water and fertilizer. In Kansas cornfields, AI-driven irrigation systems have cut water consumption by up to 30% while maintaining yields. AI achieves this by analyzing real-time data from various sources.

| AI Technology | Application in Crop Cultivation |

|---|---|

| Computer Vision | Identifies pests, diseases, and nutrient deficiencies. |

| IoT Sensors | Collect real-time data on soil moisture and weather. |

| Drones | Provide aerial imaging for large-scale crop monitoring. |

| Robotics | Automate tasks like precise spraying and harvesting. |

These tools enable Variable Rate Nitrogen Fertilizer Application (VRNFA), which has saved 4% to 37% in nitrogen use for wheat crops by applying fertilizer exactly where it is needed.

Predictive Analytics for Crop Health

AI models can forecast crop diseases and pest infestations before they become widespread. In India, the platform CropIn uses AI to monitor crop health, leading to a 30% reduction in pesticide use and a 20% increase in yield. These systems analyze environmental data, historical pest patterns, and crop conditions to alert farmers to potential threats.

By integrating data from weather, satellites, and agronomic models, the application of ai for food industry provides field-specific recommendations, reducing the need for chemical treatments by 15-25%.

This proactive approach helps farmers protect their crops, optimize resource use, and minimize environmental impact.

Monitoring Livestock Well-being

AI technology also extends to animal agriculture, significantly improving livestock welfare. Wearable sensors on cattle track heart rate, body temperature, and movement patterns. AI algorithms analyze this data to detect early signs of illness or stress, often days before a human could. For example, AI cameras helped one farm identify cow comfort issues, leading to changes that are expected to boost milk yield. This shift to proactive management reduces mortality rates and improves overall herd performance.

The Role of AI for Food Industry Logistics and Safety

AI is revolutionizing the journey of food from the processing plant to the consumer's plate. It enhances efficiency and safety in logistics, a critical stage of the supply chain. The application of ai for food industry in this area reduces costs, ensures product quality, and builds consumer trust through smarter, data-driven operations.

Intelligent Demand and Inventory Forecasting

Accurate forecasting prevents stockouts and reduces overstocking. AI systems analyze vast datasets, including historical sales, weather patterns, and social media trends, to predict consumer demand with remarkable precision. Major retailers like Walmart and Kroger use AI-driven forecasting to optimize inventory. This technology can reduce forecasting errors by up to 30%, helping companies like Rastelli Food Group recover millions in excess inventory.

Route Optimization and Cold Chain Integrity

AI optimizes delivery routes in real-time, considering traffic and weather to cut fuel consumption by up to 15%. For perishable goods, maintaining the cold chain is vital. AI-enabled IoT sensors embedded in packaging and trucks monitor conditions like temperature and humidity.

These systems send automated alerts if temperatures deviate, allowing for immediate action to prevent spoilage and ensure product freshness upon arrival.

AI-Powered Food Safety and Traceability

AI enhances food safety with advanced inspection methods. In processing plants, AI-powered computer vision systems detect contaminants and defects with greater accuracy than the human eye. Companies like Tyson Foods use this technology to ensure product consistency. When combined with blockchain, the use of ai for food industry creates a transparent and unchangeable record of a product's journey, allowing for rapid traceability from farm to store.

Reducing Waste in Retail and Restaurants

Food waste is a major challenge in retail and food service. AI helps kitchens minimize overproduction by forecasting customer demand based on sales data and seasonal trends. Smart scales and computer vision systems automatically track and categorize discarded food, providing actionable insights.

- Predictive Analytics: Forecasts daily demand to guide food preparation.

- Waste Tracking: Identifies which menu items contribute most to waste.

- Inventory Management: Optimizes purchasing to reduce spoilage.

These tools empower businesses to reduce food waste by as much as 70%, improving both sustainability and profitability. The role of ai for food industry is pivotal in creating a more efficient and less wasteful system.

AI is not a future concept but a practical tool actively improving the food supply chain today. The application of ai for food industry is making our food system more efficient and sustainable. Key applications include:

- Smarter farming for increased yields.

- Optimized logistics for freshness.

- Enhanced safety for consumer trust.

Supporting businesses that adopt these smart technologies helps build a more resilient food future for everyone.

FAQ

What is the main benefit of AI in the food supply chain?

AI boosts efficiency, sustainability, and resilience. It optimizes resources, reduces waste, and enhances food safety. This technology creates a more robust and reliable food system for everyone.

Can small farms and businesses use AI technology?

Yes, AI is becoming more accessible. Companies now offer scalable, cloud-based solutions.

These platforms allow smaller operations to benefit from AI without a massive upfront investment, helping to level the playing field.

See Also

Essential Industrial Checkweighers: A Must-Have for Every Food Processing Plant

Understanding Nozzle Technology: Insights for Diverse Applications and Industries

Innovative Materials: Transforming the Future of Heat Exchanger Manufacturing

Comparing Leading Ampoule Filling Production Line Manufacturers: A Comprehensive Guide

Future of Packaging: Top Folder Gluer Innovations for 2025 Carton Production