Pharmaceutical Checkweighers Defined and Their Essential Features

A Pharmaceutical Checkweigher uses advanced technology to deliver precise weight measurements for each product. This system operates automatically and checks every item on the line. Manufacturers rely on an Automatic Pharmaceutical Checkweigher for Packaging Lines to confirm that tablets, capsules, and bottles meet strict weight standards. Accuracy in this process protects patients and ensures compliance with industry regulations.

Key Takeaways

- Pharmaceutical checkweighers provide precise weight measurements to ensure every product meets strict quality and safety standards.

- These systems support regulatory compliance by using hygienic designs, secure data management, and thorough calibration processes.

- Automation in checkweighers increases production speed, reduces errors, and helps manufacturers save materials and reduce waste.

- Integration with production lines and other inspection systems improves efficiency and allows real-time monitoring and quick problem detection.

- Advanced data features enable full traceability, support audits, and help maintain consistent product quality and patient safety.

Essential Features of a Pharmaceutical Checkweigher

High Accuracy and Precision

A pharmaceutical checkweigher must deliver extremely accurate results. Manufacturers depend on these systems to detect even the smallest weight differences in tablets, capsules, or bottles. Most dynamic checkweighers in the industry achieve accuracy around ±0.3 grams. Some advanced models can measure down to milligrams, which is critical for sensitive drugs.

High precision prevents compliance issues and reduces product waste.

To achieve this level of accuracy, manufacturers use several advanced technologies:

- Force balance technology enables weighing accuracy up to ±0.5 mg, ideal for drugs like anticancer or immunosuppressive capsules.

- Electromagnetic Force Restoration (EMFR) technology provides microgram sensitivity for ultra-high precision.

- Automatic sensitivity checks verify weigh cell performance in under a minute.

- Enhanced fail-safe structures remove capsules during power outages, preventing errors.

- Capsule handling mechanisms ensure reliable feeding, weighing, and rejection at high speeds.

Static electricity often causes hidden weighing errors. Manufacturers address this by integrating static detection technology and using antistatic accessories. Regular calibration and adherence to Good Weighing Practice (GWP®) also help maintain consistent results. Proper installation, cleaning, and maintenance further reduce errors.

Regulatory Compliance (FDA, GMP, etc.)

Pharmaceutical checkweighers must meet strict regulatory standards. These include FDA 21 CFR Part 11, GMP guidelines (FDA 21 CFR 210, 211, and EU GMP), and EU Annex 11. Compliance ensures product quality and patient safety.

Key requirements include:

- Equipment must use non-reactive, easily cleanable materials like stainless steel.

- Hygienic design prevents contamination.

- Preventive maintenance and calibration are mandatory.

- Qualification protocols (IQ, OQ, PQ) confirm proper installation, operation, and performance.

- Data integrity features such as role-based access control, audit trails, electronic signatures, and secure data storage support ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate).

- Batch management and integration with manufacturing execution systems (MES) support regulatory audits and batch release.

Ongoing compliance requires scheduled calibration, preventive maintenance logs, change control, and re-validation after major changes.

Automation and Throughput

Automation plays a vital role in modern pharmaceutical checkweighers. Automated systems reduce manual weighing tasks, lower labor costs, and minimize human error. Real-time data and Industry 4.0 integration enable predictive maintenance and process control, which further reduces errors and operational costs.

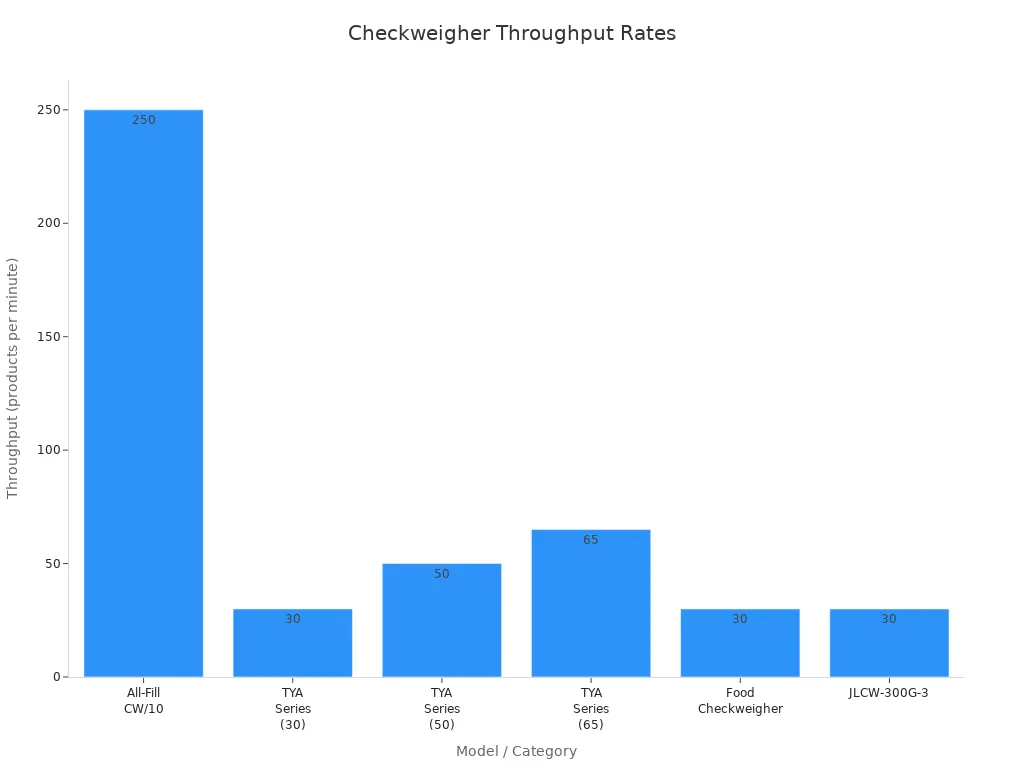

Manufacturers benefit from high throughput rates. The following table shows typical throughput rates for different models:

| Model / Category | Throughput (products per minute) | Notes on Application / Industry Usage |

|---|---|---|

| GCW100-A | 120 | Pharmaceutical (capsules, tablets, blister packs), food, personal care, toys, hardware |

| All-Fill CW/10 | Up to 250 | High-speed, fast and accurate weighing, suitable for chemical and pharmaceutical sectors |

| TYA Series | 30, 50, 65 | Used widely in pharmaceutical, electronics, food, chemical industries |

| Food Checkweigher (general) | 30 | Designed for weight control in food, chemical, automotive industries |

| JLCW-300G-3 | 30 | Suitable for pharmaceutical health care, daily chemical, food industries |

Checkweighers in pharmaceutical production typically operate at up to 100 products per minute. Some high-speed models reach 250 products per minute, balancing speed and accuracy. The chart below compares throughput rates of various models:

Automated pharmaceutical checkweighers also integrate with other systems, such as metal detectors or X-ray inspection units. This integration improves quality control and reduces the risk of defective products reaching consumers. AI and machine learning features allow real-time adjustments, further reducing error rates and improving product quality.

Integration with Production Lines

Pharmaceutical manufacturers need checkweighers that fit smoothly into their existing production lines. A well-integrated system keeps the process efficient and maintains high product quality. Companies follow several steps to achieve seamless integration:

- They check if the new checkweigher matches their current equipment and machinery.

- They make sure there is enough space and install the unit according to the manufacturer's instructions.

- They connect the checkweigher to the conveyor system and set up the software to match product weight limits and other settings.

- They test and calibrate the system to ensure it finds and rejects products that do not meet standards.

- They train operators and maintenance staff so everyone knows how to use and care for the equipment.

- They schedule regular calibration and maintenance to keep the system accurate.

- They use the data from the checkweigher to study production trends and improve processes.

A Pharmaceutical Checkweigher often uses standard interfaces like USB ports and printers to share data with other systems. Physical features such as guide rails and bridge plates help products move smoothly through the line. Different reject mechanisms, including pusher arms and air blowers, remove products that do not meet weight requirements. Electrical signals, like lamp towers or horns, alert staff to problems right away.

Manufacturers also connect checkweighers to metal detectors and emergency stops. This setup keeps the line safe and ensures only quality products move forward. Real-time monitoring and data collection help companies spot problems quickly. They can fix issues like faulty equipment or overweight packaging before they cause bigger delays. These actions reduce downtime, improve speed, and keep products within weight limits. Data-driven insights help companies save on raw materials and boost quality assurance.

Some advanced systems, like Bizerba’s checkweighers with BRAIN2 OEE software, collect and analyze data in real time. This allows teams to monitor and improve availability, performance, and quality. Fast changeovers and easy-to-use touchscreens make setup simple and reduce training time. All these features work together to raise overall equipment effectiveness (OEE) and keep production running smoothly.

Data Management and Traceability

Accurate data management is essential in pharmaceutical manufacturing. Companies must track every product and keep detailed records to meet strict regulations. Modern checkweighers support these needs with advanced data features.

- Systems designed for the pharmaceutical market comply with FDA 21 CFR Part 11 and EU Annex 11. They control user access and record all important actions in audit trail files.

- Integration with software suites like Yudoo 4.0 allows centralized management of production data, workflows, and digital quality. These tools support Track & Trace, automation, and serialization, making it easier to follow each product through the supply chain.

- Automated and real-time data recording prevents manual errors. Secure, centralized storage keeps records safe and easy to find during audits.

- Audit trails capture details such as instrument ID, time stamps, methods, raw material information, and calibration history. This supports full traceability and quick retrieval of batch data.

- IoT and AI features enable real-time monitoring, predictive maintenance, and remote diagnostics. Cloud dashboards provide instant access to inspection data and analytics.

- Cybersecurity measures, including firewalls and VPNs, protect sensitive data from threats. Proper audit trails for AI-driven decisions help companies stay ready for FDA inspections.

Pharmaceutical Checkweighers use password-protected user profiles and electronic signatures to secure data. Audit tracking logs every action, making it easy to trace any changes back to the right person and time. These features ensure data authenticity and reliability, which are critical for compliance.

Companies that use these advanced data management tools can quickly respond to audits, maintain product quality, and meet regulatory demands. Full traceability and secure storage make it easier to manage batch records and support long-term data retention.

How a Pharmaceutical Checkweigher Works

Step-by-Step Weighing Process

A Pharmaceutical Checkweigher follows a precise sequence to ensure every product meets strict weight standards. The process begins when products enter the infeed section. The conveyor spaces each item so only one product reaches the weighing platform at a time. Sensors, such as photoelectric switches, detect the arrival of each product. The load cell then measures the product’s weight as it passes over the weighing platform. The controller receives this weight signal and compares it to preset limits. If the weight falls within the acceptable range, the product continues down the line. If not, the system prepares to remove it.

Operators must clean the checkweigher and confirm calibration before starting. They use the user interface to select the correct product program and monitor individual weights as products move through the system.

Main steps in the weighing process:

- Feed and space products on the conveyor.

- Detect product entry using sensors.

- Measure weight with a load cell.

- Process and compare weight data.

- Sort or reject products based on results.

- Provide feedback to upstream machines for process adjustments.

Reject Mechanisms for Out-of-Spec Products

When a product does not meet weight specifications, the Pharmaceutical Checkweigher activates its rejection system. The system uses several types of rejectors, such as pneumatic pushers, drop-down arms, or air jets. These mechanisms remove underweight or overweight products from the main conveyor and place them in a separate rejection box. Visual and audible signals, like colored lights and alarms, alert operators to any issues. The system also records each rejection for quality control and compliance.

- Pneumatic pushers gently move products off the line.

- Drop-down rejectors allow products to fall into a collection bin.

- Air jets quickly blow lightweight items into a separate area.

- Diverter arms guide products to the correct path based on weight.

Operators can review rejection data to identify trends and improve the process.

Real-Time Monitoring and Feedback

Modern checkweighers use advanced load cell technology and real-time data analysis. The system displays live weight readings and status updates on a user-friendly interface. Operators see immediate feedback if a product falls outside the target range. The checkweigher logs all weight data for each batch, supporting regulatory compliance and traceability.

The system connects directly to filling equipment. When it detects a trend of over- or under-filling, it sends signals to adjust the filling process. This feedback loop helps maintain consistent product quality and reduces waste. Continuous monitoring allows early detection of equipment drift or environmental changes, keeping the production line efficient and compliant.

Real-time monitoring and feedback ensure every product meets quality standards and supports quick corrective actions.

Types of Pharmaceutical Checkweighers

In-Line Checkweighers

In-line checkweighers operate directly on moving production lines. These systems weigh products as they travel along conveyor belts. Manufacturers choose in-line models for high-throughput environments. The design allows for fast and accurate weighing without stopping the line. Operators see immediate results and can remove products that do not meet weight standards. In-line checkweighers support efficient production and help maintain quality control.

Dynamic weighing technology enables these machines to measure products in motion. This feature makes them ideal for large-scale pharmaceutical manufacturing. In-line models balance speed and accuracy, ensuring each item meets strict requirements. They often integrate with other inspection systems, such as metal detectors, to enhance safety and compliance.

Tabletop and Laboratory Models

Tabletop and laboratory checkweighers provide higher precision for delicate or high-value products. These static models require each product to stop for weighing. Operators use them for small batches, research, or quality assurance tasks. Tabletop models excel in environments where accuracy matters more than speed.

Manufacturers rely on these systems for weighing small tablets, capsules, or specialty items. The careful handling reduces the risk of damage. Laboratory models often feature advanced sensors and calibration options. These machines help ensure that every product meets exact specifications. The distinction between in-line and tabletop models highlights the trade-off between throughput and precision in pharmaceutical manufacturing.

Tabletop checkweighers offer the highest accuracy, making them suitable for sensitive drugs and research applications.

High-Speed Bulk Checkweighers

High-speed bulk checkweighers handle large volumes of packaged products at rapid rates. These machines verify package completeness and detect missing instruction leaflets. Operators use them to identify open flaps and askew packages, preventing disruptions on the line. The systems provide bin full warnings and monitor air pressure to ensure proper reject operation.

- Detect missing instruction leaflets by identifying small weight changes.

- Identify open flaps and askew packages to avoid production issues.

- Provide bin full alerts and air pressure monitoring for reject mechanisms.

- Confirm successful rejection of defective products with counterchecking.

- Use lockable reject bins with sensors to notify operators when bins are full.

- Support process validation and documentation for regulatory compliance.

- Help avoid downtime from upstream packaging problems, improving efficiency.

- Verify case weights at the end of the packaging line.

- Integrate after filling and packaging equipment to maintain product integrity.

- Enable reject verification and fail-safe operation to prevent defective products from reaching consumers.

- Minimize vibration and ensure smooth handling at high speeds.

- Facilitate electronic tracking and documentation for FDA and DSCSA regulations.

High-speed bulk checkweighers play a key role in maintaining production efficiency and regulatory compliance. Their advanced features help manufacturers meet strict quality standards and avoid costly errors.

Combination Checkweighers with Metal Detection or X-ray Inspection

Combination checkweighers with metal detection or X-ray inspection offer advanced protection for pharmaceutical products. These systems combine weight verification and contaminant detection in a single inline unit. Manufacturers use them to ensure dosage uniformity and prevent contamination, meeting strict FDA and EU GMP guidelines.

Operators rely on metal detectors to find ferrous, non-ferrous, and stainless steel particles. Multi-frequency electromagnetic fields scan each product, even through packaging. This process helps prevent metal contamination in tablets and capsules. X-ray inspection systems add another layer of safety. They detect non-metallic foreign objects such as glass, stone, and high-density plastics. These systems also verify fill levels and count components, which is important for ampoules, blister packs, and vials.

Combination checkweighers automatically reject products that fail weight or contamination checks. This reduces the risk of recalls and regulatory fines.

Manufacturers benefit from several key features:

- Hygienic stainless steel construction supports clean production environments.

- Customizable reject mechanisms remove non-conforming products quickly.

- High-speed operation keeps production lines moving without bottlenecks.

- Integrated data logging and audit trails provide traceability and support compliance with regulations like 21 CFR Part 11.

The following list shows how these systems improve quality control:

- Checkweighers confirm product weight and detect missing tablets or liquids, maintaining dosage uniformity.

- Metal detectors serve as the first defense against metal contamination.

- X-ray inspection systems find both metallic and non-metallic foreign objects and verify fill levels.

- Combining these technologies ensures thorough contaminant detection and weight verification at every stage.

- Data logging and compliance features help manufacturers meet regulatory standards.

Combination checkweighers with metal detection or X-ray inspection give pharmaceutical companies confidence in their product safety and quality. These systems help maintain operational efficiency and support strict regulatory requirements.

Key Benefits of Pharmaceutical Checkweighers in Manufacturing

Ensuring Patient Safety

Patient safety stands as the top priority in pharmaceutical manufacturing. A Pharmaceutical Checkweigher helps maintain strict control over product weight, which is vital for consistent dosing. Many facilities use checkweighers with a tolerance accuracy of ±0.05 grams to verify package weights. This high level of precision ensures that each tablet or capsule contains the correct amount of active ingredient. For example, high-speed systems like the MG2 Selekta can process up to 500,000 units per hour. These systems use fail-safe sensors to detect and remove any product that does not meet weight standards. By removing under- or over-dosed tablets before packaging, manufacturers protect patients from receiving incorrect dosages and help maintain batch uniformity.

Consistent dosing and strict weight control are essential for product quality and patient safety.

Supporting Regulatory Compliance

Pharmaceutical manufacturers must follow strict regulations to ensure product quality and safety. Checkweighers support compliance by providing thorough qualification processes, such as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). These steps confirm that equipment is installed, operates, and performs as required. Well-documented IQ/OQ/PQ records make regulatory inspections smoother by offering clear traceability and audit trails. Digital tools also help by logging calibrations and creating audit trails automatically. This documentation helps prevent data integrity issues, product recalls, and regulatory penalties.

- Checkweighers automate the weighing process, reducing human error.

- They track and record weight data for audits.

- Sophisticated rejection systems ensure only compliant products reach the market.

Enhancing Operational Efficiency

Pharmaceutical Checkweighers improve operational efficiency in several ways. Automation increases production speed and reduces manual errors. These systems ensure each product meets weight specifications, which prevents both overfilling and underfilling. By removing out-of-spec products automatically, manufacturers reduce waste and streamline production. Real-time data collection supports better inventory management and process optimization.

- High-speed checkweighers process products rapidly, eliminating bottlenecks.

- User-friendly interfaces allow quick identification and correction of issues.

- Integration with other systems enables recipe recall and automated batch control.

Efficient checkweighing systems help manufacturers avoid costly downtime and maintain smooth, continuous production.

Reducing Product Waste

Pharmaceutical manufacturers face constant pressure to reduce product waste and improve sustainability. Checkweighers play a vital role in this effort. These systems use precise weighing technology to keep products within strict weight limits. When a checkweigher detects an item that does not meet specifications, it removes the product before packaging. This early detection prevents defective items from reaching the market and reduces the need for costly recalls.

Automation in checkweighers increases production efficiency. Operators rely on these machines to minimize overfill and underfill. By keeping each product within legal weight requirements, companies lower material costs and avoid unnecessary giveaways. This process supports sustainability goals and helps manufacturers remain profitable.

Modern checkweighers focus on optimizing material usage. Advanced models use sensors and software to track every product. They identify trends in overfilling or underfilling and provide feedback to upstream equipment. This feedback loop allows quick adjustments, reducing waste and improving overall quality.

Sustainability initiatives encourage manufacturers to adopt checkweighers that minimize packaging waste. These systems help companies meet environmental targets by reducing the amount of unused or excess material.

Many pharmaceutical facilities choose checkweighers designed for low energy consumption. These machines divert waste efficiently and support circular economy principles. By reducing rework and minimizing the environmental footprint, checkweighers help companies achieve long-term sustainability.

The following list highlights key ways checkweighers reduce product waste:

- Detect and remove defective products early in the process

- Prevent overfill and underfill, lowering material usage

- Support compliance with weight regulations, reducing recalls

- Optimize packaging and material use for sustainability

- Enable real-time adjustments to minimize waste

Pharmaceutical checkweighers stand as essential tools for waste reduction. Their advanced features support both profitability and environmental responsibility.

A Pharmaceutical Checkweigher provides precise weight control and supports strict regulatory compliance in pharmaceutical manufacturing. These systems deliver high accuracy, rapid throughput, and reliable data management. Manufacturers benefit from improved efficiency, reduced waste, and enhanced product quality.

Selecting the right checkweigher requires careful consideration of several factors:

- Integration with existing production lines

- Maintenance requirements and spare part availability

- Compliance with industry standards

- Flexibility for future growth

- Budget and cost

- Data collection and reporting features

- Ease of use and sanitation

- Durability and reliability

- Weight range and capacity

- Speed and throughput

- Product handling capabilities

| Challenge Category | Specific Issues | Solutions |

|---|---|---|

| Mechanical Issues | Component wear, belt misalignment, jams | Routine inspections, calibration, cleaning |

| Calibration Issues | Incorrect setup, zero scale errors | Frequent recalibration, proper initial setup |

| Electrical & Software | Power interruptions, sensor failures, glitches | Upgraded power supply, sensor testing |

| Environmental Factors | Temperature, humidity, vibrations | Controlled environment, monitoring |

| Operational/User Errors | Incorrect setup, poor training | Ongoing operator training, correct configuration |

| Product Handling | Uneven weight, sticking, blockages | Adjust packaging, recalibrate sensors |

| Regulatory Compliance | FDA, GMP standards | Collaboration with equipment providers |

Manufacturers who invest in advanced checkweighers gain long-term benefits:

- Increased efficiency and output

- Improved accuracy and quality control

- Cost savings from reduced waste

- Strong regulatory compliance

- Automation that lowers labor costs

- Data-driven process optimization

Pharmaceutical Checkweighers play a vital role in maintaining compliance, accuracy, and operational excellence. Careful selection and proper implementation ensure reliable performance and support future growth.

FAQ

What is the main purpose of a pharmaceutical checkweigher?

A pharmaceutical checkweigher ensures every product meets strict weight standards. This system helps manufacturers maintain quality, protect patient safety, and comply with industry regulations.

How often should a checkweigher be calibrated?

Manufacturers should calibrate checkweighers regularly. Most facilities follow a monthly or quarterly schedule. Calibration frequency depends on production volume, regulatory requirements, and equipment usage.

Can a checkweigher detect foreign objects in products?

A standard checkweigher measures weight only. For foreign object detection, manufacturers use combination systems with metal detectors or X-ray inspection units.

What types of products can a pharmaceutical checkweigher handle?

Pharmaceutical checkweighers can weigh tablets, capsules, blister packs, bottles, and vials. Some models also handle cartons and cases at high speeds.

Why is data management important in pharmaceutical checkweighing?

Data management ensures traceability, supports regulatory audits, and maintains product quality. Accurate records help manufacturers track every batch and respond quickly to compliance checks.

See Also

Top Manufacturers Of Ampoule Filling Production Lines Compared

Leading Locations To Purchase X-Ray Inspection Equipment China

Popular Folder Gluer Innovations For Carton Lines In 2025

Six Essential Industrial Vacuum Cleaners For Business Use

Contemporary Techniques For Synthesizing Aminoguanidine Bicarbonate Industrially