Choosing Your Raisin Sorter Optical or X-Ray?

An optical sorter serves as the primary raisins sorting machine for most processors. It excels at removing common field debris and sorting for quality. However, an X-ray sorter is crucial for detecting dense foreign materials like stones and glass. Optical systems cannot see these contaminants. The best solution for complete safety combines both technologies.

Optical Sorters: Your First Line of Defense for Quality

An optical sorter is the workhorse of any modern raisin processing line. This technology acts as the first line of defense, ensuring a high-quality product by removing a wide range of defects and unwanted organic material. Processors rely on this raisins sorting machine to protect their product's value and consistency.

Excelling at Color and Shape Defect Removal

Optical sorters use advanced imaging technology to analyze every single raisin. The system identifies imperfections with incredible precision. This process ensures a uniform and appealing final product.

- High-intensity LEDs illuminate raisins as they pass through the inspection zone.

- High-resolution cameras capture detailed images of each item from multiple angles.

- Intelligent software analyzes these images, detecting subtle differences in color that indicate mold or immaturity.

- The system also identifies defects based on shape and size, ejecting shriveled or malformed raisins.

- Infrared (IR) and near-infrared (NIR) imaging can even help identify foreign materials with a similar color but different composition.

The Best Tool for Ejecting Stems and Capstems

Stems and capstems are the most common types of field debris found with raisins. An optical sorter is the most efficient tool for their removal. Modern laser sorters offer an impressive optical resolution, some as fine as 0.3 mm. This capability allows the machine to easily spot and eject even the smallest capstems attached to the fruit. Removing this organic material is essential for delivering a clean, ready-to-eat product that meets consumer expectations.

Grading Raisins for Consistent Product Quality

Achieving a consistent grade is critical for market success. Optical sorters automate the grading process, sorting raisins based on predefined quality and size parameters. This helps processors meet established industry standards, such as those set by the USDA.

USDA grades for raisins specify key attributes for quality. These standards include requirements for color, moisture content, and flavor. They also define size classifications, such as 'Small' (formerly 'midget') and '3-Crown size or larger', ensuring product uniformity across the market.

By using an optical sorter, processors can reliably separate their product into distinct grades, maximizing the value of their entire crop.

X-Ray Sorters: The Ultimate Safety Net

While optical sorters manage product quality, an X-ray sorter acts as the ultimate safety net. This technology provides an essential layer of protection against dense contaminants that are invisible to cameras. It is a non-negotiable tool for processors committed to the highest standards of food safety.

Unmatched Detection of High-Density Contaminants

X-ray inspection systems excel at identifying foreign materials based on density differences. They are specifically engineered to find and remove the most dangerous contaminants, including glass, metal, mineral stone, and dense plastics. These high-density materials are common culprits in costly food recalls. An X-ray system's ability to detect metal shavings or glass shards is crucial for preventing consumer injury and protecting a brand's reputation. This proactive approach mitigates the significant financial losses associated with recalls and regulatory fines.

Finding Foreign Material Embedded in the Product

Contaminants are not always on the surface. A stone or piece of glass can become embedded inside a raisin, making it impossible for an optical sorter to see. X-ray technology solves this problem by inspecting through the product.

- It effectively detects high-density foreign materials hidden within the fruit.

- Advanced systems can pinpoint contaminants like stones, glass, and dense plastics.

- This capability ensures that even hazards obscured by the product itself are identified and ejected.

A Critical Final Safety Check Before Packaging

Processors should place an X-ray raisins sorting machine just before final packaging. This placement serves as a critical control point in a food safety plan, aligning with Hazard Analysis and Critical Control Points (HACCP) principles and Food Safety Modernization Act (FSMA) preventive controls.

This final inspection confirms that no dense contaminants were introduced during processing. It provides a verifiable paper trail for regulators and demonstrates a clear commitment to consumer safety, building essential trust in the brand.

By performing this check at the last possible moment, companies ensure their product is safe as it goes into the bag, safeguarding both consumers and the business.

Head-to-Head: Which Raisins Sorting Machine for Which Contaminant?

Choosing the right technology requires a clear understanding of its strengths. An optical sorter and an X-ray system excel at removing different types of foreign material. This head-to-head comparison clarifies which machine to use for specific contaminants commonly found in raisins.

Stems and Field Debris

Winner: Optical Sorter 🏆

Optical sorters are the superior tool for removing stems, capstems, and other organic field debris. These systems use high-resolution cameras that can be programmed to identify the unique shape and color of stems.

Processors can utilize specific settings, sometimes called 'Raisin Mode' or 'Super Raisin Mode', to aggressively target and eject stems. A stricter setting will even remove perfect raisins that have a small stem still attached, ensuring an exceptionally clean final product.

X-ray sorters, in contrast, are ineffective for this task. X-ray technology identifies objects based on density. Stems and raisins have very similar low densities, making them indistinguishable to an X-ray system. Therefore, an optical sorter is the essential machine for this primary cleaning stage.

Stones, Glass, and Metal

Winner: X-Ray Sorter 🏆

X-ray sorters provide unmatched protection against high-density contaminants like stones, glass, and metal fragments. These materials pose a significant food safety risk. An X-ray raisins sorting machine is the only reliable solution for their detection.

Optical sorters struggle with this task. The detection process for an optical sorter relies on color differentiation. When a stone or piece of dark glass has a color similar to a raisin, the optical system cannot effectively identify it as a contaminant. This limitation makes it an unreliable safety check for these specific hazards.

X-ray technology overcomes this challenge by ignoring color and analyzing density.

- Advanced X-ray systems use linear array technology to effectively identify metal, stone, and glass in bulk raisins.

- Many systems are highly sensitive, capable of detecting stones as small as 2 mm in diameter.

- This capability ensures the removal of dangerous foreign objects that optical sorters would miss.

Mold and Discoloration

Winner: Optical Sorter 🏆 (with a note on X-ray capabilities)

Optical sorters are the primary technology for identifying and removing moldy, discolored, or immature raisins. These systems use a combination of technologies to ensure product quality and visual appeal. Advanced optical sorters employ Near-Infrared (NIR) spectroscopy and computer vision to spot defects. NIR technology can detect subtle differences in chemical composition and water content associated with mold, while computer vision models accurately identify visual imperfections.

Interestingly, some modern X-ray systems also list mold detection as a feature. Certain X-ray inspection machines designed for pre-packaging inspection of products like beans and peppers can be applied to raisins. These systems use unique software to identify mold as a non-metal contaminant. However, this is not a primary function of most X-ray machines. The optical sorter remains the most direct and efficient tool specifically engineered for quality defects like mold and discoloration.

High-Density Plastics

Winner: X-Ray Sorter 🏆

X-ray sorters are the definitive choice for detecting fragments of high-density plastic. These contaminants can be introduced during processing and are difficult to spot visually. An X-ray system identifies these plastics by checking the density of every item that passes through its inspection field.

The general rule is that any material denser than water is detectable by an X-ray system. This means plastics that would sink in water can be found and ejected. For even greater precision, processors can use dual-energy X-ray technology. This advanced method identifies foreign materials based on their chemical composition, making it highly effective at detecting dense plastics along with other hazards like metal and glass. Optical technologies like NIR, while used in recycling to separate plastic types, are not designed to find dense plastic fragments hidden in a product stream.

Designing the Optimal Raisin Sorting Line

Creating an effective sorting line involves a multi-stage approach. Each stage uses specific technology to target different contaminants, ensuring both product safety and quality. This strategic combination maximizes efficiency and brand protection.

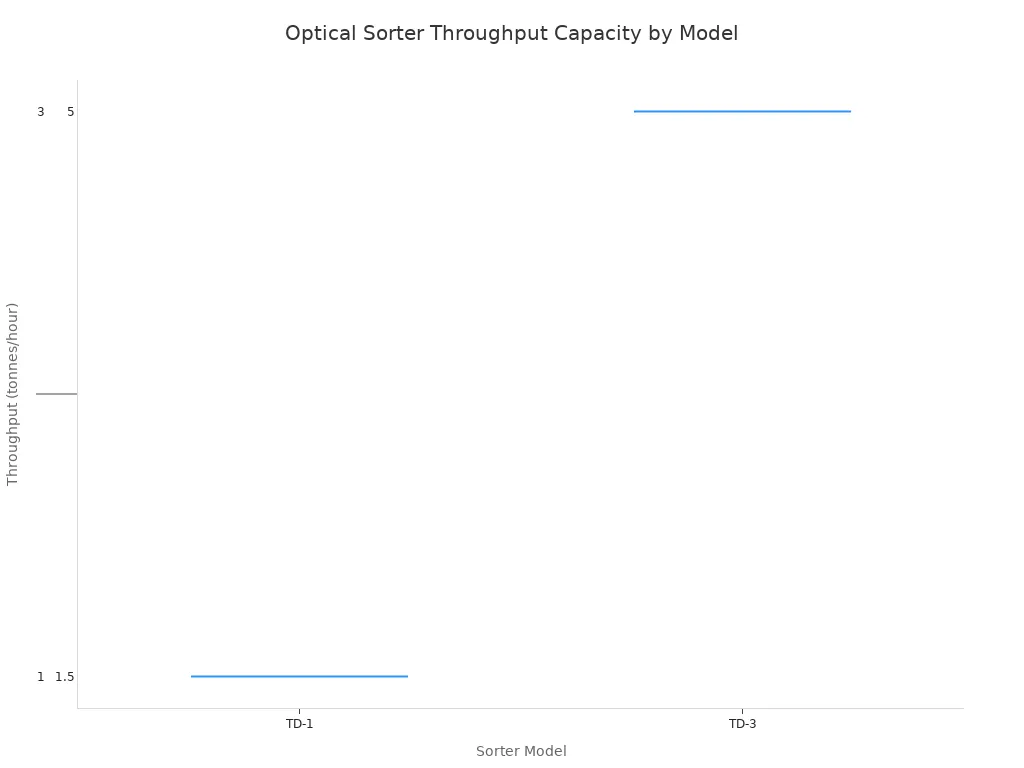

Stage 1: Initial Quality Sort with Optical Technology

The process begins with an optical sorter. This machine serves as the primary workhorse for quality control. It removes the bulk of unwanted material right after initial cleaning. The sorter's high-resolution cameras and lasers identify and eject stems, capstems, and discolored or moldy raisins. Large-scale processors rely on these systems for their high throughput capacity.

| Model | Throughput (t/h) |

|---|---|

| TD-1 | 1-3 |

| TD-3 | 1.5-5 |

| TD-5 | 3-8 |

| TD-6 | 5-12 |

| TD-8 | 6-14 |

| TD-10 | 8-16 |

Stage 2: Critical Density Inspection with X-Ray

Next, the product moves to an X-ray inspection system. This stage is the critical safety check. The X-ray raisins sorting machine detects high-density foreign materials that optical sorters cannot see. It finds and removes dangerous contaminants like stones, glass, and metal fragments. Placing this inspection after the initial optical sort ensures that the X-ray system focuses only on finding the densest hazards.

Stage 3: Final Polish and Grade Verification

The final stage often involves a secondary pass through an optical sorter. This step acts as a "final polish." It verifies that the raisins meet the precise size and quality specifications for their intended grade. This ensures a consistent, premium product goes into the final package.

This final verification step is crucial for maximizing crop value. It allows processors to confidently sort their product into different grades, from standard to premium, meeting specific customer requirements and market demands.

An optical sorter is the workhorse for quality control, removing off-color raisins, mold, and stems. Processors implement an X-ray sorter as the essential safety guardian to eliminate dense hazards like stones and glass. For maximum brand protection, the industry best practice combines both technologies in a multi-stage system.

FAQ

Can one machine handle all raisin sorting needs?

No single machine can do it all. Optical sorters manage quality and organic debris. X-ray systems detect dense physical hazards. Processors need both for comprehensive sorting.

Which sorter is more important for food safety?

An X-ray sorter is critical for food safety. It finds dangerous contaminants like glass, metal, and stones. This technology provides the final safety check before packaging.

What about the cost difference between the two systems?

Optical sorters typically have a lower initial investment. X-ray systems cost more but provide essential protection against high-density hazards, safeguarding a brand from costly recalls.

See Also

Top Chinese Suppliers for X-Ray Inspection Machine Procurement

Capsule Sorters: Essential for Effective Pharmaceutical Defect Removal

Tablet Sampling Machines: A Comprehensive Guide for Lab Selection

Essential Capsule Checkweighers for Smart Buyers in the Year 2025

Selecting the Ideal A1 A2 Milk Test Kit for Dairy Operations