Maximizing Dried Pea Quality Optical or Mechanical Sorting?

Optical sorters are definitively superior to mechanical sorters for maximizing dried pea quality. Their advanced systems offer unparalleled precision. They detect subtle defects in color, size, and shape. This capability allows processors to meet the demands of a rapidly expanding market for products like green peas.

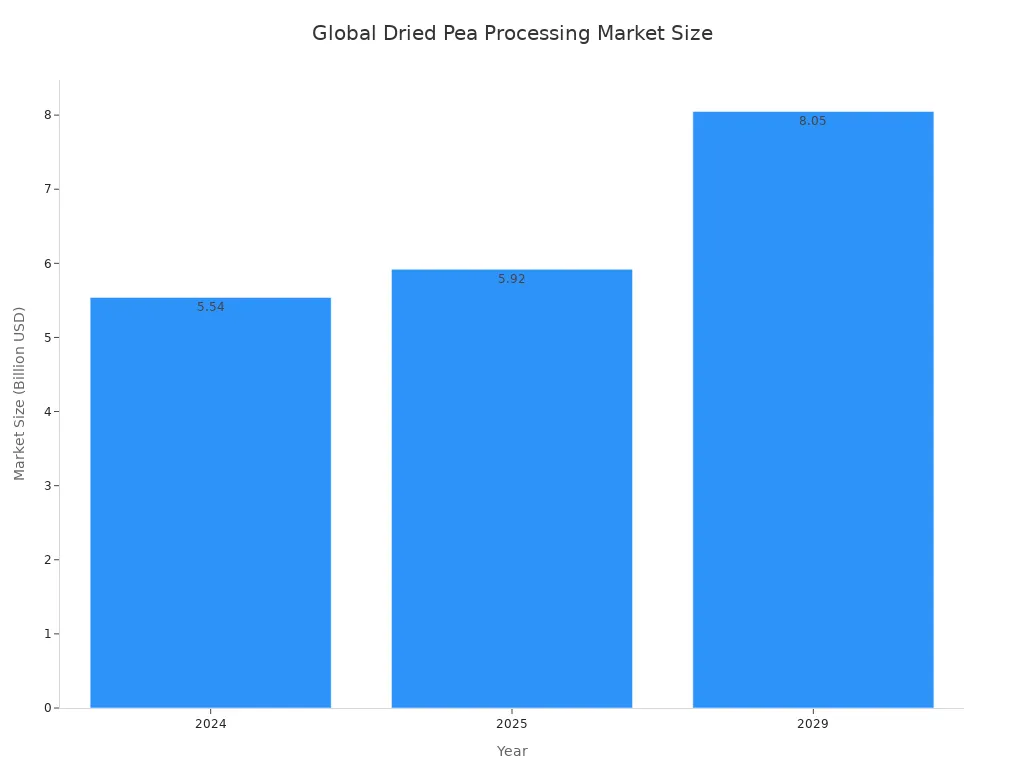

The global dried pea market is projected to grow from $5.92 billion in 2025 to $8.05 billion by 2029. Choosing the right dried peas sorting solution is crucial for capturing this growth.

Core Sorting Mechanisms Explained

Understanding the fundamental differences between mechanical and optical sorters is key to selecting the right equipment. Each technology uses a distinct method to separate good products from defects and foreign materials. The choice directly impacts final product quality and operational efficiency.

Mechanical Sorters: Separation by Physical Traits

Mechanical sorters operate by separating products based on physical characteristics. These machines use screens, shakers, and drums to sort peas by specific attributes. The process is effective for basic grading and removing grossly oversized or undersized items.

Key sorting parameters include:

- Size and shape

- Weight and density

- Firmness and texture

This method provides a foundational level of cleaning. However, mechanical sorters cannot distinguish items based on subtle color differences or identify foreign materials that share similar physical properties with the peas.

Optical Sorters: Separation by Visual Data

Optical sorters utilize advanced imaging technology to analyze and sort products with incredible precision. High-speed cameras and sensors scan each pea as it passes through the machine. This system captures detailed data on every item.

Advanced Detection: Optical sorters employ a combination of RGB (Red, Green, Blue), infrared (IR), and ultraviolet (UV) cameras. This allows them to detect contrasts invisible to the human eye, identifying issues like chemical composition or internal damage.

Sophisticated software processes this visual data in milliseconds. It identifies and ejects discolored peas, damaged items, and foreign contaminants like stones, glass, or sticks. This technology ensures a superior level of purity and quality that mechanical systems cannot achieve.

Head-to-Head: Optical vs. Mechanical for Pea Quality

When evaluating sorters, processors must compare their performance across key metrics. The differences in accuracy, contamination control, and throughput directly influence the final product's value and the operation's profitability. A direct comparison reveals the distinct advantages of each technology.

Accuracy in Defect Removal

Optical sorters provide a level of accuracy that mechanical systems cannot match. Advanced processing plants that utilize optical color sorters can achieve a final product purity rate of 99.99%. This precision comes from the technology's ability to analyze visual data for each pea, a task where traditional mechanical methods are ineffective.

Mechanical sorters effectively remove peas that are the wrong size or density. However, they are blind to critical quality defects that do not affect these physical traits. Optical sorters excel at identifying these subtle issues.

- Off-color or discolored seeds

- Split or broken peas

- Insect damage or blemishes

- Mold and other signs of disease

The VistaSort Color Sorter, for example, is engineered specifically to remove these damaged or off-type kernels. This capability is essential for producers aiming for the highest grade of product, as optical systems perform with a speed and accuracy that mechanical separation cannot achieve for these complex sorting tasks.

Foreign Material Contamination Control

Removing foreign material (FM) is a non-negotiable aspect of food safety. Mechanical sorters can filter out some contaminants, but optical sorters offer superior protection against a wider range of physical hazards. Stones, for instance, are a common foreign material found in pea harvests. A stone of similar size and weight to a pea can easily pass through a mechanical sorter. An optical sorter, however, instantly identifies the stone by its color, texture, and light-reflecting properties, ejecting it from the product stream.

Adherence to global food safety standards is mandatory for market access. These regulations identify numerous materials as critical physical hazards that processors must eliminate.

Optical sorters are instrumental in meeting stringent food safety protocols like HACCP and BRC Global Standards. These systems effectively identify and remove many of the most dangerous contaminants.

| Standard/Regulation | Common Physical Hazards Identified |

|---|---|

| USDA HACCP | Metal, Glass, Plastic |

| FDA PCHF | Metal, Glass, Stones |

| GFSI Standards | Ceramics, Porcelain, Wood, Brittle Plastic |

| BRC | Requires physical separation equipment like optical sorters |

This comprehensive detection capability protects consumers from harm and shields brands from costly recalls and reputational damage.

Throughput and Good Product Recovery

Throughput, measured in tons per hour, is a critical factor for operational efficiency. Mechanical sorters often boast very high throughput for simple, high-volume tasks. A mechanical length sizer, for example, can grade whole potatoes at up to 36 metric tons per hour. Using a digital sorter for this same bulk task would significantly restrict throughput.

However, for the detailed work of quality sorting, optical sorters deliver impressive and reliable capacity. Industrial optical sorters for peas typically process between 0.5 and 2 tons per hour. While this figure is lower than a bulk mechanical grader, it is optimized for precision. The efficiency of automated sorters can decrease as throughput increases, so operating within the designed capacity ensures maximum accuracy.

A crucial metric is good product recovery. Mechanical sorters, relying on screens and drums, can inadvertently discard good peas that are slightly misshapen or on the edge of a size specification. Optical sorters minimize this "false reject" rate. Their precise air jets target only the defective item or foreign material, ensuring that the maximum amount of sellable product is retained. This higher yield of good product often makes a superior dried peas sorting solution more profitable, even if the raw throughput appears lower than a bulk mechanical system.

Choosing the Right Dried Peas Sorting Solution

Selecting the ideal dried peas sorting solution requires a careful analysis of both upfront expenses and long-term value. Processors must look beyond the initial price tag to understand the full financial impact of their equipment choice. A thorough evaluation of costs and returns will illuminate the most profitable path forward.

Comparing Initial Investment and Operating Costs

Mechanical sorters typically have a lower initial purchase price, making them an attractive option for businesses with limited capital. However, the total cost of ownership extends far beyond the initial investment. Optical sorters, while requiring a higher upfront cost, often deliver greater long-term value.

Modern optical sorters are engineered for efficiency. Manufacturers design them with lower energy consumption and require less compressed air. Their improved reliability and easier maintenance also reduce long-term operating costs.

This focus on efficiency means that over the equipment's lifespan, an optical sorter can prove to be the more economical choice.

Calculating the Return on Investment (ROI)

A comprehensive Return on Investment (ROI) calculation is essential for justifying the investment in a superior dried peas sorting solution. This analysis quantifies how quickly the equipment will pay for itself through increased revenue and cost savings. A robust ROI calculation considers multiple factors:

- Labor Costs: Automation reduces the need for manual sorting staff, lowering expenses related to wages, benefits, and insurance.

- Material and Waste Costs: Precise sorting minimizes the rejection of good products, reducing floor waste and maximizing yield.

- Maintenance Costs: This includes parts, service visits, and potential downtime for sanitation and repairs.

- Production Rate: The ability to handle high demand efficiently translates directly to increased revenue.

Ultimately, a better product allows processors to satisfy customers and improve sales. The advanced capabilities of an optical dried peas sorting solution enable processors to meet premium market demands, enhancing brand reputation and unlocking higher profitability.

When Each Sorter Makes the Most Sense

Deciding between optical and mechanical sorting depends entirely on a processor's quality goals and market position. Each system has a distinct and valuable function within the food processing industry. The choice defines the final product's quality, safety, and brand perception.

The Case for Optical Sorters

Optical sorters are indispensable for any business aiming to produce premium-grade dried peas. Processors use this technology to meet stringent quality and food safety standards. It is the industry standard for a wide range of products, including nuts, seeds, and grains, where consumer safety and product appearance are paramount.

Advanced optical systems act as a critical safeguard before packaging. They use high-resolution cameras, infrared (IR), and even chlorophyll analysis to find defects invisible to other systems.

This technology allows a superior dried peas sorting solution to achieve several key objectives:

- Identify subtle defects: It detects and removes off-color seeds, split peas, and items with insect damage.

- Ensure uniformity: The system can differentiate between whole and split peas or hulled and un-hulled products for a consistent final look.

- Eliminate foreign material: It effectively ejects dangerous contaminants like stones, glass, plastic, and even moldy kernels, protecting brand reputation from costly recalls.

The Role of Mechanical Sorters

Mechanical sorters maintain a crucial role in the initial stages of processing. They are highly effective for bulk cleaning and basic grading. Processors use these machines to remove grossly oversized or undersized peas and some foreign material before the product moves to more refined sorting stages. They serve as an economical first pass, preparing the product stream for the precision work of an optical sorter. For operations where only basic size separation is required, a mechanical sorter can be a sufficient and cost-effective tool.

For businesses producing premium dried peas, optical sorters are an essential investment. The technology's superior ability to remove subtle defects and foreign materials directly creates a higher-value product. This capability enhances brand reputation and boosts profitability.

While mechanical sorters serve a purpose in basic cleaning, adopting optical sorting is the key to market leadership in the competitive food processing industry.

FAQ

Can optical sorters handle different types of peas?

Yes. Processors configure optical sorters for various pea types. The system's software adjusts to specific color, size, and shape parameters for products like:

- Green peas

- Yellow peas

- Split peas

What is the main advantage of a mechanical sorter?

A mechanical sorter offers a lower initial investment. It provides high-speed, cost-effective sorting for basic tasks like removing oversized or undersized peas before more detailed inspection.

How does an optical sorter improve food safety?

Optical sorters identify and eject dangerous foreign materials. This technology removes contaminants like stones, glass, and plastic, protecting consumers and upholding brand integrity.

See Also

Capsule Sorters: Essential Technology for Flawless Pharmaceutical Product Quality

Top Capsule Checkweighers for 2025: A Buyer's Essential Selection Guide

Boosting Pharma Efficiency: The Impact of Advanced Capsule Decapsulation Technology

Pharmaceutical Checkweighers: Understanding Their Core Functions and Key Attributes

Tablet Sampling Machines: Your Comprehensive Guide to Laboratory Equipment Selection