The Pros and Cons of On-Farm Barley Sorting

An on-farm barley sorting solution can boost revenue. Farmers can upgrade grain to malting quality. They can then access premium markets like craft breweries. However, the investment is substantial. It involves high equipment costs, ongoing maintenance, and increased labor. Profitability depends on the farm's scale, market access, and operational management.

Financial Gains: Boosting Your Bottom Line

An on-farm sorter directly impacts a farm's profitability. It unlocks new revenue streams and reduces operational expenses. Farmers gain greater control over their product's value from the moment it leaves the combine. This control translates into tangible financial rewards.

Command Higher Premiums for Malting Grade

The most significant financial advantage is the ability to upgrade feed barley into a high-demand malting product. Craft breweries and distillers pay a premium for grain that meets their exacting standards. Sorting allows farmers to capture this price difference. The current market illustrates this potential gain.

| Category | Price ($/t) | Premium ($/t) |

|---|---|---|

| Ex-farm Malting Barley | 175.40 | 22.30 |

| Ex-farm Feed Barley | 153.10 | N/A |

This $22.30 per ton premium adds up quickly across a harvest, creating substantial new revenue.

Reduce Dockage and Elevator Penalties

Elevators penalize farmers for loads containing foreign material, broken kernels, or other imperfections. An on-farm sorter cleans the grain before it ever leaves the property. This process ensures the final product meets strict quality specifications. Key sorting targets include:

- Removing foreign material and insects

- Achieving plump, mature kernels of uniform size

- Minimizing peeled or broken kernels to less than 5%

- Ensuring protein content is within the desired 9.5% to 12.5% range

Meeting these targets eliminates costly dockage fees and maximizes payment for every bushel sold.

Cut Commercial Storage and Transport Costs

Hauling grain to a commercial elevator involves significant transportation expenses. These costs can erode profits, especially over long distances. On-farm sorting opens the door to direct sales, reducing unnecessary mileage. Trucking rates add up, with some operators reporting costs for local grain hauling.

One user on a trucking forum reported a rate of "about $1.70/mile, RT miles" for hauling corn. Another user suggested "2.50/mile" as a fair rate.

By sorting on-site, farmers can load trucks for direct shipment to maltsters or brewers. This streamlined process cuts out the middleman and keeps transport dollars in the farmer's pocket. 💰

Operational Advantages of In-House Control

Beyond direct financial returns, bringing barley sorting in-house gives farmers powerful control over their post-harvest operations. This control translates into a higher quality product, improved efficiency, and even new business opportunities. Managing the process on-site empowers growers to optimize every stage from field to final sale.

Achieve Superior Quality and Consistency

An on-farm sorter allows a producer to meticulously manage grain quality. They can fine-tune the equipment to meet the precise specifications of premium buyers. This ensures each batch is consistent. Key quality metrics for malting barley include:

- Protein Content: Must be within a specific range, often between 9.5% and 12.5%.

- Enzymatic Activity: Measured by diastatic power (DP) and alpha-amylase (AA).

- Malt Extract (ME): Indicates the amount of soluble material available for brewing.

- Free Amino Nitrogen (FAN): Essential for healthy yeast fermentation.

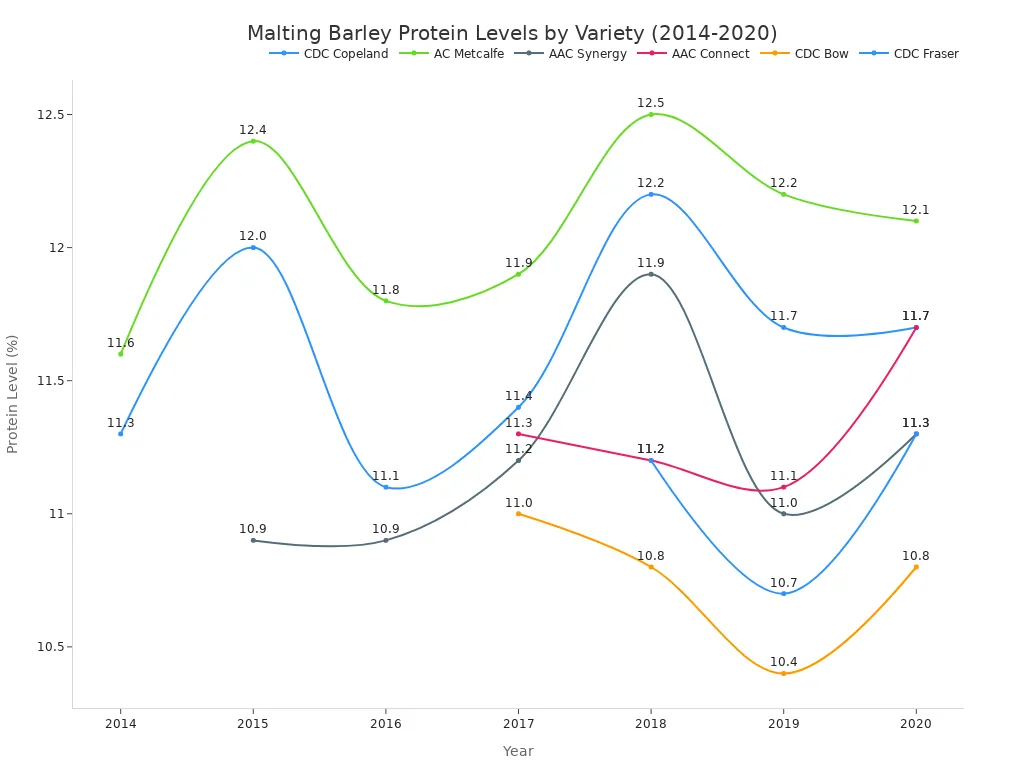

Controlling these factors is critical, as protein levels can vary significantly by variety and year.

An on-farm system enables farmers to sort and blend grain to consistently hit these targets.

Gain Flexibility and Avoid Bottlenecks

Harvest time often creates long lines and delays at commercial elevators. Limited storage capacity at these facilities can bring a farmer's entire operation to a standstill.

On-farm grain sorting and storage allow farmers to avoid these harvest-time bottlenecks. They are not dependent on elevator schedules or dump line capacity. This freedom ensures combines and grain carts keep moving efficiently during critical harvest periods. 🚜

This independence gives farmers the flexibility to harvest when conditions are optimal, not just when the elevator is ready.

Create New Revenue with Sorting Services

An on-farm sorter is a significant asset that can generate income beyond a farmer's own crops. Growers can offer custom sorting services to neighboring farms that do not own similar equipment. This creates a new revenue stream that helps offset the initial purchase price and maintenance costs. It transforms a major capital expense into a service-based profit center for the operation.

The Financial Hurdles: Understanding the Full Cost

While the potential for profit is attractive, investing in an on-farm sorter is a major financial commitment. The total cost of ownership extends far beyond the initial sticker price. Producers must carefully evaluate the full spectrum of expenses before making a decision.

High Upfront Equipment Purchase Price

The most immediate barrier is the cost of the machinery itself. A new optical color sorter, which uses advanced camera technology to identify and remove imperfections, can cost between $50,000 and $100,000. This price reflects equipment capable of processing 5 to 30 tons per hour. Due to this significant capital outlay, many farmers require specialized financing.

Fortunately, several funding options exist. Farmers can explore government-backed loans, traditional equipment loans, or leasing arrangements to manage the purchase.

- USDA Farm Storage Facility Loan (FSFL) Program: Offers long-term, fixed-rate loans for storage and handling equipment.

- Ag Equipment Loans: Provided by agricultural lenders for specific machinery purchases.

- Leasing: Allows for lower upfront costs with the option to buy the equipment later.

Ongoing Maintenance and Parts Expenses

The expenses do not stop after the initial purchase. These complex machines require regular service to maintain accuracy and efficiency. Ongoing costs include:

- Scheduled professional maintenance and calibration.

- Replacement of wear-and-tear parts like belts, lights, and ejector components.

- Keeping a small inventory of critical spare parts to minimize costly downtime during peak seasons. 🔧

A dedicated budget for maintenance is essential for the long-term success of the investment.

Hidden Infrastructure and Utility Costs

Integrating a sorter into a farm operation often involves additional "hidden" costs. The sorter itself requires a dedicated, weather-proof space, which may mean constructing a new building. Furthermore, these machines have significant power demands, potentially requiring an upgrade to three-phase electrical service. Farmers must also account for the cost of supporting equipment, such as extra augers, conveyors, and storage bins needed to handle the separated grain grades.

Is an On-Farm Barley Sorting Solution Right for Your Operations?

Beyond the balance sheet, a barley sorting solution introduces significant operational challenges. Farmers must assess their capacity to handle increased complexity in labor, maintenance, and logistics. These factors are critical to determining if the investment is a practical fit for the farm.

Increased Labor and Training Requirements

Operating advanced sorting equipment is not a task for an untrained worker. It demands a skilled operator who can manage the technology and make informed decisions. A successful operator often possesses a unique combination of skills and knowledge.

- Mechanical Knowledge: Understanding the machine's design, use, and repair is fundamental.

- Production and Processing: Familiarity with quality control and cost management ensures efficient operation.

- Critical Thinking: The ability to assess performance and make corrective actions is vital for maintaining grain quality.

- Technology Training: Operators need to be comfortable with the software and AI tools that run a modern barley sorting solution.

This need for specialized labor adds a new layer of human resource management to the farm's responsibilities.

Managing Equipment Downtime and Repairs

Equipment breakdowns are an unavoidable reality. When a sorter goes down during a busy period, it can halt the entire post-harvest workflow. This risk makes a proactive maintenance strategy essential.

A farm must have a clear plan for repairs. This could involve training an on-site employee for routine fixes or establishing a relationship with a reliable service technician who can respond quickly. Unplanned downtime directly translates to lost revenue and efficiency.

Storing and Handling Multiple Grain Grades

A sorter effectively splits one crop into multiple products, such as premium malting barley and standard feed grain. This separation creates a new logistical challenge. Each grade requires its own dedicated storage bin and handling equipment, like augers or conveyors. Farmers must implement strict procedures to prevent cross-contamination, which could downgrade a valuable batch of malting barley and erase potential premiums. This careful management of inventory adds complexity to daily operations.

A barley sorting solution offers a clear trade-off. Farmers gain control and profit potential in exchange for major capital and operational duties. The right choice depends on a detailed cost-benefit analysis for the specific operation.

Before deciding, a farmer must calculate the potential return on investment. This calculation should project premium gains against the total cost of ownership for the barley sorting solution.

FAQ

How long until a farmer sees a return on investment?

The payback period varies by farm scale and market access. Operators often recoup their investment within three to five years from premium sales and lower elevator penalties.

Can a sorter clean other grains besides barley?

Yes, most modern sorters are versatile. A farmer can calibrate the machine to clean other crops like wheat, oats, or soybeans, increasing the equipment's utility. ✅

How much grain is lost during the sorting process?

Modern sorters are very efficient. The machine typically rejects 1% to 5% of the total volume. The exact amount depends on the initial grain quality and machine settings.

See Also

Custom Cargo Lifts: Business Advantages, Disadvantages, and Key Considerations

Capsule Sorters: Essential Tools for Effective Defect Removal Explained

Carrying Bars: Unveiling Their Industrial History and Significance

Essential Industrial Checkweighers: Top 3 for Every Food Plant

Support Columns: Steel Versus Wood, Advantages, and Drawbacks Compared