How a Mustard Seeds Optical Sorter Can Boost Your Profits

A mustard seeds optical sorter directly boosts profitability. It increases revenue with premium-grade seeds while slashing operational costs through automation. This enhanced efficiency allows businesses to capitalize on a rapidly expanding market.

Market Opportunity 📈

- The global mustard seed market is projected to grow from USD 5.1 billion in 2025 to USD 7.3 billion by 2035.

- This growth represents a Compound Annual Growth Rate (CAGR) of 3.7% over the forecast period.

Increase Revenue Streams with Superior Seed Quality

Superior product quality is the most direct path to increased revenue. An optical sorter transforms a standard harvest into a premium commodity, unlocking new financial opportunities at every stage of the sales process. This technology empowers businesses to meet the market's demand for excellence.

Achieve 99.9%+ Purity for Premium Pricing

An optical sorter uses advanced cameras and ejectors to remove imperfect seeds, foreign materials, and color defects with unmatched precision. This process allows processors to consistently achieve purity levels of 99.9% or higher. Such exceptional quality distinguishes the product in a competitive market.

Financial Impact: By marketing mustard seeds as "premium grade," businesses can command significantly higher prices per kilogram. This purity premium directly translates into greater revenue and higher profit margins on the same volume of product.

Unlock Access to High-Value International Markets

Many international markets impose strict quality and safety standards on imported agricultural products. An optical sorter ensures that every shipment meets these rigorous requirements, removing contaminants that would otherwise lead to rejection at the border. This capability opens doors to lucrative export opportunities. For organic mustard products, suppliers must adhere to the Organic Food Production Act and USDA organic regulations, a compliance standard made achievable through precise sorting.

Secure Larger Contracts with Food Manufacturers

Large-scale food manufacturers and packaged goods companies depend on ingredient consistency and safety for their production lines. They cannot risk a product recall due to foreign materials. An optical sorter provides the quality assurance these large buyers demand, making a supplier a more reliable and attractive partner. They often require suppliers to hold key quality certifications, including:

- ISO (International Organization for Standardization)

- IFS (International Featured Standards)

- BRC (Brand Reputation Compliance)

- HACCP (Hazard Analysis Critical Control Point)

Meeting these standards helps businesses secure larger, more stable, and more profitable contracts.

Slash Operational Costs and Maximize Margins

Beyond increasing revenue, an optical sorter directly cuts major operational expenses. This technology streamlines the production process, reduces reliance on manual labor, and minimizes costly errors. The result is a significant boost to a company's bottom line and overall financial health.

Drastically Reduce Manual Sorting Labor Costs

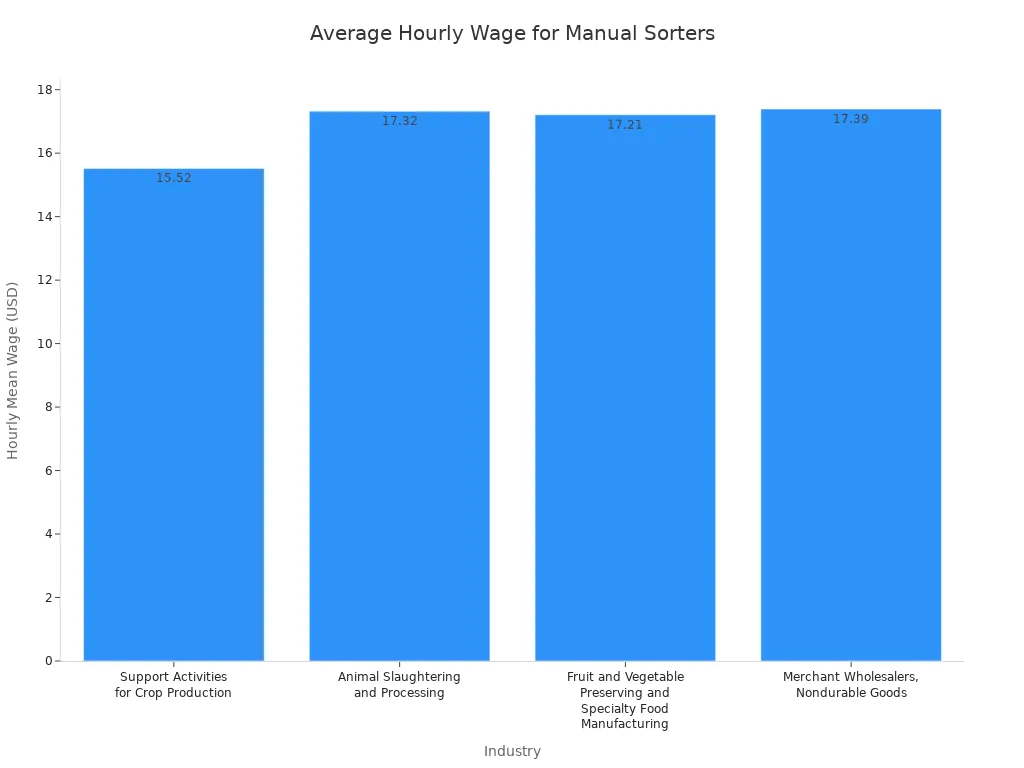

Manual sorting is one of the most significant and recurring expenses in seed processing. Businesses must account for hourly wages, benefits, training, and management overhead for a large workforce. Automating this function with an optical sorter virtually eliminates these costs. A single machine performs the work of numerous human sorters with greater speed and accuracy, freeing up capital for other growth areas. The financial impact of replacing this variable expense is substantial, especially considering industry wages.

Minimize Product Waste to Maximize Sellable Yield

Every good seed mistakenly discarded is lost profit. Manual sorting is prone to human error and fatigue, leading to a higher rate of "false rejects" where valuable product is wasted. Optical sorters operate with superior precision.

- They use high-resolution cameras and lasers to scan each seed.

- The technology analyzes color, size, shape, and structural properties.

- It compares every seed against pre-set quality criteria for acceptance or rejection.

This precise process ensures that only defective seeds and foreign materials are removed. It maximizes the sellable yield from every batch, converting more of the raw harvest into revenue.

Eliminate Costs Associated with Rework and Rejection

Mistakes in sorting lead to expensive consequences. A batch that fails a quality control check requires rework, consuming additional labor, energy, and machine time. Worse, a shipment rejected by a client can lead to financial penalties, costly return shipping, and damage to a supplier's reputation. An optical sorter provides the consistency needed to get the job right the first time, every time. This reliability eliminates rework expenses and prevents costly client rejections, protecting both margins and business relationships.

How a Mustard Seeds Optical Sorter Boosts Production Efficiency

Efficiency is the engine of profitability. A mustard seeds optical sorter replaces slow, linear processes with high-speed, continuous operation. This upgrade transforms a facility's production capacity, enabling businesses to process more volume in less time and convert inventory into cash more quickly.

Accelerate Throughput from Kilograms to Tons Per Hour

Manual sorting is a significant production bottleneck. An automated system shatters this limitation by processing thousands of individual seeds per second. This incredible speed allows businesses to scale their output dramatically. Modern multi-chute optical sorters can process up to 20 tons of mustard seeds per hour, a volume that is impossible for human teams to match. This capability allows a processor to fulfill large orders on tight deadlines and confidently expand operations.

Enable Continuous 24/7 Operation Without Breaks

Unlike a human workforce, a mustard seeds optical sorter operates without fatigue, breaks, or shift changes. It provides the potential for continuous 24/7 production, maximizing the use of a facility's assets. This reliability is maintained through simple, scheduled service.

Key Maintenance for Peak Performance:

- Regular cleaning of cameras and ejectors.

- Calibration of sensors to ensure accuracy.

- Software updates to enhance sorting algorithms.

- Professional support contracts for remote and on-site service.

These straightforward procedures ensure minimal downtime and consistent performance around the clock.

Improve Cash Flow by Fulfilling Orders Faster

Increased throughput directly enhances a company's financial health. Faster processing shortens the Cash Conversion Cycle (CCC) by reducing Days Inventory Outstanding (DIO). This means capital is not tied up in stored inventory. For example, the food industry averages a 32-day inventory turnover, a cycle that efficient sorting helps to shorten. This speed and reliability also improve a supplier's performance score, leading to stronger negotiating power and better contract terms with major buyers.

Ensuring Food Safety and Brand Integrity

Protecting consumers is the highest priority in food processing. A mustard seeds optical sorter is a critical defense for ensuring food safety. This technology safeguards a company's most valuable asset: its brand reputation. It provides the precision needed to build consumer trust and secure long-term business stability.

Guarantee Removal of Foreign Materials

Optical sorters excel at identifying and ejecting a wide range of contaminants that compromise product safety and quality. They effectively remove both field-level debris and biological contaminants from the product stream. Common foreign materials include:

- Field stones, weed seeds, and other foreign material

- Fungi such as Alternaria, Aspergillus, and Fusarium

These machines use a combination of advanced technologies to achieve unparalleled accuracy. High-speed cameras and sensors scan every seed, while powerful algorithms analyze the data to detect any anomaly.

| Technology Type | Detection Capabilities |

|---|---|

| AI-powered Vision Systems | Detects defects, foreign materials, and color variations. |

| X-ray Technology | Detects dense foreign objects like metal, glass, or stones. |

| Laser Technology | Detects subtle differences in shape, size, and texture. |

| High-speed Ejection Systems | Utilizes compressed air to quickly remove unwanted items. |

Protect Your Brand Reputation from Recalls

A single product recall can devastate a business. It leads to financial losses, logistical nightmares, and severe damage to consumer confidence. An optical sorter acts as a powerful insurance policy against this risk.

The High Cost of Failure ⚠️ A contaminated product reaching the market can trigger expensive recalls, regulatory fines, and lasting harm to a brand's public image. Consistent, automated sorting is the best prevention.

By ensuring every batch is free of harmful materials, the technology protects a company’s reputation for quality and safety. This reliability helps build a loyal customer base that trusts the brand.

Meet and Exceed Strict Regulatory Standards

Food processors operate under intense scrutiny from regulatory bodies. They must comply with strict standards like Hazard Analysis Critical Control Point (HACCP) to legally sell their products. An optical sorter provides the consistency and traceability required to meet these mandates. The machine's performance data offers proof of due diligence in removing contaminants. This capability allows businesses to not only meet but exceed regulatory expectations, positioning them as industry leaders in food safety.

Investing in a mustard seeds optical sorter is a direct path to higher profits. This technology provides a significant competitive advantage by ensuring superior product quality and consistency. Businesses should analyze current sorting costs and calculate the potential return on investment to secure future profitability.

FAQ

How does the sorter handle different mustard seed varieties?

The machine uses adjustable software. Processors create custom sorting profiles for yellow, brown, or black mustard seeds, ensuring high accuracy for each specific type.

What is the typical return on investment (ROI)?

Most businesses achieve a full return on investment within 12 to 24 months. This results from reduced labor costs, higher yields, and premium product pricing.

Can the machine sort other products besides mustard seeds?

Yes, its flexible technology sorts other small seeds and grains. A simple software adjustment reconfigures the machine for different products, maximizing its overall utility.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality Assurance

Boosting Pharmaceutical Efficiency with Advanced Capsule Decapsulation Technology

Top Capsule Checkweighers for Smart Pharmaceutical Investment in 2025

Three Must-Have Industrial Checkweighers for Optimal Food Plant Operations

Automatic UV Coaters: Crucial for Achieving Peak High-Speed Printing Performance