5 Key Features in a Pepper Sorting Machine

Manual pepper sorting creates high labor costs and inconsistent product quality. Market expectations for uniformly colored, sized, and blemish-free peppers continue to rise. A modern pepper sorting machine effectively meets these strict standards. This technology ensures consistent quality control and allows processors to scale their operations efficiently.

Boost Accuracy with Advanced Imaging

Advanced imaging systems are the core of a modern pepper sorting machine. They provide the "eyes" that see with superhuman precision, ensuring every pepper meets strict quality standards. These systems use high-resolution cameras and specialized lighting to capture detailed images of each pepper from multiple angles. This technology far surpasses the capabilities of the human eye, leading to unparalleled accuracy and consistency in sorting.

Precision Color and Blemish Sorting

A key function of advanced imaging is sorting peppers by color and identifying surface defects. High-resolution cameras capture images across multiple light spectrums, including visible, ultraviolet, and near-infrared (NIR). This multispectral approach reveals subtle variations the human eye cannot see. It helps detect issues like sunscald, blossom-end rot, and early signs of disease long before they become obvious.

Sophisticated AI algorithms analyze these images in real-time. Processors can set specific color parameters to meet industry standards, such as the USDA requirement that 90% of peppers in a batch show a specified color. These systems use powerful models to differentiate acceptable products from defective ones with incredible accuracy.

AI in Action: Modern sorters employ various AI models for classification:

- Deep Convolutional Neural Networks (CNNs) analyze color and NIR imagery to identify defects.

- Support Vector Machines (SVMs) classify peppers based on texture and color features.

- BackPropagation neural networks can achieve sorting accuracy above 94% by evaluating color, size, and shape.

Consistent Shape and Size Grading

Consumers and retailers expect uniformity in size and shape. Advanced imaging technology, including 3D systems, provides the data needed for precise grading. These systems create a complete digital model of each pepper.

This allows the machine to measure length, diameter, and volume with high precision. It can also analyze shape characteristics to sort different varieties, from bell peppers to jalapeños. Processors can easily configure the machine to sort peppers into specific size categories required by major retailers. For example, U.S. Fancy Sweet Peppers must have a minimum diameter of 3 inches, a standard the machine can enforce flawlessly. This ensures that every package meets buyer specifications, enhancing brand reputation and reducing waste.

Gain Control with Customizable Sorting

Advanced imaging provides the data, but customizable software gives processors control. A modern pepper sorting machine empowers operators to define what constitutes an acceptable product. This flexibility is crucial for meeting diverse buyer specifications and adapting to different pepper varieties or harvest conditions. Operators can quickly adjust sorting parameters, ensuring the final output aligns perfectly with market demands.

Intuitive User Interfaces (HMI)

A powerful machine is only effective if operators can use it easily. Modern sorters feature intuitive Human-Machine Interfaces (HMIs) with graphical dashboards. These systems are designed for rapid learning, allowing new hires to become productive with minimal training. The HMI screen often includes integrated tools for troubleshooting and can be customized with pop-up instructions. Furthermore, many systems offer secure remote access. This feature enables technicians to perform diagnostics, install software upgrades, and provide support from any location, maximizing uptime and reducing operational costs.

Adjustable Defect Sensitivity

Customizable software allows processors to fine-tune defect sensitivity with precision. Operators can set specific sorting rules for color, size, and material. This capability is essential for sorting peppers by ripeness, where optical sensors and AI algorithms analyze color variations to meet specific maturity standards. Processors gain granular control over the sorting process.

Key adjustable parameters often include:

- HSL Color: Adjusting hue, saturation, and lightness thresholds.

- GREY Sensitivity: Defining acceptable levels of discoloration.

- Chromatic Tone: Controlling the range of accepted color tones.

This level of control ensures that every pepper meets the exact quality requirements, from color uniformity to the absence of specific blemishes.

Scale Production with a High-Throughput Pepper Sorting Machine

Efficiency in a processing facility depends on the machine's ability to handle large volumes without sacrificing accuracy. A high-throughput pepper sorting machine allows businesses to scale production to meet growing market demands. This capability transforms sorting from a bottleneck into a streamlined, high-speed process, directly boosting profitability and operational capacity. Processors can handle larger harvests and fulfill bigger contracts with confidence.

Matching Capacity to Your Needs

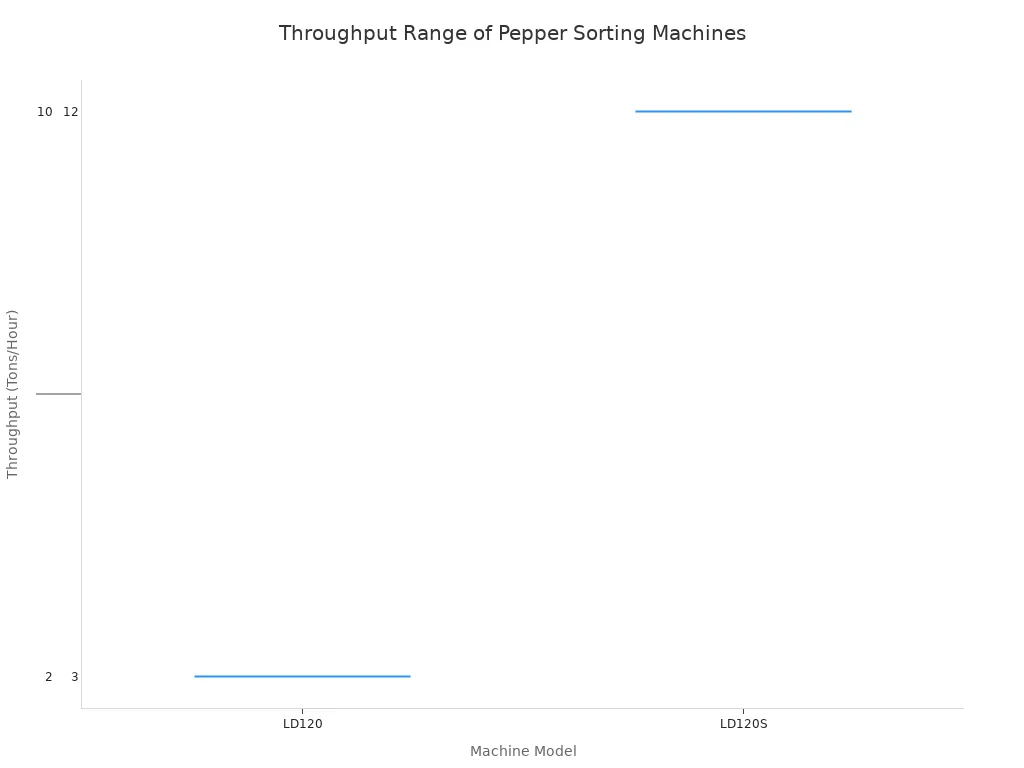

Selecting a sorter with the right capacity is a critical decision. Processors must evaluate their current and projected production volumes to choose a machine that aligns with their operational scale. Manufacturers offer a range of models, each designed for different throughput requirements, from a few tons per hour for smaller operations to over ten tons per hour for large-scale industrial facilities. This ensures that every business can find a solution that fits its specific needs without over-investing in unnecessary capacity.

Smart Ejection Systems

High throughput is only valuable if the sorting is precise. Smart ejection systems use targeted air jets to remove defective peppers from the production line with incredible speed and accuracy. These systems are engineered to minimize the accidental rejection of good products, a common issue known as "good-in-bad." Advanced features ensure that only unwanted items are removed, maximizing yield and revenue.

Key Ejection Technologies That Reduce Waste:

- High-Velocity Ejectors: Custom-designed ejectors use less compressed air while increasing capacity and reducing the rejection of good peppers.

- RISE-UP System: An adjustable ejector bank moves closer to the product stream, improving accuracy by compensating for the uneven falling speeds of peppers.

- Automatic Air Pressure Regulator: This system automatically adjusts air pressure for different products, giving operators precise control to minimize waste.

Preserve Quality with Gentle Handling

High-speed sorting is ineffective if it damages the product. Peppers are delicate and bruise easily, so preserving their quality throughout the process is paramount. A superior pepper sorting machine integrates gentle handling mechanisms from start to finish. This focus on careful transport protects the product’s integrity, reduces food waste, and ensures a premium final product reaches the consumer.

Damage-Free Conveying Systems

The journey through the sorter begins on the conveyor belt, where initial damage can occur. Modern systems use specialized conveying solutions to prevent bruising and abrasions. The design and material of the belt are critical for protecting the peppers.

Key features of a damage-free conveyor include:

- Specialized Materials: Belts are made from food-grade materials like PVC, urethane, or rubber. These surfaces are smooth, durable, and resistant to corrosion.

- Sanitary Design: Smooth belt surfaces and sanitary construction facilitate effective washdowns. This design minimizes areas where bacteria or foreign materials can accumulate.

- Sizing Features: Some conveyors incorporate rectangular openings directly into the belt system, allowing for gentle and efficient sizing of peppers as they move.

Soft Landing and Collection

After the machine sorts the peppers, the collection process must be equally gentle. Dropping produce from a height into a bin can cause significant impact damage. Advanced sorters solve this problem with automated bin-filling systems designed for a soft landing. These systems carefully manage the drop height to protect each pepper.

Several technologies guarantee gentle collection:

- Vertical Bin Fillers: These systems feature a "De-elevator" mechanism that lowers into the bottom of the bin. It slowly rises as the container fills, keeping the drop distance to a minimum.

- Gentle Conveying: Soft fingers on the de-elevator belt gently carry produce into the bin, further reducing impact.

- Automated Positioning: An incremental positioning system automatically adjusts the filler's height, ensuring a consistently minimal drop and preserving product quality.

Ensure Safety with Hygienic Design

Food safety is non-negotiable in any processing operation. A hygienic design prevents microbial growth and cross-contamination, protecting both consumers and brand reputation. Modern sorting machines are built with sanitation in mind, featuring materials and construction that simplify cleaning and comply with global food safety regulations. This focus ensures the final product is not only high-quality but also safe.

Food-Grade and Washdown-Ready

Top-tier machines use materials specifically chosen for safety and durability. Food-contact surfaces, such as screen meshes and conveyor belts, are made from food-grade stainless steel 304 or 316. These materials resist corrosion and do not harbor bacteria, making them ideal for washdown environments. Manufacturers often provide material certifications to verify compliance.

The European Hygienic Engineering and Design Group (EHEDG) sets strict standards for equipment in food processing. EHEDG-certified components guarantee that parts are easily cleanable and prevent bacterial growth, supporting a sanitary production environment and ensuring compliance with regulatory requirements.

Easy Access for Cleaning

Efficient cleaning minimizes downtime and reduces labor costs. A well-designed machine incorporates features that make sanitation quick and thorough. Open-frame construction and sloped surfaces eliminate crevices where food particles and bacteria can accumulate. This design allows water to drain freely during washdowns.

Key features that facilitate easy cleaning include:

- Tool-free disassembly for quick access to internal components.

- Cantilever shaft designs that allow for easy removal of mesh screens.

- Quick-change screens that can be swapped out in minutes.

These elements allow operators to perform complete sanitation protocols with minimal effort, ensuring the machine is always ready for safe production.

Selecting the right pepper sorting machine is a strategic investment that enhances brand reputation and profitability. Processors should evaluate suppliers on their ability to provide comprehensive support beyond the initial sale.

Key Support Services:

- Remote diagnostics and technical service

- On-site installation and training

- Spare parts logistics

This partnership minimizes downtime and optimizes long-term performance. A sorter with these five key features empowers a business to meet the highest quality standards and secure a decisive competitive edge.

FAQ

How much does a pepper sorting machine cost?

Costs vary based on capacity, imaging technology, and features. Processors should request quotes from suppliers to find a machine that fits their budget and operational needs.

Can one machine sort different types of peppers?

Yes. Modern sorters use customizable software. Operators can create and save sorting profiles for various pepper types, such as bell peppers, jalapeños, and chilis.

What maintenance do these machines require?

Regular maintenance includes daily cleaning and periodic checks of belts and ejectors. Manufacturers provide detailed schedules to ensure optimal performance and longevity for the equipment.

See Also

Essential Folder Gluer Innovations Shaping 2025 Carton Production Lines

Capsule Sorters: Key to Eliminating Product Defects and Ensuring Quality

Three Indispensable Industrial Checkweighers for Modern Food Processing Facilities

Boosting Pharma Efficiency: Modern Capsule Decapsulation Machine Advancements Explained

Top Capsule Checkweighers for Savvy Buyers to Evaluate in 2025