What to Look For in a Dried Dates Sorting Machine in 2026

The global dried dates market is projected to reach USD 4.305 billion in 2026. A modern dried dates sorting machine must therefore deliver exceptional performance.

Core technologies like AI-powered defect detection and multi-spectral imaging are non-negotiable. These advanced systems process up to six tonnes per hour, ensuring top-tier accuracy and maximizing throughput.

Intelligent Sorting: AI and Advanced Sensor Fusion

A state-of-the-art dried dates sorting machine no longer relies on a single sensor. Modern systems achieve unparalleled accuracy through advanced sensor fusion. This process combines data from multiple sources—like cameras, lasers, and X-rays—to create a complete digital profile of each date. The system's AI then analyzes this fused data at the feature or decision level, enabling it to identify defects with a precision that far exceeds any single-sensor approach. This integrated intelligence is the new benchmark for quality control in 2026.

Multi-Spectral and Hyperspectral Imaging

Standard RGB cameras see dates the same way a human eye does, limiting them to three broad channels of color. This often fails to distinguish between healthy tissue and subtle defects. Multi-spectral and hyperspectral imaging systems operate on a different level. They capture data across numerous discrete wavelength bands, from ultraviolet (UV) to near-infrared (NIR).

This detailed spectral information allows the system to identify problems invisible to the naked eye. For dried dates, this technology is critical for detecting:

- Early-stage fungal growth, such as Fusarium or Alternaria species, which show unique spectral signatures.

- Subsurface insect damage or infestation that has not yet broken the skin.

- Low moisture content or undesirable chemical changes within the fruit.

By leveraging technologies like Pixel Fusion™, which combines data at the pixel level, these systems create a sharp contrast between good product and foreign material, ensuring only the highest quality dates proceed to packaging.

3D Laser for Shape and Size Grading

Uniformity is a key marker of premium quality. A 2026 dried dates sorting machine incorporates 3D laser scanning to move beyond simple 2D measurements. The laser system creates a complete topographical map of each individual date as it passes through the machine. This provides precise data on length, width, volume, and overall shape. Processors can use this information to grade dates with extreme consistency, ensuring that products destined for retail packs meet exact size and weight specifications. This eliminates manual guesswork and guarantees a uniform final product.

Integrated X-Ray for Foreign Material Detection

Food safety is non-negotiable. Integrated X-ray inspection provides a crucial safety net by detecting dense foreign materials that optical sensors might miss. The system identifies contaminants by analyzing differences in density between the date and the foreign object. Modern X-ray technology is incredibly sensitive, capable of finding contaminants as small as 0.3mm.

Common foreign materials detected by X-ray systems include:

- Metal fragments (ferrous, non-ferrous, and stainless steel)

- Stones, pits, or rock fragments

- Shards of glass or ceramic

- High-density plastics and bone

This capability provides a final, critical check, protecting consumers and brand reputation from the significant risks posed by physical contaminants.

Self-Learning AI Algorithms

The "brain" behind modern sorting is the self-learning AI algorithm. Unlike traditional rule-based systems that require constant manual adjustment, AI-powered sorters continuously improve over time. These deep learning models are trained on millions of images, allowing them to understand what a "perfect" date looks like and instantly flag deviations.

| Metric | Traditional Methods | AI-Based Methods |

|---|---|---|

| Accuracy | 70–85% | Up to 98%+ |

| False Positives | Frequent | Reduced by 40–60% |

| Adaptability | Poor (rule-based) | High (self-learning) |

| Speed | Minutes to hours | Real-time (milliseconds) |

This adaptability is a game-changer. Using techniques like 'Recipe-Based Learning,' the AI can adapt to new date varieties, seasonal changes, or previously unseen defect types without needing an engineer to reprogram it. The system learns from the data it processes, refining its accuracy with every batch.

AI reduces costly mistakes by distinguishing between natural color variations and actual damage. This intelligence leads to fewer good fruits being discarded, directly improving yield and profitability.

Ultimately, a dried dates sorting machine equipped with self-learning AI delivers faster, more reliable, and more accurate results, making it an essential investment for any forward-thinking processor.

Key Operational Features of a Modern Dried Dates Sorting Machine

Beyond the core intelligence of AI and sensor fusion, the operational mechanics of a sorter determine its real-world performance and profitability. A machine's ability to act on its decisions quickly, maintain hygienic standards, and provide actionable data is what separates a good investment from a great one. These key features ensure that the advanced sorting technology translates into maximum efficiency, safety, and return on investment.

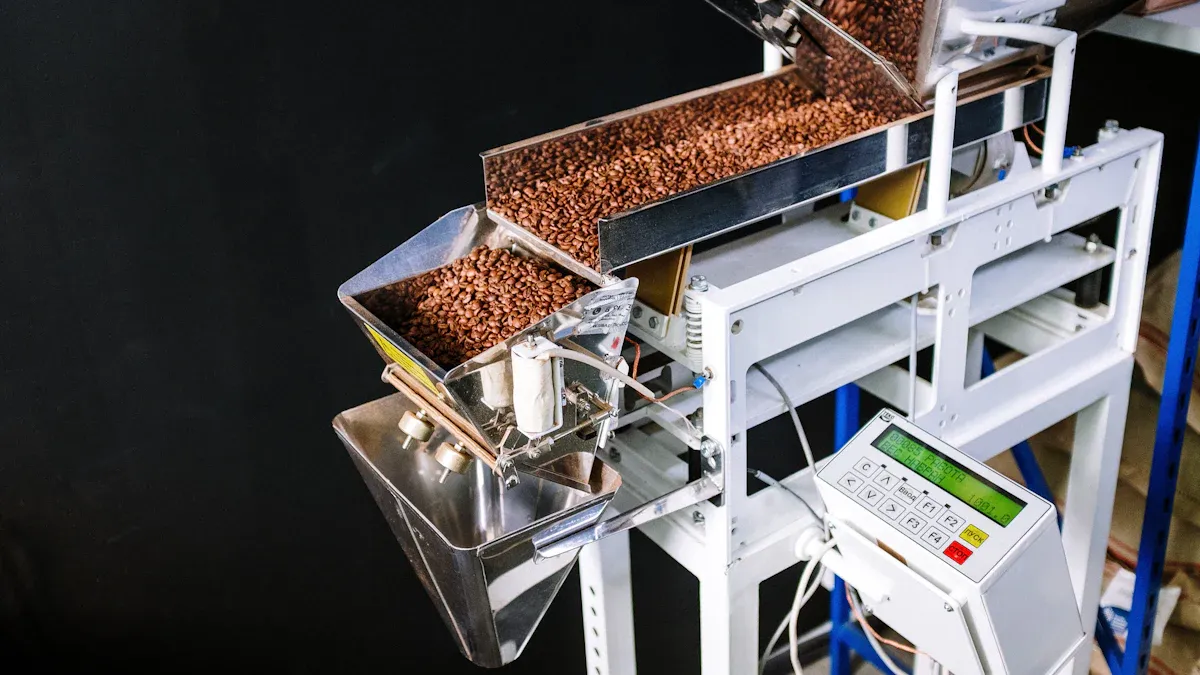

High-Speed Precision Ejection System

Once the AI identifies a defective date or foreign object, the machine must remove it instantly and accurately. A high-speed precision ejection system is critical for this task. Modern systems use targeted bursts of compressed air from advanced pneumatic systems to eject unwanted items without physical contact. This non-contact method is essential for handling delicate dried dates, preserving the integrity of the good fruit and preventing damage.

The impact of this technology is significant. A precise system ensures that only the target item is removed, minimizing the accidental loss of good product. This directly boosts yield and reduces waste.

- Gentle Handling: The use of calibrated air jets ensures that accepted dates continue to packaging completely undamaged.

- Maximum Yield: By differentiating between relevant and irrelevant defects, these systems increase the saleable quantity of the product. Companies report yield increases of up to 25% after implementing automated optical sorting with precision ejection.

- High Throughput: The system operates at incredible speeds, keeping pace with the sorter's analysis and maintaining a high processing capacity without sacrificing accuracy.

This combination of speed, precision, and gentle handling makes the ejection system a cornerstone of a profitable sorting operation.

Sanitary Design for Easy Cleaning

In food processing, hygiene is paramount. A 2026 dried dates sorting machine must feature a sanitary design that complies with global food safety standards like those from the FDA and EHEDG. This involves strategic material choices and thoughtful construction to prevent microbial growth and simplify cleaning.

Key elements of a modern sanitary design include:

- Material Selection: The use of 316L stainless steel is standard for food-contact surfaces. Its molybdenum content provides superior resistance to corrosion from fruit acids and cleaning agents. Surfaces are often electropolished to be smooth and non-porous, resisting microbial adhesion.

- Hygienic Components: FDA-compliant seals made from materials like EPDM synthetic rubber prevent contaminants from entering internal mechanisms. These components are designed without cavities or sharp corners where impurities could collect.

- Tool-less Disassembly: Modern machines allow operators to remove belts, rollers, and screens quickly without any tools. This feature drastically reduces the time needed for daily cleaning and inspection, minimizing downtime and lowering labor costs.

An efficient sanitary design is not just about compliance; it's about efficiency. Optimized Clean-in-Place (CIP) processes and easy-to-clean components can reduce water usage by up to 95% and significantly shorten cleaning cycles, extending operational uptime.

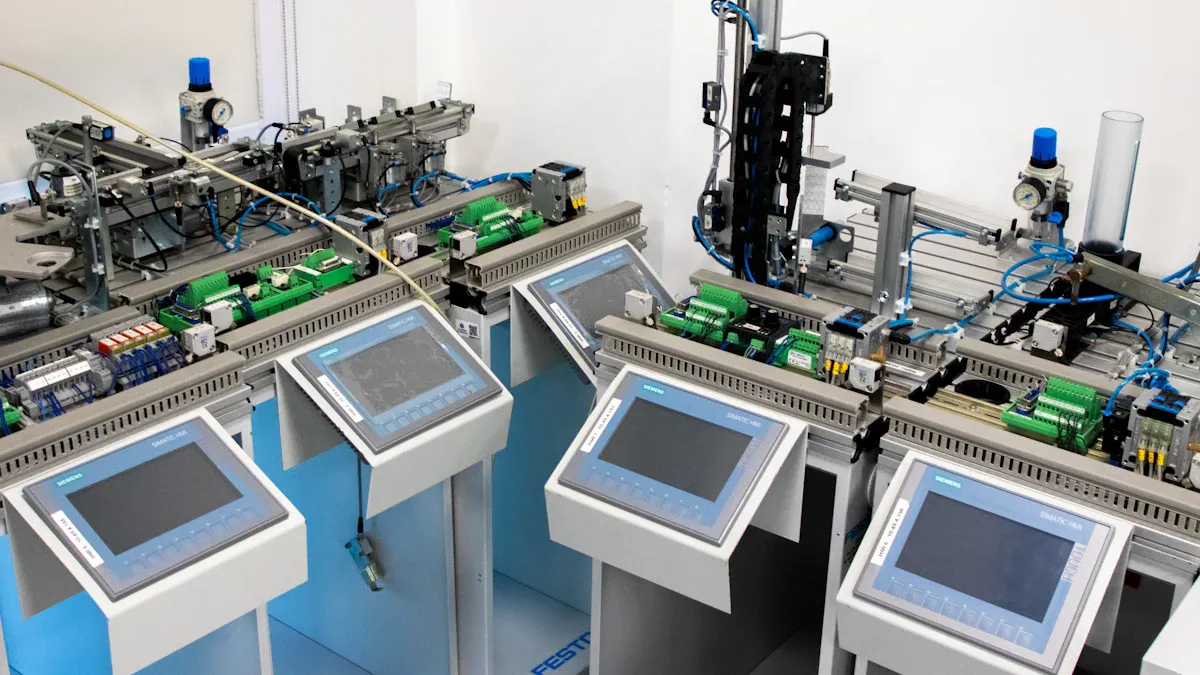

Intuitive Human-Machine Interface (HMI)

The most powerful technology is ineffective if operators cannot use it easily. An intuitive Human-Machine Interface (HMI) acts as the central command center, bridging the gap between the operator and the machine's complex AI. A well-designed HMI prioritizes clarity, simplicity, and consistency, using standard icons and a clear visual hierarchy.

Modern HMIs function as real-time performance dashboards, providing operators with:

- Live Visualization: Real-time footage of the sorting process, with AI inspection results overlaid.

- Performance Dashboards: Displays of key metrics like throughput, defect rates, and yield, allowing operators to monitor production targets.

- Quality Analytics: Charts and graphs that track defects by category, shift, or hour, enabling users to identify trends and address quality issues proactively.

This immediate access to data empowers operators to make informed decisions on the fly, monitor system health, and even override actions when necessary, ensuring the dried dates sorting machine runs at peak performance.

Predictive Maintenance and Data Analytics

To maximize uptime and prevent costly breakdowns, leading sorting machines in 2026 incorporate predictive maintenance and advanced data analytics. These systems move beyond reactive or scheduled repairs by using sensor data to forecast failures before they happen.

| Maintenance Strategy | Downtime Impact | Cost Savings |

|---|---|---|

| Reactive (Fix when broken) | High | None |

| Preventative (Scheduled) | Moderate | Moderate (8-12%) |

| Predictive (AI-driven) | Reduced by 30-50% | Up to 40% |

The system works by continuously monitoring operational parameters like temperature, vibration, and power draw. Machine learning algorithms analyze this data, identify patterns that indicate component wear, and trigger an alert for proactive maintenance. This can reduce unplanned downtime by up to 40%.

Furthermore, the data collected provides powerful analytics for process optimization. Reports can be generated to:

- Identify the root causes of product defects.

- Recommend optimal process parameters to improve quality.

- Analyze historical production output to identify efficiency trends.

- Map the connection between inbound materials and production flow to simplify supply chain planning.

This data-driven approach transforms the sorter from a standalone piece of equipment into an integrated hub for quality and efficiency improvement.

A future-proof 2026 sorter requires specific, non-negotiable criteria to maximize quality, safety, and profitability.

Essential Sorter Checklist:

- AI-Driven Analysis

- Multi-Sensor Fusion (Imaging & X-Ray)

- High-Speed, Sanitary Design

Adopting these systems delivers rapid ROI, with payback periods often under two years, protecting brand reputation and optimizing production.

FAQ

What is the typical ROI for a 2026 sorting machine?

These machines deliver a rapid return on investment. Processors often see a full payback in under two years through increased yield, reduced labor costs, and enhanced product quality.

Can one machine sort different varieties of dates?

Yes. The AI uses 'Recipe-Based Learning' to adapt its sorting parameters. Operators can easily switch between pre-set recipes for different date varieties like Medjool or Deglet Noor.

Does AI eliminate the need for a human operator?

No, AI enhances the operator's role. The system empowers operators with real-time data and analytics, allowing them to make informed decisions and optimize the entire sorting process efficiently.

See Also

Essential Capsule Checkweighing Machines for Smart Buyers in 2025

Innovative Folder Gluer Advancements for Modern Carton Production Lines 2025

Top Destinations for Acquiring X-Ray Inspection Equipment from China

Three Indispensable Industrial Checkweighers for Every Food Processing Facility

Understanding Tablet Sampling Machines: A Comprehensive Laboratory Selection Handbook