Buying a Cumin Seeds Optical Sorter? Ask These Questions

The global cumin market is projected for significant growth, making seed quality paramount.

| Attribute | Details |

|---|---|

| Market Size Value In 2024 | US$ 1 Billion |

| Market Size Value By 2033 | US$ 1.8 Billion |

| Growth Rate | CAGR of 6.5% from 2025 to 2033 |

Impurities like dust and stones cause financial losses. Buyers must therefore ask one critical question:

What is the machine's specific accuracy for removing common cumin contaminants?

This question assesses the performance of a cumin seeds optical sorter and its ultimate return on investment.

Evaluating the Core Technology of a Cumin Seeds Optical Sorter

A machine's effectiveness is determined by its internal components. Buyers should focus on the sensors, cameras, and software algorithms that form the heart of any cumin seeds optical sorter. These elements directly influence sorting precision and, consequently, the final product's market value. A thorough technical evaluation moves beyond marketing claims to verify true capability.

Sensor Types and Detection Capabilities

The first step involves understanding the machine's "eyes." Modern sorters use a variety of sensors to analyze each seed. Buyers should ask manufacturers to detail the specific sensor technologies employed.

Note: Advanced systems often feature customizable camera options with multispectral sensor data. This technology provides superior detection capabilities compared to older, laser-based sorters, often at a lower total cost of ownership.

Key questions to ask include:

- What types of sensors does the machine use (e.g., RGB, InGaAs, UV)?

- Can the sensors detect defects beyond color, such as mold, stems, or foreign materials like small stones and plastics?

- Does the system integrate Internet of Things (IoT) capabilities for remote monitoring and diagnostics?

The integration of high-resolution sensors with powerful processors running machine learning algorithms allows for real-time analysis of physical attributes. This capability is crucial for identifying subtle imperfections in cumin seeds.

Camera Resolution and Defect Detection

High-resolution cameras are essential for identifying minute defects. A higher pixel density allows the machine to "see" smaller imperfections, leading to a cleaner final product. Buyers must inquire about the camera's resolution and its practical impact on defect detection. A low-resolution system might miss discolored seeds or tiny foreign materials, compromising the entire batch.

A powerful cumin seeds optical sorter combines high-resolution imaging with intelligent software. This software uses image recognition and pattern analysis to make split-second sorting decisions. AI-driven models, trained on vast datasets of good and bad seeds, enable the machine to identify and eject contaminants with exceptional precision. The synergy between hardware and software defines the machine's ability to distinguish between acceptable seeds and unwanted material.

Sorting Accuracy and Carryover Rate

Ultimately, performance is measured by two key metrics: sorting accuracy and carryover rate. Sorting accuracy refers to the percentage of contaminants correctly identified and removed. The carryover rate measures the amount of good product that is mistakenly ejected along with the defects.

An ideal machine maximizes accuracy while minimizing carryover. Industry benchmarks provide a useful starting point for evaluation.

- A minimum sorting accuracy of 98% is a common standard.

- Advanced AI-powered sorters can achieve up to 99.5% accuracy.

For cumin seeds specifically, a high-performance machine can achieve a sorting accuracy of 98.5% by analyzing color uniformity, seed integrity, and impurity content. This level of precision effectively removes moldy and immature grains.

Equally important is the carryover rate, often expressed as a ratio of good product to bad product in the reject stream.

For a high-performance cumin seeds optical sorter, an optimized carryover rate should be greater than 35:1. This means for every 35 good seeds retained, only one good seed is lost in the reject stream.

A low carryover rate is critical for maximizing yield and profitability. Buyers should request performance data from live demonstrations using their own product samples to verify these crucial metrics.

Assessing Machine Performance and Long-Term Value

A sorter's initial accuracy is only part of the equation. Buyers must also evaluate its real-world performance, operational costs, and the support structure behind it. These factors determine the machine's long-term value and its overall impact on profitability. A durable, efficient, and well-supported machine minimizes downtime and maximizes return on investment.

Throughput and Capacity Matching

A sorter's throughput, measured in tons per hour (TPH), must align with the processing line's capacity. A machine with insufficient throughput creates a bottleneck, slowing down the entire operation. Conversely, an oversized machine leads to unnecessary capital expenditure and higher energy consumption.

Buyers should ask for the sorter's effective throughput specifically for cumin seeds. Different commodities flow at different rates. A machine rated for 5 TPH with larger grains might only process 3 TPH of smaller, lighter cumin seeds. Matching the sorter's capacity to your production needs is essential for maintaining a smooth and efficient workflow.

Ejector Speed and Durability

Ejectors are the high-speed valves that physically remove contaminants from the product stream. Their speed and durability are critical to performance. Faster ejectors can handle higher throughputs with greater precision, reducing the amount of good product that is accidentally removed.

Durability is equally important, as ejectors are mechanical components subject to wear and tear. Buyers should inquire about the expected lifespan of the ejector valves and the cost of replacement.

Individual ejector valves can cost between $24 and $350. The total replacement cost depends on the number of valves in the machine. Some suppliers offer discounts for bulk orders. For example, certain manufacturers provide a price reduction from $155 to $120 per set for orders of 50 units or more, a potential 20-30% savings.

Understanding these long-term maintenance costs is crucial for calculating the machine's total cost of ownership. A machine with cheaper but less durable ejectors may cost more over its lifetime.

Software Usability and Remote Access

Modern sorting machines rely on complex software. The user interface (UI) should be intuitive enough for operators to manage without extensive training. A user-friendly interface allows for quick adjustments and reduces the chance of operator error. Key features of effective software include:

- An intuitive interface with simple controls for adjusting sorting parameters.

- The ability to save multiple sorting programs for different batches of cumin.

- Real-time monitoring of performance metrics like throughput and ejection rates.

Advanced software often incorporates AI and machine learning. These systems continuously improve their detection capabilities by learning from the product they sort. AI models can adapt to changes in raw material, identify new defect types, and maintain high accuracy over time. This continuous learning process makes the cumin seeds optical sorter more robust and efficient.

Did You Know? 🧠 AI models are not static; their performance can "drift" due to changes in lighting, camera aging, or new types of contaminants. To counter this, advanced systems use continuous monitoring, scheduled retraining cycles, and human-in-the-loop reviews to maintain peak accuracy.

Remote access capabilities also allow technicians to diagnose issues, update software, and provide support without an on-site visit, minimizing downtime.

Power Consumption and Operational Costs

Energy consumption is a significant operational cost. Buyers should request data on the machine's power usage under typical operating conditions. Comparing the energy efficiency of different models can reveal substantial long-term savings.

Maintenance is another major operational expense. Annual maintenance costs for an optical sorter can be a percentage of its initial purchase price.

| Cost Type | Percentage of Initial Price Annually |

|---|---|

| Typical Maintenance Costs | 3% to 7% |

| Aim for Maintenance Costs | <5% |

Asking for a detailed breakdown of expected maintenance costs, including spare parts and service fees, helps create an accurate financial forecast.

After-Sales Support and Live Demonstrations

Reliable after-sales support is non-negotiable. Downtime directly impacts revenue, so a manufacturer's ability to provide timely service is critical. Buyers should clarify the terms of the warranty and the availability of technical support.

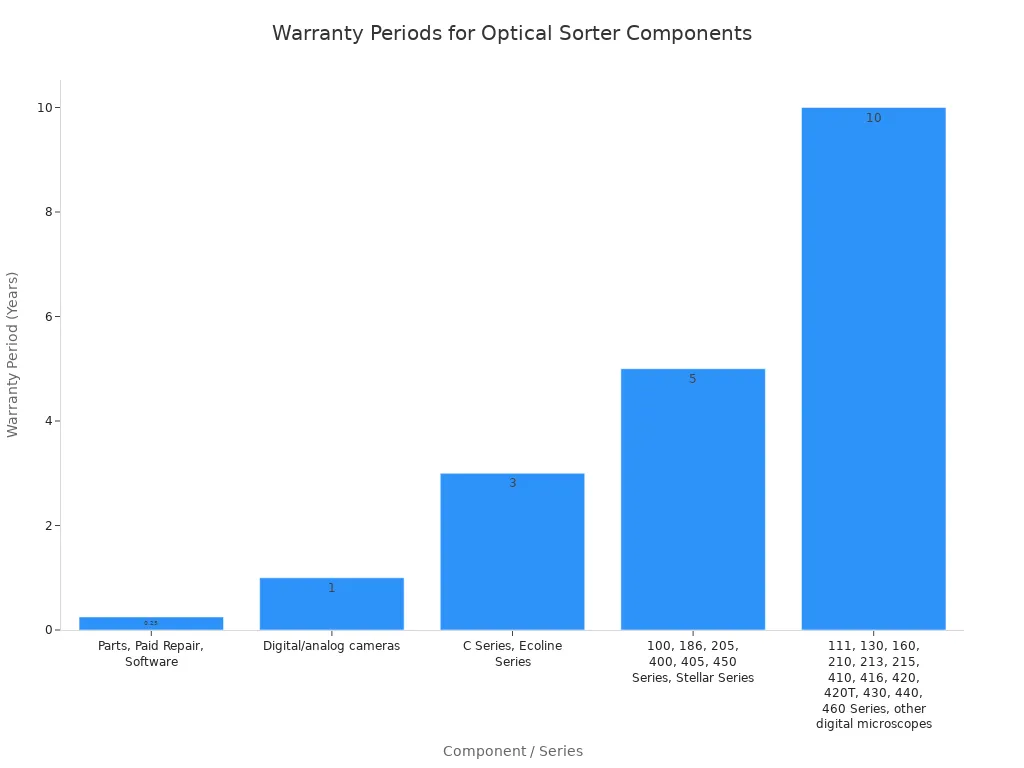

- Warranty: Warranty periods vary significantly. Some offer a basic 90-day warranty, while others provide multi-year coverage on key components. It is vital to understand what is covered (parts, labor) and for how long.

- Service Response Time: Inquire about the guaranteed response time for on-site service. Some manufacturers, like Metak, promise a 24-hour response, while others ensure "immediate intervention" through a service contract.

- Live Demonstration: Finally, never purchase a sorter without a live demonstration using your own cumin seeds. This is the ultimate test of the machine's capabilities. During the demo, focus on verifying key performance metrics.

A live test allows you to confirm sorting accuracy (aim for >99.5%), false rejection rate, and the missed defect rate. Requesting third-party test reports or videos of these metrics can further validate a manufacturer's claims. This step provides tangible proof of performance before you commit to a purchase.

Asking specific questions empowers buyers to verify performance claims. This diligence helps them select a cumin seeds optical sorter capable of achieving "Europe Quality" purity above 99.5%. Such a machine enhances product value, opens premium export markets, and delivers a strong return on investment through superior quality assurance.

FAQ

What is the price of a cumin seeds optical sorter?

Prices vary based on capacity, sensor technology, and features. Buyers should request detailed quotes from manufacturers to compare models and find the best value for their specific needs.

Does the manufacturer provide installation and operator training?

Reputable suppliers offer comprehensive on-site installation and training. This service ensures operators can manage the machine effectively and maximize its performance from day one.

Can the sorter be customized for different types of cumin?

Yes. Advanced sorters feature programmable software. Operators can create and save sorting profiles for different cumin varieties, ensuring optimal accuracy for various product characteristics.

See Also

Top Capsule Checkweighers: Essential Considerations for Buyers in 2025

Finding Premier X-Ray Inspection Machines: A Guide to Chinese Suppliers

Capsule Sorters Explained: Crucial for Effective Defect Removal Processes

Tablet Sampling Machines: Your Comprehensive Guide for Laboratory Selection

Automated Virus Sampling Tube Assembly Lines: A Smart Investment Decision?