Is a Premade Pouch Packing Machine Worth It?

A premade pouch packing machine is a strategic asset for businesses ready to scale. The flexible packaging market continues its expansion; Smithers forecasts a 3.4% compound annual growth rate through 2026. This growth highlights the value of automation. A machine like a seasoning pouch packing machine helps companies enhance their brand image and reduce long-term labor costs. The equipment provides a clear advantage for businesses with consistent product runs. However, the high initial investment makes it less suitable for small startups or companies with extremely varied packaging needs.

The Key Benefits That Justify the Cost

An investment in a premade pouch packing machine delivers returns far beyond simple packaging. It transforms a company's operational capabilities, financial health, and market position. Businesses that adopt this technology gain a significant competitive edge through superior efficiency, reduced operational costs, and a stronger brand presence. These core benefits provide a powerful justification for the initial capital expenditure.

Dramatically Boost Production and Efficiency

Manual or semi-automated packing processes create a natural ceiling on production output. Human operators can only work so fast and require breaks. A premade pouch packing machine shatters this limitation. It operates continuously at speeds that are impossible to sustain manually, filling and sealing hundreds of pouches per minute. This automation directly translates to a massive increase in throughput.

This enhanced efficiency allows a business to:

- Meet High-Volume Orders: Fulfill large contracts for major retailers without production delays.

- Respond to Market Demand: Quickly scale up production during seasonal peaks or promotional periods.

- Reduce Lead Times: Get products to market faster, improving cash flow and customer satisfaction.

The difference in output is stark. A machine removes the bottlenecks inherent in manual labor, ensuring a smooth, predictable, and rapid production flow from start to finish.

| Metric | Manual Packing | Automated Pouch Machine |

|---|---|---|

| Speed | 5-10 pouches/minute | 30-100+ pouches/minute |

| Operation | Limited by shifts/breaks | Capable of 24/7 operation |

| Consistency | Varies by operator/fatigue | Uniform and constant |

Reduce Long-Term Labor Costs

The high initial cost of a pouch packing machine is often a primary concern. However, this perspective overlooks the substantial long-term savings on labor. The packaging industry faces significant workforce challenges. Over half (58%) of companies report annual employee turnover rates between 10% and 29%, with another 26% facing turnover greater than 30%. This constant cycle of hiring and training is a major operational expense.

Automation directly addresses this issue. A single machine can perform the work of multiple employees, reducing the need for manual line workers. This does not necessarily mean eliminating jobs. Instead, it allows for a strategic reallocation of human capital.

Automation Elevates the Workforce 🧑🔧 Thoughtful implementation of automation improves the work environment and boosts retention.

- It reduces repetitive tasks. Machines handle the physically demanding and monotonous work, allowing experienced employees to work longer and more safely.

- It improves job satisfaction. Roles shift from manual labor to more engaging oversight tasks like quality control, line monitoring, and machine troubleshooting.

- It enables upskilling. Automation creates clear pathways for career growth, transforming line workers into skilled technicians and data analysts.

Investing in training for these new automated systems further strengthens employee retention. Research shows that employees are significantly less likely to leave if they feel their company provides skills for the future. Automation turns a labor cost center into an investment in a more skilled and stable workforce.

Enhance Product Quality and Brand Image

In a crowded marketplace, a product’s packaging is its first introduction to the consumer. It acts as a "salesman on the shelf," influencing purchase decisions before a customer even knows what is inside. A premade pouch packing machine ensures every single package meets a high standard of quality, directly enhancing brand perception.

Automated systems provide dramatically higher sealing consistency and more accurate fills. This precision is critical. A specialized machine, such as a seasoning pouch packing machine, guarantees that each pouch contains the exact weight of product, eliminating costly overfills and preventing customer complaints from underfills. Strong, uniform seals protect product integrity, extend shelf life, and prevent leaks that can damage a brand's reputation.

Beyond functional quality, the visual appeal of the packaging shapes consumer perception. Professional packaging communicates value and builds trust.

- Brand Value: Packaging delivers both functional value (protection, quality) and emotional value (positive feelings). A flawed package can create negative emotions and harm business value.

- Brand Identity: The package is a key part of a brand's identity. It visually represents the brand's name, colors, and symbols to create a distinct market presence.

- Brand Promise: The package design conveys the manufacturer's promise of quality. A crisp, perfectly sealed pouch reinforces this promise, while a sloppy one undermines it.

Studies show that even subtle design cues, like using angular packaging or lower-saturation colors, can make a product seem more expensive and of higher quality. Consistency between a package's shape and its color scheme leads to a stronger, more positive consumer response. An automated machine produces this level of consistency every time, ensuring the brand's message is delivered flawlessly on every single unit.

Improve Workplace Safety and Management

A company's most valuable asset is its people. Manual packaging environments, however, often expose employees to significant physical risks. The repetitive and physically demanding nature of these tasks is a direct cause of frequent workplace injuries. Overexertion from lifting or lowering items contributes to more than a third of all on-the-job injuries.

These incidents create a challenging environment for both employees and management. Common injuries associated with manual handling include:

- Musculoskeletal disorders from repetitive motions.

- Strains, sprains, and other soft tissue damage.

- Back injuries, including spinal damage and slipped discs.

- Cuts and lacerations from tools or packaging materials.

- Hand, foot, and shoulder injuries.

Automating the packaging process with a premade pouch machine directly mitigates these dangers. The equipment takes over the most strenuous and repetitive tasks, creating a safer workplace. Automated systems eliminate the need for employees to manually lift heavy items or perform thousands of identical motions per shift. This automation prevents common repetitive trauma injuries like back pain and carpal tunnel syndrome. Machines do not get injured or develop chronic pain, which reduces a company's workers' compensation costs and ensures employees perform safer, more engaging work.

A Shift in Management Focus 📈 Automation transforms operational management. Instead of reacting to safety incidents, scheduling around employee absences, and constantly recruiting to cover turnover, managers can focus on proactive goals. Their time shifts to optimizing production schedules, analyzing performance data, and developing strategies for growth.

This improvement in safety has a ripple effect on management. A safer work environment leads to higher employee morale and lower turnover. Managers spend less time processing injury claims and managing absenteeism. They can dedicate more resources to training and upskilling their team. The predictability of an automated system also simplifies production planning, making it easier to forecast output and meet deadlines without overburdening the workforce. Ultimately, a safer facility is a more efficient and manageable one.

The Drawbacks and When to Reconsider

While a premade pouch packing machine offers compelling advantages, it is not a universal solution. The significant capital outlay, operational rigidity, and specialized labor requirements demand careful consideration. For some businesses, these drawbacks can outweigh the benefits, making it a premature or unsuitable investment. A thorough evaluation of these challenges is critical before making a final decision.

The High Initial Investment

The most immediate and significant barrier to adopting a premade pouch packing machine is its substantial upfront cost. This is not a minor equipment purchase; it is a major capital expenditure that requires careful financial planning. The price spectrum is wide, depending on the level of automation and production speed a business requires.

| Machine Type | Price Range |

|---|---|

| Entry-level (Semi-Automatic Pouch Sealers) | $5,000 - $15,000 |

| High-speed (Fully Automatic Rotary Pouch Machines) | $30,000 - $70,000+ |

The sticker price, however, only tells part of the story. Businesses must also budget for numerous "hidden" costs that can significantly increase the total investment. Inefficient workflows and inadequate training alone can lead to expenses exceeding 10% of direct labor costs due to errors and increased supervision.

Beyond the Purchase Price 💰 The total cost of ownership includes several necessary expenses that are often excluded from the initial quote. A comprehensive budget should account for:

- Installation and Commissioning: Technicians must assemble, calibrate, and test the equipment on-site. These fees often include travel and specialized tools.

- Shipping and Freight: The cost to transport a large, heavy piece of industrial machinery to your facility.

- Operator Training: Staff must learn to use the new machine safely and efficiently. This involves time and direct training costs, whether on-site or remote.

- Spare Parts Inventory: Stocking essential high-wear parts is crucial to minimize downtime during unexpected breakdowns.

- Preventative Maintenance: A budget for regular service from certified technicians ensures the machine's longevity and performance.

- Utility Upgrades: The machine may require specific power, compressed air, or other infrastructure upgrades to your facility.

Failing to account for these additional expenditures can strain a company's finances and delay the machine's successful implementation.

Limited Flexibility for Frequent Changes

Premade pouch packing machines excel at high-volume, consistent production runs. Their design prioritizes speed and uniformity over rapid adaptability. This creates a challenge for businesses with a wide variety of products, frequent seasonal offerings, or a high-mix, low-volume production model. Each time a company switches the pouch size, product type, or fill volume, the machine requires a changeover.

While modern equipment has become much more efficient, the process still halts production. A state-of-the-art rotary premade pouch machine can complete a changeover in less than 5 minutes, making short runs of 20-100 bags feasible. This is a dramatic improvement over older technology.

| Feature | Premade Pouch Machines | Form Fill Seal (FFS) Machines |

|---|---|---|

| Setup time | Faster setup | Longer setup as it involves the film unwinding and forming |

Even with this speed, the cumulative downtime can become substantial for companies that need to switch formats multiple times per shift. It is also important to note that the actual changeover time can vary based on the operator's skill level and other fluctuating conditions. For a business that thrives on agility and constant product innovation, the structured nature of an automated line can become a bottleneck rather than a benefit.

The Need for Technical Expertise

Automated machinery transforms the nature of the workforce. It replaces the need for many manual laborers with a need for a few highly skilled technicians. Operating and maintaining a premade pouch packing machine requires a specific knowledge base that goes far beyond simple on/off functions.

An effective operator or technician must have:

- Familiarity with all areas of the packing machine's operation.

- Knowledge of pouch materials and equipment maintenance protocols.

- Proficiency in filling operations and product inspection.

- The ability to set and adjust parameters like temperature, speed, and pressure.

- An understanding of how each procedure affects overall machine performance.

Furthermore, preventive maintenance is not optional; it is essential for protecting the investment. These tasks require a higher level of technical training and should only be performed by qualified personnel. Key maintenance activities include:

- Inspecting and replacing machine filters (air, oil, water).

- Checking belts, bearings, and gears for wear.

- Tightening loose screws, bolts, and nuts.

- Checking, sharpening, and replacing the cutter to ensure clean seals.

This need for expertise represents a long-term commitment to either hiring skilled technicians or investing in comprehensive training for existing staff. The cost to formally train a technician illustrates this financial commitment.

A business must be prepared to support this skilled workforce. Without it, the company risks extended downtime, inefficient operation, and costly repairs, undermining the very purpose of the automation investment.

Space and Infrastructure Requirements

A premade pouch packing machine is a significant piece of industrial equipment. Its successful integration extends beyond the purchase price into the physical layout and utility capacity of a facility. Businesses must conduct a thorough site assessment before committing to a purchase. This evaluation prevents costly delays and ensures the machine can operate at peak performance from day one.

The machine's physical footprint is the first consideration. It requires not only space for the unit itself but also adequate clearance on all sides. This surrounding area is essential for daily operation, routine maintenance, and safe operator movement.

Plan for the Entire Workflow, Not Just the Machine 📐 A successful layout accounts for the complete production path. This includes space for staging empty premade pouches, positioning the product filler, and conveying finished packages away from the machine. A cramped workspace can create bottlenecks that negate the machine's efficiency gains.

Beyond physical space, the machine has specific infrastructure demands. A facility must be able to supply adequate and stable utilities. Failing to meet these requirements can lead to poor performance, equipment damage, or safety hazards. Key utility considerations include:

- Electrical Power: The machine needs a dedicated power supply. Specifications vary, with some models requiring 230V and others 320V. Power consumption can range from 1.5 HP to 5 HP or more.

- Power Phase: Many industrial machines operate on a 3-phase power supply for stable, efficient performance. A facility wired only for single-phase power would require a significant and costly electrical upgrade.

- Compressed Air: Pneumatic systems power many of the machine's movements. The equipment requires a clean, dry air supply at a specific pressure, often around 8 bar, with consumption rates of 2 HP or more.

Manufacturers provide precise electrical specifications to ensure safe and correct installation. Adhering to these guidelines, particularly for grounding, is critical for protecting both the equipment and the operators.

| Power Supply (V) | Ground Resistance (Ω) | Ground Wire Dimension (mm²) |

|---|---|---|

| 220 | ≤100 | 5.5 |

| 400 | ≤10 | 4 |

A pre-purchase facility audit is a non-negotiable step. A business must confirm that its electrical panels, wiring, and air compressors can handle the additional load. Factoring in the cost of any necessary infrastructure upgrades is essential for creating an accurate budget and a realistic project timeline.

Key Factors to Evaluate Before You Buy

An investment in automation requires a clear strategy. Before purchasing a premade pouch packing machine, a business must conduct a thorough internal audit. This process involves analyzing production targets, product characteristics, and material compatibility. A careful evaluation of these key factors ensures the chosen equipment aligns with both current needs and future growth, preventing a costly mismatch between technology and operational reality.

Assessing Your Production Volume Needs

The first step is to quantify current and projected production volumes. A company must move beyond general estimates and analyze hard data. This includes daily output targets, peak seasonal demands, and contractual obligations with retailers. This data provides a clear benchmark for the required machine speed, measured in pouches per minute (PPM). A business with modest but growing demand might find a 30-40 PPM machine sufficient. A large-scale operation supplying national chains will need a high-speed system capable of 80-100+ PPM.

Future-Proof Your Investment 📈 Select a machine that not only meets today's needs but also accommodates future growth. A system operating at 90% capacity from day one leaves no room for expansion. A good rule of thumb is to choose a machine with at least 20-30% more capacity than your current peak production requires.

Analyzing Product and Pouch Compatibility

Not all products and pouches are created equal. The physical properties of the product—whether it is a liquid, granule, or fine powder—dictate the type of filler required. Likewise, the pouch material, size, and features (like zippers or tear notches) must be compatible with the machine's grippers, sealing jaws, and opening mechanisms. A business must test its specific products and pouches on a potential machine before purchase. This testing confirms that the system can handle the materials without jams, spills, or poor seals, ensuring a smooth and efficient packaging process.

Is a Seasoning Pouch Packing Machine Right for You?

Packaging fine or abrasive powders, such as spices and seasonings, presents unique challenges that demand specialized equipment. A standard machine may struggle, but a dedicated seasoning pouch packing machine is engineered to handle these difficulties effectively. These systems incorporate specific features to manage the complexities of powder filling.

Key challenges a seasoning pouch packing machine addresses include:

- Dust Control: Fine powders create airborne dust that can contaminate seal areas, leading to weak or incomplete seals. These machines use dust collection hoods and specialized nozzles to minimize particle spread.

- Material Compatibility: Abrasive seasonings can cause premature wear on standard machine components. A seasoning pouch packing machine often uses hardened or coated parts to resist abrasion and extend the equipment's lifespan.

- Heat-Sealing Issues: Powder residue in the seal area can interfere with the heat-sealing process. Advanced models use features like air jets or vibration to clear the seal zone just before sealing, ensuring product integrity.

For businesses specializing in spices, drink mixes, or other powdered products, investing in a purpose-built seasoning pouch packing machine is often a critical decision for maintaining quality and operational efficiency.

Evaluating Your Facility and Staff Readiness

A successful automation project depends on more than just the machine itself. A business must conduct a strategic assessment of its physical plant and its workforce. This evaluation ensures the facility can support the new equipment and the staff possesses the skills to operate it effectively. A mismatch in either area can lead to costly delays and operational friction.

First, a company must confirm its facility is prepared for the new production line. A thorough readiness check prevents installation surprises and promotes a smooth startup. Key preparation steps include:

- Equipment Inspection and Calibration: All supporting machinery, from fillers to conveyors, must be inspected for wear and calibrated to precise standards.

- Materials Preparation: A business needs an efficient inventory system to ensure all necessary pouches and product materials are organized and available to prevent line stoppages.

- Safety Checks and Compliance: The workspace must have functional emergency stops, proper safety guards, and clear markings. This ensures compliance with regulations and protects employees.

- Clear Communication Protocols: Management should establish clear communication channels and conduct pre-setup briefings. This aligns the team on roles and responsibilities for a streamlined process.

Assess Skills to Bridge the Gap 🧑🏫 Identifying the current skill level of the workforce is not about finding fault. It is a strategic process for discovering knowledge gaps. This allows a company to design targeted training programs that turn existing employees into expert technicians.

Equally important is evaluating staff readiness for automation. A business can use several methods to gauge its team's technical aptitude. Creating a skills inventory or a visual skills matrix helps categorize employee competencies. These tools provide a clear picture of who has the necessary skills and who requires further development. Companies can also use periodic assessments, such as managerial observations or self-evaluations, to track progress. This data allows a business to build effective training programs with clear objectives, ensuring the team is ready to maximize the new machine's potential.

Calculating Your Return on Investment (ROI)

Determining the return on investment for a premade pouch packing machine requires a comprehensive analysis. A business must look beyond the initial purchase price. The true value emerges from operational savings, increased production capacity, and enhanced market position. A clear calculation justifies the capital expenditure and outlines the path to profitability.

Analyzing Your Cost Per Pack

A primary driver of ROI is the reduction in cost per package. Manual filling processes often lead to significant product giveaway. Operators tend to overfill pouches to ensure they meet minimum weight requirements, which creates a constant drain on material costs. Automation eliminates this inefficiency. An automated system delivers precise fill volumes, minimizing overfills and reducing the number of scrapped underfilled bags. This precision can achieve up to a 30% reduction in product giveaway.

Process Control Comparison ⚖️ Automated systems allow a business to set its target fill weight much closer to the minimum required weight, drastically cutting waste.

| Process Characteristic | Manual/Legacy Process | Automated Process |

|---|---|---|

| Required Target Fill | High to absorb variation | Closer to minimum weight |

| Standard Deviation | High and unpredictable | Low and predictable |

| Giveaway Impact | High, constant material drain | Near zero; material saved |

Factoring in Throughput and Uptime

The speed and reliability of the machine directly impact revenue. Throughput, or the number of pouches packed per minute, determines a company's total production capacity. A machine that doubles or triples output allows a business to fulfill larger orders and enter new markets. Equally important is uptime. A reliable machine that operates consistently with minimal downtime ensures that production schedules are met. High throughput combined with maximum uptime generates more sellable products per shift, accelerating the return on investment.

Evaluating Brand Lift and Market Share

The financial benefits of automation extend to brand equity. Consistently professional packaging enhances brand perception and builds consumer trust. This "brand lift" is a valuable, though less tangible, asset. A premium appearance can justify a higher price point and foster customer loyalty. Over time, a stronger brand reputation can lead to an increased market share. This long-term strategic advantage is a crucial component of the overall ROI calculation.

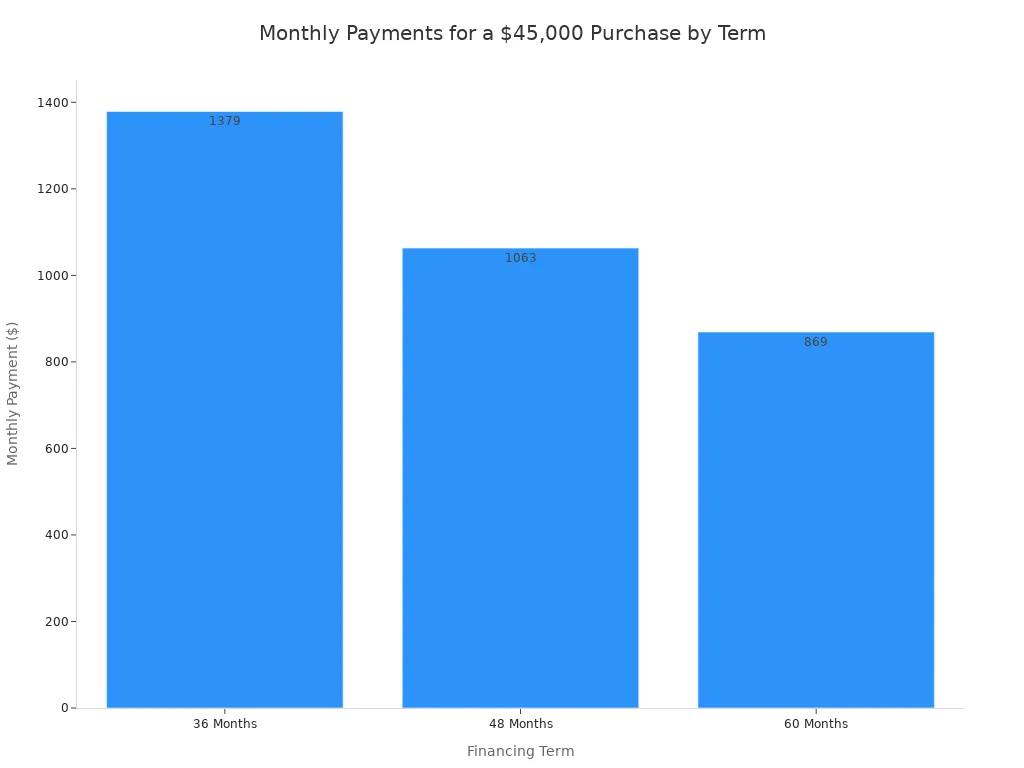

Comparing Financial Models: Leasing vs. Buying

Choosing how to finance a premade pouch packing machine is as critical as selecting the machine itself. The decision between leasing and buying directly impacts a company's cash flow, balance sheet, and long-term strategy. Each model offers distinct advantages and drawbacks that align with different business priorities.

A direct comparison highlights the fundamental trade-offs between the two approaches.

| Aspect | Equipment Leasing | Equipment Purchasing |

|---|---|---|

| Upfront Costs | Low monthly payments conserve cash | High initial investment required |

| Long-term Costs | Higher due to interest and fees | Lower over the equipment’s lifespan |

| Ownership | No equity until end of lease term | Full ownership and potential resale value |

| Technology Risk | Minimal; easy to upgrade | Equipment may become outdated |

| Maintenance | Often covered by the leasing contract | The owner's full responsibility |

Leasing is an attractive option for businesses that prioritize cash flow preservation and technological flexibility. It requires minimal upfront capital, with financing options often including 0% down payments. This model allows a company to access newer, more efficient equipment without a large initial outlay. Leasing terms typically range from 24 to 72 months. The predictable monthly payments make budgeting simpler, and maintenance is often handled by the leasing company, reducing operational burdens.

Conversely, buying the machine is a long-term investment strategy. While it demands a significant upfront investment, purchasing is more cost-effective over the equipment's lifespan. Ownership provides complete control over the machine's use and customization. It also becomes a valuable asset on the company's balance sheet, offering potential tax benefits through depreciation. This path is ideal for established businesses with stable production lines and the capital to invest in a long-term asset.

A premade pouch packing machine represents a strategic investment. It delivers significant value for businesses targeting high-volume, consistent production with a premium look. Companies with available capital and stable product lines find the long-term efficiency gains and labor savings make it a worthwhile choice. A specialized seasoning pouch packing machine exemplifies this benefit. Conversely, businesses with tight budgets or highly variable production may find semi-automated options a more prudent initial step.

FAQ

What is the difference between a premade pouch machine and an FFS machine?

A premade pouch machine fills and seals bags that are already formed. A Form-Fill-Seal (FFS) machine creates the pouch from a flat roll of film, fills it, and then seals it. Premade pouch machines generally offer faster changeovers and a more premium final look.

How long does it take to train an operator?

Basic operator training typically takes a few days to a week. Achieving proficiency in complex changeovers and troubleshooting may require several weeks of hands-on experience. The machine's complexity and the operator's technical aptitude influence the exact timeline.

Can I use different pouch sizes on one machine?

Yes, most machines can handle a range of pouch sizes. However, switching between sizes requires a changeover process. This involves adjusting or replacing parts like the pouch grippers and opening devices. Each changeover results in a temporary halt in production.

Tip for Flexibility 💡 A company should confirm the machine's specified size range and the time required for changeovers before purchasing. This ensures the equipment aligns with its production needs for different products.

What is the typical lifespan of a premade pouch machine?

A well-maintained premade pouch packing machine has a typical lifespan of 10 to 20 years. Longevity depends heavily on consistent preventive maintenance, the quality of replacement parts, and the operational environment. Regular service from certified technicians is crucial for maximizing the machine's operational life.

See Also

Exploring Plate Pack Benefits and Comprehensive Cost Analysis for 2025

Unveiling Trending Folder Gluer Features for Advanced 2025 Carton Production Lines

A Head-to-Head Comparison: Leading Ampoule Filling Production Line Manufacturers

Boosting Pharmaceutical Efficiency: Modern Capsule Decapsulation Machine Innovations Explained

Essential Capsule Checkweighers for Smart Buyers to Consider in 2025