A licorice products optical sorter can boost your quality

The expanding licorice market presents a key opportunity for producers. Global market forecasts show strong, consistent growth for licorice confectionery products.

- The market is projected to reach USD 2.862 billion by 2035.

- It is forecasted to grow at a CAGR of up to 6.4% through 2029.

A licorice products optical sorter is a justifiable investment to capture this growth. The primary return comes from reducing labor costs and minimizing waste, achieving a quality that can command premium pricing.

Key Benefits of Automating Your Quality Control

Automating quality control with an optical sorter moves a licorice business from subjective, manual checks to objective, data-driven analysis. This technological leap offers transformative benefits for quality, speed, and resource management. Producers can consistently meet high standards. They can also scale operations efficiently to capture growing market demand.

Achieve Flawless Product Quality

Human inspection is inherently limited. Inspectors experience fatigue, distractions, and variations in judgment. These factors lead to inconsistent quality control. A licorice products optical sorter eliminates these variables entirely. It uses advanced cameras and AI-driven software to inspect every single piece of licorice with unparalleled precision. The machine identifies and ejects items with defects like incorrect shapes, color deviations, or embedded foreign materials.

Machine vision systems provide a level of accuracy that manual inspection cannot match. This technology enhances detection rates and significantly reduces the costs tied to human error.

| Method | F1-Score/Accuracy | Speed (frames/second) |

|---|---|---|

| Optical Sorter | 98.25% | 14.12 |

| Manual Inspection | ~95% | 6 |

Note: AI-driven technologies represent the most viable alternative to manual visual inspection. They overcome common issues like human error, inspection omissions, and fatigue-induced detection problems, ensuring a superior final product.

Boost Production Speed and Throughput

Manual quality control creates a significant bottleneck in the production line. The speed of the entire process is limited by how quickly human inspectors can visually check and sort products. Automation shatters this limitation.

Optical sorters operate at speeds far exceeding human capabilities. Some color sorter machines, for example, can process food items at rates of up to 300 kg per hour. This incredible throughput allows a business to:

- Increase its total production volume without adding more labor.

- Meet large orders and seasonal demand spikes with confidence.

- Accelerate the time from production to packaging, improving overall efficiency.

This boost in speed directly translates to higher revenue potential. A business can produce and sell more licorice in the same amount of time, maximizing its operational capacity.

Cut Down on Product Waste

Product waste, or "false rejects," is a hidden cost in manual inspection. Well-intentioned inspectors often discard perfectly good products to be safe. This cautious approach erodes profit margins. The high accuracy of an optical sorter minimizes this issue. It precisely identifies true defects, ensuring that good products continue down the line.

Furthermore, automation allows for the strategic reallocation of labor. Many low-skilled workers performing routine inspection tasks fear that smart machines will replace their jobs. This apprehension can negatively impact job satisfaction and performance. Businesses can mitigate this by retraining these employees for more complex, value-added roles. Moving staff from monotonous sorting to positions like machine operation, quality assurance analysis, or maintenance accomplishes two goals:

- It reduces the risk of human error and associated product waste.

- It invests in the workforce, improving employee skills and job satisfaction.

This shift creates a more efficient, resilient, and profitable operation by optimizing both technology and human capital.

Analyzing the Financial Investment

An optical sorter represents a significant capital expenditure. A thorough financial analysis is essential before making a purchase decision. Businesses must look beyond the sticker price to understand the total cost of ownership and calculate the potential return. This analysis empowers producers to make an informed choice based on data, not just ambition.

The Upfront Capital Cost

The initial purchase price of a licorice products optical sorter is the most visible expense. This cost varies widely based on the machine's size, capabilities, and technological sophistication. While the figure can seem daunting for a small or medium-sized business, several financing avenues can make the investment manageable. Producers do not always need to rely on cash reserves.

Businesses can explore multiple funding strategies to acquire this technology:

- Equipment Financing: This popular option allows a company to secure a loan using the sorter itself as collateral. Lenders often provide quick approvals and funding. Interest rates can range from 6.5% to 34.99% APR, with repayment terms typically spanning one to seven years.

- Alternative Equipment Financing: Some providers streamline the approval process, focusing more on current business performance than on perfect credit scores. This path requires less paperwork and can offer same-day funding for businesses with strong monthly revenue.

- Bank Loans: Traditional banks offer equipment loans but usually have stricter requirements. The process involves extensive paperwork, excellent credit, and a detailed business plan. Approval can take weeks or even months.

- SBA Programs: Government-backed programs, like the Manufacturer’s Access to Revolving Credit (MARC), can provide working capital for manufacturers. However, these options still involve the standard, often lengthy, SBA approval process.

Factoring in Installation and Integration

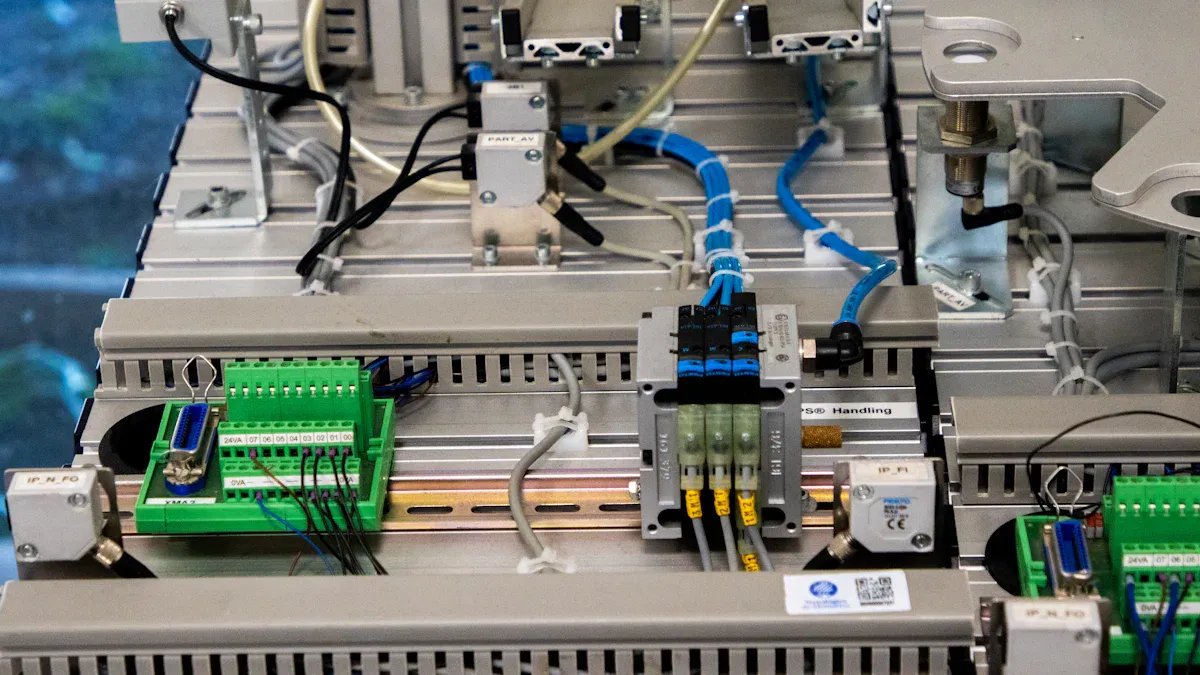

The total investment extends beyond the machine's purchase price. Installation and integration into an existing production line introduce additional costs. A facility may require electrical upgrades to support the new equipment. The production floor might need reconfiguration to accommodate the sorter's footprint. These modifications add to the overall project budget.

The type of sorter a business chooses can significantly impact these secondary costs. The physical design of the machine influences the complexity of its installation.

Belt-fed sorters, unlike chute-fed systems, are installed horizontally. This design minimizes facility modifications and reduces installation costs by avoiding significant elevation changes. Additionally, their compact footprint simplifies installation and reduces the required floor space in existing facilities.

Choosing a model that fits easily into the current layout can save a business considerable time and money during the integration phase.

Calculating Your Return on Investment (ROI)

The ultimate measure of a successful investment is its Return on Investment (ROI). This calculation shows how much profit the equipment generates relative to its cost. A positive ROI confirms that the sorter is not just an expense but a profit-generating asset. The standard formula is straightforward:

ROI (%) = (Net Annual Benefit / Total Investment) x 100

To use this formula, a business must identify two key figures:

- Total Investment: This includes the machine's purchase price plus all associated costs like installation, shipping, and initial training.

- Net Annual Benefit: This is the new value created by the sorter each year. It is calculated by adding up the gains (e.g., labor savings, increased throughput, revenue from higher-quality products) and subtracting any new annual costs (e.g., maintenance, service contracts, energy consumption).

For example, imagine a packaging system costs a total of $200,000 to purchase and install. After one year, the business calculates that it saved $120,000 in manual labor costs and reduced product waste by $30,000. The net annual benefit is $150,000. The ROI would be:

($150,000 / $200,000) x 100 = 75%

This 75% ROI demonstrates that the equipment is highly profitable and will pay for itself in less than two years.

Operational Realities of a Licorice Products Optical Sorter

Integrating a new machine involves more than just installation. Businesses must prepare for the operational demands of the technology. This includes training staff, scheduling maintenance, and planning for potential disruptions to ensure the investment delivers its full value.

Staff Training and Skill Requirements

Adopting a licorice products optical sorter requires an investment in employee skills. Operators must understand how to manage the equipment effectively. Most vendors provide comprehensive training programs to ensure a smooth transition. These programs typically cover essential topics for daily operation.

- Machine operation and controls

- Changes to sorting settings and parameters

- Basic maintenance and cleaning procedures

This training empowers staff to run the machine efficiently and handle minor issues, which helps maximize uptime and performance.

Ongoing Maintenance and Service

An optical sorter is a precision instrument that needs regular care to maintain its accuracy. Proactive maintenance is crucial for long-term reliability. Many businesses opt for a service agreement with their vendor. These agreements safeguard the investment by providing expert support and ensuring peak performance. A standard service plan often includes remote diagnosis of faults, annual visits by engineers, and replacement of key wear parts.

The Risk of Production Downtime

Unexpected downtime is a significant financial risk, as it halts production and increases costs. Common causes include issues with compressed air quality, dirty sensor windows, and outdated software calibrations.

A structured maintenance schedule is the best defense against breakdowns. Regular cleaning and calibration enhance detection accuracy, extend the equipment's life, and prevent costly interruptions. Adhering to the vendor's maintenance plan helps maintain peak efficiency and protects the return on investment.

Making the Right Choice for Your Business

Selecting the right optical sorter requires a systematic evaluation of technology, vendor support, and real-world performance. A careful approach ensures the chosen equipment aligns with a company's specific production goals and financial framework.

How to Evaluate Different Sorters

Businesses should assess sorters based on their hardware capabilities and software intelligence. The software should be user-friendly for operators and analysts. Intuitive software with well-organized features allows staff to retrieve information and manage the machine easily. A complicated interface may require extensive training, which can hinder operational efficiency. The evaluation process is an excellent opportunity to gauge how quickly employees can learn to use the system's features.

Questions to Ask Vendors

A vendor's reliability is as important as the machine itself. Producers should ask detailed questions about after-sales support to understand the long-term partnership. Key inquiries include:

- What type of user training is provided for operation and maintenance?

- Is there a guarantee for spare parts availability, and for how long?

- What is the warranty coverage for core components?

- What are the response times for remote technical support?

- Does the supplier have regional representatives to support the local market?

The Importance of Requesting a Demo

A product demonstration is the ultimate test for a licorice products optical sorter. It moves the evaluation from theory to practice.

💡 Pro Tip: Always insist on a demo using your own licorice products. This allows you to see exactly how the machine handles your specific shapes, colors, and potential defects. A successful demo validates the vendor's claims and provides confidence that the investment will deliver the expected quality improvements.

The decision to invest hinges on a key trade-off. A business accepts a high initial cost for unparalleled quality control and long-term profitability. The next step involves a detailed cost-benefit analysis to calculate potential ROI from labor savings and reduced waste. Finally, producers should request vendor demos using their own licorice products.

FAQ

What types of defects can an optical sorter detect?

The sorter identifies defects like incorrect shapes, color variations, and foreign materials. It ensures only products meeting precise quality standards move forward in the production line.

Is an optical sorter suitable for all licorice products?

Yes, these machines handle various licorice forms. Vendors calibrate sorters for specific products like twists, bites, or ropes, making the technology highly adaptable for diverse production needs.

How quickly can a business expect a return on investment?

The payback period varies based on production volume. A positive ROI is often achievable in under two years from significant savings in labor costs and reduced product waste.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality and Defect Elimination

Comparing Leading Ampoule Filling Line Manufacturers for Optimal Production Performance

Three Indispensable Industrial Checkweighers for Enhanced Food Plant Accuracy and Safety

Exploring Cutting-Edge Folder Gluer Innovations Shaping 2025 Carton Packaging Lines