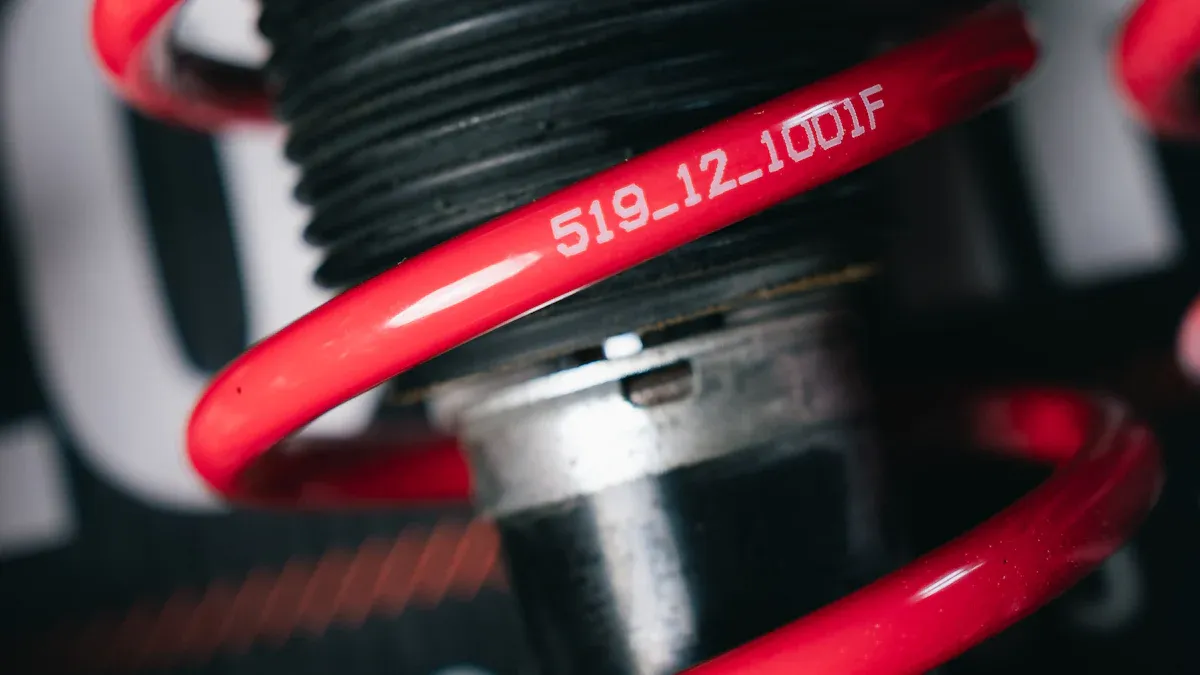

Your Go-To Material Inconel X-750 Round Bar for Springs

Inconel X-750 round bar stands as the premier material choice for high-strength springs and fasteners. This advanced alloy delivers unmatched reliability, performing consistently within the most demanding operational environments.

Its exceptional high-temperature strength ensures stability under extreme heat. Superior corrosion resistance and an excellent defense against creep and relaxation guarantee long-term performance and structural integrity for critical components. This combination of properties makes it an indispensable solution for high-stakes applications.

Key Takeaways

- Inconel X-750 is a strong metal. It works well in very hot places.

- This metal helps springs and fasteners last longer. It stops them from breaking or losing shape.

- Inconel X-750 fights rust and damage from chemicals. This keeps parts safe in harsh environments.

- Special heat treatments make Inconel X-750 even stronger. This helps it work better in tough jobs.

- Many industries use Inconel X-750. These include airplanes and chemical plants.

Unmatched High-Temperature Strength and Creep Resistance

Inconel X-750 demonstrates remarkable strength and stability in extreme thermal environments. This nickel-chromium superalloy maintains its structural integrity at temperatures where many other materials would fail. Its resistance to creep—the tendency of a material to deform permanently under prolonged stress—makes it a top-tier choice for components that must perform reliably under constant load and high heat. This combination of properties ensures predictable, long-term performance in the most challenging conditions.

Benefits for Springs

Springs operating at high temperatures require a material that resists losing its strength and form. Inconel X-750 excels in this area, offering superior performance compared to conventional alloys.

| Property | Inconel X-750 | Stainless Steel 316 |

|---|---|---|

| Temperature Resistance | Performs well up to 1300°F (700°C) | Performs well up to 800°F (427°C) |

This alloy's ability to withstand extreme heat directly translates to enhanced spring reliability. Furthermore, its excellent relaxation resistance is critical for maintaining consistent spring force over time.

- The alloy is precipitation-hardenable, containing titanium and aluminum to bolster its strength.

- It effectively resists stress relaxation at temperatures reaching 704°C (1300°F).

- This ensures springs maintain their required preload, preventing failure in critical systems like gas turbines and jet engines.

Benefits for Fasteners

Fasteners are the hardware that holds critical assemblies together. In high-temperature machinery, they must resist loosening and failure. An Inconel X-750 Round Bar provides the ideal raw material for manufacturing high-strength fasteners that will not yield under pressure. These fasteners retain their clamping force and tensile strength even after prolonged exposure to intense heat. This reliability prevents joint failure, enhances operational safety, and reduces the need for frequent maintenance or replacement in high-stakes industrial and aerospace applications.

Superior Corrosion and Oxidation Resistance

Beyond its thermal stability, Inconel X-750 provides a robust defense against chemical degradation. The alloy’s high chromium content forms a formidable, passive oxide layer on its surface. This barrier safeguards the material from a wide variety of industrial corrosives and high-temperature oxidation, ensuring components maintain their integrity in aggressive operational settings. Its performance far exceeds that of many conventional alloys, making it a reliable choice for long-term service.

Protecting Springs in Harsh Environments

Springs often operate in environments where moisture, chemicals, and chlorides pose a constant threat. Inconel X-750 excels in these conditions. It demonstrates significantly superior resistance to stress corrosion cracking from high-temperature chlorides when compared to materials like 316 stainless steel. This makes it ideal for applications in chemical processing and marine environments.

The alloy’s resilience extends to a broad spectrum of corrosive media. It effectively withstands acids and seawater, preventing the pitting and crevice corrosion that can lead to premature spring failure. This comprehensive protection ensures consistent performance and safety.

Ensuring Fastener Longevity

Fasteners made from an Inconel X-750 Round Bar guarantee exceptional durability in corrosive and high-heat applications. The material’s ability to resist oxidation at extreme temperatures is critical for components used in jet engine and aircraft exhaust systems.

- It maintains excellent oxidation resistance at temperatures up to 980°C (1800°F).

- Its protective oxide layer prevents material loss and structural weakening over time.

This reliability is recognized by leading industry standards. Organizations specify Inconel X-750 for fatigue-critical components in corrosive service. Key specifications include:

- ASTM B637 / ASME SB-637

- NACE MR0175 (ISO 15156-3)

Adherence to these standards confirms that fasteners manufactured from this alloy meet the stringent requirements for safety and performance in oil and gas, aerospace, and power generation industries.

The Power of Heat Treatment on Inconel X-750 Round Bar

Heat treatment unlocks the full potential of an Inconel X-750 Round Bar. This controlled process of heating and cooling modifies the alloy's internal structure, dramatically enhancing its mechanical properties. The Society of Automotive Engineers (SAE) outlines standard procedures in specifications like AMS 5667-5671. Optimal properties for high-temperature service often involve a multi-step process, such as solution treating at 2100°F, stabilization at 1550°F, and precipitation treating at 1300°F. This precise thermal conditioning is what transforms the alloy into a high-performance material.

Achieving High Tensile Strength for Springs

Heat treatment directly increases the tensile strength of Inconel X-750, a critical factor for spring performance. After a 'No. 1 Temper' heat treatment, spring wire can achieve a minimum ultimate tensile strength of 155 ksi (1069 MPa). This impressive strength comes from changes at the microscopic level. The age-hardening process creates a stronger, more resilient internal structure.

- It forms hard gamma prime (γ′) precipitates and M23C6 carbides within the material.

- These new phases increase the alloy's bulk hardness and internal stress.

- The heat-treated alloy shows a 3–10 times lower wear rate at high temperatures.

- A protective glaze layer of oxides also forms, reducing friction and wear.

This microstructural reinforcement ensures springs maintain their shape and force under extreme loads.

Creating High-Strength, Reliable Fasteners

For fasteners, heat treatment delivers both strength and long-term reliability. The process optimizes strength at temperatures between 700°C and 975°C, creating components that resist failure. A key benefit is the enhanced resistance to stress corrosion cracking (SCC).

Direct aging within the precipitation temperature range significantly improves the alloy's defense against SCC. In its fully age-hardened condition, Inconel X-750 demonstrates excellent resistance to chloride-induced cracking, a common failure mode in harsh industrial and marine environments.

This treatment ensures fasteners maintain their integrity, preventing catastrophic joint failures in critical systems. The result is a high-strength, dependable fastener that guarantees safety and performance.

Key Applications and Industry Use Cases

The exceptional properties of Inconel X-750 make it a critical material across several high-stakes industries. Its reliability under extreme conditions ensures safety and performance where other alloys would fail. Engineers specify this superalloy for components that must withstand intense heat, corrosive attack, and mechanical stress.

Aerospace and Gas Turbines

The aerospace industry relies heavily on Inconel X-750 for its most demanding applications. The material's resistance to creep and oxidation is crucial for reliable engine operation. In gas turbines, it is crafted into essential components like turbine wheels, blades, and guide vanes. Jet engines utilize the alloy for afterburner parts, springs, bolts, and seals. Its performance ensures engines operate safely at extreme temperatures.

The alloy also played a vital role in space exploration. The powerful Rocketdyne F-1 engine, which powered the Saturn V rocket, used Inconel X-750 for the tubes of its thrust chamber. This application showcases the material's ability to handle the immense heat and pressure of rocket propulsion.

Chemical Processing and Marine Environments

Inconel X-750 provides robust solutions for corrosive environments. Its superior resistance to chemical attack and seawater makes it indispensable for the chemical processing and marine industries.

In chemical plants, safety valves depend on reliable spring performance. Inconel X-750 springs are used in:

- Trunnion and Floating Ball Valves: Here, the springs maintain a constant seal, compensate for thermal expansion, and ensure the valve functions correctly under high pressure.

- Oil & Gas Equipment: Wave springs made from the alloy provide dependable service in harsh downhole conditions.

The marine industry uses Inconel X-750 for its excellent performance in seawater. It is a key material for manufacturing military submarines and offshore drilling equipment. Critical components like propeller shafts, subsea flow lines, and fasteners benefit from its strength and corrosion resistance, guaranteeing long-term durability in the open ocean.

For critical applications demanding reliability under extreme heat and corrosive attack, the Inconel X-750 Round Bar is the proven, superior material choice. Its performance is validated by stringent standards like ASTM B637 and a battery of quality assurance tests, from mechanical analysis to pitting corrosion tests. This makes it the definitive solution for manufacturing durable springs and fasteners that will not fail. Engineers specify this high-performance alloy to guarantee security and long-term operational success in their most challenging projects. ✅

FAQ

What makes Inconel X-750 ideal for springs?

Inconel X-750 is a precipitation-hardenable superalloy. This specific characteristic allows heat treatment to create exceptional high-temperature strength and creep resistance. The alloy maintains its spring force under extreme heat and stress, ensuring long-term reliability where other materials would fail.

Is Inconel X-750 magnetic?

Inconel X-750 is generally non-magnetic in its annealed condition. However, certain age-hardening heat treatments can induce slight magnetism in the material. Engineers should consider this property for applications where magnetic interference is a concern.

Can Inconel X-750 be welded?

Yes, fabricators can weld Inconel X-750 using common welding methods.

For optimal performance, a post-weld heat treatment is crucial. This process restores the alloy's high-strength properties and ensures the integrity of the welded joint in demanding service conditions.

What specifications govern Inconel X-750 round bar?

Several key industry standards define the requirements for Inconel X-750. These specifications guarantee material quality and performance for critical applications.

- Aerospace: AMS 5667, AMS 5671

- General Industrial: ASTM B637 / ASME SB-637

- Oil & Gas: NACE MR0175 (ISO 15156-3)

See Also

Achieving Optimal Outcomes: Steel Processing for Heat Exchanger Performance

Welding Pass Partition Plates: Expert Guidance for 2025 Success

WT20 Thoriated Tungsten Electrodes: Enhancing TIG Welding Performance

Selecting Pressure Vessel Materials: ASME BPVC Section VIII Guidelines

Molybdenum Plugs: Evaluating Their Role in Seamless Steel Pipe Production