What You Should Know About X-Ray Food Inspection

X-ray food inspection is a non-invasive quality control process that uses low-energy X-rays to detect physical contaminants. Its role is vital, as foreign material contamination remains a primary reason for product recalls globally.

- In the US (2002-2023), product contaminants, including foreign objects, were responsible for 91% of food and beverage recalls.

- In Q1 2025, non-bacterial contaminants caused 550 of the 1,242 food recalls across the EU and UK.

Consequently, the adoption of systems for processes like x ray metal inspection in food industry is expanding rapidly. The inspection happens without harming the food, ensuring it remains completely safe to eat.

| Metric | Value |

|---|---|

| Market Value (2023) | US$ 1,528.8 million |

| Projected Market Value (2032) | US$ 2,904.1 million |

| CAGR (2024–2032) | 7.39% |

How X-Ray Food Inspection Works and What It Detects

X-ray inspection technology may sound complex, but its operational principle is straightforward. A system scans products moving along a conveyor belt, creating a grayscale image based on density. Sophisticated software then analyzes this image in real-time to identify and reject any items that fail to meet safety and quality standards.

The Core Process: From Beam to Image

At the heart of every X-ray inspection system are several key components working in unison. These include an X-ray generator, a detector, and a computer control system, all housed within a protective cabinet.

The process unfolds in a few simple steps:

- An X-ray generator, often a tube containing a heated cathode and a copper anode, produces a controlled beam of low-energy X-rays.

- This beam passes through the food product as it moves along a conveyor.

- Materials within the product absorb some of the X-ray energy. Denser materials, like metal or glass, absorb more energy, while less dense materials, like the food product itself, absorb less.

- A detector on the opposite side captures the remaining X-rays that pass through. It converts this energy into electrical signals.

- Advanced software, such as SimulTask™ PRO, processes these signals to construct a detailed grayscale image. Denser contaminants appear as darker spots on the image, creating a clear contrast that the system can identify.

Note: Detectors use either an indirect or direct method for this conversion. Indirect detectors turn X-rays into visible light first, while direct detectors convert X-ray photons straight into an electrical charge. Both methods produce the data needed for image analysis.

Automated Detection and Rejection

Creating an image is only the first step. The system must then interpret the image and act on it. This is where automation, powered by intelligent software, becomes critical.

Modern systems use sophisticated algorithms to analyze images for anomalies. These algorithms can be:

- Deterministic: These are pre-trained machine learning (ML) algorithms that follow a clear, predetermined logic path. Operators can set specific parameters for what to accept or reject, giving them direct control.

- Artificial Intelligence (AI): AI provides a more holistic analysis, identifying patterns that might not be obvious to a human operator. It learns from vast datasets to continuously improve accuracy.

Once the software identifies a contaminated or non-conforming product, it triggers a rejection mechanism. These automated systems remove the item from the production line without stopping the flow. Common rejection methods include:

- Air Jets: A burst of compressed air blows lightweight items (like cookies or packaged snacks) off the conveyor.

- Pusher Rejection: A mechanical paddle physically pushes heavier or larger products (like bread loaves or cases) into a rejection bin.

- Tipdown Rejection: A section of the conveyor belt tips downward, allowing taller or longer products (like baguettes) to slide gently off the line.

The Role of X Ray Metal Inspection in Food Industry

While traditional metal detectors are common, the role of x ray metal inspection in food industry is expanding due to its superior capabilities. Metal detectors work by creating an electromagnetic field and sensing disruptions caused by metal. However, their performance can be limited by product characteristics and packaging.

X-ray inspection offers a more robust solution. The technology is largely unaffected by product temperature, moisture, or salt content—factors that can trigger false rejects in metal detectors. This makes x ray metal inspection in food industry an ideal choice for products like cured meats, cheese, and sauces. Furthermore, it can "see" through a wider variety of packaging materials.

Here is a comparison of the two technologies:

| Feature | X-ray Inspection | Metal Detection |

|---|---|---|

| Contaminant Types | Detects metal, glass, stone, bone, and high-density plastics. | Detects ferrous, non-ferrous, and stainless steel. |

| Packaging | Effective with foil, metallized film, and glass jars. | Cannot inspect products in foil or metallized film. |

| Product Effect | Unaffected by high moisture, salt, or temperature. | Performance can be reduced by these factors. |

| Integrity Checks | Can identify missing items, incorrect fill levels, and damage. | Cannot perform these quality checks. |

| Initial Cost | Higher initial investment. | Lower initial investment. |

The versatility of x ray metal inspection in food industry provides a comprehensive safety net that goes far beyond finding just metal.

Beyond Metal: Other Detectable Contaminants

A primary advantage of X-ray inspection is its ability to detect a wide range of non-metallic foreign bodies. Detection depends on the contaminant's density relative to the food product.

- Glass: Systems can easily spot denser leaded glass. Soda-lime glass, the most common type found in food environments, has a lower density but is still detectable with properly calibrated equipment.

- Stone and Bone: Calcified bone fragments and mineral stones are significantly denser than most food products, making them appear as dark, easily identifiable objects in an X-ray image.

- High-Density Plastics: Certain plastics, like PVC, are detectable. Advanced dual-energy X-ray technology improves the detection of low-density contaminants like flat glass or stone in "busy" products with varied textures, such as trail mix or cereals. It works by analyzing the chemical composition of materials, not just their density.

More Than Contaminants: Quality and Integrity Checks

Modern X-ray systems are multifunctional tools that also perform critical quality control checks. By analyzing the product's image, these systems help ensure consistency and prevent costly packaging errors.

Manufacturers use this capability for several key checks:

- Mass Estimation and Portion Control: The system can estimate the overall mass of a product. It verifies that packages are not underfilled or overfilled, ensuring compliance with weight regulations. For example, it can check bags of nuts or frozen vegetables to remove overstuffed units.

- Component Count: For products sold with multiple items in a package, like a box of chocolates or a variety pack of snack bars, the system can verify that all components are present.

- Seal and Package Integrity: X-ray inspection can detect trapped food particles in the seal area of a package, which could compromise shelf life. It can also identify damaged or improperly sealed containers.

- Shape and Form Verification: The system can check for broken or misshapen products, such as cracked cookies or deformed baked goods, ensuring only perfect items reach the consumer.

This dual capability for safety and quality assurance makes x ray metal inspection in food industry a powerful and indispensable technology for modern food manufacturers.

Is X-Ray Food Inspection Safe for Consumers?

The primary goal of food inspection is to enhance consumer safety. Therefore, any inspection method must itself be completely safe. Regulatory bodies like the FDA provide frameworks such as the Food Safety Modernization Act (FSMA) to guide manufacturers. These regulations require facilities to identify risks and establish their own critical limits for contaminants based on hazard analysis. The FDA's stance is clear: any unintended hard or sharp fragment can render a food adulterated. This regulatory landscape encourages manufacturers to adopt the most effective technologies available, making systems for processes like x ray metal inspection in food industry a cornerstone of modern safety protocols.

A common question from consumers is whether this technology poses any risk. The answer, supported by decades of scientific research, is a definitive no.

Does It Make Food Radioactive?

A persistent myth is that X-ray inspection makes food radioactive. This is scientifically impossible at the energy levels used in food inspection.

X-rays are a form of energy, similar to light. The low-energy X-rays used in inspection systems pass through the food product without altering its atomic structure. Their energy level is far below the threshold required to induce radioactivity. The process is like shining a flashlight on an object; the object does not continue to glow after the light is turned off. Similarly, no radiation remains in the food once it leaves the X-ray beam.

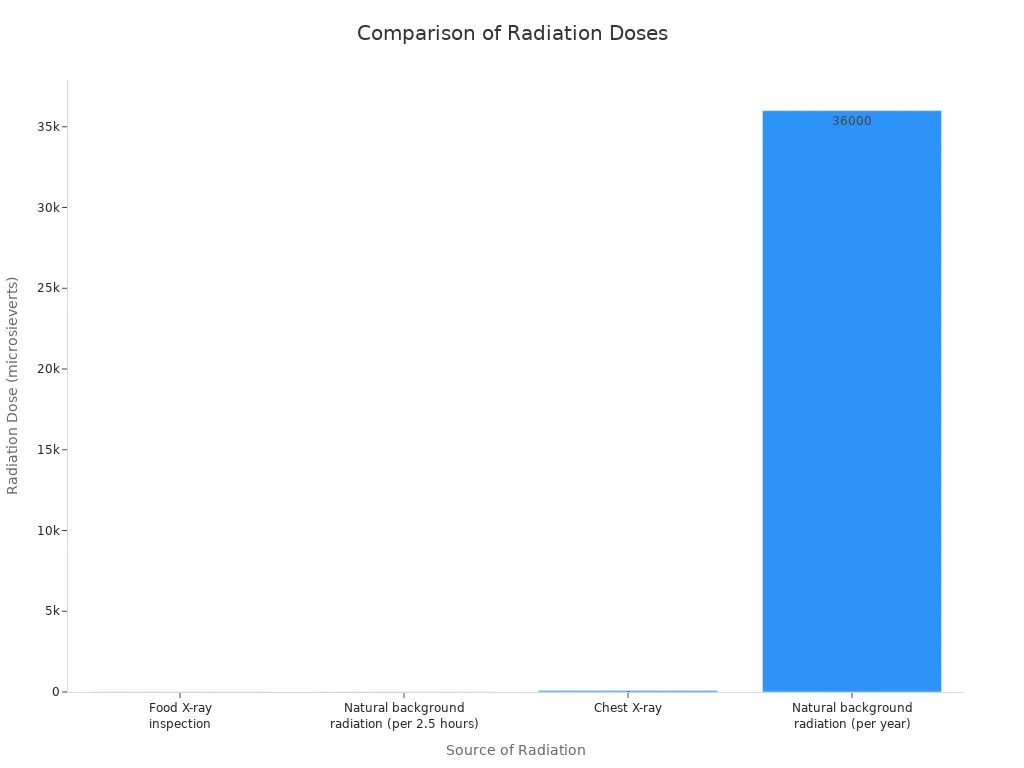

To put the radiation dose into perspective:

- A food product spends less than a second in the X-ray beam.

- The dose it receives is typically 1 millirad or less.

- This is millions of times lower than the safety threshold established by the World Health Organization (WHO).

- Eating a single banana exposes a person to more radiation than the food receives during inspection.

The radiation dose from food inspection is minuscule compared to other common sources and the natural background radiation we experience daily.

Impact on Nutritional Value, Taste, and Texture

Food must not only be safe but also retain its quality and nutritional profile. X-ray inspection has no negative impact on these crucial attributes. The extremely low radiation dose and brief exposure time are insufficient to cause any chemical or molecular changes to the food.

Scientific Consensus: A joint study group from the World Health Organization (WHO), the Food and Agriculture Organization (FAO), and the International Atomic Energy Agency (IAEA) concluded that irradiating any food commodity up to a dose of 1,000,000 rad produces no toxicological hazards and introduces no special nutritional problems. The dose from x ray metal inspection in food industry is over 10 million times lower than this established safety limit.

Here is how food quality remains protected:

| Attribute | Impact of X-Ray Inspection |

|---|---|

| Nutritional Value | Scientific studies confirm that the process does not cause changes in vitamins, including A, C, E, and the B-complex. The food's nutritional content remains intact. |

| Taste and Smell | The sensory properties of food are unaffected. The product will taste and smell exactly as it should, with no off-flavors or odors introduced by the inspection process. |

| Texture and Appearance | The physical structure of the food is not altered. A crispy cracker remains crispy, and a soft loaf of bread remains soft. The food's appearance is also unchanged. |

Research that uses X-ray imaging to analyze the internal structure of foods, such as cooked edamame, does so to understand quality differences. These studies use the technology as an analytical tool, further demonstrating that the inspection itself does not cause the changes it is used to measure. Consumers can be confident that X-rayed food is identical in quality, taste, and nutrition to un-inspected food.

X-ray food inspection is a highly effective and safe technology that protects consumers. Companies like Stephano Group use it as a critical tool to ensure product safety and quality.

Key takeaways include:

- It identifies contaminants like metal, glass, and stone based on density.

- The process does not make food radioactive or alter its nutritional value, taste, or texture.

FAQ

What types of food can be inspected with X-rays?

X-ray systems inspect a wide range of products. They are effective for raw, cooked, frozen, and packaged foods, including baked goods, dairy, produce, and ready meals.

Are there any contaminants X-ray systems cannot detect?

Yes. The technology relies on density differences. It generally cannot detect low-density contaminants like hair, wood, cardboard, or certain plastics that blend in with the food product.

How are operators protected from radiation?

Systems are fully enclosed in protective cabinets with lead-lined curtains. These features contain all radiation, ensuring operators receive no exposure above natural background levels during normal operation.

See Also

Discovering Premier Chinese Suppliers for X-Ray Inspection Equipment Purchases

Essential Industrial Checkweighing Machines Crucial for Every Food Processing Facility

Understanding Pharmaceutical Checkweighers: Key Features and Their Critical Importance

Leading Capsule Checkweighers Prospective Buyers Must Evaluate for 2025

Recognizing Indicators of Superior Quality Bovine Gelatin Powder Every Buyer Needs