How X-Ray Food Inspection Elevates Quality Control

X-ray food inspection elevates quality control. It provides a non-invasive method to detect physical contaminants and verify product integrity.

In 2023, foreign material contamination alone prompted 71 food recalls, a persistent industry challenge.

Modern x ray machines for food inspection surpass traditional methods. The market's projected 7.8% CAGR underscores the industry's investment in this comprehensive safety technology.

What Can X-Ray Inspection Detect That Other Methods Can't?

X-ray inspection systems offer a significant leap forward from traditional quality control methods. They identify a broader spectrum of foreign materials by analyzing product density. This capability allows them to find contaminants that other technologies, like metal detectors, simply cannot see. This advanced detection is a key reason regulatory bodies and global standards now endorse this technology.

- FDA FSMA: The Food and Drug Administration's Safety Modernization Act recommends X-ray inspection as a preventive control.

- BRC Global Standards: This standard mandates X-ray use for products classified as high-risk.

- GFSI Recognition: The Global Food Safety Initiative accepts X-ray inspection across all its benchmarked schemes.

Detecting High-Density Contaminants

The core principle of X-ray inspection is density. An X-ray system generates an image by measuring the amount of X-ray energy that passes through a product. Denser materials absorb more energy and appear darker on the resulting image, making them stand out. This allows the system to detect a wide range of high-density contaminants.

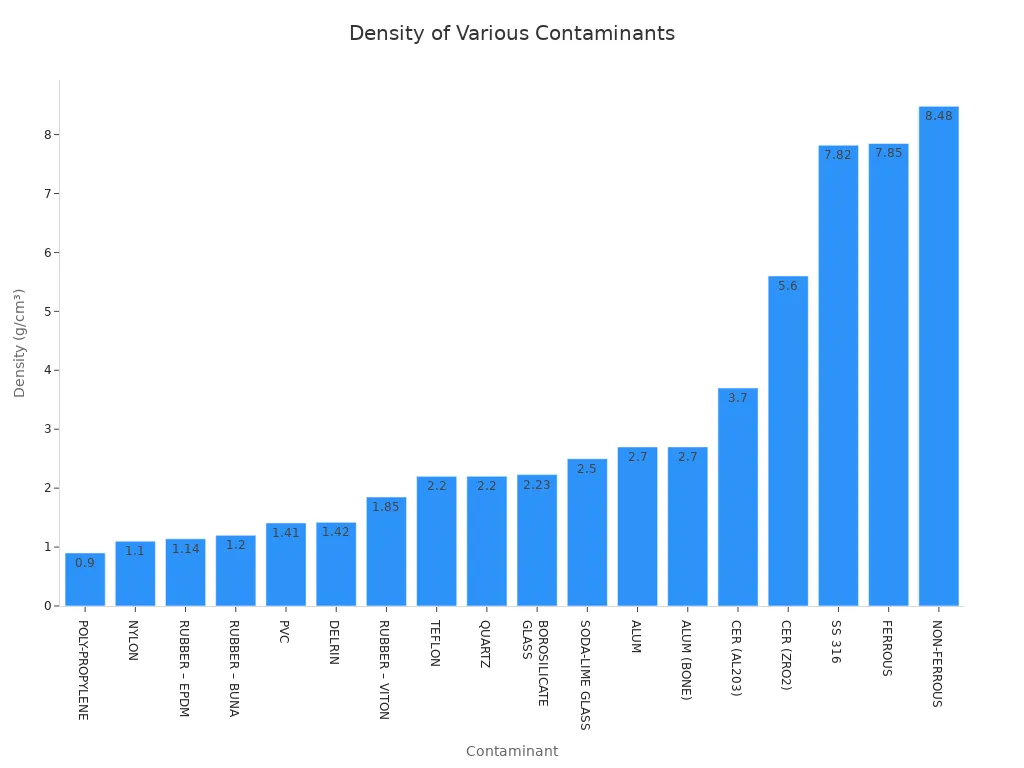

The detectability of a material is directly proportional to its specific gravity (density) relative to the product. Contaminants with a higher density than the surrounding food are easier to detect.

For example, a food manufacturer like St. Clair Foods uses X-ray inspection to find metallic and non-metallic contaminants. Their system identifies glass, stone, calcified bone, and even high-density plastics that would otherwise go unnoticed. This process enhances the quality of raw ingredients and mitigates risk before products reach consumers.

However, the system's effectiveness depends on this density contrast. Materials with a density similar to or lower than the food product are challenging to identify. These can include:

- Wood or cardboard

- Hair

- Insects

- Low-density plastics and stones

The following chart illustrates the varying densities of common contaminants, showing why some are more detectable than others.

This principle makes x ray machines for food inspection exceptionally versatile for finding physical hazards beyond just metal.

Identifying Contaminants Within Metal Packaging

A primary limitation of traditional metal detectors is their incompatibility with metal packaging. Aluminum foil, metallized films, and metal cans create a large "product signal" that interferes with the detector's electromagnetic field. This interference forces operators to reduce the machine's sensitivity, rendering it ineffective for finding small metal fragments.

X-ray inspection completely bypasses this issue. Since X-rays penetrate packaging, the system can inspect products after they are sealed, regardless of the packaging material.

- Canned Goods: Metal detectors cannot inspect food in metal cans. X-ray systems can, detecting contaminants from raw ingredients (like stones) or the production process (like broken machinery parts).

- Foil-Wrapped Products: X-ray technology easily inspects items wrapped in foil, which would blind a metal detector.

- Glass Jars with Metal Lids: The company Produits de Nos Grand-Meres faced this exact challenge. Their metal detectors could not inspect sealed glass jars. By implementing an X-ray system, they enabled glass-in-glass detection and found metal fragments inside the sealed jars, a critical quality control improvement.

This capability ensures that product safety is maintained even for items in challenging packaging formats.

Finding Product-Specific Contaminants

Modern food products are often complex, containing multiple ingredients with varying densities. A bag of trail mix or a container of mixed vegetables creates a "busy" image for a standard single-energy X-ray system, making it difficult to distinguish a contaminant from a piece of nut or vegetable.

Advanced x ray machines for food inspection solve this problem using dual-energy technology.

Dual-Energy X-ray Technology (MDX) discriminates materials based on their chemical composition (atomic number) rather than just density. This allows the system to analyze complex, multi-textured foods and accurately identify low-density contaminants like flat glass or stone that would be lost in a "busy" image.

This technology is also refined for specific product challenges. For example, inspecting poultry for bones requires incredible precision. Advanced software can be calibrated to distinguish between a natural chicken bone and a foreign object like a piece of metal or glass. These systems can identify bone fragments as small as 1.5mm in various chicken products, including breasts, nuggets, and ground meat, ensuring both safety and product integrity.

How Do X Ray Machines for Food Inspection Enhance Overall Product Quality?

Advanced x ray machines for food inspection move quality control beyond simple contaminant removal. They function as comprehensive quality assurance stations, performing multiple checks simultaneously to verify the product itself. This capability ensures that every item leaving the production line meets strict standards for completeness, integrity, and uniformity, directly protecting brand reputation and consumer satisfaction.

Ensuring Product Completeness and Integrity

A primary function of X-ray inspection is to confirm that every package is complete. The system verifies that the correct number of items is present, preventing underfilled packages from reaching the market. This is crucial for products sold by count, such as:

- A tray of cookies or biscuits

- A multi-pack of yogurt

- A bottle of vitamin capsules

- A box of chocolate truffles

X-ray systems use "count" functionality to confirm component content within sealed packages. This process ensures customers receive exactly what they paid for.

Beyond counting, these systems also assess product integrity. They can identify damaged, broken, or misshapen products inside the final packaging. For example, the system can detect a cracked biscuit or a deformed chocolate bar that would otherwise go unnoticed. This prevents defective goods from being sold, which could harm a brand's image.

By analyzing the shape, size, and count of items within a package, an X-ray system acts as a final gatekeeper. It ensures that only products meeting all quality specifications proceed down the line.

Monitoring Fill Levels and Seal Integrity

Consistent fill levels are essential for brand trust and regulatory compliance. X-ray inspection provides highly accurate fill level measurement, often detecting variations as small as 1.0 ml. This helps manufacturers avoid product giveaway and ensures consumers receive a consistent amount in every package. The technology performs several critical packaging checks:

- Fill Level Inspection: Verifies that containers like bottles, cans, and jars are filled to the correct level.

- Cap Detection: Ensures that every bottle or jar has a cap properly secured.

- Seal Inspection: Detects product trapped in the seal area of flexible packaging, which can cause leaks and spoilage.

- Container Defects: Identifies deformities in glass or plastic containers that could compromise product safety.

X-ray systems detect seal defects by analyzing how low-energy rays are absorbed by the packaging. A proper seal has a consistent density. If product is caught in the seal or if the seal is incomplete, the density changes, and the system flags the package for rejection. This capability is vital for extending shelf life and preventing contamination.

Measuring Mass and Assessing Uniformity

While traditional checkweighers measure weight, x ray machines for food inspection can determine mass with exceptional precision. This technology calculates mass by measuring a product's apparent density and volume from the X-ray image. The system's accuracy is less affected by environmental factors like factory vibrations or air currents, which can interfere with conventional load-cell checkweighers.

This method offers a significant advantage: it combines several quality checks into a single step. A single X-ray system can simultaneously detect foreign contaminants, check fill levels, and measure mass. This consolidation streamlines the production line and provides a more holistic view of product quality. For the meat industry, advanced dual-energy systems (DEXA) can even perform Chemical Lean (CL) analysis to verify fat-to-meat ratios.

The following table compares the two technologies:

| Feature | X-ray Mass Measurement | Traditional Checkweigher |

|---|---|---|

| Primary Function | Measures mass based on density and volume. | Measures weight using a load cell. |

| Multi-Functionality | Yes (contaminant detection, fill level, etc.). | No (weight measurement only). |

| Environmental Impact | Less susceptible to vibration and air. | Sensitive to vibration and air currents. |

| Product Handling | Non-contact measurement. | Contact-based measurement. |

| Best Use Case | Complex products requiring multiple quality checks. | Simple products where weight is the only concern. |

By integrating mass measurement, manufacturers gain a powerful tool for process control. Consistent mass data helps identify upstream issues, such as problems with ingredient feeders or portioning equipment, allowing for rapid adjustments that improve overall product uniformity and reduce waste.

X-ray inspection is an indispensable tool for modern quality control. It elevates standards from simple contaminant removal to comprehensive product verification. Adopting this technology is a strategic investment in brand reputation, consumer safety, and operational excellence, securing a competitive advantage for food producers in a demanding market.

FAQ

Are X-rays safe for the food itself?

Yes. The radiation dose is extremely low. It does not affect food safety, taste, or texture. Global authorities like the FDA recognize the process as completely safe for consumption.

Is the equipment safe for employees to operate?

Yes. Modern x ray machines for food inspection have robust shielding and safety interlocks. Operator exposure is negligible and remains well below all international safety standards and regulations.

Why choose X-ray over a metal detector?

X-ray systems detect a wider range of contaminants like glass, stone, and bone. They also inspect products inside foil or metal packaging, a major limitation for metal detectors.

See Also

Leading Chinese Suppliers for X-Ray Inspection Machine Procurement

Essential Industrial Checkweighers: A Must-Have for Food Processing Facilities

Understanding Pharmaceutical Checkweighers: Key Features and Core Definitions

Hygienic Design: EHEDG Guidelines Versus 3A SSI Standards Comparison