how is rock wool insulation made?

Manufacturers create rock wool insulation by melting volcanic rock and recycled industrial slag at temperatures exceeding 1500°C (2732°F). The process uses a mixture where natural rock comprises at least 70-75% of the raw material. This molten substance is spun at high speeds, creating fine fibers similar to cotton candy. These fibers are then collected, bound, and cured into final insulation products like batts or boards. The material's growing significance is reflected in its market projections.

| Metric | Value |

|---|---|

| Market Value (2024) | $3.5 billion |

| Projected Market Value (2034) | $6.8 billion |

| Compound Annual Growth Rate (CAGR) | 6.9% |

Key Takeaways

- Rock wool insulation comes from melted volcanic rock and recycled industrial slag.

- Manufacturers melt these materials at very high temperatures, over 1500°C (2732°F).

- They spin the melted rock into fine fibers, like making cotton candy.

- A special binder holds the fibers together, giving the insulation its shape.

- The insulation goes into an oven to make it strong and stable.

- Machines cut the insulation into batts or boards for buildings.

- The process uses recycled materials and reuses waste, making it sustainable.

- Rock wool is good for insulation because it resists fire and sound.

The Raw Ingredients for Rock Wool

The exceptional performance of rock wool insulation begins with a carefully controlled recipe. Manufacturers combine natural minerals, recycled industrial byproducts, and specific processing agents. Each component plays a critical role in creating the final product's unique thermal, acoustic, and fire-resistant properties.

Natural Rock Components

The foundation of the insulation is natural, igneous rock, which typically makes up over 70% of the raw material mix.

Basalt: The Volcanic Foundation

Basalt is the primary raw material. This dark, fine-grained volcanic rock provides the ideal chemical composition for creating durable fibers. Manufacturers select basalt for its inherent qualities, which directly translate to the insulation's performance.

- High Silica and Alumina Content: Gives the fibers excellent heat resistance.

- Natural Durability: Ensures the final product does not degrade over time.

- Inherent Fire Resistance: Forms the basis of the insulation's non-combustible nature.

Diabase: A Key Igneous Rock

Diabase, another igneous rock similar to basalt, is often added to the mixture. Its primary function is to act as a fluxing agent. It helps lower the melting point of the entire raw material batch and adjusts the viscosity of the molten lava. This control ensures the liquid rock flows correctly before it is spun into fibers.

Recycled Industrial Materials

Sustainability is a key aspect of modern manufacturing. The production process incorporates recycled materials to reduce environmental impact and improve efficiency.

Steel and Copper Slag

Slag is a glass-like byproduct generated during the smelting process of steel and copper. Instead of being sent to a landfill, this material is repurposed as a valuable ingredient.

A Sustainable Choice: Using slag not only diverts industrial waste but also provides essential mineral oxides, like calcium and magnesium, that enhance the durability and performance of the final rock wool fibers.

Reclaimed Briquettes

Manufacturing facilities often create briquettes from their own production waste. These are small, compressed blocks made from collected fibers and dust. By reintroducing these briquettes into the furnace, manufacturers operate a closed-loop system that minimizes waste and maximizes material usage.

Additives and Processing Agents

Certain materials are added to facilitate the manufacturing process and give the final product its structure.

Coke as a Fuel Source

Coke, a high-carbon fuel derived from coal, is layered with the rock and slag inside the furnace. It is not a primary ingredient of the fibers but serves as the critical heat source. Burning coke generates the intense temperatures—above 1500°C (2732°F)—required to melt the raw materials into a molten state.

Binders for Structural Integrity

After the molten rock is spun into fibers, a thermosetting resin binder is sprayed onto them. This binder acts like a glue. During the curing stage, heat activates the resin, bonding the intersecting fibers together. This process gives the insulation its final form, rigidity, and durable structure, whether as a flexible batt or a dense board.

Step 1: Sourcing and Preparing the Materials

Creating high-quality rock wool begins long before the furnace is lit. The process starts with a meticulous sourcing and preparation phase. Manufacturers ensure every component meets strict standards to guarantee the final product's performance. This foundational step sets the stage for the entire production cycle.

Quality Control and Inspection

Every batch of raw material undergoes rigorous inspection. This quality control is essential for maintaining consistency and producing insulation with reliable thermal, acoustic, and fire-resistant properties.

Verifying Chemical Composition

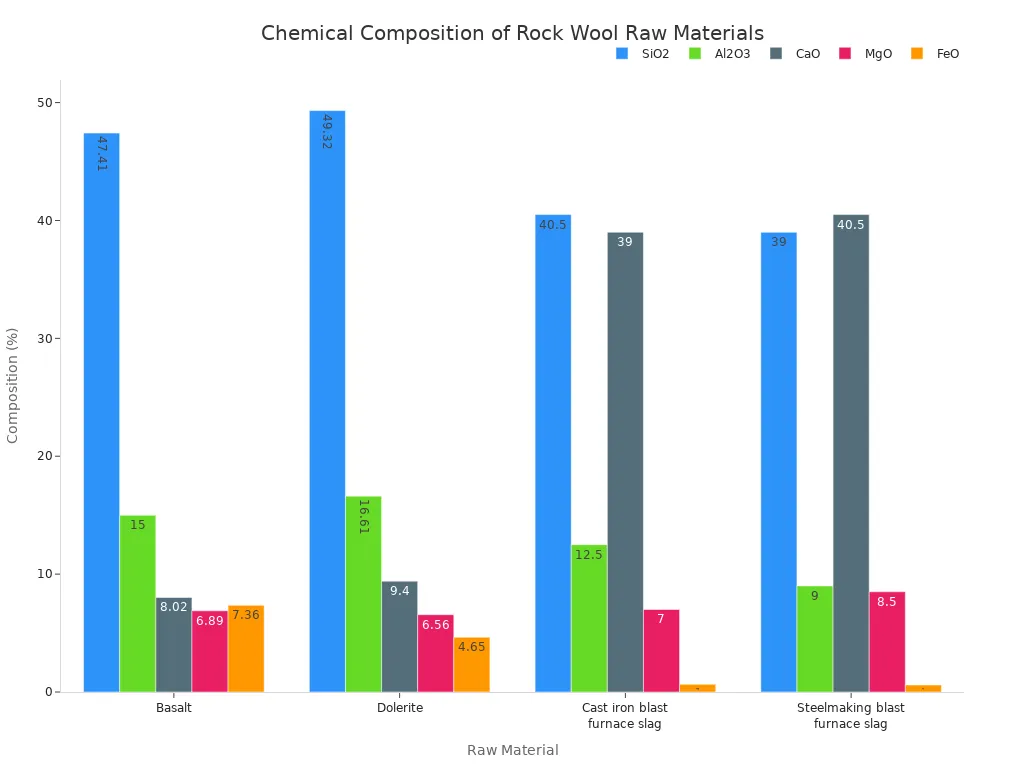

Technicians carefully analyze the chemical makeup of the incoming rock and slag. They verify the levels of key mineral oxides like silica (SiO2), alumina (Al2O3), calcium oxide (CaO), and magnesium oxide (MgO). Each material contributes a different chemical profile, and maintaining the right balance is critical for the melting process and the final fiber characteristics.

Sourcing Protocols for Rock and Slag

Manufacturers establish strict sourcing protocols to secure a consistent supply of high-quality materials.

- Basalt is chosen for its natural thermal stability and fire resistance.

- Industrial slag is sourced from steel and copper producers, supporting sustainability by repurposing industrial byproducts.

- A reliable supply chain is crucial. Any variation in raw material quality can impact the performance of the finished insulation.

Mixing the Recipe

Once the materials pass inspection, they are combined according to a precise recipe. This "charge" is calculated to achieve the desired properties in the final rock wool product.

Calculating Material Ratios

The ratio of rock to slag is a key variable that defines the type of insulation. For example, "basalt wool" contains a much higher percentage of basalt compared to standard "rock wool," which uses a greater amount of recycled slag.

Recipe Precision is Key: The specific blend of basalt, slag, and other minerals directly influences the insulation's durability, melting temperature, and overall performance.

| Product Type | Basalt Content | Slag Content |

|---|---|---|

| Basalt Wool | ≥85% | ≤5% |

| Rock Wool | 35-70% | 20-65% |

Loading into the Cupola Furnace

Before loading, machines crush the rocks into smaller, more manageable pieces, typically 5-10 cm in diameter. The crushed rock, slag, and other minerals are then weighed and mixed. This carefully measured blend is loaded into the top of the cupola furnace in alternating layers with coke, the fuel that will generate the intense heat needed for melting.

Step 2: The Melting Process

Once the raw materials are loaded, the transformation from solid rock to liquid lava begins. The cupola furnace acts as the heart of the operation, generating immense heat to liquefy the carefully prepared mixture. This stage is a powerful display of controlled thermal energy, essential for creating the foundation of rock wool.

Inside the Cupola Furnace

The cupola furnace is a tall, cylindrical shaft where the intense melting occurs. Operators manage a continuous process, feeding materials into the top as molten lava flows from the bottom.

Achieving Extreme Temperatures

The furnace achieves blistering temperatures required for melting rock. Powerful fans blow hot air into the lower section of the furnace, providing a constant supply of oxygen. This oxygen supercharges the combustion of the coke layers.

Extreme Heat Zone: The reaction between the burning coke and forced air generates temperatures exceeding 1500°C (2732°F). This intense heat creates a melting zone in the lower portion of the furnace.

The Role of Coke in Melting

Coke serves exclusively as the fuel source. It does not become part of the final rock wool fibers. The alternating layers of coke and raw materials are critical for efficient operation. As the charge descends through the furnace, the burning coke provides uniform heat. This ensures all the rock and slag melt completely and consistently, preventing solid chunks from disrupting the process.

Creating the Molten Lava

The extreme heat inside the furnace triggers a dramatic physical change. Solid, raw ingredients transform into a homogenous, flowing liquid with the consistency of volcanic lava.

From Solid Rock to Liquid Form

The journey from solid to liquid is a gradual descent. The materials heat up as they move down the furnace shaft. Upon reaching the melting zone, they liquefy and trickle through the coke bed. This process mixes the different components into a single, uniform molten substance.

| Material State | Location in Furnace | Description |

|---|---|---|

| Solid | Top Section | Crushed rock, slag, and coke are loaded. |

| Liquid | Bottom Section | Materials melt into a homogenous lava. |

Tapping the Furnace

At the base of the furnace, operators "tap" the molten pool. They open a specialized spout, allowing the glowing, red-hot lava to flow out in a controlled stream. This stream is directed along a trough toward the next stage of production: the spinner wheels. The flow rate must be carefully managed. A consistent stream of lava is crucial for producing uniform fibers in the fiberization step. This precise control ensures the quality of the final insulation product.

Step 3: Fiberization: Spinning Rock into Wool

This stage marks the most dramatic transformation in the entire production line. The molten lava, flowing from the furnace, is converted from a liquid into a mass of fine, flexible fibers. This process, known as fiberization or spinning, relies on incredible speed and precise control over physical forces. It is the moment solid rock truly becomes wool.

High-Speed Spinner Wheels

The core of the fiberization process is a sophisticated spinning machine. This machine features a series of wheels, typically four, that rotate at exceptionally high speeds. The molten lava is poured directly onto these wheels, which work together to tear the liquid apart and fling it outward as tiny fibers.

How the Spinning Machine Works

The spinner wheels rotate in opposite directions, creating immense centrifugal force. Operators carefully direct the stream of molten rock onto the point where the wheels nearly touch. Advancements in engineering have continuously improved the efficiency of these machines. While spinner wheels previously had a limit of 9,000 RPM, modern technology allows for a new top rotational speed of 15,000 RPM.

Operators manage several input parameters to control the final fiber properties. These include the rotational frequencies of the spinner wheels, the melt string impingement point, the melt's rheological properties, and the velocity of the blow-in air flow.

To address the high energy consumption of this stage, manufacturers often implement sustainability measures.

- Energy Efficiency: Modern facilities use energy-efficient motors and drive systems to decrease the power required for the spinning process.

- Cooling Methods: Innovative cooling techniques are employed to minimize water usage while managing the heat generated by the machinery.

The "Cotton Candy" Effect

The visual result of the spinning process is often compared to making cotton candy. As the molten rock hits the rapidly rotating wheels, it is instantly thrown outward, stretching into billions of thin filaments. This transformation happens in a fraction of a second, governed by several key scientific principles.

- Rapid Cooling: The molten material solidifies almost instantly upon contact with the cooler spinner wheels. This process achieves extreme cooling rates, sometimes between 10⁴ and 10⁶ Kelvins per second (K/s), which is essential for forming the fiber's structure.

- Shear Forces: The immense rotational speed creates powerful shear forces that pull the liquid lava into long, thin streams.

- Surface Tension: This property of the liquid rock helps hold the melt together just long enough for the centrifugal force to eject it as continuous fibers rather than disconnected droplets.

Transforming Liquid into Fiber

The journey from a homogenous liquid to a fibrous mass is a matter of physics and thermal dynamics. Each droplet of lava undergoes a violent but controlled transformation into a durable fiber.

Ejecting Molten Rock

A consistent stream of lava flows from the furnace trough and cascades onto the spinning wheels. The properties of this molten rock are critical. The chemical composition and temperature of the melt determine its viscosity, or thickness. A lower viscosity allows the machine to produce finer fibers, but if the material is too fluid or hot, the resulting fibers can become brittle. Real-time monitoring ensures the melt has the perfect consistency for optimal fiber formation.

Using Airflow to Elongate Fibers

As the fibers are flung from the spinner wheels, they are immediately caught in a high-velocity airstream. This blast of air serves two purposes: it further elongates the fibers, stretching them to their final diameter, and it helps guide them toward the collection chamber. This controlled airflow also influences the final structure of the fibers. The fiber's outer "skin" cools faster than its "core." This differential cooling causes stress to build in the skin, which helps stretch the fiber and align its internal structure. This step is crucial for developing the strength and flexibility of the final rock wool product.

Step 4: Forming the Rock Wool Mat

After the fiberization stage, the billions of newly created fibers are airborne. The next critical step is to gather these fibers and form them into a thick, continuous blanket known as a primary mat. This process takes place inside a large, enclosed collection chamber, where manufacturers add essential components to give the insulation its final structure and properties.

The Collection Chamber

The collection chamber is a large-scale system designed for one purpose: to deposit the airborne fibers into a uniform layer. The centrifuge's air system blows the fibers, along with any initial additives, directly into this chamber. Operators meticulously manage the environment inside to prevent clumping and ensure an even distribution. They use adjustable air ducts and fans to regulate the airflow, guiding the fibers to settle consistently.

Gathering the Airborne Fibers

As fibers enter the chamber, they are suspended in a turbulent airstream. The goal is to control this chaos. A powerful exhaust system creates negative pressure, or a vacuum effect, which pulls the fibers downward. This suction ensures the fibers are drawn uniformly onto a moving conveyor belt or a large, rotating collection drum at the bottom of the chamber.

Forming the Primary Mat

The fibers accumulate on the conveyor, forming a soft, thick, and continuous blanket. The consistency of this primary mat is crucial for the final product's performance. Manufacturers rely on several key design features to achieve this uniformity.

- Negative Pressure System: A vacuum pulls fibers evenly onto the collection surface.

- Consistent Conveyor Speed: The belt moves at a steady pace, ensuring the mat has a consistent thickness from start to finish.

- Shaking Device: A mechanism gently shakes the mat after formation, further distributing the fibers for optimal evenness before it moves to the next stage.

Applying Binders and Oils

The primary mat at this point is just a loose collection of fibers. To give it strength, durability, and water resistance, manufacturers apply a combination of a binding agent and specialized oils.

Spraying the Binder for Strength

Nozzles spray a thermosetting resin, typically an epoxide binder, over the entire surface of the mat. This binder coats the fibers and acts as a powerful adhesive.

The binder is essential for providing the final product's mechanical properties. It creates strong bonds between the fibers, giving the insulation its compressive, tensile, and bending strengths, which allows it to hold its shape.

Adding Oil for Dust and Water Resistance

Along with the binder, a small amount of oil is sprayed onto the mat. This oil serves two important functions. First, it suppresses dust, making the final rock wool product easier and safer to handle and install. Second, it enhances the material's hydrophobic (water-repellent) qualities. The precursors for the epoxide binder are often derived from natural vegetable oils, such as linseed and soybean oil, through a process called epoxidation, integrating sustainability into the chemistry of the product.

Step 5: Curing and Cutting the Final Product

The soft, binder-coated mat now enters the final stages of manufacturing. In this phase, operators use heat, pressure, and precision cutting to transform the delicate blanket into a durable, high-performance insulation product. This step solidifies the material's structure and tailors it for specific applications.

The Curing Oven

The uncured mat moves along the conveyor belt and into a long curing oven. This oven applies consistent heat to trigger a critical chemical reaction that gives the rock wool its final strength and stability.

Polymerizing the Binder

Inside the oven, hot air circulates at temperatures between 190°C and 250°C (374°F and 482°F). This intense heat activates the water-soluble phenolic resin that was sprayed onto the fibers. The heat causes a process called polymerization, where the binder molecules link together to form a strong, rigid polymer network.

Creating a Stable Structure

As the binder cures, it hardens and permanently bonds the intersecting rock wool fibers. This process transforms the loose mat into a cohesive and stable slab. The result is a product that is rigid, yet flexible enough to handle, and capable of holding its shape for decades without sagging or deteriorating.

Compression and Density Control

Before the binder fully cures, the mat passes through a series of large rollers. This compression stage is essential for determining the final thickness and density of the insulation, which directly impacts its performance.

Using Rollers to Set Thickness

Operators precisely adjust the gap between the compression rollers. This action squeezes the mat to a specific, uniform thickness. A thicker, less compressed product will have a lower density, while a thinner, more compressed product will have a higher density. This control allows manufacturers to create a wide range of products for different needs.

How Density Impacts Performance

Density is a critical factor in insulation performance. A higher density generally improves thermal resistance because more interwoven fibers create smaller air pockets, reducing heat transfer.

Performance Note: Common densities for rock wool range from 60 kg/m³ to 160 kg/m³. While higher density typically yields a better R-value, its effect on acoustic performance is more complex. Lower densities can be more effective at blocking low-frequency sounds (below 1250 Hz).

Cutting to Size

Once the cured slab exits the oven, it is ready to be cut into its final commercial forms. High-speed saws and blades trim the edges and slice the continuous slab into manageable products.

Creating Batts and Boards

The cured rock wool is cut into standard-sized batts and boards. These dimensions are designed to fit perfectly between common wall studs and ceiling joists, simplifying installation. Common widths include 16 inches and 24 inches to match residential and commercial framing.

| Dimension Type | Standard Sizes (Metric) | Application |

|---|---|---|

| Thickness | 25mm – 150mm | Batts, rolls, and boards |

| Width | 400mm – 600mm | Fits standard stud spacing |

| Length | 1.2m – 2.4m | Easy handling and installation |

Producing Loose-Fill Insulation

Not all rock wool becomes batts or boards. Some material is sent to a granulator, which shreds the cured product into small, fibrous tufts. This creates loose-fill insulation, a product designed to be blown into attics, wall cavities, and other hard-to-reach spaces.

Step 6: Packaging and Quality Assurance

The final stage of production ensures the finished rock wool is ready for distribution and meets rigorous industry standards. This phase involves compressing the insulation for efficient shipping and conducting a series of critical quality tests. These last steps guarantee the product performs as expected once it reaches a job site.

Compressing and Wrapping

After cutting, the insulation products move to an automated packaging line. Here, machines prepare the batts and boards for transport, balancing logistical efficiency with product integrity.

Packaging for Efficient Transport

Automated equipment compresses the rock wool batts before sealing them in durable poly bags. This compression significantly reduces the product's volume, allowing more units to fit onto a pallet and into a truck. This process lowers transportation costs and reduces the carbon footprint associated with shipping. The packaging is designed for easy handling and clear labeling, showing key product information like R-value and dimensions.

Protecting the Insulation

The plastic wrapping serves a dual purpose. It protects the insulation from moisture, dirt, and damage during transit and storage. It also holds the product in its compressed state.

Important Note: Compression temporarily reduces the insulation's thickness by squeezing the air pockets. When an installer opens the package, the rock wool is designed to spring back to its full, intended thickness. This recovery is essential for the product to achieve its specified R-value, as the trapped air is what provides the thermal resistance.

Final Quality Checks

Before any product leaves the factory, it undergoes a final round of quality assurance testing. Technicians pull samples from the production line to verify that every batch meets or exceeds performance standards for safety and effectiveness.

Testing Thermal Resistance (R-Value)

Technicians test the product's thermal performance using a heat flow meter apparatus, following standards like ASTM C518. This test measures how effectively the insulation resists the flow of heat. The resulting R-value confirms that the product provides the thermal protection advertised on its packaging. Manufacturers adhere to several key standards to ensure consistent thermal properties.

- ASTM C665: For blanket insulation in light frame construction.

- ASTM C612: For mineral fiber block and board insulation.

- CAN/ULC S702.1: The Canadian standard for mineral fiber thermal insulation.

Fire and Acoustic Performance Tests

Rock wool's reputation is built on its exceptional fire resistance and sound-dampening qualities. Technicians conduct tests to certify these properties.

| Property Tested | Value | Test Standard |

|---|---|---|

| Flame Spread Index | 0 | ASTM E84 |

| Smoke Developed Index | 0 | ASTM E84 |

| Combustibility | Non-combustible | ASTM E136 / CAN/ULC S114 |

These results confirm the material will not contribute to a fire. Acoustic performance is also verified using standards like ASTM E1332, which measures the insulation's ability to reduce sound transmission. This comprehensive testing ensures every product delivers superior safety and comfort.

The creation of rock wool insulation is a testament to modern manufacturing. This process transforms raw volcanic rock and recycled industrial slag into a high-performance product. The production hinges on a few key stages:

- Melting materials at extreme temperatures above 1500°C (2732°F).

- Spinning the molten lava into fine, intertwined fibers.

- Binding, curing, and cutting the fibers into their final form.

This controlled method results in a durable, fire-resistant, and effective insulation material used in buildings worldwide.

FAQ

Is rock wool natural or man-made?

Rock wool is a man-made product created from natural materials. Manufacturers melt volcanic rock and recycled slag at high temperatures. They then spin this molten liquid into fine fibers, transforming raw minerals into a high-performance insulation product.

Why is slag used in rock wool production?

Manufacturers use industrial slag to improve sustainability and performance. This recycled byproduct from steel production diverts waste from landfills. It also adds mineral oxides that enhance the final fiber's durability and fire resistance.

How hot does the furnace get? 🔥

The cupola furnace reaches extreme temperatures exceeding 1500°C (2732°F). This intense heat is necessary to melt the solid rock and slag into a liquid, lava-like substance. The molten material is then ready for the fiberization stage.

What gives rock wool its shape and rigidity?

A thermosetting resin binder gives rock wool its structure. Manufacturers spray this binder onto the fibers after they are formed. A trip through a curing oven activates the resin, permanently bonding the fibers together into a stable mat.

Is the manufacturing process wasteful?

No, the process is highly efficient. Manufacturers operate a closed-loop system that minimizes waste.

They collect fiber scraps and dust, compress them into briquettes, and reintroduce these briquettes back into the furnace. This practice maximizes material usage.

How do manufacturers control the insulation's density?

Operators control density using large compression rollers. The rollers squeeze the uncured mat to a specific thickness before it enters the curing oven. More compression creates a higher-density product, which affects its thermal and acoustic properties.

Does compressing rock wool for packaging damage it?

No, the compression is temporary and does not damage the product. The packaging simply reduces volume for efficient shipping. When an installer opens the package, the rock wool springs back to its original thickness, ensuring it achieves its specified R-value.

See Also

Edible Gelatin: Production Process and Composition Unveiled

Bovine Gelatin Powder: Ingredients and Manufacturing Explained

Assessing Molybdenum Plugs for 2025 Seamless Steel Pipe Manufacturing

WT20 Thoriated Tungsten Electrodes: Enhancing TIG Welding Performance

Exploring Molybdenum High-Temperature Furnaces: Insights for 2025