Never Settle for Impure Flax Seeds Optical Sorter Solutions

An optical sorter elevates flax seed quality. It uses high-resolution cameras and intelligent software to scan each seed in real-time. This technology precisely identifies and ejects foreign materials, discolored seeds, and damaged kernels with targeted air jets. The process results in a final product with superior purity, enhanced safety, and increased commercial value.

The global flax seeds market is growing rapidly. Market.us estimates its value at USD 1.3 Billion in 2024, projecting an 8.2% CAGR through 2034. This growth highlights the need for advanced processing. A flax seeds optical sorter ensures producers meet rising consumer demand for high-quality, pure products.

How a Flax Seeds Optical Sorter Achieves Precision Sorting

A flax seeds optical sorter transforms raw, harvested product into a pure, high-value commodity through a sophisticated three-step process. This system combines advanced imaging, intelligent analysis, and mechanical precision to achieve what manual or basic mechanical cleaning cannot. Each step is critical for ensuring the final product meets the highest quality and safety standards.

Step 1: High-Speed Inspection with Advanced Cameras

The sorting process begins as flax seeds are fed into the machine and accelerated down a chute. They pass in a single layer through an inspection zone, where they are scanned by high-tech cameras at incredible speeds. Modern sorters have moved beyond standard RGB cameras, which only see color, size, and shape. Today’s leading systems utilize more advanced imaging technologies.

- Hyperspectral Imaging: This technology is a game-changer. It captures data across a wide spectral range (e.g., 380-1018 nm), going far beyond visible light. It allows the sorter to analyze the intrinsic biochemical properties of each seed, detecting subtle defects like fungal growth or internal damage that are invisible to the naked eye.

- High-Resolution Sensors: Cameras with resolutions like 2048x2048 pixels and advanced SCMOS detectors capture incredibly detailed images of every single seed. This allows the system to identify even the smallest imperfections or contaminants.

- Near-Infrared (NIR) Spectroscopy: By analyzing light in the NIR spectrum (900-2500 nm), the sorter can assess chemical composition, identifying issues related to moisture content or oil quality.

Note: Standard RGB cameras are limited to morphological data (color, texture). Hyperspectral imaging integrates spectroscopy, allowing it to detect latent attributes like chemical composition and internal anatomy, which is crucial for identifying subtle defects.

Step 2: Intelligent Data Processing for Defect Detection

The massive amount of image data captured by the cameras is instantly sent to the sorter's central processing unit. This is where the machine's "brain" goes to work, using powerful software and machine learning algorithms to make split-second decisions.

This intelligent software analyzes each seed against pre-defined quality parameters set by the operator. It uses sophisticated algorithms to classify objects based on the spectral and spatial data it receives. Common algorithms include:

- Partial Least Squares-Discriminant Analysis (PLS-DA): Classifies seeds based on damage or other characteristics.

- Principal Component Analysis (PCA): Reduces complex data to help identify patterns and distinguish good seeds from contaminants.

This combination of high-speed imaging and intelligent processing enables the flax seeds optical sorter to achieve remarkable throughput and accuracy. Some multi-chute systems can process up to 20 tons per hour, depending on the impurity level. The precision is equally impressive, with many models achieving sorting accuracy greater than 99.9%.

| Product Model | Throughput (T/h) | Sorting Accuracy (%) |

|---|---|---|

| 6SXZ-126V | 0.5~4.0 | ≥99.99 |

| 6SXZ-315V | 2.0~7.0 | ≥99.99 |

| 6SXZ-630V | 4.0~11.0 | ≥99.99 |

Step 3: Precise Ejection of Unwanted Material

The final step in the process is the physical removal of contaminants and defective seeds. When the system's software identifies an unwanted particle, it calculates its exact position and trajectory. It then sends a signal to a specific air jet.

An electronic control module, or ejector board, triggers a high-speed solenoid valve. This releases a precise, powerful burst of compressed air aimed directly at the target. The entire action—from detection to ejection—occurs in milliseconds. Top-tier systems have a response time of 10 milliseconds or less, which is fast enough to remove a single bad seed from a stream moving at over 2 meters per second.

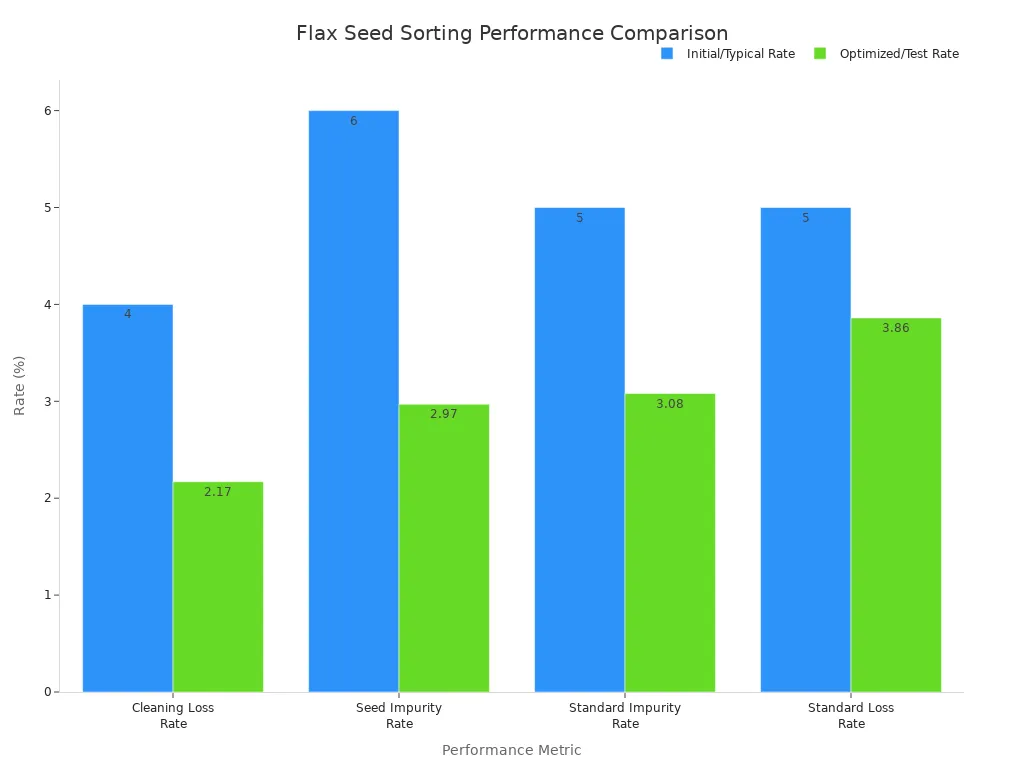

A key goal of this step is to maximize purity while minimizing the loss of good product, often called the "good-in-bad" ratio. Operators can optimize machine parameters to achieve the best results. For example, adjusting the vibrating screen frequency and fan wind speed can significantly reduce cleaning loss.

By fine-tuning these settings, processors can lower the cleaning loss rate from a typical 4% to as little as 1-2%. This ensures that the final batch of flax seeds is exceptionally pure and the yield is maximized, making the flax seeds optical sorter an invaluable tool for modern food production.

Key Contaminants and Defects Targeted by Optical Sorting

An optical sorter’s primary function is to purify the product stream by identifying and removing any material that is not a perfect flax seed. These unwanted elements fall into three main categories: foreign materials from the field, defective kernels damaged during processing, and invisible safety threats like fungal contamination. Advanced sorting technology targets each of these with remarkable precision.

Foreign Materials: Weed Seeds and Other Grains

Flax is often harvested alongside various other plants, leading to contamination from weed seeds and other grains. These foreign materials reduce the overall purity and can sometimes introduce unwanted flavors or toxins. An optical sorter uses its high-resolution cameras to distinguish these contaminants based on differences in size, shape, and color.

Common weed seeds that contaminate flax harvests include:

- Cuscuta epilinum (flax dodder)

- Lolium remotum (flax rye-grass)

- Galium spurium (false cleavers)

- Camelina alyssum/sativa (false flax)

- Agrostemma githago (corn cockle)

- Persicaria lapathifolia/maculosa (pale persicaria/redshank)

The sorter identifies these intruders in milliseconds and ejects them, ensuring the final product consists solely of pure flax seeds.

Defective Kernels: Damaged and Discolored Seeds

The journey from field to facility can be rough on delicate flax seeds. Mechanical processes during harvesting, threshing, and drying often cause physical damage. Market-bound flax can contain 10 to 40 percent cracked seeds and other dockage.

Pro Tip: Proper combine adjustment is crucial to minimize initial seed coat damage. Incorrect settings, such as excessive rotor speed or a narrow concave gap, significantly increase the percentage of cracked kernels.

Damage can arise from several sources:

- Mechanical Impact: The threshing process itself can crack seed coats. These cracks create entry points for fungi and accelerate spoilage.

- Drying Stress: High temperatures used during grain drying can cause stress cracks, breakage, and discoloration. Research shows that cross-flow dryers tend to produce more stress-cracked kernels than concurrent-flow dryers.

- Moisture Content: Grain with higher moisture content is more susceptible to developing stress cracks during the drying phase.

Optical sorters excel at identifying these imperfections. They spot subtle cracks, chips, and discoloration that signal a compromised seed, removing it to protect the quality and integrity of the entire batch.

Safety Threats: Fungal Bodies (Sclerotia) and Mycotoxins

Perhaps the most critical function of a modern flax seeds optical sorter is detecting invisible food safety threats. Fungi can produce harmful byproducts called mycotoxins. Studies show flax seeds can contain high levels of these compounds, ranking third after garlic and red pepper among certain spices for non-regulated mycotoxin content.

Common mycotoxins of concern include:

- Aflatoxins

- Ochratoxin A

- Fumonisins

- Zearalenone

- Vomitoxin

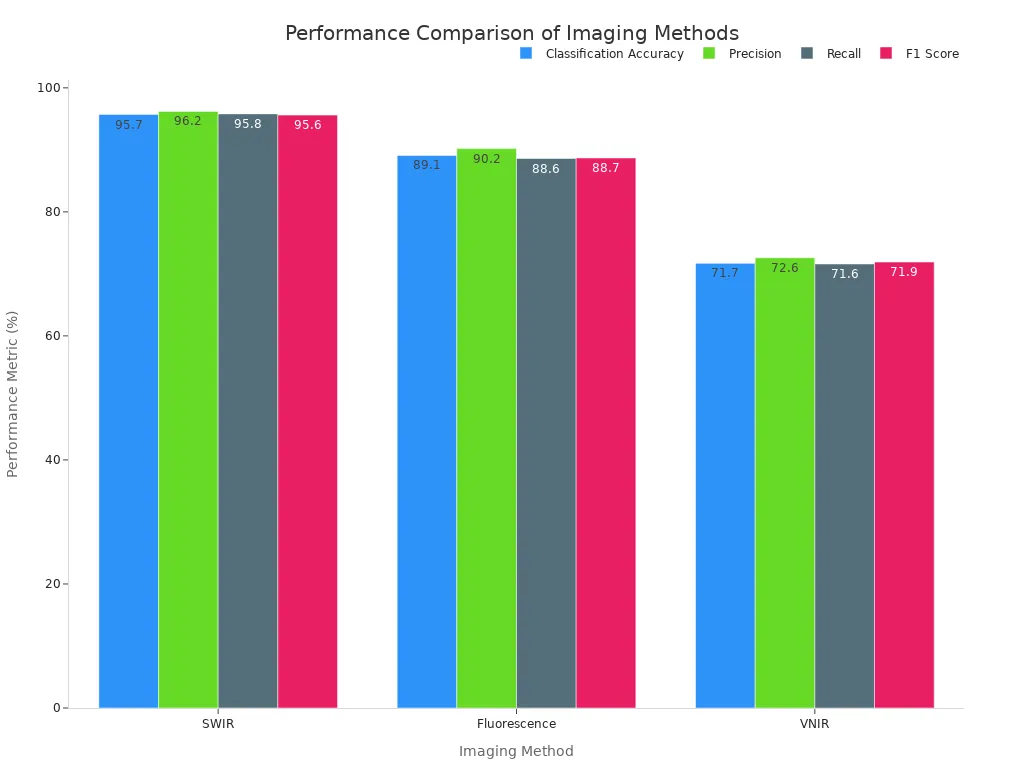

Standard cameras cannot see these dangers. This is where advanced imaging technologies like Short-Wave Infrared (SWIR) hyperspectral imaging become essential. SWIR cameras detect the unique chemical and molecular signatures of fungal bodies and mycotoxins. They analyze how light in the SWIR spectrum (900-1700 nm) reflects off a seed, identifying the specific biochemical presence of fungal growth, even when it is invisible to the human eye.

The data clearly shows the superiority of SWIR technology for this task. When compared to other imaging methods, SWIR achieves significantly higher accuracy in identifying contaminated seeds.

| Imaging Method | Classification Accuracy (SVM Model) | Precision | Recall | F1 Score |

|---|---|---|---|---|

| SWIR | 95.7% | 96.2% | 95.8% | 95.6% |

| Fluorescence | 89.1% | 90.2% | 88.6% | 88.7% |

| VNIR | 71.7% | 72.6% | 71.6% | 71.9% |

This chart visually demonstrates how SWIR technology outperforms other methods in every key performance metric for detecting contamination.

By leveraging this technology, processors can effectively remove these dangerous contaminants, delivering a product that is not only pure but also safe for consumption.

A flax seeds optical sorter is a transformative technology. It moves beyond simple cleaning to deliver true product purification. By precisely removing defects from foreign grains to mycotoxin-infected seeds, it ensures superior purity and safety. Adopting this technology enhances product value, strengthens brand reputation, and helps meet stringent quality standards.

FAQ

What is the main benefit of a flax seeds optical sorter?

It boosts purity and commercial value. The machine removes foreign materials and damaged seeds. This process ensures a premium product that meets high industry standards.

Can the sorter handle different types of flax seeds?

Yes, operators can adjust sorting parameters. This flexibility allows the machine to process various flax seed types and sizes, optimizing performance for different product batches.

How does an optical sorter improve food safety?

It detects and ejects seeds with fungal growth. Advanced SWIR imaging identifies mycotoxin contamination invisible to the eye, ensuring the final product is safe for consumption.

See Also

Capsule Sorters: Essential Technology for Effective Defect Elimination in Production

Leading Precoating Materials Revolutionizing Filtration System Performance by 2025

Three Essential Industrial Checkweighers for Optimal Food Plant Operations

Demystifying the Operational Principles of Advanced Sterile Filtration Devices

Key Capsule Checkweighers for Informed Buyer Decisions in 2025