Beyond the Hype Real AI Wins at Coca-Cola and Unilever

Global leaders Coca-Cola and Unilever deploy AI for concrete business gains, moving beyond publicity. Their strategies prove AI's value in a competitive market.

A recent report highlights this trend, showing 69% of CPG leaders now achieve AI-driven revenue growth.

These brands demonstrate how ai in the food industry delivers measurable results.

Coca-Cola's AI Playbook: From Marketing to Manufacturing

Coca-Cola demonstrates a dual-pronged AI strategy. The company applies artificial intelligence to both inspire creative consumer engagement and drive immense operational efficiency. This approach provides a comprehensive model for AI adoption, delivering value from the initial marketing concept to the final manufactured product.

The "Create Real Magic" Campaign

Coca-Cola moved beyond traditional advertising with its "Create Real Magic" campaign. This initiative represents a masterclass in using generative AI for brand engagement. The company launched "Create Real Magic," a first-of-its-kind platform combining OpenAI's advanced GPT-4 language model with the DALL-E image generator. It invited fans to become co-creators, generating original artwork using a curated set of the brand's iconic visual assets.

The strategy extended to major events. For its holiday advertising, Coca-Cola used generative AI to produce a refreshed version of its classic "Holidays Are Coming" ad. The company also enabled a digital "conversation" with Santa, powered by technologies like Microsoft's Azure AI Speech, which could be transformed into a shareable social media asset.

The campaign generated overwhelmingly positive consumer feedback. Sentiment analysis revealed strong associations with key brand values:

- Inspiration & Creativity (30%): The brand was seen as a catalyst for artistic expression.

- Energizing (25%): Coca-Cola reinforced its image as a revitalizing beverage.

- Magic and Adventure (20%): The campaign successfully evoked a sense of wonder.

- Universal Appeal (15%): The ad highlighted the brand's timeless and broad popularity.

However, deploying AI for emotional campaigns is not without risk. Experts caution that an over-reliance on algorithms can undermine the authenticity that consumers crave, especially from a heritage brand.

The use of AI in Coca-Cola's Christmas campaign raises concerns about brand authenticity, especially regarding human connection and emotional storytelling. While AI can offer innovation, speed up production, and cut costs, focusing solely on these benefits can backfire... Ultimately, people connect with people, not algorithms, and this is something AI cannot replace.

AI-Powered Quality Control

Coca-Cola's AI implementation extends deep into its manufacturing and supply chain operations. On a production line that produces billions of bottles annually, even a minuscule 0.01% defect rate can result in millions of wasted products. The company uses AI-powered computer vision systems to mitigate this risk. These systems perform real-time inspections, identifying a wide range of potential issues with incredible precision.

AI tools scan for numerous defects that are difficult for the human eye to catch consistently, including:

- Improper fill levels

- Incorrect cap installation or seal integrity issues

- Inaccurate or smudged label placement

- Bottle distortions or misalignments

- Presence of foreign particles

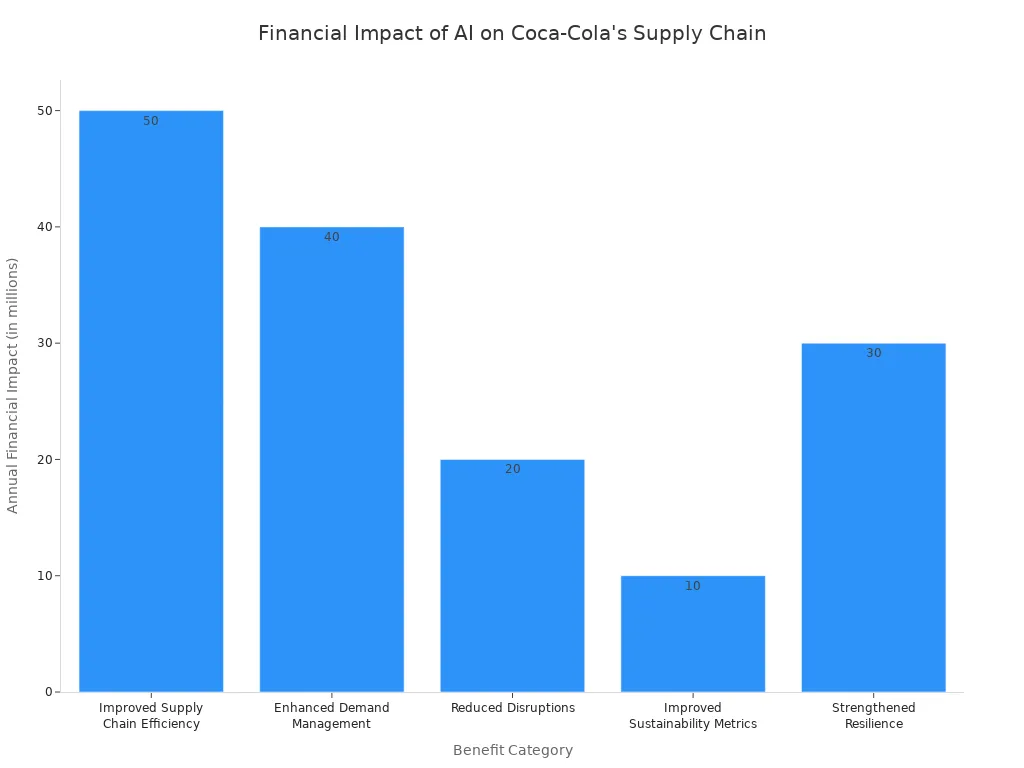

This proactive quality control does more than just reduce waste; it delivers substantial financial returns. AI-driven optimizations across the supply chain have generated an estimated $150 million in total annual financial benefits.

| Benefit Category | Annual Financial Impact |

|---|---|

| Improved Supply Chain Efficiency | $50 million |

| Enhanced Demand Management | $40 million |

| Reduced Disruptions | $20 million |

| Improved Sustainability Metrics | $10 million |

| Strengthened Resilience | $30 million |

| Total Financial Benefits | $150 million |

The financial impact stems from improved forecasting, optimized delivery routes, and predictive maintenance. These efficiencies also bolster Coca-Cola's sustainability goals by reducing fuel consumption and overproduction.

Furthermore, the company's AI system analyzes production trends to predict potential machinery failures. This allows maintenance teams to intervene before large-scale errors occur, strengthening operational resilience. This same principle of digital simulation extends to product development, where AI helps create "digital twins" of new beverage formulations. This process drastically reduces the time and cost associated with bringing innovative products to market.

Unilever's Strategy for AI in the Food Industry

Unilever takes a deeply integrated approach to AI, embedding it across its operations from consumer insight discovery to final product delivery. The company leverages advanced analytics to not only understand what consumers want today but also to predict what they will desire tomorrow. This forward-looking strategy is a cornerstone of its success with ai in the food industry.

Unearthing Trends with Data Analytics

Unilever excels at using AI to listen to the digital world. The company employs a sophisticated 'social listening' approach, analyzing vast amounts of social media data to identify emerging consumer trends in real-time. This method helped it discover a growing demand for smaller, on-the-go treats, leading to the creation of the Magnum Mini ice cream. The product launch was a major success, contributing 13% to total ice cream sales in its initial markets. This same technique allowed the Knorr brand to localize its #UnlockYourGreenFlag campaign by analyzing dating culture conversations, boosting engagement across 23 global markets.

This data-driven insight directly fuels product innovation. Unilever’s DataLab uses generative AI and predictive models for in-silico R&D, dramatically accelerating the development cycle. This application of ai in the food industry has produced tangible results:

- Hellmann’s Vegan Mayonnaise: To meet the growing vegan trend, AI models predicted ingredient compatibility and consumer flavor preferences. This allowed Unilever to replace egg proteins with plant-based alternatives, like modified corn starch, and optimize the formula for multiple countries without lengthy physical trials.

- Knorr Zero Salt Cube: AI analyzed millions of flavor combinations to create a zero-sodium stock cube. The system identified the perfect blend of ingredients like glucose syrup and spices to mask the absence of salt, a feat nearly impossible with conventional methods.

To manage this complex process, Unilever developed in-house systems like Polaris, an AI-powered platform that optimizes its global product portfolio by recommending which products to grow, fix, or delist. The company also empowers its teams with no-code AI platforms, allowing analysts to build predictive models using a simple drag-and-drop interface. This strategy has paid off, leading to a 30% increase in the success rate of new product launches.

With great data comes great responsibility. Unilever acknowledges the ethical dimensions of using consumer data and has implemented a robust AI assurance process to govern every new application.

The company partners with the firm Holistic AI to manage this review process. Each AI solution is scored using a 'traffic-light' system to ensure it meets strict standards for fairness, privacy, and transparency.

- A proposal for a new AI use case is submitted for internal review.

- Potential ethical risks like bias or privacy are identified and mitigations are planned.

- After development, statistical tests check for fairness and efficacy.

- Applications are scored; a 'red' score signifies non-compliance and results in rejection.

This framework ensures that human oversight remains critical and that the use of ai in the food industry remains ethical and accountable.

Optimizing Cold Chain Logistics

For a company with a massive portfolio of perishable goods like ice cream, managing the cold chain is a monumental task. Unilever applies AI to transform this logistical challenge into a competitive advantage. The company’s Integrated Operations (iOps) program uses advanced analytics to create a smarter, more resilient supply chain.

Unilever deploys a suite of AI technologies to maintain product integrity from the factory to the freezer. The system analyzes real-time data from multiple sources:

- IoT Sensors: Provide ground-truth data on temperature and stock levels inside freezers and trucks.

- Weather Data: AI models analyze weather forecasts to predict spikes in demand for products like ice cream, allowing for proactive adjustments in production and distribution.

- AI-Enabled Freezers: Over 100,000 smart freezers globally use image recognition to provide real-time inventory updates, preventing stockouts and reducing excess inventory that could lead to waste.

This intelligent system delivers powerful results. By analyzing historical sales data alongside weather predictions, AI-driven demand forecasting minimizes overproduction and spoilage. In its factories, a live AI system optimizes production variables, saving up to 10% on raw materials like chocolate and dairy.

The impact extends to transportation. In the UK, Unilever uses digital twins to simulate its ice cream and frozen food distribution network. This model considers vehicle telemetry, traffic, and weather to optimize delivery routes. The initiative resulted in a 6% increase in delivery punctuality and double-digit improvements in energy efficiency, proving that a well-executed AI strategy can deliver both financial and sustainability wins.

Coca-Cola and Unilever demonstrate AI's dual value. They enhance creative engagement and drive operational efficiency. Their success with ai in the food industry offers a clear lesson for other brands.

The key takeaway is to apply AI to solve specific business problems, not just adopt technology for its own sake.

Success comes from identifying a clear challenge and deploying AI as the targeted solution.

FAQ

What is the main lesson from these AI case studies?

Success comes from applying AI to solve specific business problems. Brands identify a clear challenge, then deploy AI as a targeted solution to achieve measurable results.

How do these companies use different types of AI?

Coca-Cola uses generative AI for creative marketing. Unilever uses predictive analytics for trend forecasting and supply chain optimization. Both use computer vision for quality control and operations.

Why is AI so effective in the food and beverage industry?

AI processes vast data for trend spotting and accelerates product R&D. It also optimizes complex supply chains. This enhances creativity, efficiency, and profitability in a competitive market.

See Also

Unveiling Designer Ingenuity Through the Artistry of Computer Chips

Essential Industrial Checkweighers: A Must-Have for Every Food Processing Plant

Comparing Leading Ampoule Filling Production Line Manufacturers: An In-Depth Look

A Retrospective: Examining CRN's Significant Growth and Industry Impact

Six Indispensable Industrial Vacuum Cleaners for Optimal Business Operations