Next-Generation Dried Pear Sorting Technology Explained

An automated technology, optical sorting, utilizes high-speed cameras and sensors. It inspects every single dried pear on the production line. This process instantly identifies and removes imperfect pears and foreign materials. The result is a safer, higher-quality product for consumers. A dried pears sorting machine is crucial for achieving this level of excellence.

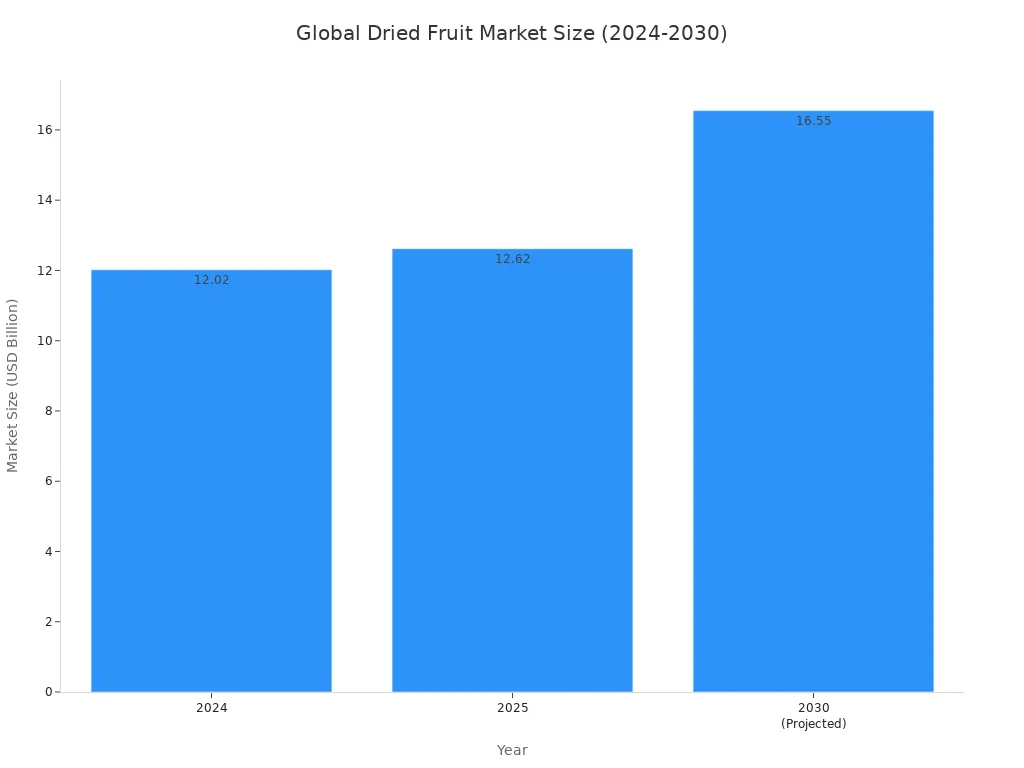

The global dried fruit market is experiencing significant growth. Projections show the market expanding from USD 12.02 billion in 2024 to USD 16.55 billion by 2030. This expansion highlights the increasing consumer demand for high-quality dried fruit products.

Note: Advanced sorting technology plays a vital role in meeting this growing demand by ensuring product consistency and safety, which are key drivers in the market.

How a Dried Pears Sorting Machine Works

A dried pears sorting machine executes a sophisticated three-step process to guarantee product quality. This operation happens in fractions of a second, ensuring a continuous and efficient production flow. Each step plays a critical role in identifying and removing imperfections.

Step 1: High-Speed Camera Inspection

First, dried pears travel at high speeds on a conveyor belt. The dried pears sorting machine uses advanced cameras and sensors to capture detailed images of every single pear from multiple angles. These are not ordinary cameras; they operate across different light spectrums to see what the human eye cannot.

Advanced systems employ InGaAs-based short-wave infrared (SWIR) and NIR detectors. This technology allows the machine to analyze the fruit's chemical composition, assessing internal qualities like moisture levels and sugar content for superior taste and texture.

Step 2: Real-Time Image Analysis

Next, the system's software instantly analyzes these images. It compares each pear to a database of pre-defined quality standards set by the producer. The powerful processing unit identifies defects with incredible accuracy. The analysis flags items based on:

- Color variations or discoloration

- Size and shape irregularities

- Blemishes, mold, or foreign material

This digital inspection ensures that only pears meeting the exact specifications proceed to the next stage.

Step 3: Precise Air-Jet Rejection

Finally, when the analysis identifies a defective pear or foreign object, the dried pears sorting machine acts immediately. The system pinpoints the exact location of the unwanted item on the conveyor. A series of small, powerful air jets are positioned along the line. The machine targets the identified item with a precise puff of air, knocking it into a rejection bin. This action removes the unwanted pear seamlessly without interrupting the flow of high-quality products.

The Direct Benefits for Your Dried Pears

Implementing next-generation optical sorting technology delivers significant and measurable improvements to the final product. This advanced process elevates dried pears beyond basic quality control. It creates a premium product defined by safety, visual perfection, and exceptional flavor. Each benefit directly results from the machine's precision and analytical power.

Unmatched Food Safety

Food safety remains the highest priority for producers and consumers. Optical sorters provide a powerful defense against a wide range of contaminants. The technology identifies and removes dangerous foreign materials with incredible accuracy. This ensures the final product is free from physical hazards. Sophisticated systems can detect and eject numerous unwanted items, including:

- Plastic fragments

- Shards of glass or metal

- Stones and wood chips

- Extraneous vegetable matter (EVM) like leaves or stems

Beyond visible debris, optical sorters also combat microscopic threats like mycotoxins. Certain molds produce these toxic compounds, such as aflatoxin, which are invisible to the naked eye. Advanced sorters use UV light to scan each pear. Aflatoxin naturally fluoresces a greenish-gold color under UV light, allowing the machine to instantly identify and reject the contaminated fruit. This capability is crucial for meeting strict international food safety regulations.

| Mycotoxin | Category of Dried Fruits | Aflatoxin B1 (µg/kg) | Sum of Aflatoxins (B1, B2, G1, G2) (µg/kg) | Ochratoxin A (µg/kg) |

|---|---|---|---|---|

| Aflatoxins | Dried fruits to be sorted/treated | 5.0 | 10.0 | N/A |

| Aflatoxins | Dried fruits as sole ingredient | 2.0 | 4.0 | N/A |

| Aflatoxins | Dried figs | 6.0 | 10.0 | N/A |

| Ochratoxin A | Dried vine fruits & dried figs | N/A | N/A | 8.0 |

| Ochratoxin A | Other dried fruits | N/A | N/A | 2.0 |

Consistent Color and Appearance

Consumers associate vibrant, uniform color with quality and freshness. A dried pears sorting machine ensures every pear in the package meets a precise aesthetic standard. It differentiates between acceptable, natural color variations and undesirable discoloration from mold, rot, or over-drying. The system achieves this through a combination of advanced imaging technologies.

- High-Resolution Cameras capture detailed images to spot subtle surface defects and color inconsistencies.

- Multi-Spectral Imaging uses a wider spectrum of light to detect internal defects like rot that are not yet visible on the surface.

- Near-Infrared (NIR) Sensors assess the pear's internal structure, identifying early signs of mold or decay.

- Artificial Intelligence (AI) allows the system to learn and make smarter decisions, distinguishing between harmless blemishes and genuine spoilage.

This meticulous inspection guarantees a visually appealing product. It removes discolored, blemished, or misshapen pears, resulting in a package filled with consistently beautiful fruit.

Superior Taste and Texture

The quality of a dried pear ultimately comes down to its taste and texture. Optical sorting technology directly enhances this sensory experience. By removing under-ripe, over-ripe, or mold-affected pears, the system eliminates sources of off-flavors and unpleasant textures.

Technology Tip: Advanced NIR and SWIR sensors analyze the chemical composition of each pear. This allows the machine to assess internal qualities like moisture and sugar content. Pears with improper moisture levels, which lead to a tough or mushy texture, are rejected. This ensures every pear has the ideal chewiness and sweetness. 🍐

This internal analysis goes beyond surface-level inspection. It guarantees that the pears in the final package are not only safe and visually perfect but also consistently delicious. The result is a premium eating experience with uniform flavor and texture from the first bite to the last.

Optical sorting technology is essential for producing premium dried pears. This advanced process improves product quality by up to 99% and can deliver a return on investment in under two years. Leading producers like Mariani utilize this system, guaranteeing a final product free from defects, contaminants, and inconsistencies.

FAQ

How fast can a sorting machine process dried pears?

The technology processes thousands of individual pears per minute. This high-speed capability ensures a continuous and efficient production flow without sacrificing accuracy, meeting the demands of large-scale operations.

Can this technology sort other types of dried fruit?

Yes. Producers can calibrate the system to sort various dried fruits like apricots, figs, and raisins. The software's quality parameters are adjustable for different product sizes, colors, and textures.

What is the main advantage over manual sorting?

Optical sorters provide superior speed, consistency, and accuracy. They operate 24/7 and detect microscopic defects invisible to the human eye, ensuring a higher standard of safety and quality.

See Also

Capsule Sorters: Essential Technology for Flawless Product Defect Elimination

Exploring Innovative Folder Gluer Features for Advanced 2025 Carton Production

Tablet Sampling Machines: A Comprehensive Guide for Optimal Lab Selection

Crucial Revisions and Updates in Bearing Box Freight Classification Standards

Pharmaceutical Checkweighers: Understanding Their Definition and Core Functionalities