A 2025 Guide to Improving Fig Quality with Optical Sorters

A dried figs sorting machine enhances product quality by removing figs with discoloration or improper size. It guarantees food safety by ejecting foreign materials and figs with aflatoxin. This technology directly increases profitability, boosts throughput, reduces labor costs, and maximizes yield.

Enhancing Product Quality and Safety

Modern fig processors rely on advanced technology to meet stringent quality and safety standards. An optical sorter inspects each fig with incredible speed and precision. It uses a combination of high-resolution cameras and specialized sensors to analyze color, size, shape, and even chemical composition. This process ensures that only the highest quality figs reach the consumer, protecting both public health and brand reputation.

Eliminate Color and Blemish Defects

A fig's appearance is the first indicator of its quality to a consumer. Processors must therefore remove any product that fails to meet visual expectations. Optical sorters excel at this task by identifying and ejecting figs with a wide range of cosmetic flaws. These systems guarantee a final product with a uniform and appealing look.

Common defects that impact market value include:

- Areas of discoloration

- Superficial blemishes

- Deteriorated figs, identified by off-colors from sugar crystallization or damage

High-resolution color cameras scan every fig, comparing it against pre-defined quality parameters. Any fig exhibiting unwanted color variations or surface marks is instantly removed from the processing line by a precise puff of air. This automated vigilance ensures a consistent, premium-grade appearance batch after batch.

Remove Damaged and Misshapen Figs

Physical integrity is just as important as color. Damaged or irregularly shaped figs detract from product value and can indicate underlying quality issues. Bird pecking is the main cause of physical damage to figs during cultivation. Insects and fungi also contribute significantly to these defects.

Premium-grade standards demand consistency. For example, U.S. Grade A requires whole figs to be "practically uniform in size." Different fig styles also have specific shape expectations:

- Lerida Figs: Valued for high visual appeal, they are hand-pressed into a flat, disk shape.

- Protoben Figs: These are plump, rounded, and retain their natural, more compact shape.

- Pulled Figs: These are characterized by a flat, slightly sticky appearance.

A modern dried figs sorting machine uses a combination of cameras and laser scanning to create a 3D model of each fig. It analyzes the fig's size, volume, and shape, ejecting any that are broken, misshapen, or fail to meet the specific criteria for styles like Lerida or Protoben.

Target Aflatoxin with Specialized Sensors

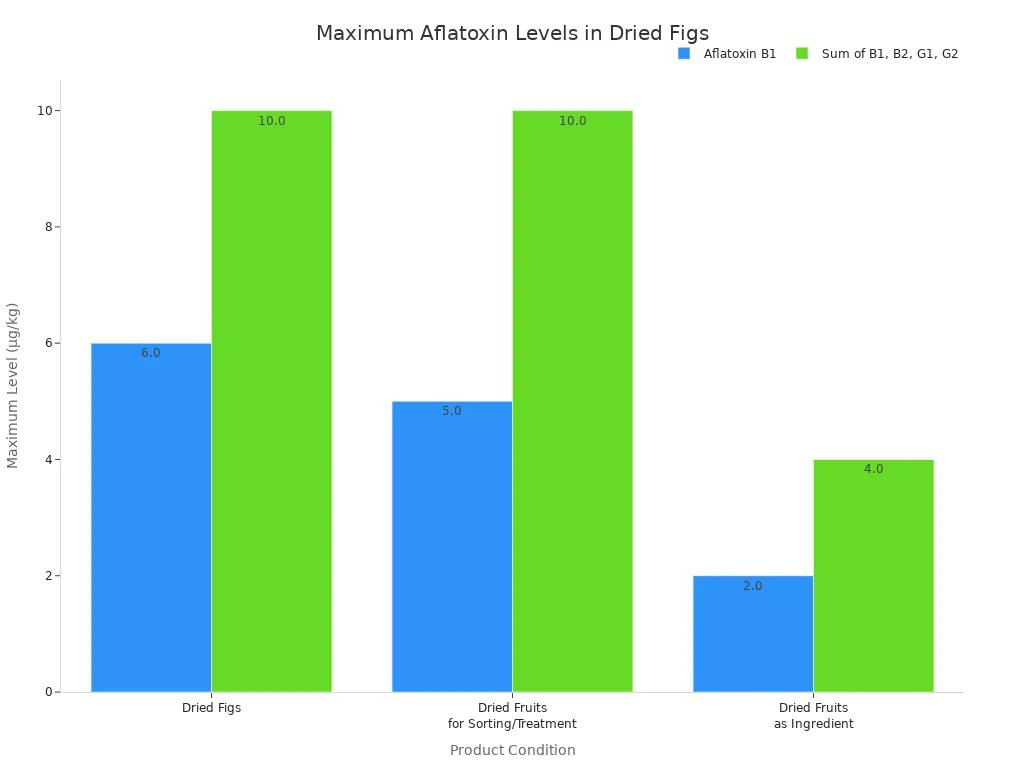

Aflatoxin is a toxic compound produced by certain molds, posing a severe health risk to consumers. Global food safety agencies enforce strict limits on its presence. The European Union, for instance, prohibits dried figs from entering the market if they exceed a maximum level of 6.0 μg/kg for Aflatoxin B1 or 10.0 μg/kg for total aflatoxins. In contrast, the USA has a more lenient total aflatoxin limit of 20 ppb with no specific limit for Aflatoxin B1.

| Aflatoxin Type | Maximum Level (μg/kg) in the EU |

|---|---|

| Aflatoxin B1 (dried figs) | 6.0 |

| Sum of B1, B2, G1, G2 (dried figs) | 10.0 |

| Aflatoxin B1 (for sorting/treatment) | 5.0 |

| Sum of B1, B2, G1, G2 (for sorting/treatment) | 10.0 |

Note: Detecting aflatoxin is non-negotiable for food safety. Advanced sorters use specialized sensors that can identify contamination invisible to the human eye.

These sorters employ multispectral UV fluorescence imaging. Aflatoxin-producing molds create a compound called kojic acid, which emits a bright greenish-yellow fluorescence (BGYF) under UV light. Sorters equipped with UV lighting and specialized cameras detect this glow. A prototype system using this method achieved a 98% success rate in detecting and separating contaminated figs, far surpassing older manual screening methods that could misidentify contaminated and clean figs.

Eject Foreign Material Contaminants

Foreign materials like stones, plastic, glass, or wood pose a significant safety hazard and can lead to costly recalls and brand damage. In one notable case, several brands of fig spread were recalled because they potentially contained stones, creating a choking and mouth injury risk.

| Product Type | Brand(s) | Reason for Recall |

|---|---|---|

| Fig Spread | Earl’s, Recipe, Woolrich | May contain foreign material (stones) |

| Fig Spread with Balsamic Vinegar | Woolrich | May contain foreign material (stones) |

To prevent such incidents, advanced optical sorters utilize Short-Wave Infrared (SWIR) technology. SWIR sensors can differentiate materials based on their chemical makeup. Organic products like figs have high moisture content and absorb SWIR light, making them appear dark in sensor images. In contrast, inorganic foreign materials like stones or plastic reflect SWIR light and appear bright. An InGaAs sensor captures these differences, allowing the system to instantly identify and eject contaminants with unmatched accuracy.

Identify Mold and Rot

While some blemishes are cosmetic, mold and rot are serious defects that indicate spoilage. Dried figs are susceptible to various molds, primarily from the Aspergillus family.

- Aspergillus flavus and Aspergillus parasiticus are common and can produce aflatoxins.

- Other species like A. niger (black mold) and Penicillium can also grow during processing and storage.

- Different molds cause distinct discoloration, from the bright green of A. flavus to the dark green of A. parasiticus.

An optical sorter differentiates harmful mold from simple blemishes using multiple technologies. As mentioned, it detects the BGYF signature associated with aflatoxin-producing molds. Beyond that, its high-resolution color cameras can be programmed to identify the specific colors associated with different types of rot. Furthermore, newer systems incorporate Near-Infrared (NIR) sensors. These sensors can detect subtle variations in moisture content and chemical composition, allowing the sorter to identify internal rot or decay that may not be visible on the fig's surface.

How a Dried Figs Sorting Machine Boosts Efficiency and Profitability

Beyond ensuring quality and safety, optical sorting technology delivers a powerful return on investment by transforming operational efficiency. Processors who adopt these systems gain a significant competitive advantage. They streamline their production lines, reduce operational waste, and ultimately increase their profitability.

Increase Throughput and Reduce Labor Costs

Manual sorting is a primary bottleneck in fig processing. It is slow, labor-intensive, and subject to human limitations. A modern dried figs sorting machine shatters these constraints by automating the entire inspection process. These systems operate at speeds far exceeding human capability, processing several tons of product per hour. This dramatic increase in throughput allows processors to meet demanding production schedules and scale their operations effectively.

The shift from manual labor to automation directly addresses several key challenges:

- High costs associated with hiring, training, and retaining a large sorting workforce.

- Inconsistent performance due to worker fatigue or variations in judgment.

- The inability to operate continuously for 24/7 production cycles.

By automating the sorting line, a facility can reallocate its workforce to more value-added tasks. This reduces direct labor expenses and minimizes the indirect costs of managing a large manual team. The result is a leaner, more efficient, and highly productive operation. 📈

Maximize Yield by Minimizing Good Product Rejection

Profitability in food processing depends heavily on maximizing yield—the amount of sellable product generated from the raw material. A critical factor in yield loss is the false rejection rate, where perfectly good products are mistakenly discarded. Human sorters, especially during long shifts, are prone to making these costly errors.

A dried figs sorting machine minimizes this waste with its exceptional accuracy. The system evaluates each fig against objective, pre-programmed quality standards. It does not get tired or lose focus. This consistency ensures that good figs are not accidentally removed from the production line.

| Feature | Manual Sorting | Automated Sorting |

|---|---|---|

| Accuracy | Variable, decreases with fatigue | Consistently high (98%+) |

| Consistency | Low; varies between sorters | High; based on fixed parameters |

| False Rejects | Higher rate, increases over time | Extremely low and predictable |

| Speed | Slow; limited by human ability | Very fast; tons per hour |

By precisely separating only the defective items, the sorter maximizes the volume of premium-grade figs. This careful preservation of good product translates directly into higher revenue and improved profit margins for the processor.

Investing in a dried figs sorting machine is a direct investment in superior quality, safety, and profitability. The technology drives operational efficiency and maximizes product yield.

Adopting these systems is essential for modern processors. It protects brand reputation and secures a competitive edge by building consumer trust through enhanced quality control.

FAQ

How does the sorter handle different fig varieties?

Processors adjust software settings for each fig variety. The sorter then analyzes unique size, shape, and color profiles, ensuring accurate sorting for styles like Lerida or Protoben.

Can an optical sorter detect internal rot?

Yes, advanced sorters use Near-Infrared (NIR) technology. This allows the machine to detect subtle differences in moisture and composition, identifying internal decay not visible on the fig's surface.

How fast can these machines sort figs?

A modern optical sorter processes several tons of dried figs per hour. This high-speed capability dramatically increases production line throughput compared to slower, inconsistent manual sorting methods.

See Also

Capsule Sorters: Essential Tools for Effective Defect Elimination and Quality Control

Top Capsule Checkweighers for Buyers to Evaluate in the Coming Year

Innovative Folder Gluer Features Revolutionizing Carton Production Lines in 2025

Three Key Methods PHE Plates Boost System Efficiency by 2025

Essential Industrial Checkweighers Every Modern Food Processing Plant Requires Today