Your Hemp Seeds Optical Sorter Questions Answered Simply

The hemp seed market grows rapidly; Zion Market Research projects it will reach about USD 13.89 billion by 2032. A hemp seeds optical sorter uses cameras and AI for up to 99.9% purity. Mechanical sorters are a less precise, affordable option, separating seeds by physical traits like size.

How Do Optical and Mechanical Sorters Work?

Understanding the technology behind each sorter clarifies its role in achieving seed purity. Optical sorters act as a digital inspector, while mechanical sorters function as a physical sieve. Each uses a distinct method to separate desirable seeds from contaminants.

The Optical Sorter: A High-Tech Eye

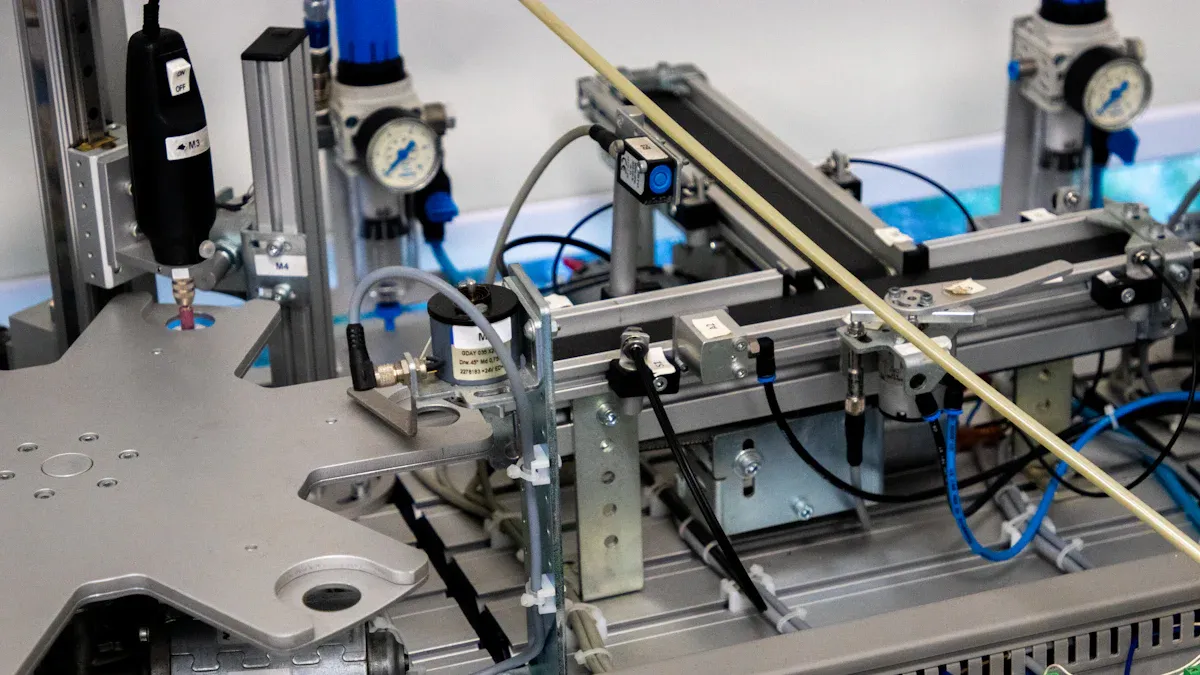

A hemp seeds optical sorter uses advanced imaging to achieve precision sorting. The process is a rapid, multi-stage operation.

- Feeding: Vibratory feeders gently spread hemp seeds into a single, uniform layer.

- Inspection: High-speed CCD cameras capture full-color images of every seed from multiple angles. AI-powered deep learning algorithms analyze these images in real-time. The system detects subtle defects like discoloration, spots, wrinkles, or incorrect shapes that traditional machines miss.

- Ejection: When the AI identifies a defective seed or foreign material, it signals a high-speed air jet. The jet fires a precise puff of air, ejecting the unwanted particle from the main product stream with incredible accuracy.

Pro Tip: Advanced systems integrate Near-Infrared (NIR) and Short-Wave Infrared (SWIR) technology. This allows the sorter to detect internal defects and material composition differences invisible to the human eye.

The Mechanical Sorter: A Physical Filter

Mechanical sorters separate seeds based on physical characteristics like size, shape, and density. They do not use cameras or AI. Two common types are screen graders and gravity separators.

A screen grader uses a series of stacked screens with different-sized perforations. As seeds pass over them, smaller seeds fall through the holes while larger ones remain on top, effectively sorting the batch by size.

A gravity separator uses a vibrating, inclined table. It separates seeds by density. Heavier, more viable seeds travel to the higher side of the table, while lighter, immature seeds and debris vibrate toward the lower side. This method is excellent for bulk cleaning but lacks the precision of optical sorting.

Why Use a Hemp Seeds Optical Sorter Over a Mechanical One?

Choosing between sorting technologies directly impacts product quality, operational efficiency, and brand reputation. While mechanical sorters offer a baseline level of cleaning, a hemp seeds optical sorter provides distinct advantages that are critical for producers aiming for the premium market. These benefits extend beyond simple purity to include speed and the preservation of seed integrity.

Unmatched Accuracy and Purity

The primary advantage of an optical sorter is its incredible precision. Mechanical sorters, which rely on size and density, can achieve a respectable separation efficiency of over 98.5%. However, they cannot detect subtle but critical flaws. A hemp seeds optical sorter elevates purity to a new level, consistently reaching up to 99.9%.

This superior accuracy comes from its advanced imaging technology. High-resolution cameras and AI algorithms identify a wide range of defects that mechanical methods miss entirely.

- Color Variations: It detects discoloration from improper drying, sun damage, or mold.

- Structural Defects: It spots cracked, wrinkled, or misshapen seeds.

- Chemical Composition: Advanced systems use hyperspectral imaging to analyze a seed's internal makeup, identifying its viability, ripeness stage, and even the presence of disease.

By removing compromised seeds, an optical sorter directly improves the final product's shelf life. Cracked or damaged seeds degrade faster and can harm the nutritional value of a batch. Eliminating these defects ensures greater shelf stability and protects the quality of premium shipments.

Higher Speed and Throughput

In a commercial operation, time is money. Optical sorters are engineered for high-volume processing without sacrificing accuracy. A specialized optical sorter can process between 1 and 3 tons of hemp seeds per hour. This high throughput allows businesses to scale production efficiently, meeting market demand without creating bottlenecks in the cleaning process.

Mechanical sorters, particularly gravity separators, often operate at slower speeds. They may also require more frequent stops for cleaning and calibration. The continuous, automated workflow of an optical sorter maximizes uptime and delivers a much higher volume of market-ready product in the same amount of time.

Gentler Handling for Better Seed Viability

Hemp seeds, especially those intended for planting or for producing high-quality oils, are delicate. Aggressive mechanical handling can cause cracks and abrasions, damaging the seed coat and reducing viability.

Optical sorters offer a significantly gentler process.

- Vibratory Feeding: Seeds are gently moved onto the inspection belt, minimizing impact.

- Non-Contact Inspection: Cameras and sensors analyze the seeds without touching them.

- Air Jet Ejection: A precise puff of compressed air is the only force used to remove defects. This non-contact method ensures that good seeds continue their path untouched and undamaged.

This gentle handling is crucial for preserving the seed's physical integrity, which is essential for maintaining germination potential and the quality of cold-pressed oils.

What Is the True Cost and ROI of Each Sorter?

An optical sorter is a significant investment, but it can deliver a substantial return by improving product quality and operational efficiency. A mechanical sorter has a lower initial cost, making it an accessible entry point for basic cleaning, but its long-term value is limited by its lower precision and efficiency.

Here’s a breakdown of the true cost and return on investment (ROI) for each.

Initial Investment: Optical vs. Mechanical

The upfront cost is the most significant difference between optical and mechanical sorters. Optical sorters represent a major capital expenditure, while mechanical sorters are far more affordable.

An industrial-scale optical sorter from a reputable manufacturer like GROTECH can range from $50,000 to $100,000. More budget-friendly options are available, with some models priced around $14,800 to $15,800 per unit. In contrast, a new mechanical sorter, such as a gravity separator, costs significantly less.

| Sorter Type | Average Price Range (USD) |

|---|---|

| Optical Sorter | $14,800 - $100,000+ |

| Mechanical Sorter | $1,600 - $1,800 |

Note: The price of an optical sorter varies based on its capacity, camera resolution, and advanced features like NIR or SWIR sensors.

Long-Term ROI: Quality and Efficiency

While the initial cost of an optical sorter is high, its long-term ROI often justifies the expense through labor savings, waste reduction, and access to premium markets.

Case studies show that upgrading to an optical sorter can yield impressive results. One facility reported the following improvements:

- Labor Costs: Reduced by 65% by replacing four manual graders with one machine operator.

- Throughput: Increased from 200 lbs/day to 500 lbs/day.

- Reject Rate: Dropped from 10% to just 3%, saving valuable product.

This combination of benefits led to a full ROI in just 10 months. For most mid-sized operations, a payback period of 12 to 18 months is realistic. The ability to sell a 99.9% pure product opens doors to higher-paying markets, further accelerating the return. Mechanical sorters have lower operational costs but do not provide the same level of waste reduction or premium market access, limiting their overall financial return.

Which Sorter Should Your Operation Choose?

Selecting the right sorter depends entirely on an operation's business goals, budget, and quality standards. The choice balances the high precision of optical sorting against the affordability of mechanical methods. Each machine serves a distinct purpose in the production line.

Choose Optical for Premium Quality

An operation should choose an optical sorter when its goal is to produce a premium, food-grade product for top-tier markets. This technology is essential for achieving the 99.9% purity that commands higher prices and builds brand trust. Meeting strict international standards for contaminants is also critical for export. Different regions have unique regulatory limits.

Global THC Limits for Hemp Seed Products (mg/kg)

Hemp Byproduct USA EU Canada Whole Seed 10 5 10 Seed Meal N/A 5 10

Achieving this level of purity consistently requires the precision that only an optical sorter can provide.

Choose Mechanical for Budget and Basic Needs

A mechanical sorter is the practical choice for startups, smaller farms, or businesses with limited capital. It provides essential pre-cleaning and basic sorting by removing oversized foreign material, dust, and some defective seeds. While it cannot achieve the purity required for premium food products, it is an effective tool for improving the overall quality of a harvest for less demanding applications like animal feed or initial processing.

The Hybrid Approach: Using Both

Most large-scale, efficient facilities adopt a hybrid approach, integrating both sorter types into a single, seamless workflow. This method delivers the best of both worlds: cost-effective bulk cleaning and high-precision final sorting.

- Pre-Cleaning: A mechanical sorter first removes large debris, stalks, and stones. This protects the more sensitive optical sorter from damage and overload.

- Final Polishing: The pre-cleaned seeds then flow to the hemp seeds optical sorter. Its cameras and AI perform the final, critical inspection, ejecting discolored, damaged, or misshapen seeds to guarantee 99.9% purity.

This integrated system maximizes throughput and ensures a final product of the highest possible quality.

The decision presents a clear trade-off: an optical sorter's precision versus a mechanical sorter's affordability. An operation's choice must align with its business goals. Premium market ambitions demand an optical sorter. Top-tier facilities often use a hybrid system, leveraging mechanical pre-cleaning and optical polishing for ultimate quality.

Future Outlook 🔮 The technology continues to advance with a focus on:

- Single seed detection and sorting.

- Comprehensive spectral signature databases.

- Intelligent, integrated grading equipment.

FAQ

Can an optical sorter handle different seed sizes?

Yes. Operators program the sorter's software for various seed sizes. The machine adjusts its parameters to ensure accurate sorting for different hemp varieties or batches.

How much maintenance does an optical sorter require?

Optical sorters need regular maintenance for peak performance. Key tasks include:

- Daily cleaning of cameras and the viewing area.

- Periodic calibration and software updates by technicians.

Can optical sorters remove non-hemp contaminants?

Yes, they excel at this task. The system identifies and ejects foreign materials like stones, glass, and unwanted grains. This capability is crucial for food-grade product safety.

See Also

Selecting the Ideal Tablet Sampling Machine for Your Laboratory Needs

Capsule Sorters: Essential Tools for Effective Defect Elimination

Versatile Nozzle Solutions for Gardening, Bioprinting, and Lubrication Applications

Demystifying the Operational Principles of Sterile Filtration Devices

Comparing Leading Manufacturers of Ampoule Filling Production Lines