The Ultimate Guide to Gummy Candy Optical Sorters in 2025

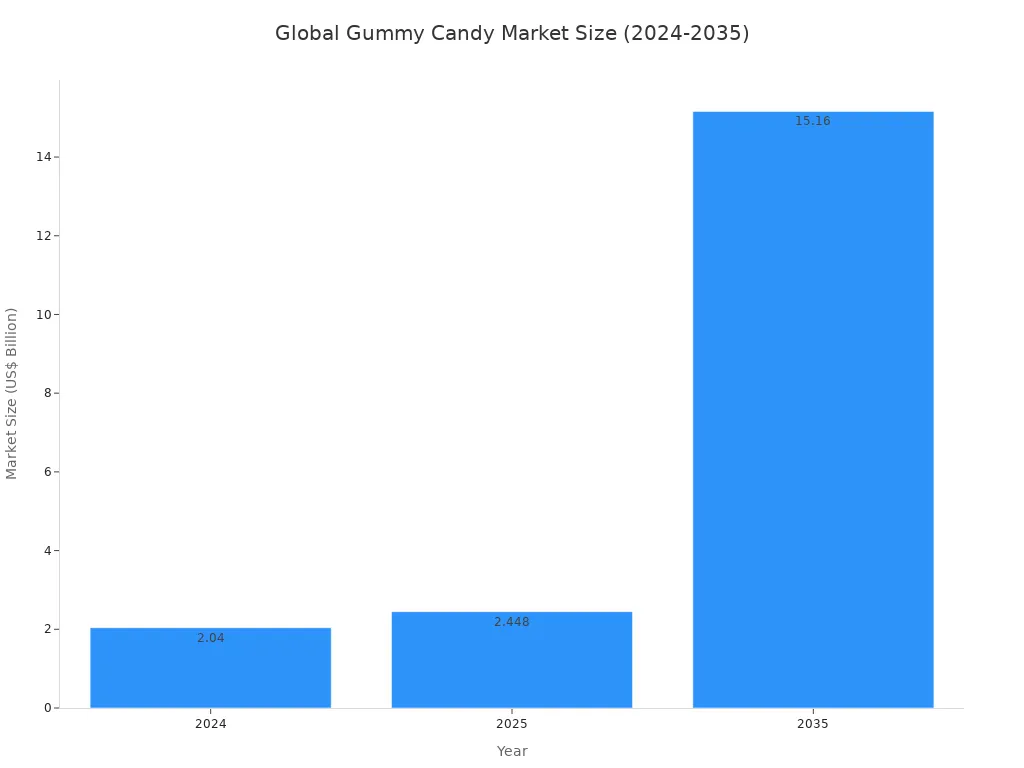

The global gummy candy market is experiencing explosive growth, demanding higher production standards from manufacturers. This rapid expansion highlights the need for advanced quality control technology.

A gummy candies optical sorter is an automated machine that meets this challenge. It uses advanced cameras, sensors, and AI to inspect products. The system identifies and removes items with defects in color, shape, or size, ensuring superior product quality and consistency for consumers.

How a Gummy Candies Optical Sorter Works

A gummy candies optical sorter operates through a sophisticated four-stage process. Each stage is meticulously engineered to ensure maximum accuracy and efficiency. The machine first stabilizes the products, then captures detailed images, analyzes them with artificial intelligence, and finally ejects any non-conforming items. This seamless workflow transforms quality control from a manual task into a high-speed, automated science.

Infeed and Product Stabilization

The sorting process begins with the infeed system. This stage carefully prepares the gummies for inspection. Proper handling is critical to prevent damage to the delicate candies and to ensure they are presented to the cameras correctly. The system uses several mechanisms to achieve a stable and consistent product flow.

- Gentle Handling Conveyors: These specialized conveyors move gummies smoothly along the line. They minimize impact and protect the product's shape and texture.

- Vibration Feeders: This equipment gently shakes the products to spread them evenly across the conveyor surface. This action prevents gummies from clumping together, ensuring each one can be inspected individually.

- Alignment Mechanisms: These systems orient each gummy into an ideal position before it reaches the inspection zone. Correct alignment is crucial for the cameras to capture a clear and comprehensive view of every product.

High-Resolution Image Capture

Once the gummies are stabilized, they enter the inspection zone. Here, advanced imaging systems act as the machine's eyes. High-resolution cameras capture detailed pictures of each candy from multiple angles. This comprehensive view is made possible by a sophisticated lighting environment. Modern sorters use high-brightness, full-spectrum LED cold light sources. These lights replicate natural sunlight to reveal the slightest color variations and defects. Some systems also employ multispectral technology, using RGB, SWIR (Short-Wave Infrared), and IR wavelengths to identify chemical differences invisible to the human eye. This powerful combination of high-definition 5400-pixel sensors and controlled lighting ensures the system captures a perfect, true-color image for analysis.

AI-Powered Defect Analysis

The captured images are instantly sent to the system's central processor, which functions as its brain. This is where AI-powered software performs its critical analysis. The AI algorithms compare each gummy's image against a pre-programmed set of quality parameters. These standards define the ideal color, shape, size, and texture. The software can identify a wide range of defects in milliseconds, including:

- Incorrect colors or color spots

- Malformed or conjoined shapes

- Size deviations (too large or too small)

- Embedded foreign materials

Pro Tip: Manufacturers can use AI-assisted training to improve sorting accuracy. Operators simply tag images of products as 'good' or 'reject,' allowing the machine learning model to quickly learn and adapt to new product types or specific defect criteria.

Precise Air-Jet Ejection

The final stage is the physical separation of defective products. When the AI identifies a non-conforming gummy, it signals a bank of high-speed air jets. The system tracks the exact position of the defective item on the conveyor. At the precise moment, the corresponding air nozzle releases a quick, powerful puff of compressed air. This action ejects the single defective gummy from the main product stream into a separate rejection bin.

The entire process is designed for maximum precision to minimize the accidental removal of good products. A modern gummy candies optical sorter achieves this through several key features:

- Belt-fed systems maintain a consistent product speed, reducing errors.

- Dual-camera setups (top and bottom) capture both sides of an object for a more thorough inspection.

- Product tracking software classifies each item, preventing good gummies from being mistakenly ejected.

- Intelligent sorting strategies can program the machine to eject the material present in the smaller quantity, maximizing the purity of the final product.

This precise and automated ejection process guarantees that only the highest quality gummies proceed to packaging, upholding brand standards and ensuring consumer satisfaction. The efficiency of a gummy candies optical sorter directly contributes to higher throughput and reduced product waste.

Why Invest and What to Look For

Investing in an optical sorter is a strategic decision that moves a confectionery business toward greater efficiency, quality, and profitability. These machines are more than just quality control tools; they are comprehensive solutions that address core manufacturing challenges. From ensuring every gummy meets brand standards to optimizing production flow, the benefits are immediate and substantial. Understanding these advantages and knowing what to look for in a machine are the first steps toward a successful implementation.

Boost Product Quality and Consistency

Consumers expect every gummy in the bag to look and taste perfect. An optical sorter ensures this level of consistency by automating the inspection process with unparalleled accuracy. Unlike manual inspection, which is prone to human error and fatigue, an automated system works tirelessly to identify and remove imperfect products.

It detects a wide range of defects, including color variations, size discrepancies, and malformed shapes like clumps or conjoined gummies. Advanced systems, such as VERYX digital sorters, use object-based sorting and sophisticated shape algorithms to achieve this. By targeting the object's center of mass, intelligent ejection technology improves accuracy and minimizes the accidental removal of good products. This precision guarantees that only gummies meeting the highest quality standards reach the consumer, protecting brand reputation and fostering customer loyalty.

Increase Production Throughput

Manual sorting creates a significant bottleneck in the production line, limiting overall output. A gummy candies optical sorter eliminates this constraint, enabling a continuous and rapid flow of products. Modern sorters can process materials at incredible speeds. Some advanced systems, like the VARISORT+, achieve high accuracy at throughputs reaching 8 tons per hour. Other models with deep learning AI and valve-block ejection can process up to 6 tons per hour.

This dramatic increase in processing capacity allows manufacturers to meet growing market demands and scale their operations effectively. A case study from the recycling industry highlights this principle: an upgraded sorting facility increased its processing capacity by 173% to 30 tons per hour. This demonstrates the direct link between sorting technology and production volume, allowing businesses to maximize their output without compromising quality.

Enhance Food Safety Standards

Food safety is non-negotiable in the confectionery industry. Optical sorters play a critical role in upholding these standards by identifying and removing foreign materials (FM) from the production line. These systems are a key component of a comprehensive food safety plan, helping manufacturers comply with regulations like HACCP (Hazard Analysis and Critical Control Points) and GFSI (Global Food Safety Initiative).

Advanced sorters use cameras and sensors to find and remove contaminants before they reach later processing stages. For example, Key Technology's VERYX digital sorters can detect and eject all types of foreign materials, including fragments of plastic or wood from broken trays. This capability significantly lowers contamination risks, preventing dangerous materials from being packaged with the final product and ensuring consumer safety.

Reduce Labor Costs and Product Waste

Automating the sorting process delivers significant financial benefits. It reduces the reliance on manual labor for inspection, freeing up employees to perform more value-added tasks. This shift directly lowers operational costs and addresses challenges related to labor shortages and training.

Furthermore, optical sorters minimize product waste. Manual sorting is often imprecise, leading to a high volume of good products being discarded along with the bad. AI-powered optical sorting, however, achieves a much higher level of accuracy.

| Sorting Method | Accuracy Rate |

|---|---|

| Manual Sorting | 65-80% |

| AI-powered Optical Sorting | >95% |

This superior accuracy means less acceptable product is wasted, maximizing yield from every production run. The combination of reduced labor expenses and minimized product loss results in a direct and measurable improvement to the company's bottom line.

Key Selection Criteria

Choosing the right optical sorter requires a careful evaluation of several factors. A thorough assessment ensures the selected machine aligns with specific production needs and delivers the best long-term value.

-

Sorting Accuracy and Capabilities: Different models offer varying levels of precision. While most sorters can handle basic color and size sorting, specialized systems provide superior performance for complex defects. Manufacturers should look for machines with advanced hardware, such as NIR (Near-Infrared) sensors, and machine learning algorithms that can accurately identify conjoined gummies, subtle color flaws, and embedded foreign materials. The accuracy of a sorter, much like specialized systems in other industries, depends on proprietary algorithms and optimized rejection mechanisms.

-

Throughput and Capacity: The sorter's capacity, measured in tons per hour, must match or exceed the facility's production volume. Selecting a machine with inadequate throughput will create a new bottleneck, defeating the purpose of the investment. Evaluate current output and projected growth to choose a system that can scale with the business.

-

Software and Ease of Use: The user interface (UI) is critical for efficient operation. Modern sorters feature intuitive, smartphone-like interfaces that allow operators to become proficient in under 30 minutes without extensive technical training. Additionally, powerful data analytics software, such as Key Discovery, transforms the sorter into an IIoT-connected device. It provides valuable data on product quality and line performance, enabling data-driven decision-making.

-

Maintenance and Durability: Regular maintenance is essential for optimal performance and longevity. Look for systems designed for easy cleaning and service. Adhering to the manufacturer's guidelines for inspecting components, lubricating parts, and using food-grade cleaning solutions will prevent contamination, minimize downtime, and extend the equipment's lifespan. Poorly maintained equipment can lead to costly failures and wasted materials.

-

Total Cost of Ownership (TCO) and Support: The initial purchase price is only one part of the total investment. A comprehensive TCO analysis should include:

- Purchase price

- Installation and training

- Energy consumption

- Annual maintenance (typically 3-7% of the initial price)

- Availability of after-sales support

Prices vary widely, from mid-range Chinese models ($5,000-$30,000) to premium systems like the Buhler Sortex A (around $46,000) or high-end TOMRA machines ($400,000-$700,000). Prioritize suppliers who offer robust support, including remote diagnostics, certified training programs, and strong performance warranties.

A gummy candies optical sorter is a critical investment for manufacturers seeking to enhance quality, efficiency, and brand trust. By automating inspection, this technology delivers a significant return on investment through superior output and prepares companies for future advancements like AI-powered sorting and hyperspectral imaging.

FAQ

Can an optical sorter handle sticky gummies?

Yes. Modern sorters use non-stick coatings and specialized conveyors. These features prevent clumping and ensure a smooth, consistent flow of product for accurate inspection and sorting.

How long does it take to switch between different gummy products?

Product changeover is rapid. Operators can load pre-saved sorting profiles from the user interface. This feature minimizes downtime and allows for quick transitions between different gummy types.

Can these sorters integrate with existing production lines?

Absolutely. These machines are designed for seamless integration. Their compact footprint allows them to fit easily into existing production lines, typically between the cooling and packaging stages.

See Also

Essential Folder Gluer Innovations for Modern Carton Production Lines in 2025

Capsule Sorters: Key to Efficient Defect Elimination in Pharmaceutical Manufacturing

Top Capsule Checkweighers for Smart Buyers to Evaluate in 2025

Three Indispensable Industrial Checkweighers for Every Modern Food Processing Plant

Leading Precoating Materials Revolutionizing Filtration System Performance and Efficiency by 2025