The Complete Guide to Selecting Ginger Processing Equipment

A business first calculates its required processing volume. Different machines offer varied capacities, from manual methods to motorized units.

The final product form dictates the necessary equipment, from a ginger sorting machine to grinders. This investment aligns with a rapidly expanding global market.

Global Processed Ginger Market Outlook 📈 The demand for processed ginger is growing, driven by health trends and culinary applications.

Metric Value Market Value in 2024 USD 4.01 Billion Market Value by 2030 USD 6.88 Billion CAGR (2025-30) 9.41%

Step 1: Define Your Production Needs

A successful equipment investment starts with a clear definition of production goals. A business must first analyze its specific operational requirements. This foundational step ensures the selected machinery aligns perfectly with its objectives, preventing costly mismatches and maximizing efficiency from day one.

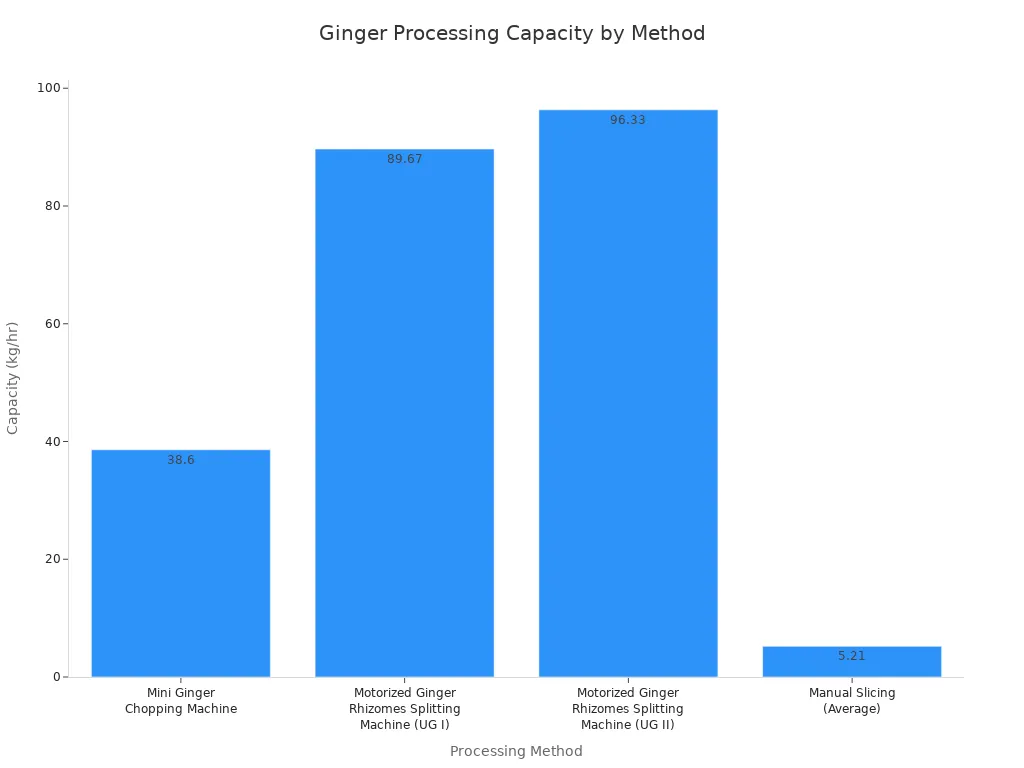

Calculate Required Capacity and Throughput

A business calculates its required processing capacity. This figure, often measured in kilograms per hour (kg/hr) or tons per day, guides every subsequent decision. Key factors influence this calculation:

- Raw Material Availability: Assess the consistent supply of fresh ginger.

- Market Demand: Evaluate the sales volume your target market can support.

- Operational Hours: Determine the number of hours the processing line will run daily.

A precise calculation prevents over-investing in oversized equipment or under-investing in a system that creates bottlenecks.

Identify Your Final Ginger Product

The intended final product directly dictates the necessary machinery. Each form of processed ginger requires a unique set of equipment. A business must identify its target product to build the correct processing line.

| Final Product | Essential Equipment |

|---|---|

| Dried Slices/Powder | Slicer, Dryer, Grinder |

| Ginger Paste | Peeler, Grinder/Pulper |

| Ginger Juice | Juicer/Extractor, Filter |

| Fresh-Cut Slices | Washer, Peeler, Slicer |

Set Your Budget and ROI Expectations

A business establishes a realistic budget for its equipment investment. This financial plan should extend beyond the initial purchase price.

Financial Planning Tip 💡 A comprehensive budget includes the initial equipment cost, shipping, installation, and operational expenses like energy and labor. Businesses should also project their Return on Investment (ROI) to gauge the long-term profitability and viability of the purchase.

Step 2: Understand the Core Components of a Ginger Processing Line

A complete ginger processing line consists of several specialized machines working in sequence. Each component performs a distinct function, transforming raw ginger rhizomes into a finished, marketable product. Understanding the role of each machine is essential for designing an efficient and effective production workflow.

Washing and Cleaning Machines

The first operational step is thoroughly cleaning the raw ginger. Washing machines remove soil, pesticides, and other surface impurities. Processors can choose from several types based on their capacity and cleaning requirements. An integrated machine that combines air bubble washing with high-pressure sprays can process high volumes with a water consumption rate of around 1 ton per hour.

- Bubble Washing Machine: This machine uses air bubbles in a water tank to gently agitate and clean the ginger, preserving its delicate skin.

- Brush Washing Machine: Rotating roller brushes scrub the ginger, effectively removing stubborn dirt. This type is versatile for many root vegetables.

- High-Pressure Spray Washer: Powerful water jets dislodge contaminants efficiently. This method is often very water-efficient.

- Rotary Drum Washer: A large, rotating drum tumbles the ginger under water jets, ideal for high-capacity, uniform cleaning.

Ginger Sorting Machine

After cleaning, a ginger sorting machine grades the rhizomes. This critical step ensures product uniformity and optimizes the efficiency of subsequent processing stages. The ginger sorting machine typically separates the ginger by size, shape, or quality. A business that invests in a reliable ginger sorting machine can significantly reduce manual labor and improve the consistency of the final product. For example, uniformly sized ginger peels and slices more effectively. The ginger sorting machine is therefore a cornerstone of an automated line. Processors often place the ginger sorting machine directly after the washing station to prepare the raw material for peeling or slicing.

Peeling Equipment

Peeling removes the outer skin of the ginger. Mechanical peelers use abrasive rollers or brushes to accomplish this task. The efficiency of these machines is not fixed; it depends on several variables. Studies show that peeling efficiency can range from 62% to over 87%. Factors like the ginger's moisture content, the machine's operating speed, and the size of the rhizomes all influence the final peeling rate. Proper sorting from a ginger sorting machine beforehand can lead to higher peeling efficiency.

Slicing and Cutting Machines

For products like dried ginger or fresh-cut slices, a slicing machine is essential. These machines provide uniform cuts, which is crucial for consistent drying and a professional product appearance. Commercial ginger slicers offer high precision. A business can typically adjust the slice thickness, with most machines offering a range between 1mm and 3mm to meet various product specifications.

Blanching Equipment

Blanching is a brief heat treatment that prepares ginger slices for drying. This step is vital for maintaining product quality. It inactivates enzymes that cause browning and preserves the ginger's natural color.

Pro Tip: The Science of Blanching 🔬 Research shows that blanching ginger slices in water at 100°C for just 60 seconds effectively reduces microbial load. This quick process helps maintain color and quality, whereas lower temperatures for longer durations are far less effective.

Drying and Dehydration Systems

Drying removes moisture from the ginger slices, extending shelf life and preparing them for grinding into powder. Multi-layer belt dryers are a popular choice for industrial-scale operations. They pass the ginger through multiple layers within a heated chamber, ensuring even and efficient dehydration.

Key operating parameters for these systems include:

- Operating Temperature: Typically ranges from 40°C to 120°C.

- Drying Cycle Time: Can be set from 0.5 hours to 5 hours, depending on the slice thickness and desired final moisture content.

Grinding and Pulverizing Machines

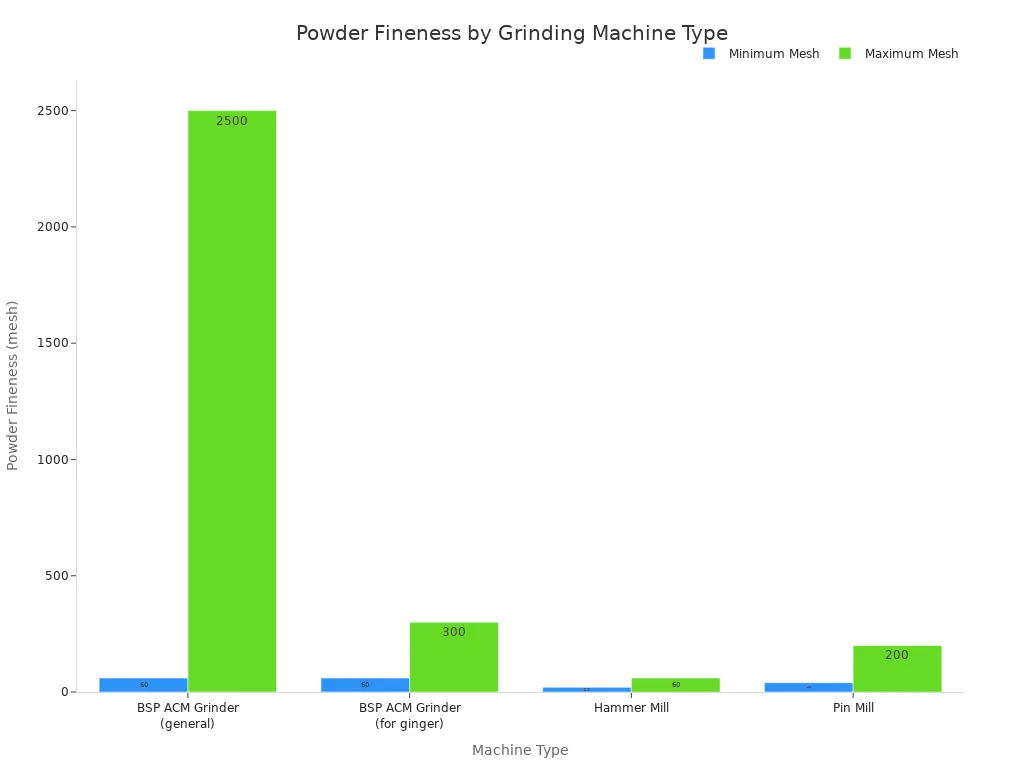

To produce ginger powder, dried ginger slices are fed into a grinding machine. The type of mill determines the final powder fineness, which is measured in mesh. A higher mesh number indicates a finer powder.

| Machine Type | Powder Fineness (mesh) |

|---|---|

| Hammer Mill | 20–60 |

| Pin Mill | 40–200 |

| BSP ACM Grinder (for ginger) | 60–300 |

For producing very fine powder, a water-cooled grinding system is highly recommended. Grinding generates significant heat, which can degrade the ginger's flavor and aroma. A water-cooling jacket prevents this.

- Quality Preservation: A water-cooling system keeps the grinding chamber temperature below 70-80°C, protecting the ginger's essential oils.

- Fineness Control: Particle size is adjustable (from 10 to 120 mesh or finer) by changing the screen.

- Hygienic Design: These systems are typically made from food-grade 304 stainless steel and are easy to disassemble for cleaning.

Packaging Machinery

The final step is packaging. The choice of machine depends entirely on the final product. Suppliers configure different packaging machines for powders, pastes, or fresh slices. For ginger powder, an auger filler is often used to dose the product accurately into bags or jars. For ginger paste, a piston filler is more appropriate. A business must clearly define its packaging needs to select the right automated solution.

Step 3: Evaluate Key Technical Specifications

Beyond the basic function, the technical details of a machine determine its long-term value and performance. A business must scrutinize these specifications to ensure the equipment meets its operational and quality standards.

Material Quality (SUS304 vs. SUS316)

The construction material directly impacts equipment longevity and food safety. Most food-grade machinery uses stainless steel, but the specific grade matters. Ginger's acidic nature makes this choice critical. SUS316 stainless steel contains molybdenum, which provides superior resistance to corrosion from acids and chlorides. This makes it the premium choice for handling ginger, especially in high-temperature conditions where corrosive attacks are more likely.

Automation and Control Systems

Modern processing lines often feature advanced automation. A Programmable Logic Controller (PLC) system can significantly enhance production efficiency.

Benefits of PLC Control Systems ⚙️

- Automates the entire production process for consistency.

- Allows operators to monitor and adjust settings via a touch screen.

- Reduces the risk of human error.

- Enables easy customization and data collection for real-time monitoring.

Energy and Water Consumption

Operational costs are a major factor in ROI. A business should request detailed information on the energy and water usage of each machine. For example, the power consumption of industrial dryers can vary significantly.

Example: Industrial Dryer Power Ratings

| Model | Rated Power (kW) | Maximum Power (kW) |

|---|---|---|

| Dryer 1 | 4 | 10 |

| Dryer 2 | 12 | 18 |

| Dryer 3 | 21 | 33 |

Evaluating these figures helps a business forecast expenses and select more energy-efficient models.

Ease of Maintenance and Cleaning

Downtime for cleaning and maintenance can halt production. Equipment designed for easy sanitation is essential for any food processing operation. Key features to look for include:

- Durable, food-grade stainless steel construction.

- Removable components, such as tubs or frames, for thorough rinsing.

- Integrated automatic spray cleaning systems with high-pressure nozzles.

- Water and residue collecting trays to keep the production area clean.

These design elements save time, reduce labor, and ensure compliance with hygiene standards.

Step 4: Choose a Reliable Equipment Supplier

Selecting the right machine is only half the battle; choosing the right partner is equally important. A reliable supplier provides not just equipment, but also expertise, support, and peace of mind. A business must thoroughly vet potential suppliers to ensure a successful long-term investment.

Verify Industry Experience and Expertise

A supplier's track record reveals its capability. Businesses should seek partners with proven success in the ginger processing industry. For example, when Bundaberg Brewed Drinks needed to secure a high-quality ginger supply, it partnered with an experienced equipment provider. The supplier designed a custom wash line to handle 2 tons of ginger per hour, solving the unique challenge of cleaning heavily soiled Australian ginger. This kind of expertise is invaluable.

A reputable manufacturer also possesses key industry certifications. These credentials demonstrate a commitment to quality, safety, and environmental standards.

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Management)

- CE (European Conformity)

- ETL (Electrical Product Safety)

A supplier with CE Certification ensures its equipment meets European quality requirements, which simplifies the import process for many customers.

Evaluate After-Sales Support and Parts

The relationship with a supplier extends far beyond the initial purchase. A business must evaluate the quality of after-sales service. This includes technical support, operator training, and the availability of spare parts.

Operational Tip: Minimize Downtime ⚙️ Inquire about the supplier's spare parts policy. A supplier with a well-stocked inventory of critical components can ship replacements quickly, significantly reducing costly production downtime.

Request and Compare Detailed Quotations

A business should request detailed quotations from its shortlisted suppliers. A simple price list is not enough. A comprehensive quote should include technical specifications, material grades (like SUS304 vs. SUS316), warranty terms, delivery timelines, and installation costs. Comparing these thorough documents allows a business to make an informed decision based on total value, not just the initial price tag.

Step 5: Making the Final Decision

The final phase of equipment selection involves careful review, negotiation, and planning. A business must approach this stage methodically to secure the best possible terms and ensure a smooth transition. This diligence transforms a major purchase into a strategic, long-term asset.

Conduct a Final Review of Specifications

A business should perform one last, thorough review of all technical specifications. It can create a final checklist to compare its requirements against the supplier's quotation. This review confirms that every detail, from material grade and capacity to automation features, aligns with its production goals. This step prevents misunderstandings and ensures the delivered equipment will perform as expected.

Negotiate Terms and Warranty

Negotiation is a critical step to optimize the investment's value. A business has several points it can discuss with the supplier to reach a favorable agreement.

- Warranty duration, which often ranges from 12 to 24 months

- Availability and pricing for a full list of spare parts

- Installation, commissioning, and operator training terms

- Response time for technical support and troubleshooting

Warranty is a key area for discussion. While many suppliers offer a standard period, the specifics can vary.

A manufacturer might state: "Our warranty period is generally one year."

This one-year term often applies to major components. A business should confirm what is covered.

| Component/Feature | Specification |

|---|---|

| Warranty | 1 Year |

| Motor | 1 HP |

| Control Panel | Specially designed for easy operation |

| Product Type | Ginger Processing Machine (Tray Dryer) |

Plan for Installation and Training

A successful purchase extends beyond delivery. The business must create a clear plan for installation and operator training. It should clarify who is responsible for commissioning the equipment. The supplier may offer on-site installation or remote guidance. Additionally, arranging comprehensive training ensures the production team can operate the new machinery safely and efficiently, maximizing productivity from the start.

A business secures a successful investment by methodically evaluating its needs, equipment specifications, and supplier reliability. This guide helps a company confidently select a processing line to enhance efficiency and profitability. A focus on long-term value over short-term cost ensures the machinery will serve the business for years.

FAQ

What is the most essential machine for a small-scale ginger business?

A small business should prioritize a quality washing and slicing machine. These core units support entry-level products and prepare ginger for future expansion into powders or pastes.

How does a business decide between producing ginger powder and ginger paste?

The decision depends on market demand and equipment. Powder requires a dryer and grinder, while paste needs a pulper. A business analyzes its target market to choose the more profitable product.

Why is CE certification important when choosing a supplier?

CE certification shows equipment meets European safety standards. It simplifies importation for many buyers and signals a supplier's commitment to quality, ensuring a more reliable and compliant purchase.

See Also

Essential Tablet Sampling Machines: A Comprehensive Lab Selection Guide

Understanding Plate Heat Exchangers: A Detailed Operational Guide

Crucial Industrial Checkweighers: Essential for Modern Food Production Facilities

Effective Steel Processing: Optimal Results for Heat Exchange Systems

Ampoule Filling Lines: A Comparative Look at Top Manufacturers