What to Look for When Buying a Spice Sorting Machine

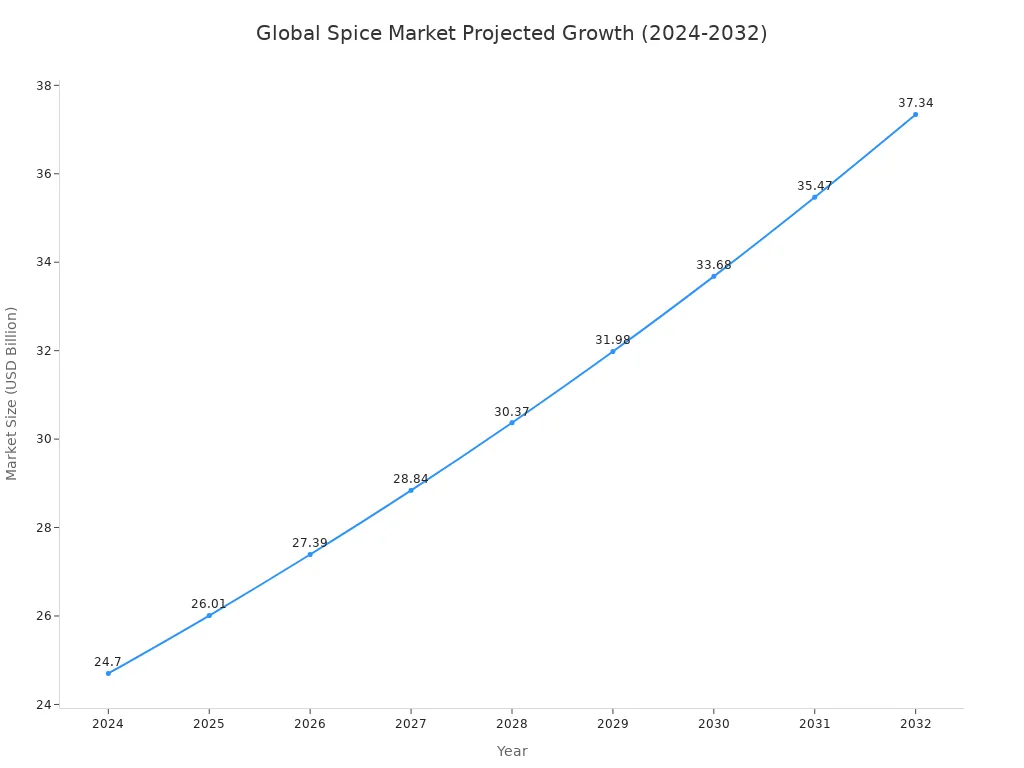

The global spice market's projected growth demands highly efficient production methods.

Note: Buyers must select technology matching their quality needs, like a specialized chili peppers and hot spices sorting machine. A business should align machine capacity with production volume and verify high accuracy to maximize yield. Evaluating the total cost of ownership ensures a wise long-term investment.

Identify Core Sorting Technologies

Selecting the right sorting technology is the most critical step in this process. Each technology targets different types of defects. A comprehensive understanding helps a business choose the most effective machine for its specific spice products.

Color Sorters

Color sorters use high-resolution cameras to inspect spices for imperfections. These machines identify and remove contaminants, diseased elements, and other foreign materials to meet food hygiene standards. They excel at distinguishing items based on color variations.

- For monk fruit, sorters remove fruit stalks, leaves, and moth-eaten fruits.

- For white pepper, they separate standard products from non-standard impurities.

- For nutmeg, the machines eject materials that fail to meet preset color and shape standards.

Shape and Size Sorters

Shape and size sorters use advanced imaging to separate products based on physical dimensions. This technology is ideal for ensuring uniformity and removing broken pieces. Modern machines use an AI super brain algorithm for deep learning and data calculation. A high computing power deep learning platform processes data efficiently, enabling precise separation of whole spices from fragments.

Density and Weight Sorters

Density sorters, like gravity destoners, separate materials based on their relative weight. These machines effectively remove heavy impurities from a stream of spices. They leverage differences in density to isolate contaminants. For example, a destoner can easily remove dense objects like small stones, glass fragments, or metal pieces from a batch of lighter cloves.

X-ray and Metal Detectors

X-ray sorters and metal detectors provide an essential layer of food safety. These systems identify dense foreign bodies that other technologies might miss. X-ray machines can detect metal, glass, high-density plastics, and stones inside the product. Metal detectors specifically target ferrous and non-ferrous metallic contaminants.

Infrared (IR) and InGaAs Sorters

Pro Tip: Infrared (IR) and InGaAs (Indium Gallium Arsenide) sorters see beyond the visible spectrum. They identify contaminants based on their unique chemical and molecular composition. This makes them invaluable for removing foreign materials that have the same color and size as the spice, such as hulls, shells, stems, and certain plastics.

Evaluate Machine Capacity and Throughput

A machine's capacity and throughput are fundamental metrics for operational efficiency. A business must select a sorter that can handle its current processing needs without creating bottlenecks. It should also accommodate future growth. Proper evaluation ensures the investment supports productivity goals from day one.

Match Capacity to Production Volume

A business must align the machine's throughput, measured in tons per hour, with its production volume. A small-scale operation processing cardamom or pepper may only need a machine with a capacity of 0.5 to 1.2 tons per hour. Medium to large-scale enterprises handling pulses or chili require significantly higher throughput. Analyzing production data helps determine the right fit.

The table below shows typical capacity ranges for different operational scales and spice types.

| Scale | Product | Capacity (tons per hour) |

|---|---|---|

| Small | Flax Seeds, Cardamom, Peeled Garlic, Pepper | 0.5 - 1.2 |

| Medium | White Sesame Seeds, Pulses, Chilli | 1.5 - 3.5 |

| Large | Pulses | 5.0 |

Consider the Number of Chutes

The number of chutes in a sorting machine directly correlates with its processing throughput. Each chute acts as a separate channel, allowing the machine to process more product simultaneously. More chutes generally mean higher capacity. For example, some industry-leading models demonstrate this relationship clearly:

- A sorter with three individual chutes can achieve a throughput of up to 20 tons per hour.

- A different model with a single, adjustable 1200-mm chute processes up to 14 tons per hour.

This shows how both the number and width of chutes contribute to overall speed.

Assess Scalability for Future Growth

An ideal sorting machine meets today's needs and supports tomorrow's ambitions. Businesses should project their growth over the next three to five years. Choosing a machine with a slightly higher capacity than currently required provides a buffer for increased demand.

Pro Tip: 📈 Some manufacturers offer modular designs. This allows a business to add more chutes or upgrade components later, providing a cost-effective path to scaling operations without replacing the entire machine.

Assess Sorting Accuracy and Efficiency

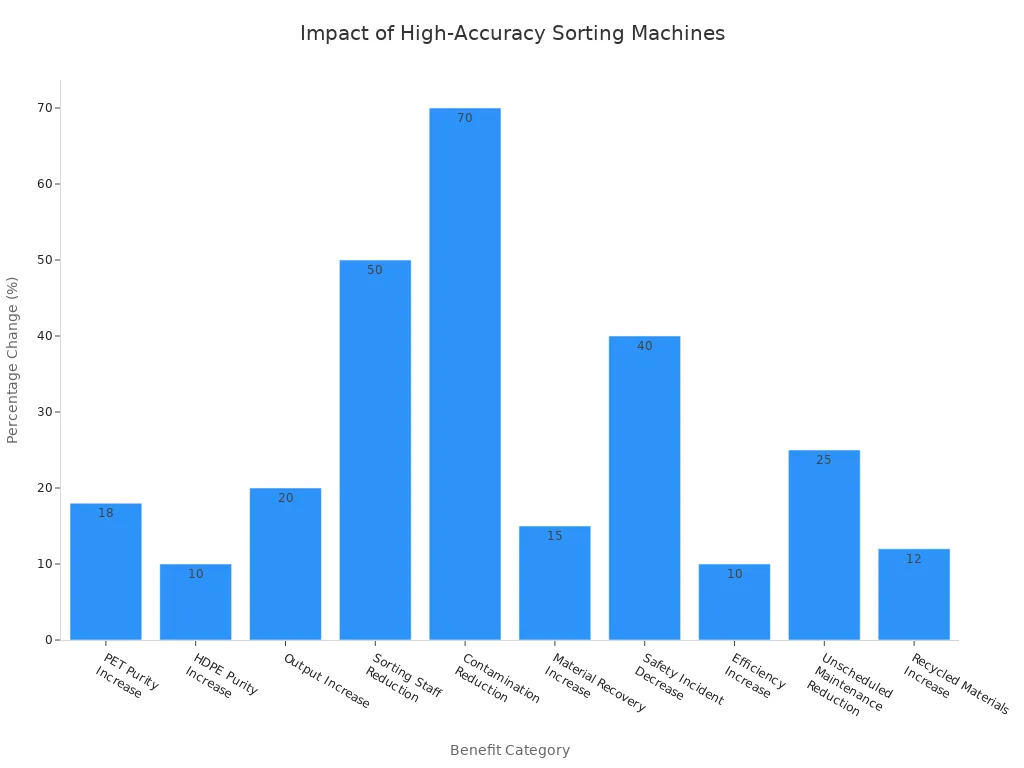

High accuracy and efficiency are the cornerstones of a profitable sorting operation. These metrics directly influence product yield, waste reduction, and overall quality. A business must carefully evaluate a machine's performance in these areas to ensure a strong return on investment.

Verify Detection Accuracy

Detection accuracy measures a machine's ability to correctly identify and remove defects. The industry benchmark for high-performance sorters is exceptionally high. Businesses should seek machines that promise near-perfect results to guarantee the purest final product. Many leading models demonstrate this capability.

Pro Tip: 🎯 Top-tier machines consistently achieve a sorting accuracy of ≥99.99%, effectively eliminating almost all foreign material and substandard spices.

The table below shows the accuracy rates for several industry-standard models.

| Model | Sorting Accuracy |

|---|---|

| R-Series (64-640) | ≥99.99% |

| BSC-Series (300-1200) | ≥99.99% |

Analyze the Rejection Rate

The rejection rate refers to the percentage of product ejected from the main stream. A critical component of this is the false rejection rate—the amount of good product mistakenly discarded as defective. Minimizing this figure is essential for maximizing yield and preventing profit loss.

- A low false rejection rate ensures valuable product is not wasted.

- The industry standard for optical sorters is typically less than 2%.

A machine that meets this standard protects a company's bottom line.

Understand the Good-in-Bad Ratio

The good-in-bad ratio measures the amount of acceptable product carried over into the reject stream. An optimal ratio means very little good spice is lost. Advanced sorters use AI and deep learning to improve this metric. These smart systems make highly granular distinctions between materials. They can identify contaminants with extreme precision, which significantly reduces the accidental loss of quality spices. This technology ensures that only true defects are removed, maximizing the recovery of sellable product.

Consider Your Specific Spice Types

Different spices present unique sorting challenges due to their varied sizes, shapes, and textures. A business must select a machine tailored to its specific product line to achieve optimal results and protect product integrity.

Determine Machine Versatility

A versatile machine offers significant long-term value, especially for businesses handling multiple spice types. Some sorters are engineered to process a wide array of products with minimal changeover time. These machines often come with presets for different spices, simplifying operations.

Pro Tip: 🌶️ Look for models that can handle diverse textures and sizes. Versatile machines can process everything from fine poppy seeds to coarse dried ginger, making them a flexible asset. For example, the Commandor series and other specialized seed sorters accept different varieties in a single machine.

Evaluate the Handling Mechanism

The machine's handling mechanism must be gentle enough to prevent damage to delicate products. Spices like cloves, star anise, and dried leaves can break easily, reducing their market value. A sorter with a smooth feeding system and a soft landing for ejected materials helps preserve the physical quality of the spices. This ensures the final product remains whole and visually appealing.

Check Compatibility with Spice Forms

Spices come in many forms, including whole, crushed, and powdered. A business must confirm that its chosen sorter is compatible with the specific forms it processes. Advanced machines support all spice textures, sizes, and moisture levels. This capability is crucial for processors who handle both dried seeds and semi-moist products, ensuring consistent performance across the board. A specialized chili peppers and hot spices sorting machine is a great example of this.

Using a chili peppers and hot spices sorting machine

Certain products demand highly specialized equipment. A chili peppers and hot spices sorting machine is engineered to overcome the unique challenges associated with these items. A quality chili peppers and hot spices sorting machine is essential for maintaining high standards. These machines excel at:

- Ensuring consistent quality across fresh, wet, and dried chili peppers.

- Removing foreign materials like stems and leaves.

- Addressing discoloration and spots on the product.

- Handling the irregular shapes common in chilies.

The ability to manage these variables makes a dedicated chili peppers and hot spices sorting machine a critical investment for producers in this niche. The right chili peppers and hot spices sorting machine handles these variations with precision.

Review Operational and Maintenance Needs

A machine's long-term value depends heavily on its daily usability and upkeep. Businesses must evaluate these factors to minimize downtime and maximize operational efficiency. A sorter that is easy to operate and maintain becomes a reliable asset rather than a constant challenge.

Prioritize Ease of Use

Complex machinery can create production bottlenecks and increase training costs. Businesses should look for machines with intuitive controls that simplify operation. User-friendly features allow operators with limited technical skills to manage the sorting process effectively. Key elements to look for include:

- An intuitive touchscreen interface for simple recipe configuration.

- Easy-touch controls for precise adjustment of sorting profiles.

- Smart sensors that instantly alert users to process discrepancies.

These features reduce the learning curve and empower staff to run the machine confidently.

Ensure Simple Cleaning Procedures

Spices can leave behind residue and oils, making regular cleaning essential for hygiene and performance. A machine designed for easy sanitation saves valuable time. Look for models with accessible components and smooth surfaces that prevent product buildup. Quick-release parts and tool-less disassembly allow for rapid and thorough cleaning, ensuring the machine is ready for the next production run with minimal delay.

Check Software and User Interface

Modern sorting machines rely on sophisticated software to deliver top performance. The user interface should provide clear, real-time insights into the sorting process. Advanced software offers powerful diagnostic tools that help maintain machine health.

Pro Tip: 💻 Software with remote monitoring allows managers to check machine status from any device. This feature enables proactive maintenance by sending alerts for errors or unusual activity, helping to prevent breakdowns before they happen.

This centralized management provides a live look at every machine's status. It helps teams identify and address inefficiencies promptly, ensuring the equipment remains operational and productive.

Evaluate Build Quality and Support

A sorting machine is a significant capital investment. Its long-term performance depends on robust construction and reliable manufacturer support. A business must assess these factors to protect its investment and ensure continuous operation.

Inspect Construction Materials

The machine's build quality directly impacts its durability and hygiene. Businesses should prioritize sorters constructed from high-grade, food-safe materials.

- Stainless Steel: Look for frames and contact parts made from stainless steel. This material resists corrosion from spice oils and cleaning agents.

- Durability: A sturdy build minimizes vibrations and protects sensitive internal components like cameras and ejectors.

A well-built machine withstands the demands of a high-volume production environment, ensuring a longer operational life.

Inquire About Technical Support

Downtime can be costly. A manufacturer's technical support is a critical lifeline when issues arise. Businesses should clarify the scope and responsiveness of the support services offered.

Pro Tip: 📞 Top-tier service can make a significant difference. For example, some leading manufacturers provide 24/7 technical assistance with locally based technicians capable of responding within two hours. This level of support guarantees that production can resume quickly.

A strong support agreement ensures expert help is always available.

Confirm Spare Parts Availability

Even the best machines require maintenance and part replacements. A business must confirm that the manufacturer can provide spare parts promptly. Long lead times for critical components can halt production for days or weeks. Ask potential suppliers about their parts inventory. A manufacturer with a local or regional warehouse can ship essential items quickly, minimizing operational delays and protecting revenue.

Calculate Total Cost and ROI

A smart investment requires a comprehensive financial analysis. Businesses must evaluate the total cost of ownership and potential return to make a fiscally sound decision. This calculation provides a clear picture of the machine's long-term value.

Look Beyond Initial Purchase Price

The sticker price is only the beginning of the total investment. A business must account for additional expenses that contribute to the total cost of ownership. These often include significant hidden costs related to installation and ongoing service.

Pro Tip: 💰 Manufacturers pass on substantial expenditures for after-sales maintenance and technical support to the customer. The labor costs for these services can also vary significantly between developed and developing countries, impacting the overall price.

Factor in Energy Consumption

Energy consumption is a major operational expense that affects profitability over the machine's lifespan. Businesses should prioritize models designed for energy efficiency. Key features to look for include:

- Low-power air ejectors that minimize compressed air usage.

- Efficient LED lighting systems for illumination.

- Smart power-saving modes during idle periods.

An energy-efficient sorter reduces utility bills and supports sustainable production goals.

Estimate Return on Investment

Return on investment (ROI) measures the profitability of the purchase. A business calculates ROI by comparing the financial gains from the machine against its total cost. A strong ROI is driven by several factors. The machine increases yield by minimizing the loss of good product. It also reduces manual labor costs and improves final product quality. This enhanced quality can open doors to premium markets, justifying the initial capital outlay.

A final decision balances advanced technology with a company's budget. A machine with appropriate capacity and high accuracy is a long-term asset, boosting profitability and brand reputation. Industry leaders like DKC Tradex confirm this outcome. Prioritizing models that are easy to operate and maintain ensures maximum uptime for a confident investment.

FAQ

Can one machine sort multiple types of spices?

Yes, versatile models process many spices. They feature pre-programmed settings for different products, which simplifies changeovers and enhances operational flexibility for a business.

How long does it take to see a return on investment (ROI)?

ROI depends on production volume and labor savings. Most businesses see a return within 18 to 24 months from higher yields and reduced manual sorting costs.

What is the main difference between a color sorter and an X-ray sorter?

Color sorters identify surface defects based on color. X-ray sorters detect dense foreign materials like metal or glass inside the product, ensuring comprehensive food safety.

See Also

Essential Capsule Checkweighers: A Buyer's Guide for the Year 2025

Discovering Top Suppliers: Where to Purchase X-Ray Inspection Machines in China

Tablet Sampling Machines Demystified: The Definitive Laboratory Selection Guide

Crucial Industrial Checkweighers: Three Essential Machines for Every Food Plant

Capsule Sorters Unveiled: Their Vital Function in Efficient Defect Removal