A Practical Guide for Choosing Dried Fruit Sorters

An exceptional dried fruit sorter is essential for processors aiming to capitalize on the expanding global market. The industry is poised for significant growth, with projections indicating a substantial increase in market value over the next decade. Processors can enhance their competitive edge by implementing a strategic, three-step approach to equipment selection. This method ensures the chosen machine, such as a specialized dried mango sorting machine, aligns perfectly with operational demands and financial objectives.

| Metric | Value |

|---|---|

| Market Size 2024 | USD 12.02 Billion |

| Projected Market Size 2030 | USD 16.55 Billion |

| CAGR (2025-2030) | 5.6% |

Step 1: Define Your Sorting Needs

A successful sorter selection begins with a thorough analysis of the processor's specific operational requirements. This foundational step ensures the final equipment choice directly addresses the unique challenges of the product and production line. Processors must first define their fruit's characteristics, identify target defects, and establish their capacity needs.

Identify Your Fruit and Its Traits

Different dried fruits possess unique physical properties that influence sorting technology. Processors must document key traits for each product they handle. A specialized dried mango sorting machine, for example, requires different calibration than one for dates. Key attributes to consider include:

- Color, shape, size, and weight

- Texture and softness

- Moisture content and density

Modern sorters can be calibrated to measure these attributes with high precision. For instance, machines can accurately predict moisture content, which is linked to firmness and density, allowing for the separation of premium products from those needing further processing.

Pinpoint Key Defects and Contaminants

Processors must create a comprehensive list of all unacceptable materials and product imperfections. This includes both foreign material and product-specific defects. Common targets for removal are small stones, leaves, and insects. Additionally, processors should identify issues like mold, which can present serious quality and safety risks. Dried figs, for example, are susceptible to specific molds like Aspergillus rot and Botrytis rot. Color defects, such as the bright greenish-yellow hue in figs linked to aflatoxin, are also critical to eliminate.

Determine Required Production Capacity

The sorter's throughput must align with the facility's overall production volume. Processors should calculate their required capacity in tons or kilograms per hour. Equipment capacities vary widely. Small-scale machines may process a few kilograms per hour, making them suitable for artisanal producers. Large-scale industrial operations, however, require robust systems capable of handling several tons per hour to maintain line efficiency and meet market demand.

Step 2: Compare Sorting Technologies

After defining sorting needs, processors must evaluate the technologies that power modern sorting equipment. Each technology targets different types of imperfections. Understanding their unique capabilities is essential for selecting a machine that delivers optimal performance and product quality. The main technologies include camera, laser, and X-ray systems, which can also be combined for ultimate detection.

Camera Sorters for Color and Shape

Camera-based sorters are the most common technology for dried fruit processing. They use high-resolution cameras to analyze every piece of fruit, making decisions based on color, size, and shape. These systems excel at identifying surface-level issues that are visible to the eye.

For color sorting, advanced machines identify even the most subtle variations. They achieve this precision through a combination of powerful hardware and intelligent software.

- Full Spectrum Illumination: State-of-the-art sorters use full-spectrum LED lighting that mimics natural sunlight. This eliminates the low-light patches common with standard LEDs, ensuring consistent illumination across the entire product.

- High-Resolution Imaging: This advanced lighting enables high-resolution RGB cameras to detect minute color differences. Processors can easily remove discolored products or separate fruit based on ripeness.

- AI-Powered Detection: Multi-spectral cameras paired with AI algorithms can learn to identify specific color-related defects, such as the greenish-yellow hue in figs that indicates potential aflatoxin contamination.

Shape sorting is another key function of camera systems. Specialized software analyzes multiple images of each fruit as it passes through the machine. For example, some systems take several diameter measurements as a dried cherry rotates, creating a complete 3D profile. Sophisticated algorithms then use this size and shape data to identify and eject misshapen products, doubles, or items with spurs.

Technology in Action: The Total View System Some advanced sorters, like those with InVision Total View technology, use multiple pairs of cameras to inspect 100% of the fruit's surface. These systems can process up to 30 items per second per lane, using machine learning to categorize defects with remarkable accuracy.

Laser Sorters for Structural Defects

Laser sorters provide a deeper level of inspection that cameras cannot achieve. They work by scanning products with lasers and analyzing the properties of the reflected light. This technology can "see" the structural composition of an object, making it invaluable for detecting defects hidden beneath the fruit's surface.

Lasers excel at identifying materials with different structural properties than the fruit itself. For instance, a laser sorter can easily distinguish between the soft flesh of a date and a hard, embedded pit fragment. It can also detect unwanted organic material like stems, leaves, or pieces of shell that may have a similar color to the fruit but a different texture. This makes laser sorting a critical step for ensuring food safety and removing hard-to-find foreign material.

X-ray Systems for Dense Contaminants

X-ray inspection is the gold standard for detecting dense foreign contaminants. This technology identifies materials based on their density, not their color or structure. An X-ray system can find dangerous contaminants like metal fragments, small stones, and high-density plastics or glass, regardless of whether they are hidden inside the dried fruit.

A common concern is whether an X-ray system will mistakenly reject fruit with naturally dense parts, such as a pit fragment. Modern X-ray equipment solves this problem by identifying differences in material density. The system's software can distinguish between the expected density of a natural element, like a seed, and the higher density of a harmful foreign object. This capability ensures precise contaminant removal without increasing false rejects, protecting both consumers and the processor's bottom line.

Sensor Fusion for Comprehensive Sorting

The most advanced sorting solutions utilize sensor fusion, a technology that combines multiple sensor types into a single machine. A sorter equipped with sensor fusion might use cameras for color and shape, lasers for structural defects, and X-ray for dense contaminants. This multi-layered approach provides the most comprehensive inspection possible.

Note: By merging data from different sensors, these systems make highly intelligent sorting decisions. For example, Key Technology's VERYX sorter uses both front- and back-mounted cameras and laser sensors. Its Pixel Fusion™ detection module combines the data streams to identify and remove foreign materials with extreme precision, a capability chosen by leading processors for sorting prunes.

A system with sensor fusion is the ultimate tool for quality control. It ensures that the final product is free from a wide range of defects and foreign materials. For high-value products, a comprehensive system like a dried mango sorting machine equipped with sensor fusion can deliver the quality and safety assurances that premium markets demand.

Step 3: Assess Critical Machine Features

Beyond the core technology, processors must evaluate specific machine features that directly impact daily operations, product quality, and long-term value. A sorter's performance is not just about its sensors; it is a combination of its accuracy, ejection mechanism, software intelligence, and physical design. Examining these elements ensures the chosen equipment is both powerful and practical.

Sorting Accuracy and Efficiency

Sorting accuracy and efficiency are the two most critical performance metrics.

- Accuracy refers to the machine's ability to correctly identify and remove all targeted defects and foreign material (the true positive rate) while minimizing the accidental removal of good product (the false reject rate).

- Efficiency is the sorter's ability to maintain this high accuracy while processing large volumes of product at high speed.

Top-tier sorters achieve exceptional good-to-bad ratios, ensuring that valuable product is not wasted. High-capacity industrial lines require machines that can sustain this performance without compromise. Modern systems can handle impressive throughputs of up to 20 tons per hour, with conveyor belts moving as fast as 3 meters per second. This combination of speed and precision is essential for large-scale processors to maximize output and profitability.

Ejection System Precision

The ejection system is where the sorter's decision becomes action. Once the sensors identify a defect, the ejector must remove it from the product stream with pinpoint accuracy. The speed and precision of this system are vital for maintaining sorting efficiency, especially on high-capacity lines.

Most modern sorters use air-jet ejection systems. These systems activate a high-speed burst of air from a nozzle at the exact moment a defective item passes. This action removes the rejected product while allowing the good product to continue undisturbed.

Precision in Milliseconds ⏱️ Air-jet systems boast incredible speed and precision. They have response times of less than one millisecond and can achieve ejection accuracies exceeding 99%. This rapid response minimizes errors and prevents the accidental removal of adjacent good fruit, a common issue with slower, less precise mechanical alternatives like pivoting arms.

For some applications, robotic arms with specialized end-effectors offer another solution. A delta robot, for example, can perform up to 80 movements per minute. This translates to approximately 55 effective picks per minute, surpassing the average human sorter's rate of 45 picks per minute.

Software and User Interface

The software is the brain of the sorting machine. A powerful yet intuitive user interface (UI) is crucial for operators to manage the sorter effectively. Modern systems feature user-friendly controls that simplify complex operations. Key features include:

- Intuitive Touchscreen Interface: Allows operators to easily configure sorting parameters (or "recipes"), monitor performance in real-time, and access diagnostic data.

- User-Configurable Settings: Provides the flexibility to adjust parameters like defect size, color thresholds, and ejector timing to match specific product requirements.

- Remote Connectivity: Enables remote monitoring and support from technicians, helping to diagnose issues and minimize downtime.

The most advanced software incorporates Artificial Intelligence (AI) and Machine Learning (ML) to enhance detection over time. These smart systems continuously learn from the product stream. An AI-powered dried mango sorting machine, for instance, can analyze historical defect patterns to predict where new issues might arise. ML algorithms monitor for "model drift"—subtle changes in product, lighting, or defect types—and can trigger automatic recalibration or flag ambiguous items for human review. This continuous improvement cycle ensures the sorter adapts and maintains peak accuracy day after day.

Hygienic Design and Maintenance

In food processing, hygiene is paramount. A sorter's design must prevent microbial growth and facilitate easy, thorough cleaning. Processors should look for equipment that adheres to international hygienic design standards, such as those developed by the European Hygienic Engineering and Design Group (EHEDG) or the International Organization for Standardization (ISO).

Key features of a hygienic design include:

- An open-frame construction with no hollow tubes or hidden cavities where product residue can accumulate.

- Surfaces made from food-grade stainless steel that are smooth, non-porous, and sloped for easy drainage.

- Tool-less removal of belts, rollers, and other components to simplify cleaning and inspection.

A well-designed machine not only protects food safety but also reduces operational costs. Faster and more effective cleaning cycles mean less downtime and more time for production.

Case Study: Dried Mango Sorting Machine

A leading processor of premium dried mangoes sought to improve product quality and increase production capacity. The company was facing challenges with subtle color variations, occasional pit fragments, and inconsistent product texture. After a thorough evaluation, they invested in an advanced dried mango sorting machine equipped with sensor fusion (camera and laser) and an AI-powered software interface.

The results were transformative. The new system delivered quantifiable improvements across the board.

- Quality Enhancement: The sorter achieved a 99.5% correct classification rate for deteriorated or discolored mango pieces. The laser system effectively identified and removed pieces with hidden pit fragments, a critical food safety hazard.

- Throughput Increase: The machine's high-speed processing and efficient air-jet ejection system allowed the processor to double their hourly throughput without sacrificing quality.

- Superior Final Product: By sorting based on subtle color and texture indicators linked to the drying process, the company was able to create a premium product line with superior characteristics.

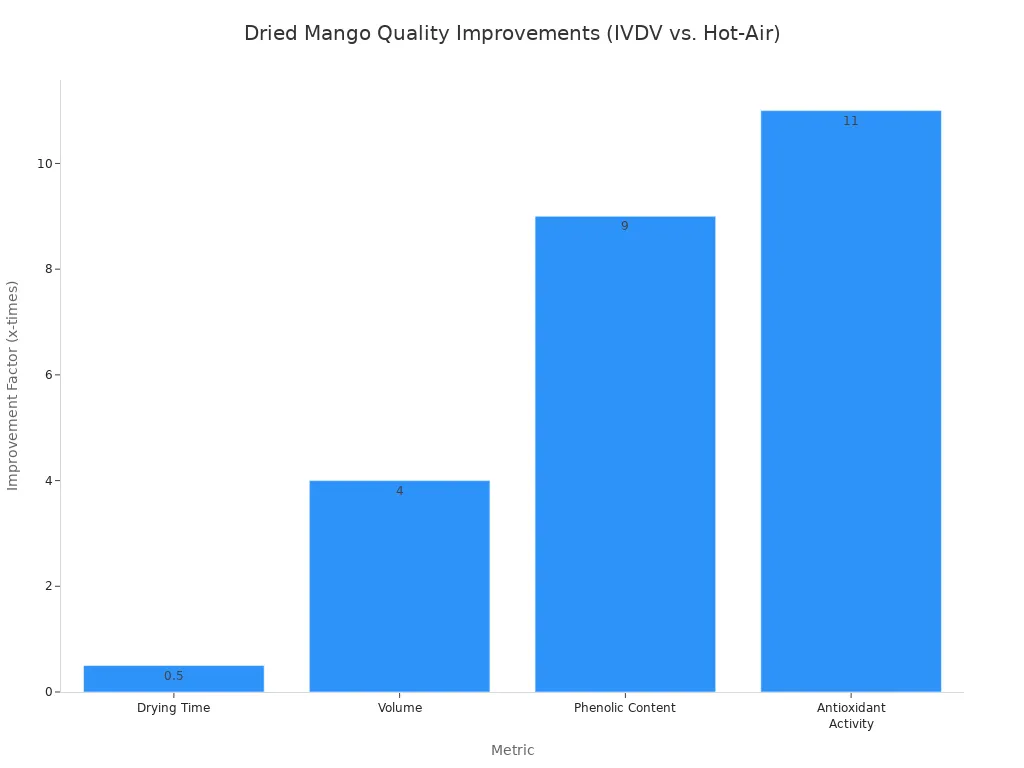

The chart below illustrates the kind of quality improvements that advanced processing and sorting can achieve, resulting in a product with enhanced color, texture, and nutritional value.

This case demonstrates how investing in the right features—from sensor technology to intelligent software—enables processors to meet the highest market standards and achieve a significant competitive advantage.

Step 4: Analyze Financials and ROI

A sorter is a significant capital investment. Processors must look beyond the initial price tag to understand its long-term financial impact. A thorough analysis of the total cost of ownership (TCO) and potential return on investment (ROI) provides a clear picture of the machine's true value.

Calculate Total Cost of Ownership

The Total Cost of Ownership includes all expenses related to the sorter over its entire lifecycle. Processors should evaluate several key factors to build an accurate financial model. A comprehensive TCO calculation considers more than just the machine's purchase price.

- Acquisition Costs: This is the initial price of the hardware, including any necessary upgrades or peripheral equipment for installation.

- Operating Costs: These are the ongoing expenses required to run the machine. They include utility costs, direct operator labor, and initial training expenses.

- Personnel Costs: This category covers administrative and support staff related to the equipment, as well as ongoing maintenance and troubleshooting labor.

Evaluating the manufacturer's post-purchase support and ensuring the technology is scalable for future growth are also critical parts of this assessment.

Estimate Your Return on Investment

Return on investment measures the profitability of the sorter. Processors can estimate ROI by calculating the value the machine generates compared to its cost. Automated sorters deliver returns by increasing revenue and decreasing operational expenses. They achieve higher throughput and greater accuracy than manual sorting, leading to a more valuable final product.

Automated systems are also more energy-efficient per ton. While manual sorting incurs indirect energy costs for lighting and facility heating, an automated sorter's primary consumption comes from its conveyors and sensors. Integrating AI can further optimize operations and reduce overall energy use. This efficiency, combined with reduced labor needs and less product waste, accelerates the return on investment.

Processors select the ideal sorter by defining needs, evaluating technology, and analyzing ROI. The final step is validating performance with a product demonstration. During a trial, processors should measure key metrics to confirm the machine's capabilities.

- Grading speed and sorting accuracy

- Fruit damage and mis-sort rates

- Uptime reliability

Specialists are available to discuss sorting requirements and schedule a product trial.

FAQ

How do sorters handle different dried fruits?

Advanced sorters use user-configurable recipes. Operators can quickly adjust settings for different fruit types, ensuring optimal performance for each product run.

Can a sorter detect aflatoxin?

Yes, some sorters use specialized cameras and AI. They identify the specific color variations linked to aflatoxin, allowing for the precise removal of contaminated products.

What is the typical lifespan of a sorter?

Industrial sorters have a long operational life, often exceeding 10-15 years. Proper maintenance and timely part replacements are key to maximizing the machine's lifespan and performance.

See Also

Essential Guide: Selecting The Right Tablet Sampling Machine For Your Lab

Capsule Sorters: Key To Efficient Defect Elimination In Pharmaceutical Production

Boosting 2,5-Furandicarboxylic Acid Sustainability Through Data-Driven Strategies And Insights

Indispensable: Top Three Industrial Checkweighers For Every Modern Food Plant

Power Transformer Selection: A Comprehensive Guide For Novices And Beginners