Fish Optical Sorter Buying Guide for 2026

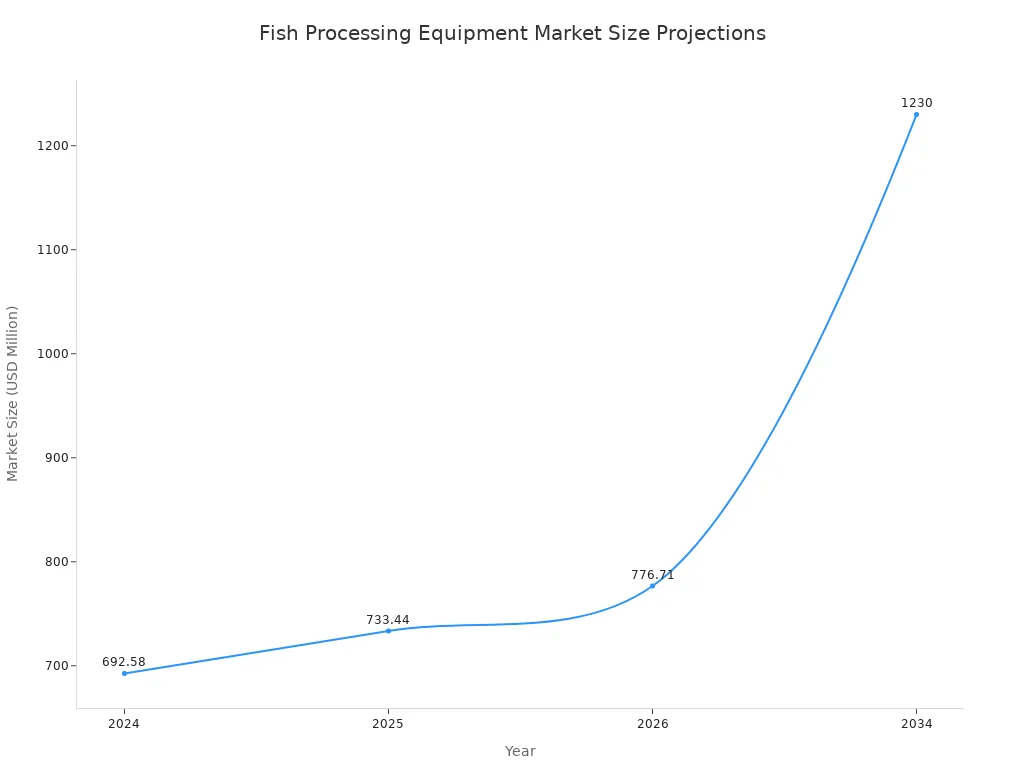

The fish processing equipment market projects significant growth, reaching an estimated $776.71 million by 2026.

Processors must match a fish optical sorter's technology to their specific operational needs. Critical evaluation factors are sorting accuracy, throughput, and total cost of ownership.

What Sorting Technologies Should You Evaluate for 2026?

The market for fish processing equipment is trending toward smarter and more reliable systems. Processors must understand the core technologies to make an informed investment. Innovations in sensor technology, machine vision, and artificial intelligence are setting new standards for quality control.

Hyperspectral vs. Multispectral Imaging

Multispectral imaging systems are a key advancement for 2026. They use multiple wavelengths of light to analyze product properties. Hyperspectral systems are more advanced, using a broader spectrum for deeper analysis, but this comes at a higher cost. The price difference stems from specialized sensors and complex optical components required for hyperspectral technology.

| Feature | Multispectral Imaging | Hyperspectral Imaging |

|---|---|---|

| Cost | Lower | Higher |

| Complexity | Simpler | More Complex |

| Best For | General Use | Specialized Research |

For many processors, multispectral imaging provides a practical and cost-effective balance of performance and price.

X-ray vs. Vision Systems for Contaminants

X-ray and vision systems serve different purposes. X-ray inspection is essential for detecting dense foreign materials inside the product. Vision systems, conversely, excel at inspecting packaging for seal integrity and label accuracy.

Pro Tip: Use X-ray systems to find internal contaminants and vision systems to verify external packaging quality.

X-ray technology identifies contaminants by detecting differences in density. It is highly effective for finding:

- Metals (ferrous and non-ferrous)

- Bone fragments (as small as 1 mm)

- Glass and stone

- High-density plastics

Advanced X-ray systems achieve bone detection rates of up to 99% in salmon fillets.

The Role of AI and Machine Learning

Artificial Intelligence (AI) revolutionizes sorting by enabling a fish optical sorter to learn and improve. AI algorithms analyze real-time data to identify subtle defects in color, texture, and shape with remarkable accuracy. Over time, AI models become more precise by training on larger datasets. This continuous learning process significantly reduces false rejections. For example, optimized AI models have cut false detections by over 75%, improving yield and operational efficiency.

How to Match a Fish Optical Sorter to Your Operation

Selecting the right equipment requires a deep analysis of your specific production environment. Processors must align a sorter's capabilities with their operational demands, from processing volume to sanitation protocols. A successful investment hinges on a clear understanding of throughput, accuracy, and long-term maintenance needs.

Calculating Your Required Throughput

Throughput measures the volume of fish your sorter can process in a given time, typically in kilograms per hour (kg/hr) or pieces per minute. Calculating your required throughput is the first step in narrowing your equipment options. An undersized machine creates bottlenecks, while an oversized one is an unnecessary capital expense.

To determine your needs, analyze your peak production volume. Use this simple formula as a starting point:

Required Throughput (kg/hr) = Peak Hourly Production Volume (kg) x 1.25 (Safety Margin)

Note: A 25% safety margin accounts for production fluctuations and future growth. Adjust this multiplier based on your business forecasts.

The type of fish you process heavily influences throughput and machine selection. Key factors include:

- Species Characteristics: The size, shape, weight, and texture of the fish dictate the necessary machine configuration. A sorter designed for small, delicate shrimp is not suitable for large, heavy tuna.

- Product State: Sorting requirements differ for live, fresh, or frozen products. Each state impacts how the product moves along the conveyor and how sensors interpret it.

- Versatility vs. Specialization: Some systems can handle multiple species with adjustable settings. However, significant differences in fish characteristics often demand a dedicated fish optical sorter for optimal performance.

Assessing Sorting Accuracy and Ejection

Sorting accuracy directly impacts your profitability by maximizing yield and ensuring product quality. Modern systems use AI-powered intelligent sorting algorithms to achieve exceptional precision. These self-learning models adapt to product variations, identify defects with high accuracy, and reduce costly false rejections.

After the sorter identifies an item for removal, the ejection system activates. The choice of ejector is critical for maintaining product integrity, especially with delicate fish fillets.

- Air Jets: These use powerful, precise bursts of compressed air to remove defective items from the production line. They are ideal for high-speed applications and lightweight products.

- Mechanical Arms or Pushers: These physically guide or push items onto a different conveyor. They are often used for heavier products or when gentle handling is the top priority.

The ejection mechanism must be fast enough to keep up with the conveyor speed but gentle enough to avoid damaging good products. The goal is to remove 100% of defects and foreign material without sacrificing valuable yield.

Evaluating Hygienic Design and Maintenance

Fish processing facilities are high-moisture environments requiring frequent, aggressive cleaning to meet food safety standards. The sorter’s design must withstand these conditions to prevent bacterial growth and ensure long-term reliability. Ingress Protection (IP) ratings classify a machine's resistance to dust and water.

For fish processing, look for equipment with high IP ratings.

| IP Rating | Dust Protection | Water Protection | Recommended Application for Fish Processing |

|---|---|---|---|

| IP67 | Dust-tight | Temporary immersion | Seafood processing equipment exposed to saltwater |

| IP69K | Dust-tight | High-pressure, high-temperature washdown | Meat, poultry, and seafood machinery in hygiene-critical areas |

Pro Tip: An IP69K rating is the gold standard for hygiene-critical zones. It ensures the machine can endure intense, high-temperature washdowns with sanitizing agents without compromising internal electronics.

Beyond IP ratings, a truly hygienic design includes:

- Sloped surfaces to prevent water pooling.

- Stainless steel construction for corrosion resistance.

- Easily accessible components for simple and thorough cleaning.

- Minimal crevices or hollow areas where bacteria can accumulate.

Finally, consider ease of maintenance. A user-friendly interface, real-time data analytics, and responsive technical support are essential for minimizing downtime and optimizing performance over the machine's lifespan.

Understanding the Financials of Your Investment

A smart investment in sorting technology requires looking beyond the initial price tag. Processors must evaluate the total cost of ownership (TCO) and project the return on investment (ROI) to make a financially sound decision. This analysis ensures the equipment delivers long-term value.

Budgeting Beyond the Initial Purchase Price

The sticker price is only one part of the total investment. A comprehensive budget accounts for all associated expenses over the machine's lifespan. Processors should factor in these additional costs:

- Installation and Integration: Costs for setup and connection to existing production lines.

- Operator Training: Expenses to ensure staff can operate and maintain the equipment effectively.

- Consumables and Utilities: Ongoing costs for compressed air, electricity, and water.

- Maintenance and Spare Parts: Budgets for routine service and replacement components to minimize downtime.

A complete financial plan prevents unexpected expenses and clarifies the true cost of the investment.

How to Calculate Your Return on Investment (ROI)

ROI measures the profitability of your investment. Accurate sorting directly boosts ROI. Systems with near 100% accuracy far exceed manual sorting standards (90-95%). This precision increases profits by over 15% through enhanced reliability and reduced error.

Higher accuracy also minimizes product giveaway, a major cost saver. Consistently graded products allow for premium pricing, further improving financial returns. Many facilities achieve a full ROI within a specific timeframe due to these combined benefits.

Use this formula to estimate your ROI:

ROI (%) = [(Net Profit from Sorter - Investment Cost) / Investment Cost] x 100

This calculation helps justify the purchase and demonstrates the equipment's value to stakeholders.

How to Vet Vendors and Make a Final Decision

Choosing the right supplier is as critical as selecting the right technology. A strong vendor partnership ensures long-term success and support for your investment. Processors should conduct thorough due diligence before committing to a purchase.

A Checklist for Evaluating Suppliers

A systematic evaluation helps processors compare potential vendors effectively. This checklist provides a framework for assessing supplier capabilities and reliability.

- Technical Support and Service: Does the vendor offer 24/7 support and local technicians?

- Industry Experience: How many years has the supplier served the fish processing industry?

- Customer References: Can the vendor provide contacts for current customers with similar operations?

- Training Programs: What level of operator and maintenance training is included with the purchase?

- Spare Parts Availability: Does the supplier maintain a ready inventory of critical spare parts to minimize downtime?

Why You Must Test Your Product First

Theoretical performance data is not enough. Processors must insist on testing their own products on the equipment before making a final decision. A live demonstration provides invaluable, real-world insights.

A product test is the only way to verify a sorter's true accuracy, throughput, and handling capabilities with your specific fish species.

This step confirms that the machine can handle your product's unique characteristics, such as size, texture, and defect types. It also allows your team to assess the user interface and ease of operation. A successful test provides the confidence needed to move forward with the investment. It validates the vendor's claims and ensures the equipment will perform as expected in your facility.

Processors select the best fish optical sorter by following a clear evaluation process. A successful 2026 investment requires these key steps:

- Define specific sorting requirements, including species, defects, and volume.

- Evaluate which technology best meets those needs and calculate the total cost of ownership.

- Thoroughly vet vendors with product tests and customer references.

FAQ

How long does a fish sorter typically last?

Most sorters last 10 to 15 years with proper care. Regular maintenance is crucial. It ensures long-term performance and maximizes the machine's operational life.

Can a new sorter integrate with my existing equipment?

Yes, vendors design modern sorters for integration. They connect with existing conveyors and software. Processors should discuss line configurations with suppliers during the evaluation phase.

What training is needed to operate a fish optical sorter?

Vendors provide comprehensive operator and maintenance training. This ensures staff can run the fish optical sorter efficiently. It also covers basic troubleshooting to minimize potential downtime.

See Also

Essential Capsule Checkweighing Machines for Smart Buyers in the Coming Year

Leading Precoating Solutions for Advanced Filtration Systems: A 2025 Overview

Innovative Folder Gluer Capabilities Shaping Carton Production Lines in 2025

Crucial Industrial Checkweighers: Essential Equipment for Every Modern Food Facility

Understanding Tablet Sampling Machines: A Comprehensive Laboratory Equipment Selection Guide