The Financial Case for Upgrading to a Ravioli Optical Sorter

An investment in a ravioli optical sorter delivers a strong, measurable return. It achieves this by cutting operational costs and boosting revenue. The financial justification rests on three pillars: drastic labor cost reduction, maximized product yield, and enhanced profitability through superior quality, making it a strategic asset for producers.

The Hidden Costs of Manual Sorting

Many producers underestimate the true financial burden of manual sorting. These costs extend far beyond wages, creating significant drags on profitability that a ravioli optical sorter can eliminate. Examining these expenses reveals a compelling case for automation.

Direct Labor and Turnover Expenses

Manual sorting lines carry substantial operational costs, with some food manufacturers spending over $155,000 annually. This figure does not even account for the high price of employee turnover. Replacing a single frontline worker can cost up to 40% of their yearly salary due to recruitment and training expenses. This constant cycle of hiring and onboarding drains resources and disrupts production efficiency, creating a persistent financial leak.

The Price of Human Error

Human sorters, no matter how dedicated, are prone to error. Fatigue, distraction, and subjectivity lead to costly mistakes.

- Good ravioli gets discarded, directly reducing product yield and revenue.

- Defective ravioli reaches the package, damaging quality and risking customer complaints.

These errors represent direct, quantifiable losses that accumulate over every shift.

Inconsistent Quality and Brand Risk

Consistent product quality builds brand trust and drives repeat purchases. Manual sorting introduces variability that puts this trust at risk. An empirical study confirms that stable product quality is essential for long-term consumer loyalty. When quality control fails, the consequences can be catastrophic.

Caution: Major food brands have faced devastating financial losses from quality control issues, demonstrating the severe risk of inadequate inspection.

| Brand | Quality Control Issue | Financial Consequence |

|---|---|---|

| Jack in the Box | E. coli in beef patties | Over $50 million in settlements |

| Blue Bell Creameries | Listeria contamination | $175 million in losses |

These examples show that inconsistent quality is not just a minor issue; it is a major financial liability.

Financial Gains of a Ravioli Optical Sorter

Transitioning from manual inspection to automated sorting creates immediate and substantial financial advantages. A ravioli optical sorter directly addresses the high costs of labor, waste, and inconsistency. It transforms these operational drains into measurable gains in efficiency, yield, and revenue.

Slashing Your Labor Budget

Automation directly reduces a plant's reliance on manual labor for sorting tasks. A single machine performs the work of a large team, operating faster and for longer periods without fatigue. This shift produces a dramatic reduction in payroll expenses, benefits, and the recurring costs associated with employee turnover. The efficiency gains are significant.

- Manual Sorting: A team of 12 people typically sorts 1 to 1.5 tons of product per hour.

- Optical Sorting: A team of just 3 people can oversee a system sorting 4 to 6 tons per hour.

This automation frees up valuable employees. They can be reassigned to higher-value roles that require human skill, further boosting overall plant productivity.

Maximizing Yield by Reducing Waste

Every piece of good ravioli mistakenly discarded is a direct loss of revenue. Optical sorters minimize these losses with exceptional precision. They use advanced sensors and intelligent software to make split-second decisions. The technology identifies defects based on color, size, shape, and even structural properties.

This precision allows the system to remove only the defective product and foreign material. It prevents the costly error of discarding acceptable items. Modern systems use object-based recognition, defining a defect by its total surface area. This feature ensures the machine ejects only truly flawed ravioli, maximizing the amount of sellable product and increasing total yield from every batch.

Boosting Revenue with Premium Quality

Consistent, high-quality products build a premium brand that consumers trust. A ravioli optical sorter ensures every package meets the highest standard. It removes broken, discolored, or malformed pieces with unwavering accuracy. This level of quality control is nearly impossible to achieve with manual sorting alone.

Producers who deliver a consistently superior product can command higher prices in the marketplace. This enhanced quality perception strengthens customer loyalty, encourages repeat purchases, and solidifies the brand's reputation as a market leader.

Ultimately, superior quality translates directly into increased revenue and a stronger competitive position.

Unlocking New Markets with Food Safety

Meeting stringent food safety regulations is a prerequisite for entering lucrative domestic and international markets. Optical sorting technology provides the documentation and reliability needed to comply with the world's toughest standards. It acts as a critical control point, identifying and removing foreign material that could lead to a recall.

Note: Compliance with regulations like the Food Safety Modernization Act (FSMA) in North America and standards set by the European Food Safety Authority (EFSA) is essential for export. Major importers like the U.S. and Germany have strict safety protocols, making advanced sorting a key enabler for market access.

By investing in this technology, ravioli producers demonstrate a commitment to food safety that opens doors to new customers and geographic regions, turning compliance from a cost center into a strategic growth driver.

Calculating Your Return on Investment (ROI)

Evaluating the purchase of a ravioli optical sorter requires a clear financial analysis. Producers can calculate a precise return on investment (ROI) to justify the capital expenditure. This calculation moves the discussion from an operational expense to a strategic financial decision.

The ROI Formula Explained

Understanding the financial return begins with a standard formula. The calculation determines the net profit generated relative to the total cost of the investment.

Net Profit / Total Investment x 100 = ROI

The "Total Investment" figure is more than the initial purchase price. It represents the Total Cost of Ownership (TCO), which includes ongoing expenses. Key TCO components are:

- Maintenance and repair costs

- Replacement parts inventory

- Operational downtime impacts

- Employee labor for operation and upkeep

A Sample Payback Period Calculation

A payback calculation demonstrates how quickly the investment pays for itself. Consider a producer who invests in a new sorting system. The annual savings from reduced labor and increased yield quickly offset the initial cost.

| Metric | Value |

|---|---|

| Initial Investment Cost | $250,000 |

| Annual Labor Savings | $150,000 |

| Annual Revenue from Increased Yield | $50,000 |

| Total Annual Savings | $200,000 |

In this scenario, the payback period is just 1.25 years ($250,000 / $200,000).

How to Get a Custom Financial Assessment

Leading equipment manufacturers offer tools to simplify this calculation. Many provide custom ROI assessment services for potential clients. Producers can input data about their current system, material value, and processing volume. The service then generates a detailed projection of annual savings and potential sales growth. This custom analysis provides the specific data needed to justify investing in a new system, turning a complex financial forecast into a simple, actionable report.

An optical sorter is a strategic financial tool, not a luxury expense. Producers recover the investment quickly through labor savings and reduced product waste. The long-term upside is even greater. It protects brand reputation from recalls that cause sales declines of 60-80% and unlocks premium pricing through superior quality.

Automation is a 'game-changer' that will lead to an era of even safer, higher-quality food. It improves quality control, ensures precision, and enhances traceability.

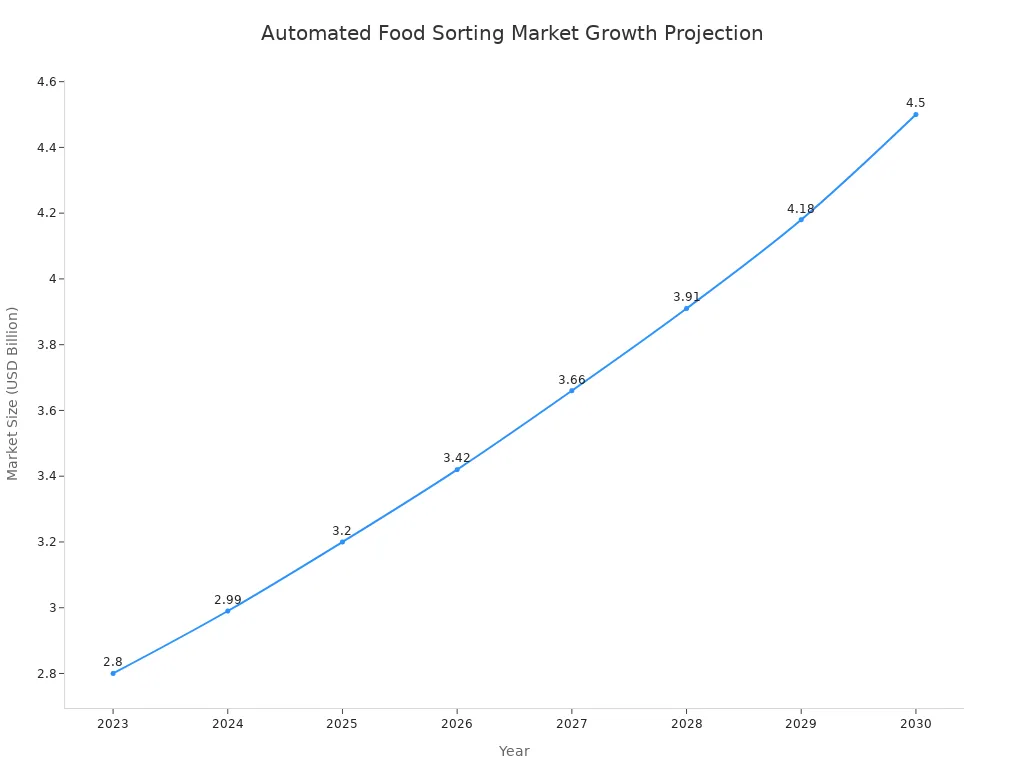

Investing in this technology secures a competitive advantage in a rapidly growing market.

FAQ

How difficult is it to operate a ravioli optical sorter?

Modern systems feature intuitive, user-friendly interfaces. Operators receive comprehensive training from the manufacturer. This process ensures a smooth transition and efficient daily operation for the plant.

What maintenance does an optical sorter require?

Routine maintenance involves daily cleaning and periodic checks of key components. Manufacturers provide detailed schedules and support to ensure optimal performance and longevity of the equipment.

Can an optical sorter integrate with my existing production line?

Yes. Manufacturers design these systems for seamless integration. They offer compact footprints and modular configurations. This allows them to fit into existing plant layouts with minimal disruption.

See Also

Essential Folder Gluer Innovations for 2025 Carton Production Lines

Top Capsule Checkweighers: A Buyer's Guide for 2025 Considerations

Plate Pack Benefits and Comprehensive Cost Analysis for the Year 2025

Capsule Sorters: Crucial for Effective Defect Elimination and Quality Control

Three Indispensable Industrial Checkweighers for Modern Food Processing Facilities