Efficiency and Expense Comparing Optical Sorters to Manual Pasta Sorting

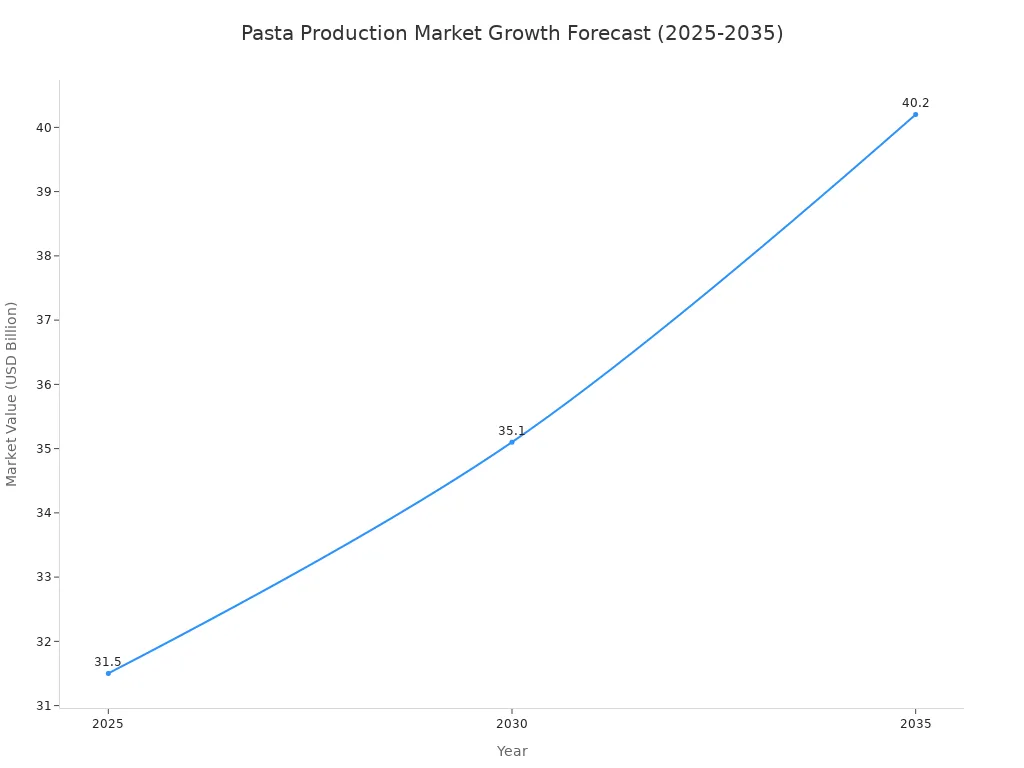

The global pasta market shows consistent growth. Producers face a critical choice between two sorting methods. Large-scale operations find long-term value in optical sorters. These machines offer unmatched efficiency and consistency. Small producers may prefer manual sorting for its low initial cost. However, it brings higher labor expenses and product inconsistency. A farfalle optical sorter, for example, handles complex shapes with precision.

Note: This decision significantly impacts a company's scalability and brand reputation in a competitive market.

The Fundamental Cost Breakdown

Producers must evaluate both immediate and long-term costs when choosing a sorting method. The financial analysis extends beyond the initial purchase price. It includes a comprehensive look at all expenses that accumulate over the equipment's or employee's lifecycle. This breakdown reveals the true cost of ownership for each approach.

Initial Capital Investment

The most significant barrier to adopting automated technology is the initial capital investment. Optical sorters represent a substantial upfront expense. Manual sorting, in contrast, requires minimal initial capital, primarily for setting up workstations.

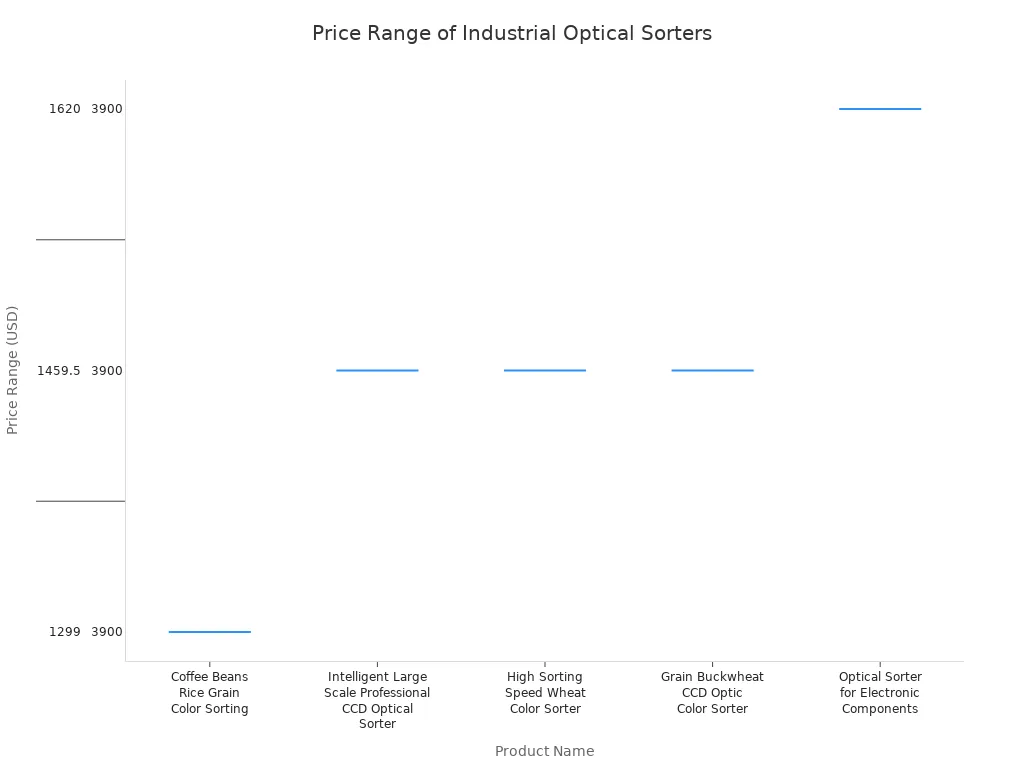

An optical sorter's price varies widely. The cost depends on its capacity, technological sophistication, and specific application. Basic models for small-scale operations or pilot tests can start around $1,300. Mid-range machines often fall between $4,000 and $7,000. However, high-throughput, high-accuracy systems command a much higher price. For example, a specialized farfalle optical sorter designed for complex shapes requires advanced imaging and ejection systems, increasing its cost. Some general-purpose industrial sorters can even reach prices between $35,000 and $39,000.

The following table provides a snapshot of the diverse market for optical sorters, illustrating how features and scale influence price.

| Product Name | Company Name | Price Range (USD) |

|---|---|---|

| Coffee Beans Rice Grain Color Sorting | Zhengzhou Lst Technology Co., Ltd. | $1,299–$1,620 |

| Intelligent Large Scale Professional CCD Optical Sorter | Zhucheng Hongya Machinery Technology Co., Ltd. | $3,900 |

| High Sorting Speed Wheat Color Sorter | Anhui Wenyao Intelligent Photoelectronic Technology Co., Ltd. | $7,000 |

| High Accuracy 7 Chutes CCD Color Sorter | Anhui Realtech Machinery Company Limited | $15,000–$19,998 |

| Optical Sorter for Electronic Components | Schnoka (Suzhou) Intelligent Equipment Co., Ltd. | $35,000–$39,000 |

For manual sorting, the initial costs are negligible in comparison. They may include tables, chairs, and lighting. This low barrier to entry makes it an attractive option for startups and small artisanal producers with limited capital.

Ongoing Operational Expenses

Ongoing expenses paint a different financial picture. Here, the consistent costs of manual labor often surpass the long-term operational costs of an automated system.

Optical sorters have predictable operational costs. These include:

- Energy Consumption: The electricity needed to power the machine, its cameras, and its pneumatic ejection system.

- Maintenance: Scheduled servicing, cleaning, and replacement of wear-and-tear parts like bulbs and ejector valves.

- Technical Support: Occasional software updates or troubleshooting from the manufacturer.

Manual sorting, however, carries significant and often unpredictable labor-related expenses. The most obvious cost is wages and benefits for the sorting staff. Yet, the hidden costs associated with employee turnover present a much larger financial burden. Repetitive, monotonous tasks like manual sorting often lead to low employee engagement and high turnover rates. In 2021, the average voluntary employee turnover across all industries was 25%.

Hiring a new employee typically costs three to four times the position’s salary, according to Edie Goldberg.

These replacement costs are not trivial. The expense of finding, interviewing, and training a replacement can be substantial. Gallup estimates that disengaged workers cost the U.S. economy $450 billion to $550 billion annually in lost productivity alone. The financial impact of replacing an employee varies by role:

- Replacing an entry-level worker costs 30% to 50% of their annual salary.

- Replacing a mid-level employee can cost up to 150% of their salary.

- Replacing a highly skilled employee can cost as much as 400% of their salary.

Furthermore, inadequate training for new sorters creates a "cost of failure." New hires are more prone to errors, leading to wasted product, customer complaints, and even equipment damage. These failures contribute to employee dissatisfaction, perpetuating a costly cycle of turnover. A farfalle optical sorter, by contrast, eliminates these human-centric variables, providing consistent performance 24/7 without fatigue or training-related errors.

Performance Metrics: Speed, Accuracy, and Yield

Beyond the initial and ongoing costs, performance metrics reveal the true operational value of a sorting method. Speed, accuracy, and yield directly influence a producer's profitability and market competitiveness. These three pillars of performance highlight the fundamental differences between automated and manual systems.

Sorting Speed and Throughput Volume

Throughput is the measure of how much product a system can process in a given time. In this area, optical sorters provide an exponential advantage over manual labor. A single optical sorter can process several tons of pasta per hour. This capability allows large-scale producers to meet high market demand consistently. The machine operates continuously, maintaining its peak speed for entire production shifts without breaks or a decline in performance.

Manual sorting operates on a much smaller scale. A diligent human sorter can inspect a limited amount of product, typically measured in kilograms per hour. This method creates a direct bottleneck for any operation looking to grow. Scaling up production requires hiring more staff, which introduces additional costs and management complexity. The disparity in throughput is one of the most compelling arguments for automation.

The table below illustrates the stark contrast in processing capacity.

| Sorting Method | Typical Throughput | Scalability | Consistency |

|---|---|---|---|

| Optical Sorter | 1–10+ tons per hour | High (adjust settings) | Constant 24/7 |

| Manual Sorting | 20–40 kg per hour per person | Low (hire more staff) | Variable (declines with fatigue) |

Accuracy and Product Consistency

Product quality is paramount in the food industry. Consumers expect a consistent product in every package. Optical sorters achieve a level of accuracy that human inspection cannot replicate over long periods.

Machines use high-resolution cameras, advanced lighting, and sophisticated software to analyze each piece of pasta. They can detect a wide range of defects with incredible precision:

- Color imperfections (e.g., burnt spots, discoloration)

- Size and shape deviations (e.g., broken or malformed pieces)

- Foreign material contamination (e.g., small stones or plastic fragments)

This process is objective and repeatable. The machine applies the exact same criteria to every single piece, 24/7. Human sorters, while skilled, are susceptible to fatigue, distraction, and subjective judgment. What one worker considers a defect, another might let pass. This variability can lead to inconsistent product quality, customer complaints, and damage to the brand's reputation. A specialized farfalle optical sorter, for instance, can identify subtle cracks or misshapen wings on the complex pasta shape, a task that would quickly lead to eye strain and errors for a human inspector.

Maximizing Yield and Reducing Waste

Yield refers to the amount of acceptable product that remains after the sorting process. High yield is crucial for profitability because every piece of good product mistakenly discarded is lost revenue. This is where the accuracy of an optical sorter provides a significant financial return.

Tip: The primary goal of sorting is to remove defects, not good product. Minimizing "false rejects"—the accidental removal of acceptable items—is key to maximizing profit.

Manual sorters often operate with a "better safe than sorry" mentality. To avoid letting a defect pass, a worker might discard a piece of pasta that is borderline acceptable. Over a full shift, these small losses accumulate into a substantial amount of wasted product.

Optical sorters are programmed with precise tolerances. They can distinguish between a true defect and a minor, acceptable imperfection. This precision minimizes the false reject rate, ensuring that the maximum amount of sellable product moves on to packaging. By reducing the waste of good pasta, a farfalle optical sorter not only improves quality but also directly increases the total output from a given batch of raw materials. This efficiency translates directly to a healthier bottom line.

Long-Term Financial and Strategic Impact

The decision between manual and automated sorting extends beyond immediate costs. It shapes a company's financial future, growth potential, and market standing. An optical sorter is a strategic asset that delivers compounding returns over its operational life.

Calculating Return on Investment (ROI)

Producers can justify the high initial cost of an optical sorter by calculating its long-term ROI. This calculation depends on several key variables. A comprehensive analysis reveals a clear path to profitability.

- Reduced Labor Costs: Automation decreases the number of operators needed. This directly lowers expenses related to wages, benefits, and employee turnover.

- Increased Throughput: Higher processing capacity allows a company to handle more volume. This spreads fixed costs over more product, reducing the per-unit cost.

- Improved Product Quality: Greater sorting accuracy leads to higher-purity output. This reduces waste and allows the final product to command premium prices.

Scalability for Future Business Growth

Manual sorting creates a ceiling for growth. Optical sorters break through this barrier. Automated systems operate continuously and process large volumes rapidly. This allows a business to meet rising market demand without proportionally increasing labor costs. A farfalle optical sorter, for example, handles complex shapes faster and more accurately than any team of human sorters. This efficiency is critical for scaling operations. One pasta company, Corno Macaroni Co., Ltd., dramatically improved sorting accuracy after adopting an optical sorter.

| Benefit | Improvement/Reduction |

|---|---|

| Manual Labor Costs | 25% reduction |

| Throughput | 30% increase |

| Waste Reduction | 20-30% reduction |

| ROI | Within 18 months |

Enhancing Brand Reputation and Quality

Consistent product quality builds consumer trust and brand loyalty. A PwC survey found that product quality is a top factor for building trust. Optical sorters ensure every package meets the same high standard. They reliably remove defects and foreign materials, such as plastic fragments, that can lead to costly product recalls and reputational damage. By preventing such incidents, a farfalle optical sorter protects the brand's image. Consumers are willing to pay more for brands they trust, making quality a direct driver of long-term success.

Making the Right Choice for Your Pasta Production

Choosing the right sorting method is a strategic decision that aligns with a company's production volume, quality standards, and growth ambitions. The optimal choice depends on a careful evaluation of these factors.

When to Invest in an Optical Sorter

A producer should invest in an optical sorter when specific operational and market demands arise. The investment becomes necessary when a company needs to achieve stringent quality control that surpasses human capability. Key drivers for this decision include the need to:

- Ensure consistent product quality by catching subtle flaws that human eyes might miss.

- Separate products based on precise visual features like color, shape, and size.

- Remove all misshapen, broken, or blemished items to meet customer expectations.

- Build brand trust and reduce product returns through unwavering consistency.

The Case for a Farfalle Optical Sorter

For pasta with intricate shapes, a specialized machine like a farfalle optical sorter becomes essential. General sorters may struggle with the unique geometry of bow-tie pasta. Mechanical sorting provides an objective advantage in these scenarios.

Quality control and the ability to differentiate between quality grades are critical factors in the food industry. Human detection of defects is often inconsistent and based on subjective criteria. In contrast, mechanical sorting with optical sensor technology not only improves efficiency but also ensures high standards based on objective criteria.

This objectivity guarantees that every piece is judged by the same high standard, a feat impossible for human sorters dealing with complex shapes over long shifts.

When Manual Sorting Remains Practical

Despite the advantages of automation, manual sorting remains a viable and practical option for certain producers. This method is ideal for artisanal pasta makers and startups. Manual methods give producers greater control over dough thickness and the shaping process. This hands-on approach is perfect for those creating unique pasta shapes in small batches. The low initial capital requirement makes it an accessible entry point for new businesses focusing on craft quality over mass production.

A producer's choice between optical and manual sorting depends on production volume, quality goals, and growth strategy. Optical sorters are a strategic investment for scaling operations and boosting profitability. Manual sorting remains a low-risk entry point for artisanal producers. Companies must analyze their data to determine their best ROI.

Leading pasta brands demonstrate the success of automation:

- Barilla: Adopted fully automated lines, achieving significant energy savings.

- Banza: Used automation to maintain consistent quality for its chickpea pasta.

- Jovial: Leveraged automation to meet demand for specialized organic products.

- DeLallo: Enhanced efficiency with automation while preserving artisanal quality.

The future of sorting technology promises even greater precision:

- AI-enabled image recognition systems will improve packaging and label sorting.

- Computer vision with deep learning will inspect products for defects and contaminants.

- High-resolution cameras combined with AI models offer faster, more consistent checks than human inspectors.

FAQ

How long does it take to see a return on an optical sorter?

Most companies see a return on investment within 12 to 24 months. This timeline depends on labor savings, increased throughput, and reduced product waste.

What maintenance do optical sorters require?

Optical sorters need regular cleaning of cameras and lights. They also require periodic checks on the pneumatic ejection system to ensure consistent performance and prevent downtime.

Can small producers benefit from optical sorters?

Yes, smaller or entry-level models offer automation benefits without the high cost of industrial-scale systems. They help artisanal brands improve consistency and prepare for future growth.

See Also

Capsule Sorters: Essential Tools for Flawless Product Quality and Defect Elimination

Boosting Pharma Efficiency: The Impact of Advanced Capsule Decapsulation Technology

Essential Industrial Checkweighers: Must-Have Solutions for Every Food Processing Plant

Future of Carton Production: Trending Folder Gluer Innovations for 2025

Smart Choices: Top Capsule Checkweighers for Buyers to Evaluate in 2025