Evaluating Automated X-Ray Systems for Seafood A 2026 Guide

Many seafood processors find a seafood automated x ray system to be a worthwhile investment. It delivers safety and quality advantages that can justify the high cost. The system's key benefits are superior contaminant detection and quality assurance. The primary drawbacks involve significant financial outlay and operational complexity. A careful cost-benefit analysis is essential. It helps determine if the system is the right choice for a specific operation. The market for these systems is growing, with projections showing a 7-9% compound annual growth rate in the US food industry through 2026. This reflects increasing adoption of advanced technology and stricter safety rules.

Why Invest? The Core Benefits of a Seafood Automated X-Ray System

Processors who adopt advanced inspection technology gain a significant competitive edge. An investment in an X-ray system delivers tangible returns through enhanced safety, superior quality, and improved operational performance. These benefits directly address the core challenges of the modern seafood industry.

Achieve Unmatched Contaminant Detection

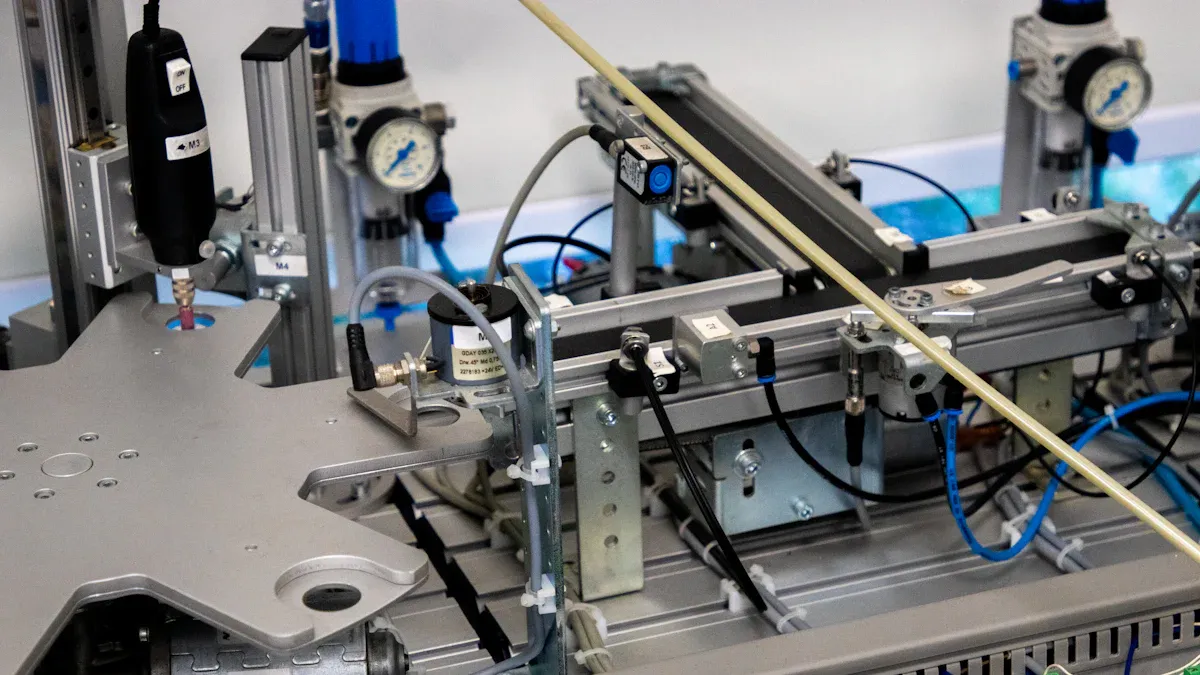

The primary function of an X-ray system is to identify and remove physical contaminants. It performs this task with a level of precision that older technologies cannot match. Unlike metal detectors, which rely on magnetic fields, X-ray systems use density differences to find hazards. This allows them to detect a much wider range of foreign bodies.

- Non-Metallic Threats: Systems can locate dense, non-metallic contaminants like glass, ceramic, rocks, and calcified bone.

- Packaging Penetration: X-ray inspection works effectively on products in metallic packaging, such as foil-lidded trays or metallized film, where metal detectors fail.

- Superior Metal Detection: They also excel at finding all types of metal, including non-ferrous and stainless steel fragments.

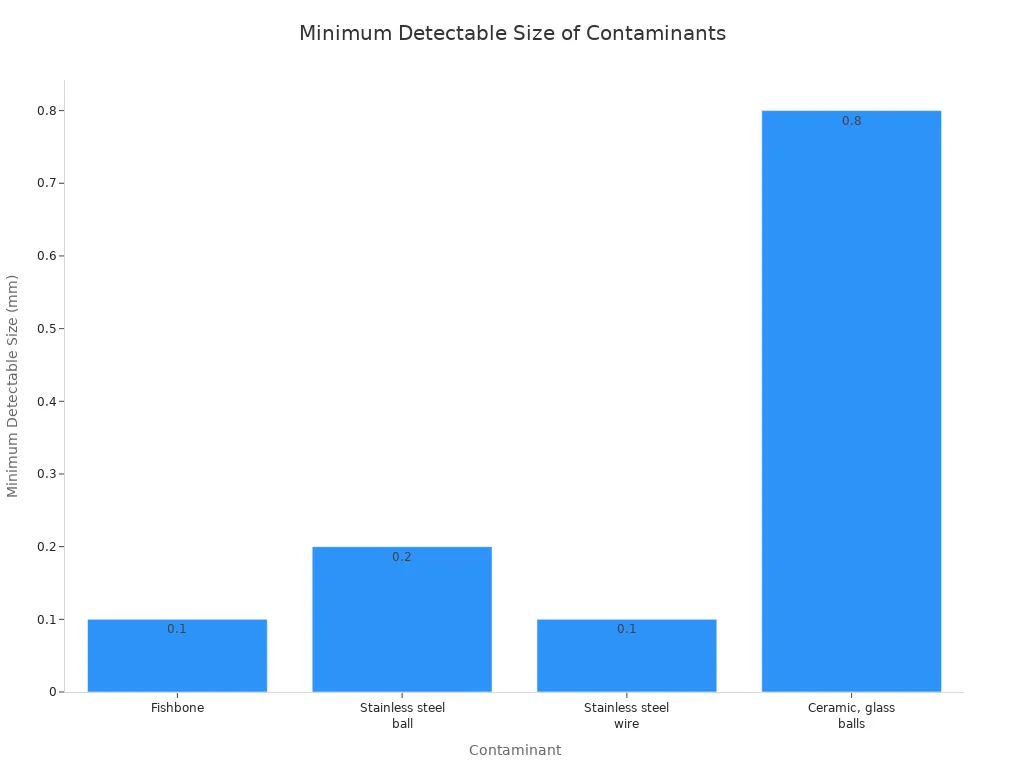

Modern systems offer remarkable sensitivity. Advanced technology like Photon-counting Detector Technology (PXT™) enables the detection of bone fragments as small as 0.5 mm in fish fillets. This precision is critical for ensuring consumer safety and meeting high-quality standards.

The minimum detectable size for common contaminants in fish highlights this capability:

| Contaminant | Minimum Detectable Size (mm) |

|---|---|

| Fishbone | 0.1 |

| Stainless steel ball | 0.2 |

| Stainless steel wire | 0.1 x 2 |

| Ceramic, glass balls | 0.8 |

Elevate Quality Control and Consistency

A seafood automated x ray system does more than just find contaminants. It serves as a comprehensive quality control station on the production line. These systems perform multiple checks simultaneously, ensuring every package meets brand specifications.

Note: By using an "auto-learn" function, the system establishes a benchmark for an ideal product. It then compares every subsequent item against this standard. This capability allows it to perform several quality checks in a single pass, including:

- Mass Measurement: Verifying the correct weight of the product and rejecting packages that are over or underfilled.

- Component Counting: Ensuring multi-part meals or packages contain the correct number of items.

- Integrity Checks: Identifying broken, deformed, or missing pieces of product within the final package.

- Seal Inspection: Detecting trapped food particles or contaminants within the seal area that could compromise product freshness and safety.

This multi-point inspection process guarantees a consistent and high-quality product reaches the consumer every time.

Boost Operational Efficiency and Throughput

Automating the inspection process yields significant gains in productivity and reduces operational costs. Manual inspection is slow, prone to error, and labor-intensive. An automated system operates continuously at high speeds, eliminating production bottlenecks.

Key efficiency improvements include:

- Increased Throughput: Systems handle high volumes of product rapidly, maximizing line productivity.

- Reduced Labor Costs: Automation reduces the need for manual inspectors, freeing up staff for higher-value tasks.

- Minimized Rework: Precise, consistent inspection eliminates human error and dramatically reduces the need for costly product rework and waste.

- Data-Driven Optimization: The system collects valuable production data, enabling managers to identify trends and make informed process improvements.

This enhanced efficiency translates directly to a stronger bottom line and a more streamlined operation.

Protect Your Brand and Expand Market Access

A single product recall can cause irreparable damage to a brand's reputation and financial standing. Investing in robust safety measures is a critical form of brand insurance. A seafood automated x ray system provides the highest level of protection against contaminant-related recalls.

Furthermore, this technology is often a prerequisite for accessing premium markets and achieving key safety certifications. Global food safety standards are becoming increasingly strict.

For example, the BRCGS Global Standard for Food Safety (Issue 9) explicitly emphasizes the need for effective foreign-body detection equipment. X-ray systems help processors meet these stringent requirements, demonstrating a commitment to safety that builds trust with both retailers and consumers. Adopting this technology can unlock new business opportunities and solidify a processor's position as a trusted, high-quality supplier.

What Are the Downsides? Key Challenges to Consider

While the benefits are compelling, adopting X-ray inspection technology involves significant hurdles. Processors must carefully evaluate the financial, operational, and technical challenges before committing. A thorough analysis of these potential downsides ensures a realistic understanding of the total investment required.

The Significant Financial Investment

The most immediate barrier to entry is the high upfront cost. Advanced X-ray inspection systems for inspecting various seafood products, including fresh, frozen, and pre-cooked items, represent a major capital expenditure. The price varies widely based on the system's capabilities and sophistication.

Entry-level automated X-ray inspection systems typically cost between $60,000 and $120,000. These units are suitable for standard applications with moderate throughput. High-end systems, which may incorporate advanced features like artificial intelligence or enhanced automation, can range from $150,000 to over $500,000.

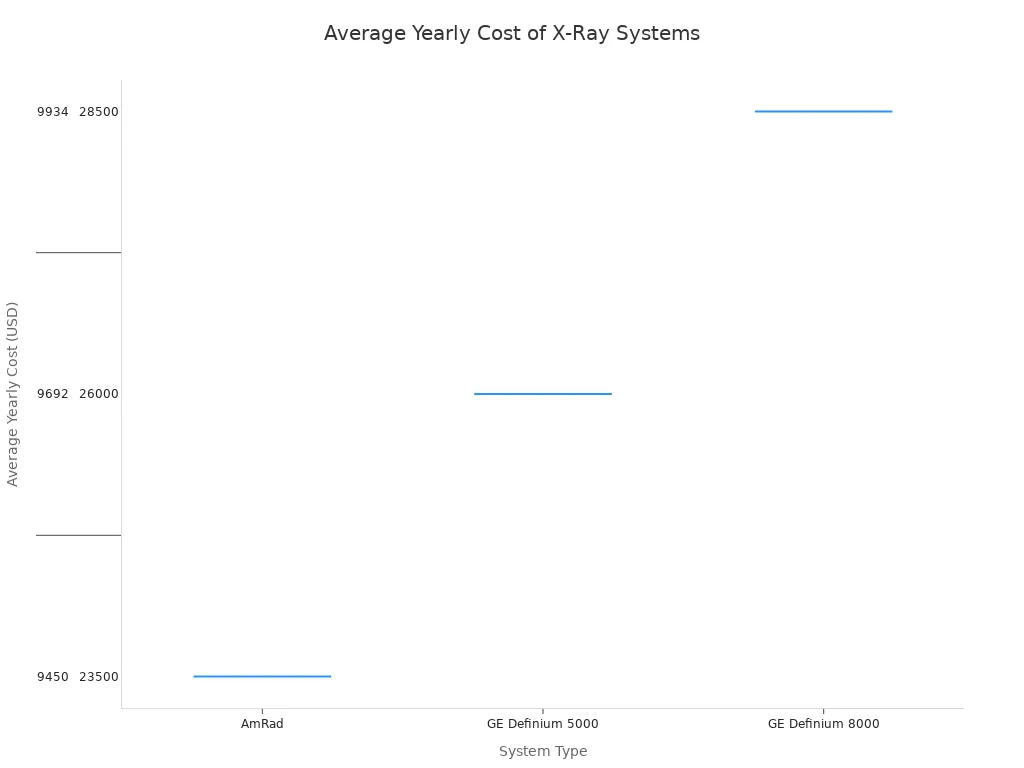

Beyond the initial purchase, processors must budget for substantial ongoing costs. These include maintenance, energy consumption, and eventual parts replacement.

- Energy Consumption: X-ray machines consume between 2 and 5 kilowatts (kW) per hour during operation, adding to daily utility expenses.

- Parts Replacement: Key components have a limited lifespan. X-ray tubes, a common replacement part, can cost between $3,000 and $9,000. For certain systems, phosphor plates may need replacement every 2 to 3 years, costing $100 to $500 per plate.

- Maintenance and Service: Annual maintenance costs generally fall between $2,000 and $10,000. Many processors opt for service contracts, which typically range from 5-10% of the system's purchase price annually.

The table below illustrates the wide range of yearly service costs associated with different X-ray system models, highlighting the need to factor long-term expenses into any ROI calculation.

| System Type | Average Yearly Cost |

|---|---|

| AmRad | $9,450 - $9,934 |

| GE Definium 5000 | $23,500 - $28,500 |

| GE Definium 8000 | $30,765 - $36,500 |

| GE Discovery XR650 | $33,915 - $39,500 |

| GE Discovery XR656 | $34,965 - $39,500 |

| GE Proteus | $17,400 - $19,975 |

| GE Silhouette | $9,608 - $10,250 |

| Siemens Ysio | $28,350 - $32,150 |

| Siemens Multix | $17,640 - $19,750 |

Operational Complexity and Staff Training

A seafood automated x ray system is a sophisticated piece of equipment. It requires skilled personnel for proper operation and maintenance. Inadequate training can lead to improper use, reduced effectiveness, and even equipment damage. Processors must invest in comprehensive training programs for their staff.

Manufacturers and third-party providers offer various training options to meet different needs.

- New Operator Training: These programs cover basic skills for new users. For example, some providers offer a half-day course covering radiation safety, operator skills, and an introduction to image analysis.

- Classroom and Online Courses: Many companies, like GE Healthcare, provide a blended curriculum. This approach combines web-based courses for independent study with in-person, hands-on training for advanced topics.

- On-Site Specialized Training: For unique operational needs, manufacturers can deliver customized training directly at the processor's facility.

This commitment to training ensures that operators can run the system efficiently, interpret images correctly, and perform routine maintenance, maximizing the return on investment.

Understanding System Limitations and Errors

No technology is perfect. X-ray systems have specific limitations and are susceptible to errors that can impact production. A primary challenge is managing the false rejection rate, where the system incorrectly flags a good product as contaminated.

Common Causes of False Rejects:

- Product Inconsistency: Changes in product temperature, moisture, or salt content can alter how the system "sees" the product, leading to errors.

- Mechanical and Hardware Issues: Problems like worn conveyor belts, loose fittings, or electrical shorts can cause malfunctions and false kick-offs.

- Software Glitches: Even minor software bugs can freeze the system or cause image delays.

- Operator Error: Inputting incorrect product settings or improper alignment can lead to faulty inspections.

Furthermore, X-ray technology has inherent limitations in detecting certain types of contaminants. The system works by identifying density differences. Low-density materials can be difficult or impossible to find.

- Undetectable Contaminants: Items like hair, string, wood, insects, and many types of plastic often go undetected because their density is similar to the food product.

- Bone Detection: The system excels at finding dense, calcified bones. However, it may struggle to detect soft, uncalcified bones.

- A Simple Test: A useful rule of thumb is that if a contaminant floats on water, an X-ray system will likely not detect it. If it sinks, detection is probable.

Processors must understand these limitations to set realistic expectations and supplement X-ray inspection with other quality control measures where necessary.

Navigating Regulatory and Safety Compliance

Operating an X-ray system involves strict adherence to safety regulations to protect workers from radiation exposure. In the United States, the Occupational Safety and Health Administration (OSHA) sets clear standards for workplaces using this technology. Compliance is not optional; it is a legal requirement.

Key OSHA requirements include:

- Exposure Monitoring: Employers must provide personal monitoring devices, like film badges or dosimeters, to employees working in restricted areas. Strict quarterly dose limits are enforced for the whole body, extremities, and skin.

- Hazard Assessments: Facilities must conduct regular surveys of radiation hazards to ensure compliance and identify necessary safety controls.

- Personal Protective Equipment (PPE): Workers must use appropriate PPE, such as lead aprons, thyroid collars, and leaded eyewear, to prevent contamination and exposure.

- Caution Signs and Labels: All radiation areas and equipment must be clearly marked with conspicuous signs featuring the universal radiation symbol.

- Employee Training: OSHA mandates annual training for all personnel on radiation risks and safe work practices.

Failure to comply with these regulations can result in severe penalties, operational shutdowns, and, most importantly, a significant risk to employee health. Processors must develop a robust radiation safety program as an integral part of their X-ray system implementation.

Is It the Right Fit? Key Factors for Your ROI Analysis

Deciding on an X-ray system requires a detailed return on investment (ROI) analysis. Processors must look beyond the initial price tag. They should evaluate how the technology aligns with their specific production scale, product characteristics, and market demands.

Assessing Your Production Scale

High-volume operations often see the clearest ROI from X-ray inspection. The system’s ability to run continuously at high speeds maximizes throughput and reduces the need for manual inspectors. For smaller processors, the high capital cost may be difficult to justify unless other factors, like product value or market requirements, are significant drivers.

Analyzing Your Product Type and Value

The form of the seafood product directly influences the required system configuration and its effectiveness.

- Whole Fish: Processors inspecting fillets for thin bones may need advanced dual-energy systems. These specialized units enhance image sharpness to detect low-density bones that standard X-rays miss.

- Minced or Fluid Products: Minced fish or pastes require a pipeline X-ray system. This configuration inspects the product as it flows, using an automatic reject valve to remove contaminated portions.

- Loose Products: For items like fish floss, vibration mechanisms can be added to separate the product and improve bone detection.

Evaluating Your Target Market Requirements

Accessing premium retail or international markets often mandates advanced inspection. Many major buyers and food safety certifications, like BRCGS, require robust foreign body detection. A seafood automated x ray system demonstrates a commitment to safety that can unlock valuable business opportunities.

Comparing Against Alternative Technologies

Processors should weigh X-ray systems against other inspection methods like metal detectors and vision systems. While metal detectors are less expensive, they have significant limitations. Vision systems are improving, but X-ray technology often provides a lower total cost of ownership due to its robust construction and longer operational life.

| Technology | Detects | Best For | Key Limitation |

|---|---|---|---|

| X-Ray System | Metal, glass, bone, stone | Contaminant detection in any packaging | Cannot find low-density items (wood, hair) |

| Metal Detector | Ferrous, non-ferrous, stainless steel | Basic metal detection in non-metal packaging | Ineffective on non-metals; struggles with wet products |

A seafood automated x ray system offers unparalleled safety and quality control. It requires a major investment and operational commitment. The decision hinges on a detailed analysis of production volume, product type, and market demands. Large processors often see a clear ROI, while smaller operations must weigh costs against alternatives.

FAQ

Are X-ray inspected seafood products safe to eat?

Yes, the food is completely safe. The radiation dose is extremely low and does not remain in the product. It has no effect on the food's safety, texture, or taste.

What is the main difference between an X-ray system and a metal detector?

An X-ray system detects contaminants based on density differences. It finds metal, glass, and bone. A metal detector only finds metal and cannot inspect products in foil packaging.

How much training do operators need for a seafood automated x ray system?

Operators require specialized training. This includes radiation safety, system operation, and image analysis. Manufacturers typically provide courses to ensure staff can run the equipment effectively and safely.

See Also

Discovering Top Chinese Suppliers for X-Ray Inspection Machine Procurement

Essential Capsule Checkweighers for Pharmaceutical Buyers to Evaluate in 2025

Three Indispensable Industrial Checkweighers for Modern Food Processing Facilities

A 2025 Performance Comparison: Shell Versus Plate Heat Exchangers

Evaluating Investment in Automated Virus Sampling Tube Assembly Line Technology