Better Yields with a Data-Driven Spelt Sorting Solution

The global spelt market shows significant growth, projecting an increase of USD 11.79 billion by 2028.

A modern spelt sorting solution leverages advanced technologies to meet quality demands. Systems using high-resolution cameras, NIR spectroscopy, and AI software precisely identify and remove defects, creating a purer and more valuable final product.

Removing Contaminants and Foreign Material

A data-driven sorting solution provides the first line of defense for product safety and purity. These systems excel at identifying and ejecting a wide range of undesirable materials from the product stream. Processors can protect consumers and enhance brand reputation by removing everything from invisible mycotoxins to visible foreign objects.

Target Ergot and Mycotoxins with NIR

Mycotoxin contamination poses a significant threat to spelt quality and safety. Many European heritage and modern spelt varieties show susceptibility to Fusarium Head Blight (FHB). This fungal disease often leads to mycotoxin contamination in the grain. Agricultural practices like reduced tillage and inadequate crop rotation can increase the risk of FHB attacks, making effective sorting essential.

Regulatory bodies enforce strict limits on mycotoxin levels. Processors must meet these standards to access key markets. For example, the EU recently updated its regulations, lowering the maximum allowable levels for common mycotoxins like Deoxynivalenol (DON) and Zearalenone.

| Product | Deoxynivalenol (ppb) | Zearalenone (ppb) |

|---|---|---|

| Other unprocessed cereals | 1,000 | 100 |

| Cereal flour and semolina | 600 | 75 |

Near-Infrared (NIR) spectroscopy offers a powerful, non-destructive method for tackling this challenge. NIR technology does not detect mycotoxins directly. Instead, it identifies indirect alterations in the grain's chemical composition caused by fungal attacks. The system analyzes spectral zones related to carbohydrates and proteins. It detects subtle changes that signal damage from contamination, allowing the sorter to eject affected kernels with precision.

Did You Know? 💡 Studies show that removing just 21.5% of the most contaminated oat grains can reduce overall toxin levels by over 95%. This highlights the immense efficiency of targeted sorting.

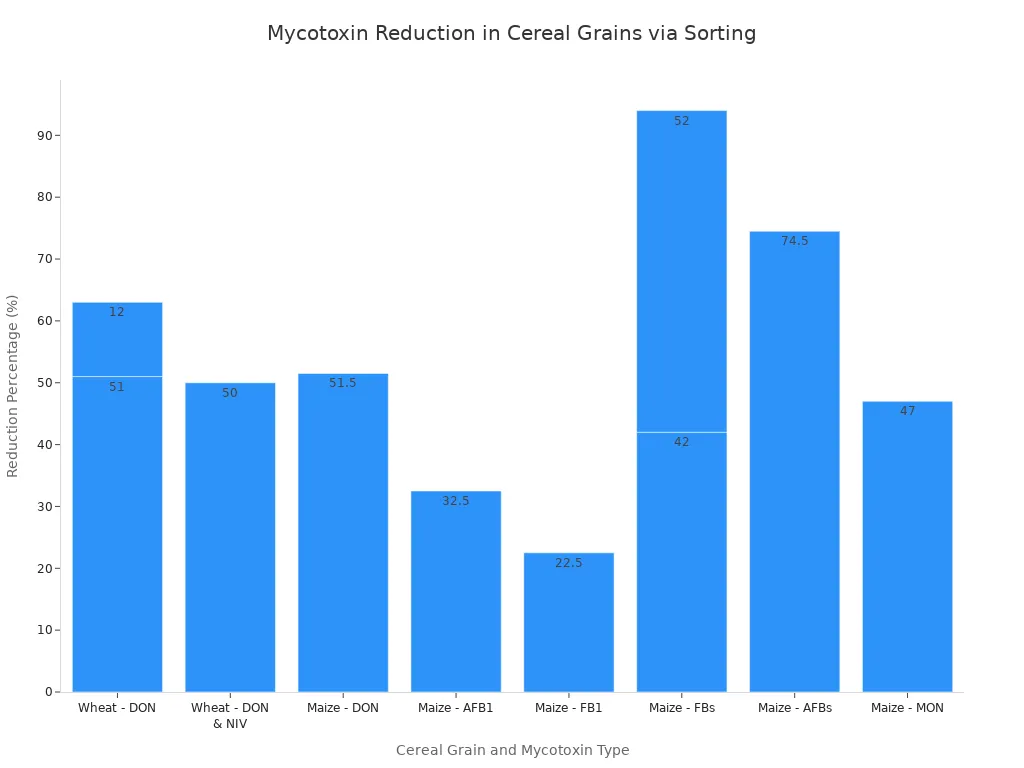

Case studies across the cereal industry confirm the effectiveness of this approach. Advanced sorting methods consistently reduce mycotoxin levels in various grains, ensuring a safer final product.

Eliminate Foreign Seeds and Grains

Product purity is a key indicator of quality. Spelt is often grown in rotation with other cereals, leading to the accidental inclusion of foreign grains like wheat or barley. Weed seeds are another common contaminant. An advanced optical sorter uses high-resolution color cameras and shape recognition software to solve this problem. The system analyzes each object in the product stream. It identifies foreign seeds and grains based on differences in size, shape, or color. High-speed air jets then precisely eject these unwanted elements, leaving a pure, uniform batch of spelt.

Eject Stones, Glass, and Plastics

Hard, dense foreign materials present a major food safety hazard. Stones, glass fragments, and dense plastics can enter the product stream during harvesting or transport. These contaminants are often similar in size and shape to spelt kernels, making them difficult to remove with traditional mechanical cleaners.

X-ray technology provides a definitive solution. Sorting systems equipped with X-ray detectors identify materials based on atomic density.

- The technology uses X-ray transmission to scan every item.

- It detects material-dependent differences in X-ray absorption.

- The system classifies and sorts materials based on their density.

- This allows it to easily differentiate dense objects like stones, glass, and metal from the lighter organic spelt kernels.

This capability ensures the final product is free from dangerous physical hazards, protecting both consumers and processing equipment from damage.

Enhancing Quality with a Spelt Sorting Solution

Beyond removing dangerous contaminants, a data-driven spelt sorting solution plays a crucial role in refining product quality. It elevates the final batch by ensuring visual appeal, consistency, and maximum value. Processors can meet the highest market standards by targeting imperfections and grading kernels with incredible precision.

Remove Discolored and Damaged Kernels

Visual quality is a primary determinant of consumer perception and market value. Spelt kernels can suffer discoloration and damage from various environmental and biological factors.

- Environmental Stress: Frost damage can cause pale brown patches and scorched spots on kernels as ice crystals form inside plant tissue.

- Bacterial Infections: Diseases like basal glume rot may lead to a dull brown or black discoloration on the glumes, sometimes resulting in shriveled seeds.

- Fungal Diseases: Fusarium head blight can produce chalky, shriveled, or discolored kernels. Other fungi, like ergot, replace healthy grains with dark, purple-black sclerotia.

An advanced optical sorter effectively addresses these issues. The system uses high-resolution CCD cameras to capture detailed images of each kernel as it passes through the inspection zone. These cameras can detect subtle color variations and imperfections as small as 0.04mm. Intelligent software analyzes these images in real-time, identifying any kernel that deviates from the pre-set quality standard. The system then commands high-speed air jets to eject the discolored or damaged kernels, ensuring only the highest quality product continues down the line.

Grade by Size and Shape for Uniformity

Uniformity in size and shape is a critical quality parameter, especially for premium markets. Consistent kernels are essential for products like whole-grain pilafs, sprouted grain lines, and brewing adjuncts, where even cooking, texture, and sensory quality are paramount. A sophisticated spelt sorting solution achieves this uniformity with remarkable accuracy.

Modern sorters employ 3D imaging technology, using dual-camera or laser systems to analyze the complete morphology of each kernel. This process provides far more data than simple screening.

The system tracks each particle as it falls, capturing up to 250 images per second from different angles. This creates a detailed "particle track" that measures length, width, thickness, area, and other shape descriptors.

This comprehensive analysis allows processors to grade spelt with unparalleled precision. Kernels can be sorted into distinct categories based on specific size and shape parameters. This capability not only creates a visually appealing, uniform final product but also allows for the creation of specialized product grades tailored to different market demands.

Maximize Yields with AI-Powered Sorting

A primary goal of any processing operation is to maximize the yield of good product. Traditional sorting methods often struggle with the "gray area," where borderline defects can lead to the unnecessary rejection of acceptable kernels. This is where AI-powered sorting delivers a significant return on investment.

AI algorithms enhance the decision-making capabilities of a spelt sorting solution. The system learns from the continuous flow of product data, becoming progressively better at distinguishing between true defects and acceptable variations. This intelligent analysis minimizes the false rejection of good grain, a concept known as the "good-in-bad" problem.

Case studies from the broader food processing industry highlight the impact of this technology. In one instance, a tomato processor increased its yield by 25% after implementing an AI-driven optical sorter. The machine's ability to precisely identify defects while minimizing the rejection of good produce directly boosted productivity and reduced waste. Applying this same principle to spelt processing ensures that more high-quality grain makes it into the final bag, directly improving profitability.

An advanced, data-driven spelt sorting solution is the definitive method for improving product quality. It directly addresses contamination, uniformity, and safety challenges. Processors should explore specific spelt sorting solution options or consult technology experts. Assessing how these systems integrate into operations is key to achieving better yields and higher quality.

FAQ

How does a sorter identify different defects?

The system uses multiple technologies. Cameras spot visual defects. NIR spectroscopy detects chemical signs of mycotoxins. X-ray technology identifies dense foreign materials like stones and glass.

What is the role of AI in a spelt sorting solution?

AI algorithms analyze product data to improve sorting accuracy. This process minimizes the rejection of good kernels, maximizing overall yield and reducing food waste for the processor.

Can sorting technology really improve yield? ✅

Yes. AI-powered systems precisely distinguish defects from acceptable grain. This intelligent sorting minimizes the false rejection of good kernels, directly increasing the final yield of saleable product.

See Also

Capsule Sorters: Essential Tools for Flawless Product Defect Removal

Achieving Peak Performance: Steel Processing in Heat Exchange Applications

Elevate Your System: Three PHE Plate Innovations for 2025

Top Capsule Checkweighers: A Buyer's Guide for 2025

Navigating Changes: Essential Bearing Box Freight Classification Updates