Daily Maintenance for Your Peanut Sorting Machine

An operator's daily maintenance routine for a peanut sorting machine involves five critical tasks. These are cleaning, inspection, lubrication, fastening, and operational checks. Performing these steps daily is essential. It ensures optimal performance. It prevents costly downtime. It also extends the equipment's lifespan.

The true impact of unplanned downtime on revenue and profitability has been vastly underestimated in process industries. A single line stoppage can result in significant financial losses, highlighting the importance of proactive maintenance.

Step 1: Thorough Daily Cleaning

A clean machine is a reliable machine. Operators begin daily maintenance with a comprehensive cleaning process. This task removes contaminants that can affect sorting accuracy and cause mechanical wear.

Remove Product Residue

Operators must first address any product residue left from the previous run. Peanut skins, broken kernels, and oil residue can accumulate quickly. Effective removal prevents buildup and maintains a hygienic environment.

- Regular vacuuming and brushing manage dry residues like peanut skins and kernel fragments.

- Specialized, non-abrasive scrapers and stiff-bristled brushes remove stubborn, baked-on deposits.

- Alkaline degreasers can break down tough oil and fat residues on accessible components.

- Partial disassembly, following manufacturer guidelines, allows access to hidden areas for a more thorough cleaning.

Clean Optical and Sensor Components

The optical system is the heart of the peanut sorting machine. Most modern sorters feature automatic cleaning systems for their optical components. These systems dynamically adjust cleaning frequency based on dust levels. The cameras are housed in an isolated, protected environment. Therefore, operators should rely on these automated functions and avoid manual cleaning of the lenses, as the protective glass is wiped automatically.

Sanitize the Machine Exterior

Sanitizing the machine's exterior is the final step in the cleaning process. This ensures a safe, hygienic food processing environment. Operators should follow a structured, multi-step procedure for maximum effectiveness.

- Perform a prerinse to wash away loose debris.

- Clean all surfaces with an appropriate detergent to remove soils.

- Rinse the machine thoroughly to remove all detergent and remaining soils.

- Apply an EPA-approved sanitizer suitable for non-food contact surfaces.

Note: Sanitization is only effective on a clean surface. Operators must ensure all soil and detergent are removed before applying a sanitizer. This practice is a critical part of an integrated food safety program.

Step 2: Comprehensive Visual Inspection

After cleaning, operators conduct a detailed visual inspection. This proactive check helps identify potential issues before they cause equipment failure. A systematic review of mechanical, electrical, and safety systems is fundamental to daily maintenance.

Examine Mechanical Components

Operators must carefully check all moving parts for signs of wear and tear. Early detection of mechanical stress prevents unexpected breakdowns and maintains performance. Key components require close attention.

- Conveyor Belts: Operators look for fraying, cracking, or improper tension. A loose belt can slip, while a tight one strains the motor.

- Gears and Bearings: Unusual noises, excessive vibration, or overheating often indicate damage. Operators inspect gears for tooth wear and bearings for signs of corrosion or lack of smooth rotation.

- Pulleys and Product Guides: They visually inspect pulleys for wear and ensure product guides have proper clearance to prevent contact with the belts.

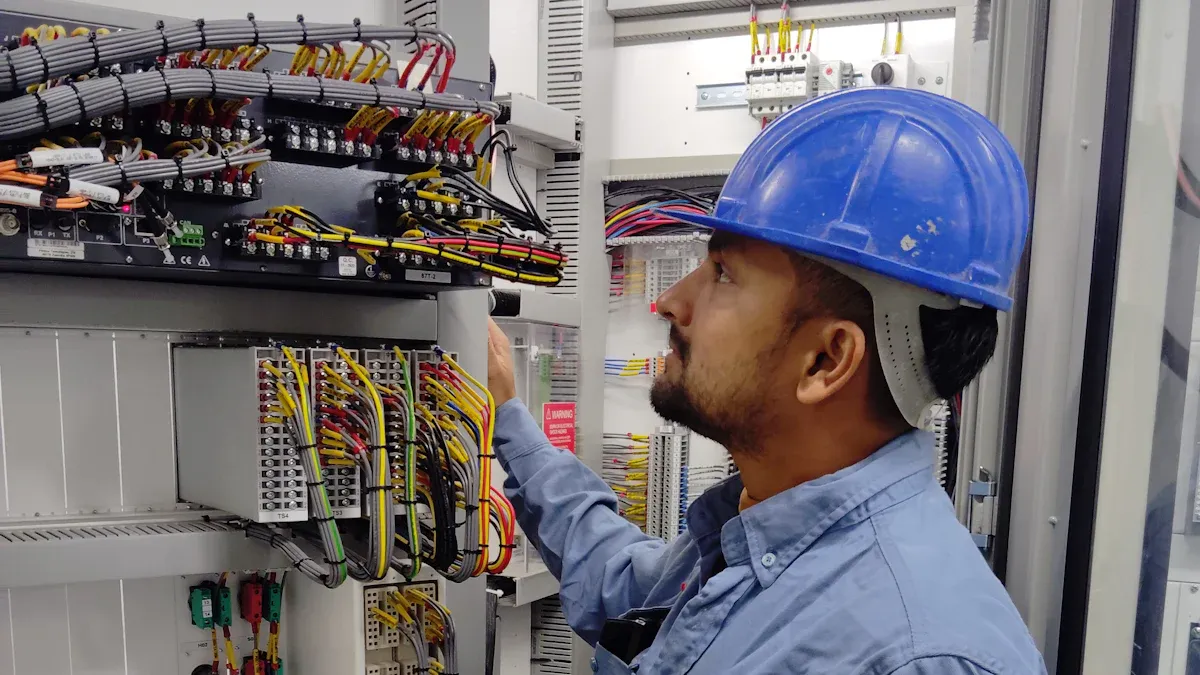

Inspect Electrical Systems

Electrical safety is critical in any processing plant. Faulty wiring in a peanut sorting machine can cause electric shock, fires, or arc flashes that shut down the entire operation. Operators should perform a safe, external inspection of electrical panels and connections. They look for burnt marks, discoloration, or loose wires. Some control panels use thermochromic indicators that change color to signal overheating.

Safety Alert ⚠️: Operators should never attempt to inspect components inside locked electrical panels. A burning smell or a hot surface requires immediate power-off and a call to a qualified electrician for diagnosis.

Verify Safety Mechanisms

A final visual check confirms all safety mechanisms are in place and functional. This step protects operators from injury. Operators verify that protective guards are secure around all moving parts, as mandated by safety standards like OSHA's 29 CFR 1910.212. They also confirm that emergency stop buttons are unobstructed and clearly visible. Ensuring these features are operational is a non-negotiable part of the daily routine.

Step 3: Essential Lubrication and Fluid Checks

Proper lubrication is the lifeblood of any mechanical system. It reduces friction, prevents overheating, and protects moving parts from premature failure. This daily step is critical for maintaining the machine's operational stability and longevity.

Identify Lubrication Points

Operators must first consult the manufacturer's manual to accurately locate all lubrication points. These often include bearings, gears, pivot points, and chains. It is vital to distinguish between different types of fittings. Some machines use oil cups, which require a steady flow of oil, while others use grease fittings.

Pro Tip: Mistaking an oil port for a grease fitting can cause catastrophic damage. Injecting thick grease into a system designed for oil will block lubrication channels, leading to bearing failure and costly repairs.

Apply Food-Grade Lubricants

Operators apply the manufacturer-specified, food-grade lubricant to each identified point. Using the correct lubricant is non-negotiable. Improper or insufficient lubrication has severe consequences.

- It accelerates component wear from metal-on-metal contact.

- It causes operating temperatures to rise, increasing the risk of damage.

- It can lead to unstable operation and loud, unusual noises.

- It ultimately results in costly mechanical failures and unplanned downtime.

Many facilities schedule this essential task for the end of the day, after the machine has been cleaned.

Remove Excess Lubricant

Applying too much lubricant can be as harmful as applying too little. Operators must wipe away any excess grease or oil with a clean cloth. Over-lubrication can rupture seals, cause internal temperatures to rise, and create a mess that attracts dust and debris. Most importantly, excess lubricant can leak and drip, creating a significant risk of chemical contamination of the peanut product. A clean, properly lubricated machine is a food-safe machine.

Step 4: Key Adjustments for Your Peanut Sorting Machine

Continuous operation generates vibrations that can loosen critical components over time. Daily adjustments ensure the peanut sorting machine maintains its precision and structural integrity. This step involves tightening fasteners, verifying alignment, and checking tension.

Secure All Fasteners

Operators conduct a systematic check of all accessible nuts, bolts, and screws. Machine vibrations can cause these fasteners to loosen, leading to component misalignment and potential safety hazards. Using the correct hand tools, they tighten any loose hardware to the manufacturer's specified torque. This simple action prevents parts from shifting during operation, which is essential for consistent performance and mechanical stability.

Check Component Alignment

Proper alignment is crucial for sorting efficiency and equipment longevity. Misaligned sensors, for example, can cause low sorting accuracy, high rejection rates, and the ejection of good products. Uneven material flow from misaligned chutes or guides also increases wear on critical parts. Operators perform a visual inspection, looking for uneven wear on belts and pulleys. For more precise checks, they may use tools like straightedges or advanced laser alignment systems to verify the correct positioning of sensors, belts, and chutes.

Verify Belt and Chain Tension

Incorrect belt and chain tension can disrupt performance and accelerate wear. Operators must check for common signs of improper tension.

- Belt slipping during startup

- Noticeable sag or looseness

- Uneven wear on belt edges

- Squeaking or grinding sounds

- The motor running hot or under strain

Expert Insight: Excessive tension strains the belt, motor, and bearings, leading to premature failure. Insufficient tension causes slippage and inconsistent material transport. Regular adjustments are key to balancing performance and component lifespan.

Step 5: Final Operational and Documentation Checks

The final step validates the maintenance work and creates a record for compliance and future reference. It combines a practical test with diligent record-keeping, ensuring the machine is ready for production.

Conduct a Power-On Test

After completing all checks, the operator safely powers on the machine. They listen carefully for any unusual sounds, such as grinding or squealing, which could indicate a problem missed during inspection. The operator also confirms that all control panel lights, screens, and indicators are functioning as expected. This initial power-on test serves as a final confirmation that the system is electrically and mechanically sound before introducing any product.

Run a Small Test Batch

Running a small test batch is essential to verify the performance of the peanut sorting machine. This test confirms that the cleaning, inspections, and adjustments have resulted in optimal sorting accuracy. Operators monitor several key performance indicators during this run.

- Sorting accuracy: The machine should achieve a target of 99% or higher.

- Throughput capacity: It should meet the expected tons per hour for the operation.

- Batch yield recovery rate: This measures the amount of good product successfully recovered.

- Consistency of rejection rate: The rate should be stable across multiple test runs.

Document Maintenance in a Log

Accurate documentation is the cornerstone of a robust maintenance program. Operators must log every completed task, noting any adjustments made or issues found. While paper logs are an option, many modern facilities use digital solutions.

Advanced Computerized Maintenance Management Systems (CMMS) and digital logbooks from providers like MasterControl or Tulip help streamline this process. These platforms automate data collection, ensure compliance with standards like FDA 21 CFR Part 11, and provide real-time insights for predictive maintenance.

This digital record creates an auditable trail, improves accountability, and helps identify recurring issues over time.

Consistent daily maintenance is non-negotiable for machine reliability. Operators prevent unexpected breakdowns by performing the five essential steps of cleaning, inspection, lubrication, fastening, and operational checks. This simple routine ensures sorting accuracy and maintains a safe work environment.

Integrating this daily workflow protects the equipment investment and guarantees consistent, high-quality product output.

FAQ

How often should operators receive maintenance training?

Operators need annual refresher training on maintenance procedures. They also require immediate training whenever the facility introduces new equipment or updates safety protocols. This ensures consistent and safe practices.

What is the biggest risk of skipping daily cleaning?

Skipping daily cleaning creates significant risks. Product residue can contaminate batches. It also causes mechanical wear, leading to inaccurate sorting and unexpected equipment failure.

Can I use a non-food-grade lubricant?

Operators must never use non-food-grade lubricants. Accidental contact with the product can cause severe chemical contamination. This creates a major food safety hazard and violates compliance standards.

Pro Tip: Always use the specific food-grade lubricant recommended in the manufacturer's manual. This protects your product, your equipment, and your business.

See Also

Essential Industrial Checkweighers: Must-Have Equipment for Modern Food Facilities

Capsule Sorters Explained: Crucial for Eliminating Imperfections in Pharmaceutical Production

Simple Maintenance Practices to Avoid Costly Dumbwaiter Elevator Malfunctions

Considering Automated Virus Sampling Tube Assembly Lines: A Smart Investment?