The Shocking Cost Of A Cabbage Sorting Machine

A cabbage sorting machine represents a significant investment for agricultural operations. This equipment's cost varies dramatically, reflecting its complexity and scale.

Prices begin near $8,000 for simple models. Advanced industrial-grade systems, however, can surpass $250,000.

A machine's technology, capacity, and long-term operational expenses ultimately determine this wide cost spectrum.

Cabbage Sorting Machine Price by Type

The price of a cabbage sorting machine directly correlates with its technological sophistication and level of automation. Manufacturers categorize these systems into three main tiers, each designed for different operational scales and processing requirements.

Entry-Level Sorters ($8,000 - $25,000)

Entry-level sorters provide basic automation for small to medium-sized farms. These machines primarily sort cabbages based on physical attributes like size and weight. They often use mechanical components, such as vibrating tables, diverging rollers, or weighing stations, to separate produce into predefined categories.

Operators typically feed cabbages onto the machine manually. The sorter then channels them into different bins or conveyor belts. While effective for initial grading, these systems still require significant labor for quality inspection, defect removal, and packing.

| Feature | Description |

|---|---|

| Technology | Mechanical (weight, size) |

| Capacity | Low to medium |

| Labor | High (manual feeding and quality control) |

| Best For | Small farms, local distributors |

These models offer a cost-effective entry point into automation, helping growers streamline a key part of their post-harvest process.

Mid-Range Optical Sorters ($25,000 - $150,000)

Mid-range systems introduce optical sorting technology. This represents a major leap in accuracy and efficiency. These machines use high-resolution cameras and sensors to analyze each cabbage as it passes along a conveyor belt. The system evaluates produce based on color, shape, and size, while also identifying external defects like blemishes, rot, or insect damage.

Sophisticated software processes these images in milliseconds. It then activates pneumatic ejectors or diverters to gently remove substandard products or sort cabbages into multiple quality grades.

A mid-range cabbage sorting machine significantly enhances product consistency. This capability allows producers to meet strict buyer specifications and command higher prices for premium-grade produce.

These sorters reduce the need for manual inspection, lower labor costs, and increase overall throughput compared to entry-level models.

Advanced Automated Systems ($150,000+)

Advanced automated systems, with prices starting at $150,000 and often exceeding $250,000, represent fully integrated post-harvest solutions. These systems go beyond simple sorting. They combine multi-sensor technology (like X-ray and hyperspectral imaging) with artificial intelligence to detect internal defects, density, and water content.

The primary value of an advanced cabbage sorting machine lies in its ability to integrate seamlessly into a complete processing line. This creates a hands-off workflow from receiving to shipping. Key integration capabilities include:

- Motor control centers that link with programmable logic controllers (PLCs) to automate the entire line, from sorting to conveyor systems and packaging.

- Vision systems that direct sorted produce into automated packing and palletizing equipment.

- Robotic palletizers that handle the stacking of cases onto pallets, while autonomous mobile robots (AMRs) transport finished pallets to storage or loading docks.

- IoT sensors that capture real-time data, connecting the equipment to plant-wide management software for remote monitoring and inventory control.

These comprehensive systems are designed for large-scale industrial operations where maximizing throughput, minimizing labor, and ensuring absolute quality control are critical.

Factors That Determine Your Total Cost

The initial price tag of a cabbage sorting machine is only one part of the equation. Several critical factors influence the total investment, from the underlying technology to long-term operational expenses. A thorough evaluation of these elements helps producers select a system that aligns with their budget and operational goals.

Sorting Technology

The type of technology used is the primary driver of a sorter's cost. Basic mechanical systems are the most affordable. Advanced systems incorporating sophisticated sensors command a much higher price due to their precision and capabilities.

Optical sorters rely on cameras and sensors for accuracy. Camera resolution directly determines the smallest defect the machine can identify. A general rule recommends using three pixels to capture the smallest detail an operator wants to find. For instance, detecting a 1mm blemish on an 800mm wide conveyor requires a high-resolution camera. The sensor type is also crucial. Global Shutter cameras are necessary for objects in motion, like cabbages on a conveyor, to prevent image distortion.

Advanced sorters utilize a combination of sensor technologies to gather comprehensive data:

- Multispectral CCD cameras detect subtle color variations invisible to the human eye, improving defect identification.

- Laser sensors measure the density and chemical composition of each cabbage.

- AI-trained vision systems learn from experience, continuously improving their ability to spot new or unusual defects.

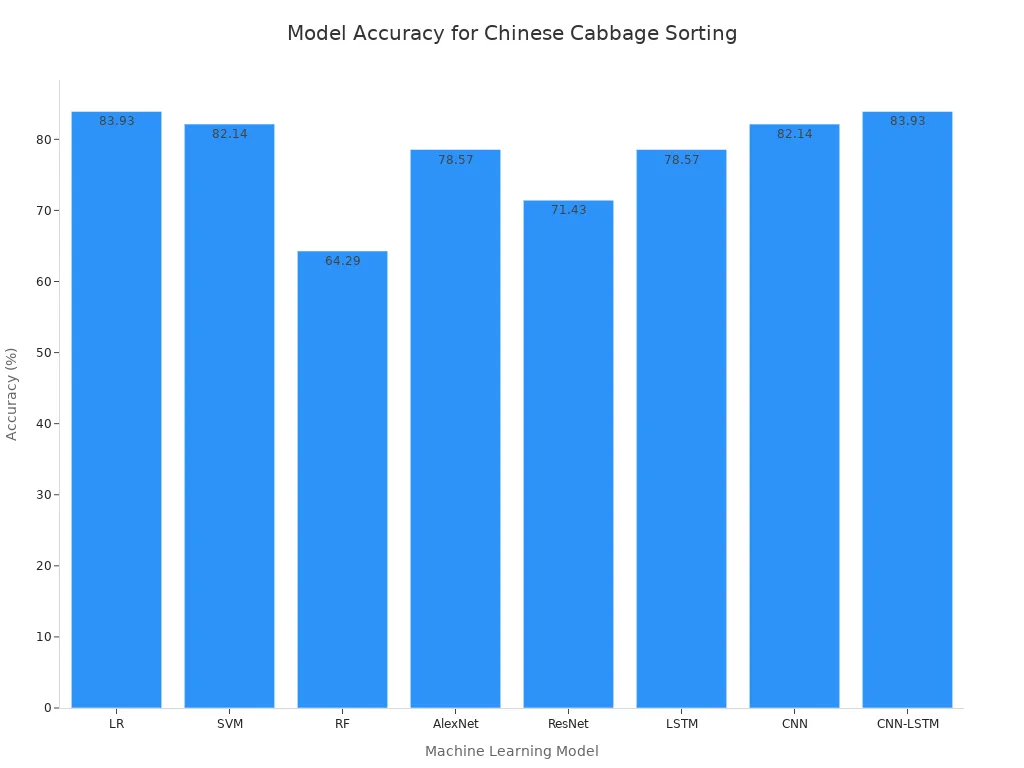

The choice of software and algorithms also impacts performance. Different machine learning models yield varying accuracy rates for specific tasks, such as determining storage time based on cabbage color and texture.

As this data shows, models like CNN-LSTM can achieve nearly 84% accuracy, but this level of performance requires significant processing power and software development, adding to the machine's cost.

Capacity and Throughput

A machine's capacity—the volume of cabbages it can process per hour—directly affects its price. A small farm may only need a sorter that handles a few tons per day. A large industrial processor, however, might require a system capable of sorting 20 tons or more per hour.

Higher throughput demands more robust construction, wider conveyor belts, faster processing speeds, and more powerful ejection systems. These enhancements increase the machine's size, complexity, and cost. Manufacturers design motors, belts, and processors to handle specific loads. Exceeding a machine's recommended capacity can lead to premature wear and breakdowns.

Customization and Features

Standard, off-the-shelf sorters offer the most economical solution. However, many operations have unique needs that require customization. These modifications add to the final cost. Common customizable features include:

- Sorting Grades: The number of output categories, typically ranging from 4 to 10.

- Weighing Accuracy: High-precision sensors that can weigh products with an accuracy of 0.1g.

- Operating Speed: Adjusting conveyor speed to process up to 600 items per minute.

- Power Supply: Configuring the equipment for specific electrical systems, such as 380v.

Some manufacturers specialize in building solutions for specific cabbage types or end products. For example, a processor making sauerkraut may need a machine that not only sorts but also cores the cabbage. Companies develop custom lines that integrate multiple functions, such as coring, splitting, and sorting, into a single automated process. These bespoke systems are engineered to solve specific operational challenges and carry a premium price.

Installation and Integration

The purchase price rarely includes the cost of installation and integration. Simple, standalone machines may require minimal setup. Complex automated systems, on the other hand, demand significant investment in this area.

Installation costs can include:

- Site Preparation: Modifying the facility to accommodate the machine's footprint, power, and data requirements.

- Technical Labor: Hiring specialized technicians to assemble, calibrate, and test the equipment.

- System Integration: Connecting the sorter to existing upstream and downstream equipment, such as washers, conveyors, and packaging machines. This often involves programming PLCs (Programmable Logic Controllers) to ensure all components work together seamlessly.

A poorly integrated system can create bottlenecks, negating the efficiency gains from the new equipment. Professional integration is crucial for maximizing return on investment.

Maintenance and Parts

The total cost of ownership extends far beyond the initial purchase. Buyers must budget for ongoing maintenance and eventual part replacements. Routine maintenance includes tasks like cleaning sensors, lubricating moving parts, and calibrating weighing systems.

Wear-and-tear is inevitable. Parts like conveyor belts, pneumatic ejectors, camera lenses, and light sources have a finite lifespan. The cost and availability of these replacement parts are important considerations.

Note: Sorters from major international brands may have higher-priced proprietary parts, while machines from other manufacturers might use more generic components that are easier and cheaper to source.

Operators should discuss service contracts and parts availability with the manufacturer before purchasing. A reliable supply of spare parts minimizes downtime and protects the investment.

Energy and Labor

Automated sorting systems consume electricity to power motors, computers, cameras, and pneumatic systems. While this adds to a facility's utility bill, the expense is often minor compared to the significant savings in labor costs.

Manual sorting is a recurring, long-term expense. Automation converts this ongoing cost into a capital investment with a high return.

| Category | Manual Sorting | Automated Sortation |

|---|---|---|

| Labor Cost | High (Recurring) | Low (Minimal Oversight) |

| Long-Term ROI | Low | High |

Automated systems can reduce direct labor needs by 40-60%. This reduction translates into substantial savings. The "fully loaded" cost of a manual worker is often 1.35 to 1.42 times their hourly wage. A worker earning $20 per hour can actually cost a business $28 per hour after taxes, benefits, and other compensation are included. Redeploying just 20 workers from a 50-person team could save a company over $1.1 million annually, which directly offsets the cost of the automation investment.

Furthermore, automation helps combat high employee turnover, which averages 46-49% annually in warehouse settings. With an estimated replacement cost of $18,600 per worker, reducing turnover creates another layer of savings. Automated systems create less physically demanding and more engaging jobs, which can reduce turnover rates by 30-40% in some facilities.

The total investment for a cabbage sorting machine spans from $8,000 to over $250,000. Producers must budget for the total cost of ownership, which includes the initial purchase plus ongoing operational expenses.

Looking ahead, the industry's shift toward AI integration and sustainability will continue to shape equipment value and operational efficiency.

Evaluating these factors helps businesses choose the right system that provides the best return on investment.

FAQ

What is the main benefit of an optical sorter?

Optical sorters use cameras to identify external defects like rot and blemishes. This improves product consistency, reduces labor, and allows producers to meet premium quality standards.

How much labor can a sorting machine save?

Automated systems can reduce direct labor requirements by 40-60%. This significant reduction in recurring wage costs provides a strong return on the initial capital investment.

Does the machine price include installation?

No, the purchase price typically excludes installation. Buyers must budget separately for site preparation, technical labor, and integration with existing production line equipment.

See Also

Essential Industrial Checkweighers: Top 3 for Every Food Processing Plant

Key Capsule Checkweighers for Buyers to Evaluate in the Year 2025

Innovative Folder Gluer Features Trending for Carton Production Lines in 2025

Money-Saving Pressure Plate Insights: Essential Facts You Need to Know

Capsule Sorters Explained: Their Crucial Role in Effective Defect Removal