A 2026 Guide to Coffee Bean Sorting Technologies

The coffee processing equipment market shows significant growth, with projections highlighting continued expansion.

| Metric | Value |

|---|---|

| Market Size 2024 | $4.115 billion |

| Market Size 2025 | $4.276 billion |

| Projected Market Size 2035 | $6.275 billion |

| Compound Annual Growth Rate (CAGR) | 3.91% (2025 - 2035) |

Optical sorters offer a cost-effective solution, removing common external defects. A coffee bean x ray machine provides superior detection for internal, density-based defects like hollow beans or foreign materials.

Core Functionality: How Each Technology Sorts Coffee Beans

Understanding the fundamental mechanics of optical and X-ray sorters reveals their distinct roles in quality control. Each system uses a unique method to analyze and eject imperfect beans, targeting different types of defects.

Optical Sorters: Sorting by Sight

Optical sorters function like highly advanced eyes. They use high-resolution cameras and broadband LED lighting to capture detailed images of each bean. The system photographs every bean, analyzing its color and shape. It compares these images against a pre-set standard of a perfect bean. This process allows the sorter to identify surface-level defects like discoloration, insect damage, or irregular shapes.

Tech Tip: Modern sorters integrate machine learning algorithms, such as Convolutional Neural Networks (CNNs). These networks automate quality classification and achieve remarkable precision.

- CNNs can reach a mean accuracy of 99.58% in cross-validation tests.

- This automation enhances consistency and allows for high-volume sorting.

When a defective bean is identified, the machine uses precise pneumatic valves to eject it from the product stream with a quick puff of air.

X-Ray Sorters: Sorting by Density

A coffee bean x ray machine sorts products by analyzing their internal structure. This technology sends low-energy X-rays through the beans as they pass through the machine. A sensor on the opposite side measures the amount of X-ray energy that is absorbed. Denser materials, like stones, glass, or metal, absorb more X-rays than a coffee bean. The system detects these variations in density. It can also identify internal issues like hollow or underdeveloped beans. Once a dense contaminant or internal defect is found, the sorter activates an ejection mechanism. These mechanisms include:

- Air Nozzles: For precise removal of small contaminants.

- Sweep Mechanisms: For ejecting heavier objects from the product flow.

This density-based approach ensures the removal of foreign materials invisible to standard cameras.

Head-to-Head Comparison: Defect Removal Capabilities

The choice between an optical and an X-ray sorter hinges on the specific defects a business aims to eliminate. Each technology excels in a distinct domain. Optical sorters are masters of surface inspection, while X-ray sorters specialize in detecting hidden, internal flaws and dense contaminants.

Where Optical Sorters Win: Surface-Level Defects

Optical sorters are the industry standard for improving coffee grade and visual appeal. Their high-resolution cameras are exceptionally skilled at identifying and removing defects visible on the bean's surface. Modern systems use laser and computer-driven technology to achieve remarkable precision. Processors can even customize the machines to target specific shades of discoloration, ensuring a uniform final product.

These sorters effectively target a wide array of common issues. Their primary function in automated dry mills is the elimination of discolored beans. They also excel at removing:

- Immature and insect-damaged beans

- Over-roasted and under-roasted beans

- Foreign materials like sticks, stones, and plastic that have a contrasting color

The accuracy of this technology is a key advantage. Modern optical sorters frequently achieve accuracy rates above 99.9% for identifying defects. They accomplish this while keeping good product loss at levels well below 1%, protecting both quality and yield.

While quantifying the exact impact on a final cupping score can be challenging, the improvement in quality is undeniable. Roasters consistently report a significant difference in the cup profile after sorting.

Kyle from Counter Culture notes a "stark contrast" when tasting the rejected beans. These rejects often have undesirable notes like "burnt popcorn, hay, hollow, or peanut shells."

Removing these defective beans leads to a more consistent and cleaner flavor. Paul Stephens of Rosso Coffee Roasters observes that unsorted coffees are less consistent and can have harsh, burnt flavors. Optical sorting cleans up these batches, making them more viable and improving their perceived quality.

Where X-Ray Sorters Win: Internal & Foreign Material Defects

A coffee bean x ray machine provides an unmatched level of food safety and quality control by inspecting the internal structure of each bean. This technology excels where optical sorters cannot: detecting defects based on density. It is the ultimate safeguard against dense foreign materials that pose a safety risk to consumers.

The precision of modern X-ray systems is impressive. Advanced hardware and software can detect high-density fragments as small as 0.3mm, a significant improvement in detection capability. This ensures the removal of tiny pieces of metal, glass, or stone that are invisible to the naked eye and optical cameras.

The sensitivity of these systems is consistently high across various machine configurations.

| System Type | Sensitivity (Stainless Steel Ball) |

|---|---|

| X-Ray Inspection for Unpackaged Bulk Products | Φ0.3mm |

| X-Ray Inspection for Packaged Products | Φ0.3mm |

| Single Beam Side Scan X-Ray Inspection | Φ0.3mm |

| Dual Beam Side Scan X-Ray Inspection | Φ0.3mm |

This high sensitivity translates directly into reliable performance, with overall sorting accuracy meeting rigorous standards.

| Parameter | Value |

|---|---|

| Sorting accuracy | 99% |

Beyond foreign materials, X-ray sorters can identify internal bean defects like hollow or underdeveloped beans. This capability ensures a more consistent roast and a better final product. For these reasons, X-ray inspection is a recommended tool for businesses adhering to global food safety standards like HACCP and BRC. Specialized systems are designed specifically for inspecting bulk goods like coffee, making them an integral part of a comprehensive safety plan.

Investment and Operational Costs: Which is More Economical?

Evaluating the financial commitment for sorting technology involves analyzing both the initial purchase price and long-term running expenses. While optical sorters present a lower barrier to entry, X-ray systems involve a more significant upfront investment tied to their advanced capabilities.

Upfront Cost Analysis

Optical sorters are generally the more affordable option, making them accessible to a wider range of coffee businesses. A coffee bean X-ray machine, in contrast, represents a substantial capital expenditure. Basic X-ray systems for standard applications start between $60,000 and $120,000. The price increases significantly based on specific features.

Key Cost Factors for X-Ray Sorters:

- Advanced Features: Models with AI or dual-energy technology can cost from $150,000 to over $500,000.

- Detection Resolution: Higher resolution for finding smaller contaminants increases the price.

- Speed and Throughput: Systems designed for high-volume production lines are more expensive.

Operational and Maintenance Costs

Operational costs differ significantly between the two technologies. X-ray sorters typically have higher energy consumption and more expensive spare parts compared to optical sorters. Modern optical sorting technology, however, is trending toward greater sustainability with reduced energy use and improved efficiency.

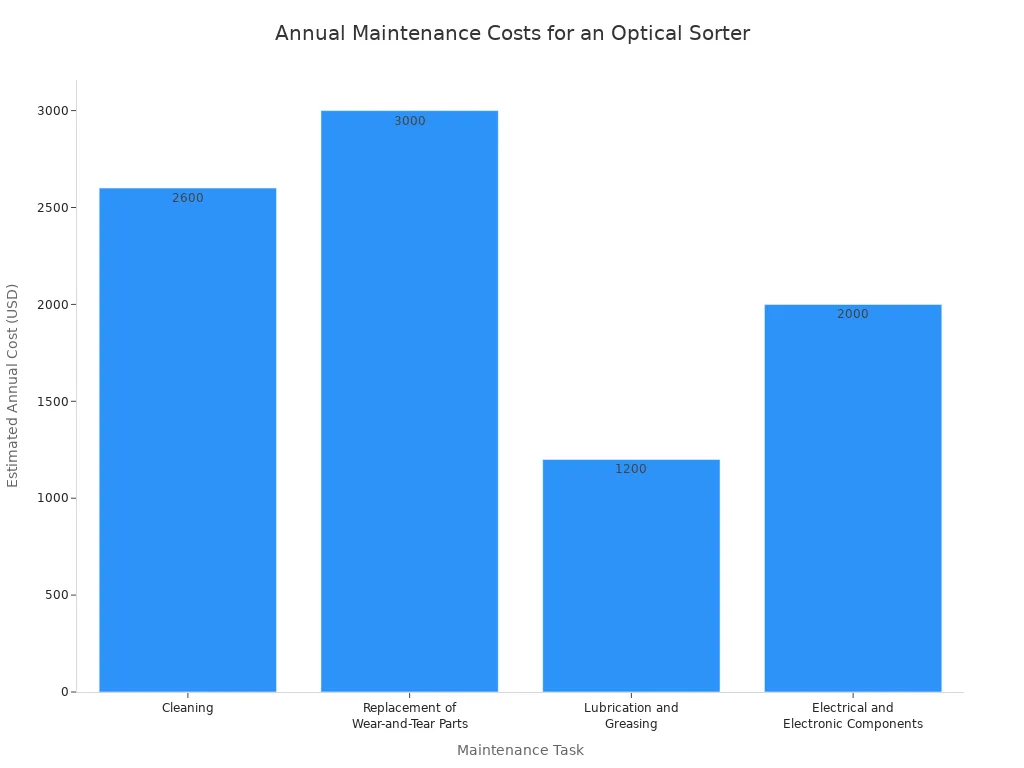

Regular maintenance is crucial for any sorter. For an optical sorter, annual upkeep is a predictable expense.

| Maintenance Task | Estimated Annual Cost |

|---|---|

| Cleaning | $2,600 |

| Replacement of Wear-and-Tear Parts | $3,000 |

| Lubrication and Greasing | $1,200 |

| Electrical and Electronic Components | $2,000 |

| Total Annual Maintenance Cost | $8,800 |

These tasks ensure the machine operates at peak performance, protecting the initial investment.

Proper care minimizes downtime and maintains sorting accuracy over the machine's lifespan.

Decision Guide: Which Sorter is Right for Your Coffee Business?

Selecting the right sorting technology is a critical decision that directly impacts product quality, operational efficiency, and brand reputation. The choice depends on a business's specific goals, from enhancing flavor profiles to guaranteeing absolute food safety. This guide breaks down the ideal scenarios for each technology.

Choose an Optical Sorter If...

A business should invest in an optical sorter when its primary goals are to improve coffee grade, ensure visual uniformity, and elevate the final cup quality. This technology is the cornerstone for specialty coffee roasters and any producer focused on delivering a consistent, visually appealing product.

Pioneers in the specialty coffee industry demonstrate the value of this investment. Counter Culture Coffee, for instance, was the first specialty roaster to adopt optical sorting for post-roast quality control. They use Bühler and Satake sorters to guarantee the consistency of their finished products. Similarly, Onyx Coffee Lab utilizes optical sorting to maintain its high standards, precisely removing defective beans from large batches.

An optical sorter is the right choice if your business aims to:

- Enhance Flavor Consistency: Investing in an optical sorter can lead to a 97% reduction in 'quakers'—underdeveloped beans that create inconsistent, off-flavors. Removing them creates a cleaner, more reliable cup profile.

- Improve Coffee Grade: These systems excel at removing a wide range of defects that impact grading. AI-powered sorters can detect discoloration, fermentation, mold, insect damage, and broken beans with incredible speed and accuracy.

- Achieve Batch Uniformity: Processors can create highly uniform batches sorted to strict color and size specifications. This capability ensures the consistent delivery of high-quality blends and single-origin offerings.

- Increase Throughput: AI-driven optical sorters process beans at speeds far exceeding manual methods. This efficiency boosts revenue while adhering to strict quality guidelines.

Choose a Coffee Bean X Ray Machine If...

A business should prioritize a coffee bean x ray machine when its main objectives are mitigating food safety risks and protecting its brand from the severe consequences of foreign material contamination. This technology is essential for large-scale operations where consumer safety is paramount.

The risks associated with contamination are substantial. A single incident involving foreign materials can lead to millions of dollars in recall costs, business disruption, and irreparable brand damage. Traditional metal detectors are insufficient, as they cannot identify common non-metallic contaminants like stones, glass, hard plastic, or rubber. Stones, in particular, are a frequent contaminant introduced during harvesting and drying.

A roasted coffee bean producer faced a persistent issue with stones in their final product. Despite using destoners and color sorters, the problem remained. By installing an X-ray inspection system, they successfully eliminated stones and other dense materials, protecting their customers and resolving a long-standing quality control failure.

Choose an X-ray sorter if your business:

- Operates on a Large Scale: High-volume production lines increase the statistical probability of contamination. X-ray inspection provides a critical safety net.

- Prioritizes Absolute Food Safety: For businesses supplying major retailers or adhering to global food safety standards (HACCP, BRC), X-ray inspection is a non-negotiable tool for risk management.

- Packages in Opaque Materials: X-ray technology can inspect products even after they are sealed in packaging like metalized foil bags or cans, providing a final quality check before shipment.

- Seeks to Protect Brand Reputation: The investment in an X-ray system is a proactive measure to prevent product recalls and safeguard the trust consumers place in your brand.

The Hybrid Approach: Using Both for Ultimate Quality

For businesses aiming for the highest possible standard of quality and safety, a hybrid approach is the definitive solution. Integrating both optical and X-ray sorters into the production line creates a comprehensive quality control system that addresses all potential defects, from surface-level imperfections to hidden foreign materials.

In this setup, each machine performs its specialized task in sequence. Companies like MEYER and Henningsaint provide advanced processing lines that exemplify this strategy. Their systems often place an optical sorter after initial cleaning and grading to remove color and shape defects. An X-ray machine then serves as the final quality gate before packaging, scanning for dense contaminants. Some manufacturers, like Techik, even offer an "Intelligent Combo X-ray and Visual Inspection Machine" that combines both functions.

This dual-technology workflow ensures every bean is checked for both aesthetic quality and internal purity.

| Technology | Primary Role in a Hybrid System | Defects Targeted |

|---|---|---|

| Optical Sorter | Quality & Grade Enhancement | Discolored, immature, insect-damaged, broken, and misshapen beans. |

| X-Ray Sorter | Food Safety & Purity Assurance | Stones, glass, metal, high-density plastics, and other foreign materials. |

By leveraging the strengths of both technologies, a coffee business can confidently deliver a product that is not only visually perfect and delicious but also unequivocally safe for consumption.

Optical sorters are the best all-around choice for businesses improving coffee grade and flavor. A coffee bean x ray machine is the superior solution for large-scale operations prioritizing absolute food safety. The best choice depends on your quality goals, risk tolerance, and budget.

Business owners find optical sorting provides "crop insurance," improving cup scores by 3-5 points for some coffees.

Future systems with artificial intelligence will further enhance sorting precision, streamlining quality control.

FAQ

Can a sorter handle both green and roasted beans?

Yes, manufacturers design sorters for both. Processors calibrate the machines for the unique color, size, and density profiles of either green or roasted coffee beans.

How fast can these machines sort coffee?

Sorting speed varies by model. High-capacity optical sorters can process several tons of coffee per hour, ensuring efficiency for large-scale operations and maintaining high throughput.

Do these machines replace manual sorting completely?

Automated sorters significantly reduce labor. However, many specialty producers still use manual sorting as a final quality check to achieve the highest possible standard for their coffee.

See Also

Essential Capsule Checkweighers: What Buyers Need for 2025 Success

Crucial Industrial Checkweighers: Three Must-Haves for Every Food Plant

Capsule Sorters Demystified: Key to Effective Defect Removal Processes

Tablet Sampling Machines: The Definitive Guide for Lab Selection

Future of Carton Lines: Trending Folder Gluer Features for 2025