Your 2025 guide to a chia seeds optical sorter

Investing in a chia seeds optical sorter is a critical strategic move. It positions processors for enhanced profitability in a growing market. The global chia seed market shows significant potential.

| Metric | 2025 Projection |

|---|---|

| Market Size | USD 1.22 Billion |

| CAGR (2025-2033) | 11.13% |

This technology is key to achieving superior seed purity and boosting operational efficiency. It directly maximizes financial returns for businesses.

The ROI of Optical Sorting for Chia Seeds

A chia seeds optical sorter delivers a strong return on investment. It enhances multiple facets of a processing operation. Businesses see improvements from product quality to financial performance. This technology is a cornerstone for modern, competitive chia seed processing.

Achieve Premium Purity and Quality

Processors can achieve exceptional product purity with this equipment. The sorter identifies and removes unwanted materials with precision. These defects include:

- Discolored or immature seeds

- Stones and sticks

- Other foreign grains

This advanced sorting capability allows companies to market their chia seeds as a premium-grade product. Consumers trust brands that consistently deliver clean, high-quality seeds. This trust translates directly into brand loyalty and higher sales potential.

Boost Processing Efficiency and Yield

Automated sorting significantly increases throughput. The machine processes large volumes of seeds much faster than manual inspection. It operates continuously with minimal downtime. This efficiency boosts the overall production capacity of a facility. Furthermore, the sorter's accuracy minimizes the rejection of good seeds. This action maximizes the final product yield from each batch, turning raw material into sellable inventory.

Reduce Labor and Operational Costs

Automation directly reduces the reliance on manual labor for sorting tasks. This shift lowers associated costs like wages, training, and benefits. A single machine performs the work of multiple inspectors with greater accuracy and speed. The consistent operation also leads to more predictable production schedules and reduces costs associated with human error and rework.

Key Features of a Modern Chia Seeds Optical Sorter

Modern sorters combine sophisticated hardware and intelligent software. This combination ensures maximum purity and efficiency. Understanding these core features helps processors select the right equipment for their specific needs.

Advanced Camera and Sensor Technology

High-resolution cameras are the eyes of the sorting system. They capture detailed images of each seed from multiple angles. These advanced sensors can detect subtle variations in color, size, and shape. This capability allows the machine to identify defects like immature seeds, foreign grains, or tiny stones with incredible precision. The quality of the camera system directly impacts the sorter's ability to produce a premium final product.

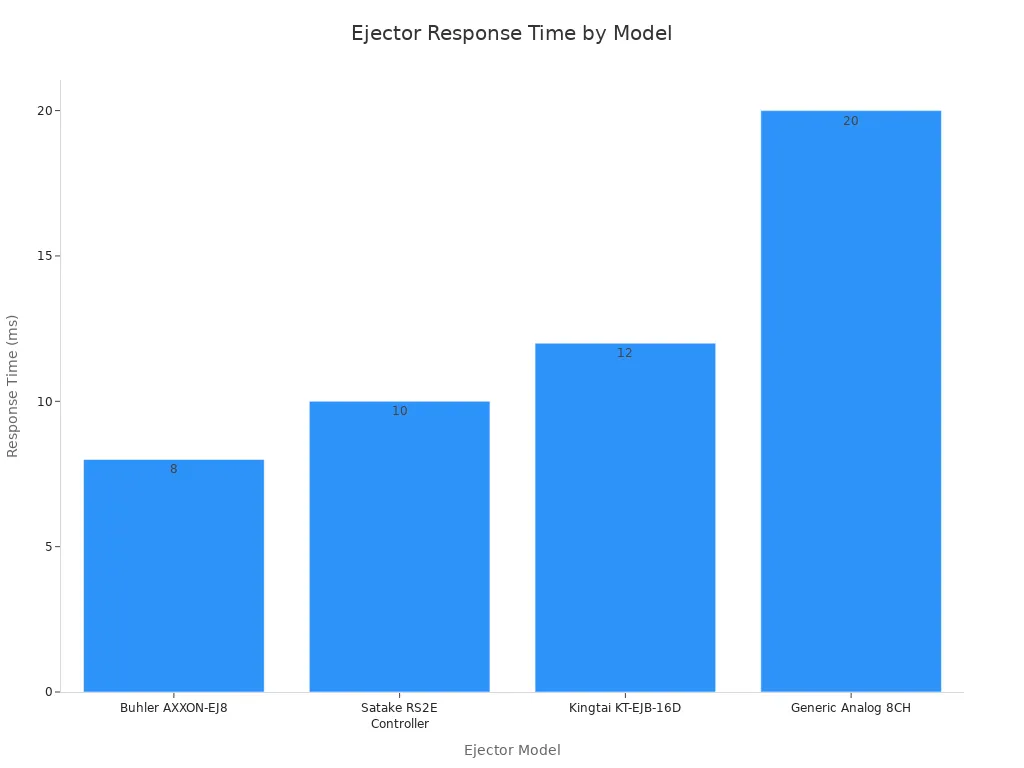

High-Speed Ejector Systems

Once a camera identifies a defective seed, a high-speed ejector system removes it from the product stream. The system uses precise puffs of compressed air. The speed of this action, or response time, is critical. A faster response ensures accurate removal without accidentally ejecting good seeds. For effective sorting, a response time of 10 milliseconds or less is ideal. The most advanced systems, using Maglev technology, can achieve response times as low as 0.8 milliseconds.

Note: The ejector's response time is a key performance indicator. Faster response times lead to higher accuracy and less product loss.

| Model | Type | Response Time | Target Users |

|---|---|---|---|

| Buhler AXXON-EJ8 | Digital, OEM | ≤8 ms | Large-scale grain processors |

| Satake RS2E Controller | Digital, OEM | ≤10 ms | Rice and tea sorting |

| Kingtai KT-EJB-16D | Digital, Universal | ≤12 ms | Moderate-volume recyclers |

| Generic Analog 8CH | Analog, Universal | ~20 ms | Small farms or labs |

Intelligent Sorting Software

The software is the brain of a modern chia seeds optical sorter. It uses AI and deep learning algorithms to analyze the images from the cameras. This "AI intelligent deep learning" allows the machine to improve its accuracy over time. The system learns to recognize complex defects like small disease spots, wormholes, and wrinkled skin. Operators can set quality parameters, and the software's self-learning capabilities continuously refine the sorting process for optimal results.

Calculating Your Financial Investment

A thorough financial analysis is essential before purchasing an optical sorter. Businesses must look beyond the sticker price to understand the total cost of ownership. This calculation includes the initial purchase, installation, and long-term maintenance. A clear financial plan ensures a smooth integration and a predictable return on investment.

Understanding Initial Purchase Costs

The initial purchase price represents the largest single expense. This cost varies significantly, with general-purpose color sorters ranging from $3,999 to $29,999 per unit. For specific applications like small seeds, a machine similar to an optical hemp seed sorter might cost between $5,000 and $6,000.

The final price depends heavily on the machine's capacity and technological sophistication.

- Capacity: Small processors handling 1-2 tons daily may need a sorter with a 500kg-1TPH capacity. Medium-sized operations processing 3-10 tons require larger systems in the 1-3 TPH range. Higher capacity directly translates to a higher initial cost.

- Technology: Sorters with advanced full-color RGB cameras, infrared (IR) sensors, and AI-driven software command a premium price.

- Brand and Build Quality: Established manufacturers with a reputation for reliability and support often have higher prices than newer or lesser-known brands.

Factoring in Installation and Training

The investment does not end with the equipment purchase. Processors must budget for installation and training to ensure the machine operates effectively from day one. Installation involves more than just placing the machine on the floor; it includes integration into the existing processing line, connection to compressed air systems, and proper electrical setup.

Training is equally critical. Operators need comprehensive instruction to:

- Run the machine efficiently.

- Create and adjust sorting programs for different batches of chia.

- Perform routine cleaning and basic troubleshooting.

Pro Tip: Many suppliers offer installation and training as part of a package deal. Businesses should inquire about bundling these services with the initial purchase. This approach can be more cost-effective and ensures that factory-certified technicians handle the setup and initial training.

Planning for Ongoing Maintenance

Ongoing maintenance is a recurring operational expense that protects the machine's performance and longevity. A proactive maintenance plan minimizes downtime and prevents costly emergency repairs. These costs fall into two main categories: preventative maintenance and replacement parts.

Preventative tasks include regular cleaning of camera lenses, checking air filters, and calibrating the ejector system. Corrective maintenance involves replacing components that wear out over time. Ejector valves are a common replacement part, and their costs vary dramatically depending on the manufacturer and technology. As the table below shows, a single valve can range from around $120 to over $30,000.

| Product Name | Company Name | Price Range (per Unit) |

|---|---|---|

| 13 Ohm or 18 Ohm Ejector Valves | Hefei Edison M&E Co., Ltd. | $125 |

| Original Meyer Color Sorter Ejector Valve | Henan Unio Machinery Co., Ltd. | $120–$155 |

| PinYang AMD/ANYSORT Ejector Spray Valve | Hubei Pinyang Technology Co., Ltd. | $350 |

| Powder Color Sorter Ejector Valve | Hefei Branagh Photoelectric Technology Co., Ltd. | $5,300–$6,000 |

| ANON High Quality Ejector Valves | Wuhan Anon Tech Trade Co., Ltd. | $16,000–$18,000 |

| VSEE Ejector Valves Tea/Plastic Sorter | Anhui Vsee Optoelectronic Technology Co., Ltd. | $33,000–$35,000 |

Creating a dedicated maintenance budget and exploring service contracts with the supplier can help manage these long-term costs effectively.

Quantifying the Financial Payback

An optical sorter is more than an operational upgrade; it is a powerful financial tool. Businesses can measure its value through increased revenue, reduced waste, and a clear return on investment. A detailed analysis reveals the significant financial benefits that justify the initial capital outlay.

Higher Revenue from Premium Grades

The most direct financial return comes from selling a higher-quality product. An optical sorter enables processors to achieve purity levels of 99.95% or greater. This exceptional purity allows companies to command premium prices and penetrate lucrative new markets. Buyers in these segments demand certified, high-purity ingredients and are willing to pay more for guaranteed quality.

Processors gain access to a wider range of customers, including:

- Retail Markets: Supplying supermarkets and e-commerce platforms with consumer-ready retail packs.

- Industrial Buyers: Fulfilling bulk orders for health food manufacturers and large-scale food processors.

- Specialized Industries: Meeting the strict requirements of the bakery, beverage, and nutraceutical sectors.

- Export Markets: Entering demanding international markets like the EU and the US, which require certifications (e.g., USDA Organic, BRC) and verifiable purity specifications.

Accessing these premium channels is a strategic move. It diversifies revenue streams and builds a brand reputation centered on superior quality, leading to sustained profitability and market leadership.

Savings from Reduced Product Loss

Every seed counts in a processing operation. Manual sorting or outdated equipment often results in good seeds being discarded along with defects. Modern optical sorters minimize this "good-in-bad" rejection. Their precision ensures that only true defects are removed from the product stream. This accuracy directly increases the final saleable yield from every batch.

This improvement in yield translates to significant cost savings. Consider a facility processing 5 tons of raw chia seeds per day. Even a small reduction in product loss has a substantial financial impact over a year.

| Metric | Without Advanced Sorter | With Advanced Sorter | Annual Impact |

|---|---|---|---|

| Product Loss Rate | 3% | 1% | 2% Reduction |

| Daily Loss (5 tons) | 150 kg | 50 kg | 100 kg Saved Daily |

| Annual Savings (250 days) | - | - | 25,000 kg |

| Value (@ $3/kg) | - | - | $75,000 Saved |

This table illustrates how optimizing yield directly protects the bottom line. The savings from reduced product loss alone can contribute significantly to the machine's payback.

A Sample ROI Calculation Model

Calculating the Return on Investment (ROI) provides a clear picture of the sorter's financial performance. The basic formula offers a starting point for this evaluation.

ROI (%) = (Net Profit / Total Investment Cost) x 100

A comprehensive model, however, must account for all financial impacts. This includes new revenue gains, operational savings, and the total investment cost. A business can build a simple model using key operational metrics to project its return.

Sample ROI Calculation (Year 1)

| Financial Component | Calculation | Amount |

|---|---|---|

| A. Total Investment Cost | Purchase + Installation + Training | ($70,000) |

| B. Added Revenue | Premium Price Uplift (e.g., 15%) | $120,000 |

| C. Cost Savings | Reduced Labor + Reduced Product Loss | $105,000 |

| D. Net Profit (B + C - A) | $120,000 + $105,000 - $70,000 | $155,000 |

| E. ROI (D / A x 100) | ($155,000 / $70,000) x 100 | 221% |

For a more sophisticated financial analysis, processors can use several accounting methods:

- Accounting Rate of Return (ARR): This calculates the average annual net income as a percentage of the initial investment.

- Net Present Value (NPV): This method subtracts the initial investment from the present value of future cash flows. A positive NPV indicates a profitable investment.

- Internal Rate of Return (IRR): This finds the discount rate at which the project's NPV equals zero. An IRR that exceeds the company's required rate of return signals a strong investment opportunity.

Using these models, a business can confidently quantify the payback period and long-term profitability of adding an optical sorter to its processing line.

How to Select the Right Sorter Supplier

Selecting the right supplier is as crucial as choosing the right technology. A strong partnership ensures long-term success and maximizes the return on investment. Businesses should conduct thorough due diligence before committing to a purchase.

Key Questions to Ask Vendors

Processors must ask targeted questions to vet potential suppliers. The focus should be on technology, security, and future-proofing. For sorters with intelligent software, data handling is a primary concern. Key inquiries include:

- What is the process for patching security vulnerabilities in the software?

- How does the system encrypt operational data, both at rest and in transit?

- What access control mechanisms are in place to manage user permissions?

- What is the policy for software updates and feature enhancements?

Answers to these questions reveal a vendor's commitment to security and innovation.

The Importance of a Product Test

A hands-on product test is non-negotiable. Processors should insist on testing their own chia seeds on the vendor's machine to see real-world results. This test provides quantifiable data on the sorter's performance. A critical metric to measure is Defect Removal Efficiency (DRE), which shows how effectively the sorter identifies and removes unwanted material.

A high DRE, ideally above 90%, indicates a highly effective sorting process. It confirms the machine can deliver the required purity levels before it is installed in the facility.

This step validates a vendor's claims and prevents costly post-purchase surprises.

Evaluating After-Sales Support

Reliable after-sales support is essential for maintaining operational uptime. Downtime directly impacts profitability, so a vendor's support structure is a key evaluation point. Businesses should inquire about guaranteed response times for technicians and the availability of spare parts. A strong industry benchmark for Mean Time to Repair (MTTR) is around one hour once a technician is on-site. A supplier with a robust service network and strategic parts inventory demonstrates a true partnership.

A chia seeds optical sorter represents a strategic investment in quality, efficiency, and future profitability. Selecting the right technology and supplier directly translates to a stronger market position. Processors should begin evaluating their needs now to secure a competitive advantage for 2025 and beyond.

FAQ

What defects can a sorter remove from chia seeds?

It removes discolored seeds, foreign grains, sticks, and stones. Advanced systems also detect subtle defects like mold spots or immature seeds, ensuring high purity for the final product.

How much chia can a sorter process per hour?

Capacities vary by model. Small units process around 500 kg per hour. Large industrial machines can handle over 3 tons per hour to meet high-volume production demands.

Can a chia seeds optical sorter integrate into an existing line?

Yes. Suppliers design the chia seeds optical sorter for integration. It fits into existing processing lines, often placed after cleaning equipment and before packaging systems for maximum efficiency.

See Also

Essential Capsule Checkweighers For Buyers To Evaluate In 2025

Innovative Folder Gluer Features Revolutionizing Carton Production Lines In 2025

Capsule Sorters: Crucial Technology For Effective Defect Elimination And Quality

Leading Precoating Materials Enhancing Filtration System Performance In 2025

Three Indispensable Industrial Checkweighers For Every Modern Food Processing Plant