The Essential Checklist for Buying a Snack Packing Machine

An automated packaging machine is a significant investment for any snack business. It demands careful consideration of multiple factors to ensure a successful outcome. The global snack market is expanding rapidly, with various research firms like Grand View Research and Technavio forecasting a compound annual growth rate (CAGR) between 4.2% and 7.4% in the coming years. This growth highlights the need for efficient production. Selecting the right packing machine for snacks requires a thorough evaluation of the product's unique characteristics, production volume needs, and packaging material requirements. Businesses must also analyze the total budget and the supplier's partnership potential.

Understand Your Snack Product First

Before evaluating any machinery, a business must deeply understand its own snack product. The product's unique characteristics are the most critical factor in selecting the right packaging equipment. A machine perfect for potato chips may be completely unsuitable for gummy candies. A thorough product analysis prevents costly mismatches and ensures optimal performance from day one.

Analyze Your Product's Physical State

The physical form of a snack dictates the type of filling and weighing system required. Different products flow and handle differently, demanding specialized machine configurations. Key physical properties to consider include:

- Free-flowing and Granular: Products like nuts, seeds, and popcorn flow easily. They are typically well-suited for multi-head weighers or volumetric cup fillers that rely on gravity.

- Fragile: Delicate items such as potato chips, pretzels, and tortilla chips break easily. Packaging systems for these snacks need gentle handling features, like reduced drop heights, to minimize product damage.

- Sticky or Oily: Snacks like gummy candies, dried fruit, or oily nut mixes can clump together. They often require specialized equipment, such as auger fillers or machines with dimpled, non-stick surfaces, to ensure a smooth and consistent product flow.

Determine Its Preservation Needs

A snack's shelf life depends heavily on its preservation requirements. Moisture, oxygen, and light can all degrade product quality over time. Understanding these sensitivities is essential for choosing a machine that can create a protective packaging environment.

Moisture content, for example, significantly impacts snack foods like potato wafers and corn chips. It can cause them to become soggy and unappealing. Knowing a snack's 'critical moisture content'—the point where quality declines—helps determine the necessary barrier properties of the packaging. High humidity can also cause sticky powders to interfere with machinery, leading to inconsistent quality and production losses.

Pro Tip: For products highly sensitive to oxygen, such as nuts or cheese cubes, consider a machine with gas flushing capabilities. This process, known as Modified Atmosphere Packaging (MAP), replaces oxygen inside the package with a gas like nitrogen to extend freshness and prevent spoilage.

Define Your Production Requirements

After analyzing the product, a business must define its operational needs. Production requirements directly influence the size, speed, and type of machine needed. A clear understanding of output targets, facility space, and future goals helps narrow down the options and ensures the chosen equipment aligns with the company's operational strategy.

What Is Your Target Output Rate?

A machine's speed, measured in bags per minute (bpm), is a critical performance metric. Businesses must calculate their current and projected sales volume to determine the necessary output. An entry-level machine may produce 15-30 bpm, which is suitable for startups. High-speed systems, like many Vertical Form Fill Seal (VFFS) machines, can exceed 100 bpm. The required speed depends entirely on the scale of the operation.

| Operation Scale | Example Machine/Solution | Typical Speed (bags per minute) |

|---|---|---|

| Small to Medium | Formost Fuji GTS | Up to 90 |

| Medium | Syntegon SVL 2310 | Around 105 |

| Large-scale | Rovema BVC Twin Tube | Up to 500 |

Matching machine speed to production demand prevents bottlenecks and supports efficient order fulfillment.

How Much Floor Space Do You Have?

Packaging machinery requires a dedicated physical footprint. Businesses must measure their available production area before shopping for equipment. It is important to account for not only the machine itself but also the surrounding space needed for operators, maintenance access, and the flow of raw materials and finished goods. VFFS machines are known for their compact, vertical designs, with smaller models occupying less than 1.5 square meters. Larger, more complex systems can require 10 square meters or more.

Facility Check: Always confirm that your facility's doorways, hallways, and ceiling heights can accommodate the machine's dimensions during delivery and installation.

Do You Need to Plan for Future Growth?

A packing machine for snacks is a long-term investment. Businesses should consider their growth projections when making a selection. Buying a machine that only meets current needs may lead to a costly replacement in just a few years. Instead, selecting a scalable or modular system provides flexibility. Some machines can be upgraded with faster components or additional fillers to increase capacity as the business expands. This forward-thinking approach protects the initial investment and supports sustainable growth.

Select the Right Packaging Type

The packaging format is a direct extension of a brand and product. It influences consumer perception and protects the snack inside. Businesses must choose a format that aligns with their product, brand identity, and operational capabilities. Common snack packaging falls into two main categories: flexible and rigid.

Bags & Pouches: Vertical Form Fill Seal vs. Pouch Packers

Flexible packaging is the most popular choice for snacks. Formats include stand-up pouches, lay-flat pillow pouches, and sachets. Companies have two primary machine options for this style.

- Vertical Form Fill Seal (VFFS) machines create pouches from a large roll of film (rollstock), fill them with the snack, and then seal them. This method is highly efficient and cost-effective for high-volume production of simpler bag styles like pillow pouches.

- Premade Pouch Packers work with bags that are already formed. The machine simply opens, fills, and seals the pouch. This equipment offers excellent flexibility for brands with many SKUs and provides a premium-looking finished product, especially for stand-up pouches with zippers.

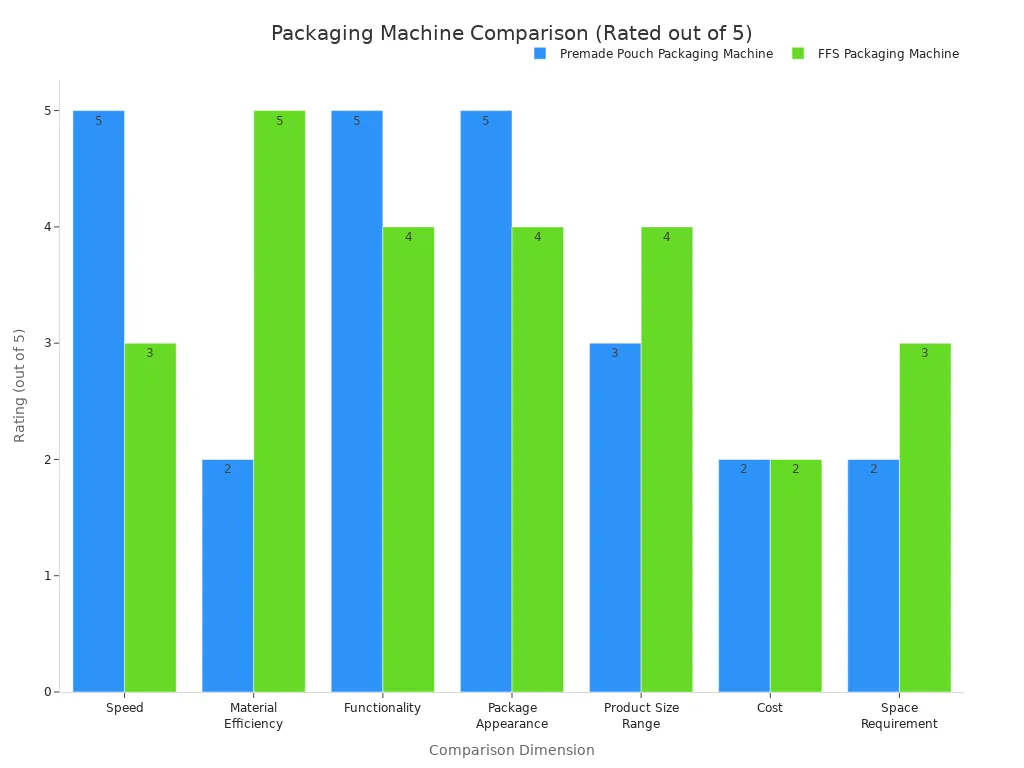

The choice depends on speed, cost, and desired appearance. The chart below offers a visual comparison.

Rigid Containers: Jar & Can Filling Lines

Some snacks, like gourmet nuts or dips, are better suited for rigid packaging. Common options include plastic or glass jars, paperboard canisters, and metal cans. These containers offer superior product protection and a premium feel. Packaging these products requires a different type of system, often a complete filling line. These lines automate the process of de-palletizing, cleaning, filling, and capping the containers.

What Material and Seal Type Are Required?

The packaging material is the first line of defense against spoilage. Its barrier properties must match the snack's preservation needs. For example, Polypropylene (PP) offers good heat resistance, while Polyethylene Terephthalate (PET) provides a strong gas and moisture barrier. For maximum protection against light, oxygen, and moisture, many brands use laminates containing a layer of aluminum foil. The chosen material directly impacts the type of sealing technology a packing machine for snacks must have, with heat sealing being the most common method for flexible films.

Key Features of a Packing Machine For Snacks

Beyond the basic functions, specific machine features determine its efficiency, reliability, and overall value. Businesses should scrutinize these details to find a machine that not only packages the product but also enhances the entire production line. Key areas to evaluate include weighing accuracy, operational simplicity, and construction quality.

The Importance of Weighing Accuracy

Weighing accuracy is paramount in snack packaging. Every gram of product giveaway—the excess product in each bag—directly erodes profit margins. While a single overfilled bag seems minor, the cumulative loss over millions of packages can be substantial. An accurate weighing system, such as a high-precision multi-head weigher, ensures each package meets its target weight without costly overages. This precision also guarantees compliance with net weight regulations, protecting the brand from legal issues.

A 1% product giveaway on a high-volume line can translate to tens of thousands of dollars in lost revenue annually. Investing in accuracy is investing in profitability.

Ease of Operation and Cleaning

A machine's daily usability directly impacts labor costs and production uptime. A packing machine for snacks with a user-friendly design minimizes the need for highly specialized operators and reduces the risk of errors. Key features to look for include:

- Intuitive HMI: A simple Human-Machine Interface (HMI) with clear graphics and controls allows for quick setup and adjustments.

- Tool-less Changeovers: The ability to switch between different products or bag sizes without special tools significantly reduces downtime.

- Sanitary Design: Smooth, accessible surfaces and Clean-in-Place (CIP) capabilities make sanitation faster and more effective, which is critical for food safety.

Build Quality and Machine Durability

The construction of a packaging machine determines its lifespan and reliability. High-quality materials and components reduce maintenance needs and prevent unexpected breakdowns. Stainless steel is the preferred material for food contact surfaces due to its corrosion resistance and durability. Cheaper materials may lower the initial cost but often lead to a shorter operational life and higher long-term expenses.

| Material Type | Typical Lifespan (Years) |

|---|---|

| Stainless Steel (SS304) | 8-12 |

| Stainless Steel (SS202) | 3-5 |

| Painted or Mild Steel | 2-4 |

A machine built with SS304 stainless steel can last 5-10 years longer than models using painted iron parts. Businesses should also verify that critical components like motors and electronics are sourced from reputable manufacturers to ensure lasting performance.

Calculate Your Total Budget

A comprehensive budget is essential for a successful equipment purchase. The total cost of ownership extends far beyond the initial price tag. Businesses must account for the upfront investment, daily operational expenses, and long-term maintenance to understand the machine's true financial impact. A thorough financial analysis prevents unexpected costs and ensures a positive return on investment.

What Is the Upfront Investment?

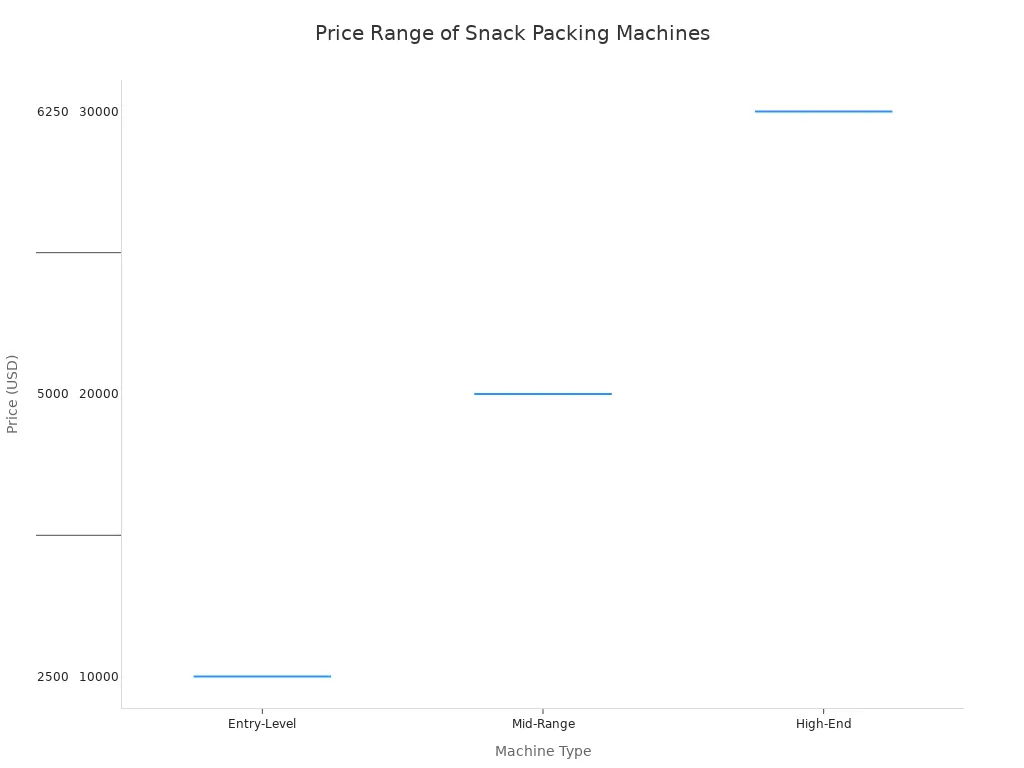

The initial purchase price is the most significant upfront cost. This price varies widely based on the machine's speed, features, and overall complexity. Entry-level systems are suitable for small-scale operations, while high-end machines offer advanced automation and speed for large production facilities. The following chart illustrates the typical price ranges a business can expect.

This cost also includes ancillary expenses like shipping, installation, and initial training.

What Are the Ongoing Operational Costs?

Daily operational costs directly affect a company's profitability. These recurring expenses are a critical part of the total budget. Key operational costs include:

- Labor: The wages for operators who run and monitor the equipment.

- Energy: The electricity and compressed air needed to power the machine.

- Consumables: The packaging film, ink, and other materials used daily.

An energy-efficient machine with a user-friendly interface can help minimize these ongoing costs, improving the overall financial return.

What Are the Long-Term Maintenance Expenses?

Proper maintenance ensures a machine's longevity and peak performance. These long-term expenses are vital for protecting the initial investment. Proactive maintenance prevents costly downtime and extends the equipment's operational life.

Financial Planning Tip: A world-class standard for maintenance budgeting is to allocate 2% to 5% of the machine's replacement asset value annually. This budget covers routine service, repairs, and necessary spare parts.

This forward-thinking financial strategy helps manage expenses and keeps the production line running smoothly.

Assess Supplier Support and Partnership

A packaging machine is more than a one-time purchase; it is the beginning of a long-term relationship with a supplier. The quality of this partnership directly impacts operational success. A great supplier provides robust support that minimizes downtime and maximizes the machine's value over its entire lifespan. Businesses should therefore carefully evaluate a supplier's service offerings before committing to a purchase.

What Installation and Training Is Included?

Proper installation and training are foundational to a successful start. A supplier should offer professional installation by certified technicians to ensure the machine is set up correctly and integrated smoothly into the production line. Following installation, comprehensive training is essential. Effective training empowers operators to run the equipment efficiently, perform routine changeovers, and handle basic troubleshooting. This knowledge transfer reduces operator error and boosts productivity from day one.

Is Technical Support Readily Available?

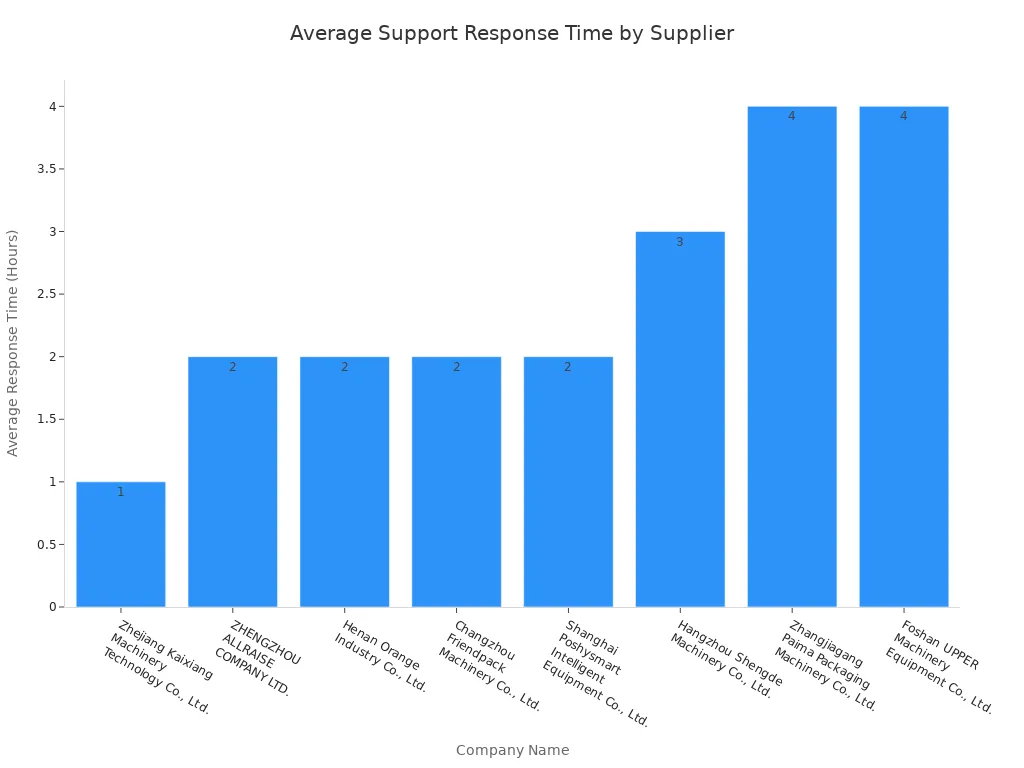

When a machine goes down, every minute of downtime costs money. Readily available technical support is non-negotiable. Businesses should inquire about the supplier's support hours, contact methods, and average response times. Many suppliers offer tiered Service Level Agreements (SLAs) that guarantee specific performance and response metrics. While benchmarks vary, some detailed agreements in the food and beverage sector set clear targets.

| SLA Tier | Target OEE | Availability | Performance | Quality | Response Time |

|---|---|---|---|---|---|

| Platinum | 95% | ≥98% | ≥97% | ≥99.5% | ≤15 min |

| Gold | 85% | ≥95% | ≥92% | ≥99% | ≤30 min |

| Silver | 75% | ≥90% | ≥88% | ≥98% | ≤60 min |

Response times can range from under an hour to a full business day. Evaluating a supplier's typical response speed provides insight into their commitment to customer uptime.

What Is the Warranty and Parts Availability?

A strong warranty protects the initial investment against unforeseen defects. Businesses should clarify the terms of the warranty, as coverage details are critical.

- Standard Period: Most new snack packing machines come with a 1 to 2-year warranty.

- Coverage: The warranty typically covers manufacturing defects in key areas like electrical components, mechanical parts, and control systems. It does not cover normal wear and tear.

Beyond the warranty, a business must confirm the supplier's policy on spare parts. A reliable supplier maintains a ready stock of critical components and can ship them quickly, ensuring that repairs happen with minimal delay.

Selecting the right equipment is a strategic decision that impacts long-term success. A business must carefully evaluate its product, production needs, packaging, machine features, budget, and supplier support. This thorough review prevents costly mistakes and secures benefits like reduced labor costs and packaging waste. Companies should use this checklist as a guide to ask suppliers detailed questions. This ensures the chosen packing machine for snacks aligns perfectly with their operational goals and supports future growth.

FAQ

What is a VFFS machine?

A Vertical Form Fill Seal (VFFS) machine is a popular packaging solution. It creates bags from a flat roll of film, fills them with product from above, and then seals them. This automated process is highly efficient for producing pillow pouches and other flexible bag styles.

How can a business reduce product giveaway?

A business reduces product giveaway by using a high-precision weighing system. Multi-head weighers accurately measure the snack for each package. This precision minimizes overfilling, which directly protects profit margins and ensures compliance with net weight regulations. Investing in accuracy saves money over time.

Why is stainless steel important for a packing machine?

Stainless steel is the industry standard for food contact surfaces. It offers excellent durability and resistance to corrosion. Its smooth, non-porous surface is also easy to clean and sanitize. This build quality ensures food safety and extends the machine's operational lifespan significantly.

Should a startup buy a high-speed machine?

Startups should carefully evaluate their needs. A high-speed machine may be an unnecessary expense if production volume is low. An entry-level or mid-range machine often provides a better return on investment. Businesses should choose equipment that matches their current output and allows for moderate future growth.

See Also

Essential Industrial Checkweighers: Top Three for Every Food Processing Plant

Key Capsule Checkweighers for Buyers to Evaluate in the Year 2025

Exploring Trending Folder Gluer Features for 2025 Carton Packaging Lines

Discovering Optimal Locations to Purchase X-Ray Inspection Machines in China

Understanding Pharmaceutical Checkweighers: Definition and Crucial Operational Features