The Essential Checklist for Buying a Kibble Optical Sorter

The global pet food market shows robust expansion, reflecting high consumer expectations for quality and safety.

| Metric | Value |

|---|---|

| Global Pet Food Market Size (2023) | USD 103.3 Billion |

| Projected Market Size (2030) | USD 139.29 Billion |

| CAGR (2024-2030) | 4.4% |

Key industry drivers include:

- Increasing pet ownership and humanization

- Rising awareness of pet health and nutrition

- Technological advancements in production

Manufacturers must meet these demands. A dry kibble optical sorter is a critical tool for protecting brand integrity. Choosing the right machine requires evaluating its detection technology, operational integration, and overall financial value.

Checklist Item 1: Technical Specifications & Defect Detection

The core function of a dry kibble optical sorter is its ability to see and remove unwanted materials. A manufacturer's first step is to scrutinize the machine's technical capabilities. This ensures the sorter can handle the specific challenges of a production line, from color variations to foreign material contamination.

Verify Camera and Sensor Technology

Different defects require different detection methods. Manufacturers must match the sorter's sensors to their potential contaminants.

- Full-Color (RGB) Cameras: These are essential for identifying color defects, such as over-toasted or under-cooked kibble and cross-contaminated pieces from other product runs.

- Near-Infrared (NIR) Sensors: NIR technology detects contaminants based on their chemical composition, making it effective for finding plastics, rubber, or other foreign materials that may share a color with the kibble.

- Hyperspectral Imaging: This advanced technology combines hundreds of spectral bands to create a unique "fingerprint" for every object, enabling the detection of the most challenging foreign materials.

Assess Resolution and Minimum Defect Size

A sorter's effectiveness depends on its ability to see small imperfections. High-resolution cameras are critical for quality assurance. Modern systems utilize CCD cameras with over 5400 pixels, achieving optical resolutions finer than 0.15mm.

Tip: Always ask for the minimum detectable defect size. Leading sorters can reliably identify foreign bodies and product flaws as small as 0.3 x 0.3 mm, ensuring even tiny contaminants are removed.

Evaluate Ejection System Precision and Speed

Detecting a defect is only half the battle; removing it is the other. The ejection system uses targeted air jets to remove contaminants from the product stream. The response time of these ejectors is crucial. Advanced systems feature maglev ejectors with response times as fast as 0.8 milliseconds, while others use intelligent valves that react in just 0.05 milliseconds. A faster response minimizes the unnecessary rejection of good products, maximizing yield.

Analyze Software and AI Sorting Capabilities

The "brain" of the sorter is its software. Modern systems use sophisticated algorithms and artificial intelligence to improve sorting accuracy. For example, some technologies use multi-sensor Pixel Fusion™ to combine data from different cameras, creating a more detailed analysis. Others employ innovative ejection and tracking algorithms to reduce false rejects. These intelligent systems learn over time, continuously improving their ability to distinguish between good kibble and subtle defects.

Checklist Item 2: Operational Integration & Production Efficiency

A technologically advanced sorter is only effective if it integrates seamlessly into a facility's existing operations. Manufacturers must evaluate how the machine will impact production flow, operator workload, and sanitation protocols to maximize its value.

Match Throughput Capacity to Your Line Speed

A sorter must keep pace with production. Manufacturers should verify the machine's throughput, typically measured in tons per hour, to ensure it aligns with their line speed. A sorter with insufficient capacity creates a bottleneck, slowing down the entire operation. Conversely, an oversized machine represents an unnecessary capital expense. The goal is to find a balanced solution that meets current and projected production demands.

Confirm Physical Footprint and Installation Needs

Space is a premium in any processing plant. Before purchasing, a company must confirm the machine's dimensions and weight to ensure it fits within the designated area. It is also vital to review installation requirements, including power supply, compressed air needs, and any necessary modifications to existing conveyors or platforms. Proper planning prevents costly delays during setup.

Test the Ease of Operation and User Interface

A complex interface can lead to operator error and downtime. An intuitive user interface (UI) empowers line workers to manage sorting processes efficiently. Key features to look for include:

- Large, bright touchscreens for clear visibility and simple programming.

- Real-time monitoring of the production line and sorting performance.

- The ability to instantly adjust defect and size tolerances.

- Performance reports that can be reviewed and exported for quality control.

Inspect for Hygienic Design and Ease of Cleaning

In pet food production, sanitation is non-negotiable. A well-designed dry kibble optical sorter facilitates quick and thorough cleaning, minimizing the risk of cross-contamination and microbial growth.

Hygienic Design Standard: Equipment should be constructed from corrosion-resistant materials like 304 stainless steel. All food-contact surfaces must be smooth and easily accessible, eliminating crevices where food particles could accumulate. This ensures compliance and protects product integrity.

Checklist Item 3: Evaluating a Dry Kibble Optical Sorter for ROI

An investment in a dry kibble optical sorter extends beyond the initial purchase price. A thorough financial evaluation considers the machine's long-term return on investment (ROI), the quality of supplier support, and the total cost of ownership. This ensures the chosen equipment delivers sustained value and operational reliability.

Compare Initial Purchase Price vs. Long-Term ROI

A lower initial price can be tempting, but true value lies in the long-term financial gains. A high-performance sorter generates ROI by improving product quality and operational efficiency. Key financial benefits include:

- Reduced Waste: Early removal of substandard items conserves usable product.

- Higher Efficiency: Automated inspection accelerates production and lowers labor costs.

- Consistent Quality: Delivering uniform, high-grade goods strengthens customer and retailer trust.

- Regulatory Compliance: The machine helps meet standards from agencies like the USDA and EFSA, avoiding costly penalties.

These factors combine to protect revenue, reduce operational expenses, and enhance brand reputation, justifying a higher initial investment.

Inquire About Training and Technical Support

Effective operation depends on well-trained staff. Suppliers should offer comprehensive training programs that empower operators and maintenance personnel. These programs often include classroom instruction and hands-on practice covering UI navigation, component replacement, and preventative maintenance.

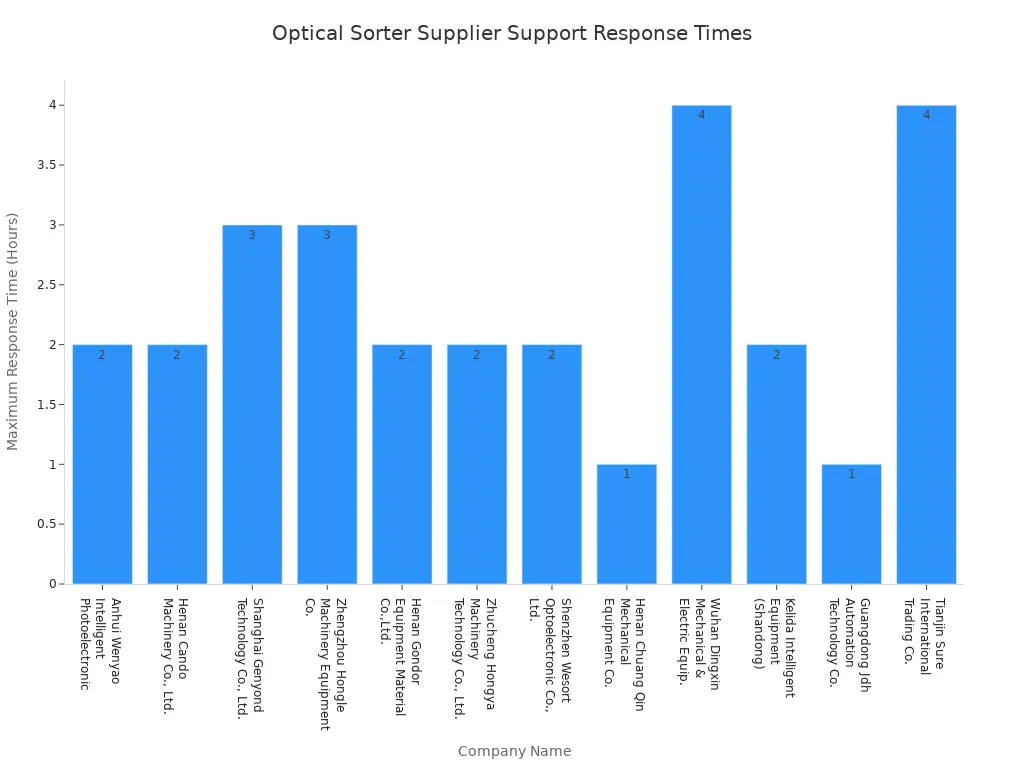

Equally important is the supplier's technical support. Downtime is expensive, so rapid assistance is critical. Industry benchmarks show that leading suppliers offer response times of four hours or less, with many achieving response times under two hours.

Check Spare Parts Availability and Cost

Even the most reliable machines require maintenance. A manufacturer must verify the availability and cost of critical spare parts. Inquire about the supplier's inventory levels, lead times for delivery, and the cost of common wear-and-tear components like ejector valves and lamps. A supplier with a well-stocked and affordable parts inventory minimizes potential downtime and keeps maintenance budgets predictable.

Demand a Product Trial with Your Kibble

Theoretical performance means little without real-world validation. The most crucial step is to demand a product trial using your specific kibble.

Actionable Tip: Provide the vendor with samples of your good product along with known defects, such as over-toasted pieces, cross-contaminants, and foreign materials. This allows you to witness the sorter's performance firsthand and confirm it meets your quality standards before making a final commitment.

Checklist Item 4: Ensuring Compliance and Future-Proofing

A forward-thinking purchase strategy involves more than just current performance. Manufacturers must verify that a dry kibble optical sorter meets today's safety standards and can adapt to tomorrow's technological advancements. This ensures long-term value and protects the investment.

Confirm Compliance with Food Safety Standards

Adherence to food safety regulations is non-negotiable. The equipment must be designed and certified to meet global and regional standards, protecting both pets and brand reputation. A manufacturer should confirm the sorter complies with multiple key standards.

- FDA (Food and Drug Administration) and USDA (United States Department of Agriculture)

- GFSI (Global Food Safety Initiative) schemes like BRCGS and IFS

- CE (European Conformity) marking for European market access

- ISO 9001 for quality management systems

Compliance helps satisfy requirements under laws like the Food Safety Modernization Act (FSMA).

Assess Modularity and Upgradeability

Technology evolves rapidly. A modular design allows a sorter to grow with a business. This flexibility enables future hardware swaps, such as adding new cameras, lenses, or lighting systems to handle different products. Some systems also offer software-license upgrades to unlock advanced features like deep-learning algorithms without requiring new hardware. This approach ensures the machine remains a state-of-the-art asset for years.

Review Data Reporting and Traceability Features

Modern sorters are powerful data collection tools. They generate detailed reports on quality and performance, including defect rates, throughput volumes, and images of rejected items.

For complete traceability, the sorter should integrate with the plant's Manufacturing Execution System (MES). This connection allows real-time data sharing, creating a comprehensive record of product quality from raw material to finished goods.

Understand Warranty and Service Level Agreements

A strong warranty reflects a supplier's confidence in their equipment. Standard warranties typically range from one to three years and may cover specific components like optical sensors. A buyer must clarify what the warranty includes, such as parts, labor, and software updates. A formal Service Level Agreement (SLA) should also be reviewed to define expectations for response times and ongoing support, guaranteeing operational continuity.

Making a confident purchasing decision requires a systematic evaluation of technical specifications, operational integration, and total cost of ownership.

Use this checklist as a non-negotiable tool when engaging with vendors. It ensures a comprehensive, side-by-side comparison for a clear choice.

Selecting the right equipment is an investment that protects brand reputation and secures a strong return.

FAQ

What are the most common defects an optical sorter finds in dry kibble?

Sorters identify color variations like over-toasted pieces. They also detect cross-contamination from other product lines and remove foreign materials such as plastic, wood, and metal fragments.

Why does a manufacturer need both color and NIR sensors?

Color cameras find visual flaws like burnt kibble. NIR sensors detect foreign materials based on chemical composition, identifying contaminants that may have the same color as the product.

How important is a product trial before purchasing?

A product trial is essential. It provides real-world proof of the sorter's ability to detect a manufacturer's specific defects, confirming its performance and suitability before investment.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality and Defect Elimination

Top Capsule Checkweighers for 2025: A Buyer's Guide to Precision Weighing

Crucial Industrial Checkweighers: Three Must-Have Systems for Every Food Processing Plant

Tablet Sampling Machines: An Essential Guide for Optimal Laboratory Equipment Selection

Pharmaceutical Checkweighers: Understanding Key Features for Accurate Drug Product Weighing