Navigating the Market A Guide to Shrimp Optical Sorters

The global shrimp processing market shows significant growth, a trend confirmed by multiple industry analyses.

| Source | Market Size 2024 (USD Billion) | Market Size 2025 (USD Billion) | CAGR (Forecast Period) |

|---|---|---|---|

| Straits Research | 49.63 | 53.91 | 9.5% (2025-2033) |

| Grand View Research | 75.24 | 79.23 | 5.5% (2025-2033) |

| SkyQuest | 79.59 | 84.13 | 5.7% (2026-2033) |

This expansion pressures processors to optimize operations. A high-performance shrimp optical sorter is crucial for meeting this demand. It enhances product quality, maximizes yield, and ensures consistency. A careful evaluation of technology and cost leads to a confident purchasing decision and a strong return on investment.

Assessing Your Core Sorting Needs

Before evaluating specific models, a processor must first conduct a thorough internal assessment. This foundational step ensures the selected shrimp optical sorter aligns perfectly with production realities and quality standards. A clear understanding of your product and operational scale is paramount.

Define Your Product and Defects

A precise definition of an acceptable product is the starting point for any sorting strategy. Processors must identify every type of imperfection that could lead to product rejection. A defect is any fault or deviation from quality specifications. Common issues range from processing errors to biological variations.

Key defects to target include:

- Shell Fragments: Pieces of shell that remain attached after peeling.

- Discoloration: Issues like melanosis (black spots), black head, or black gill.

- Foreign Material: Contaminants such as sand, gravel, or other non-shrimp matter.

- Other Imperfections: Soft shells, broken pieces, decomposition, or incorrect species.

Determine Required Throughput and Capacity

Throughput measures the volume of shrimp a sorter can process in a given time, usually in tons per hour. This metric must match or exceed your line's processing speed. A faster production line requires a sorter with a higher capacity to prevent bottlenecks and maintain a continuous product flow.

Tip: Always plan for future growth. Select a sorter with a capacity that not only meets current needs but can also accommodate anticipated increases in production volume.

Typical sorter capacities vary. For example, some mid-range models offer significant throughput suitable for many operations.

| Parameter | Example Value |

|---|---|

| Model Type | 4-Chute Sorter |

| Throughput | 3–6 tons/hour |

| Power | 2.4kw |

| Air Consumption | <4.0m³/min |

Analyzing these core needs provides the essential data to begin comparing technology and financial factors effectively.

Key Technologies in a Shrimp Optical Sorter

Understanding the technology inside a shrimp optical sorter is essential for making an informed decision. Each system uses a combination of sensors and ejection mechanisms to identify and remove defects. The most effective sorters often integrate multiple technologies to achieve the highest level of accuracy and efficiency.

Camera Technology: Color, Shape, and Size

Cameras form the foundational layer of most optical sorting systems. They capture high-resolution images of each shrimp, analyzing them for visual imperfections. This technology excels at identifying defects based on color, shape, and size.

Advanced systems utilize Hyperspectral Imaging (HSI), which provides far more image information than the human eye or standard cameras. HSI extracts detailed color features, allowing it to detect subtle discoloration like melanosis (black spots) even when these changes are not visually obvious. It can visualize shifts in color values, generating distribution maps that highlight quality changes across the shrimp's surface. This same imaging technology also analyzes textural features. By using methods like the Gray-Level Co-occurrence Matrix (GLCM), the system can identify variations in surface patterns, helping it detect physical anomalies such as small shell fragments.

Laser Sorters: Structural and Material Analysis

Laser technology provides a deeper level of inspection that complements camera-based sorting. While cameras see the surface, lasers can analyze the structural properties of an object. This capability is crucial for differentiating between shrimp meat and foreign materials that may have a similar color or transparency.

A laser sorter can distinguish between hard and soft materials. For example, a piece of shell might be the same color as shrimp meat, but the laser detects its hard texture and flags it for removal. This makes lasers highly effective at identifying impurities that cameras might miss. Key properties that laser sorters can analyze include:

- Texture: The system can measure texture variables like contrast, correlation, energy, and homogeneity. These metrics help identify foreign objects or shrimp with poor texture.

- Moisture Content: Lasers analyze spectral information influenced by chemical bonds. This allows the sorter to indirectly determine a shrimp's water content, a key indicator of freshness and quality.

X-ray Inspection: Density-Based Detection

X-ray inspection is the ultimate safeguard against high-density foreign materials. This technology works by passing low-energy X-rays through the product. A detector on the other side creates a grayscale image based on density. Denser materials, like metal or stone, appear darker and are easily identified for ejection.

X-ray systems are indispensable for finding hazardous contaminants that other technologies cannot detect. Common materials an X-ray system can identify include:

- Metal fragments (hooks, wire, staples)

- Glass shards

- Stones and ceramics

- High-density plastics and rubber

- Bone or cartilage

Compliance is Key: X-ray inspection equipment must adhere to strict safety and food processing standards. Processors should ensure any system they consider complies with global initiatives like HACCP, BRCGS, and SQF. These standards mandate regular calibration, validation, and documentation to ensure the equipment operates safely and effectively. Safety features like radiation shielding, interlocked access panels, and warning lights are non-negotiable.

Ejection Systems: Precision vs. Speed

The final step in the sorting process is ejection. Once the sensors identify a defect, the ejection system physically removes it from the product stream. These systems typically use compressed air jets to target and expel unwanted items. The primary challenge is balancing precision with speed.

A well-designed ejection system minimizes the accidental removal of good shrimp, a factor known as "good-in-bad." This is achieved through:

- High-Speed Air Valves: Modern systems use small, powerful air nozzles that can fire with extreme speed and accuracy.

- Intelligent Targeting: The sorter's software calculates the exact location and trajectory of the defect. It then activates the specific air jet needed to remove only that item.

- Product Stabilization: A stable and consistent product flow on the conveyor belt allows for more precise targeting, reducing the chance of ejecting adjacent good shrimp.

By maximizing precision, a sophisticated ejection system protects product yield and boosts profitability. It ensures that only true defects are removed, preserving the valuable product.

Evaluating Operational and Financial Factors

An investment in advanced sorting technology extends beyond the initial purchase price. A thorough evaluation of operational and financial factors is critical to ensure the chosen system delivers long-term value. Processors must analyze the day-to-day usability, maintenance requirements, and overall financial impact to select a machine that is both effective and profitable.

Ease of Use and Software Interface

A powerful sorter is only effective if operators can use it efficiently. The software interface is the primary point of interaction between the operator and the machine. An intuitive, user-friendly interface reduces the learning curve, minimizes operator errors, and allows for quick adjustments during production runs.

Key features of a strong software interface include:

- Graphical User Interface (GUI): A clear, visual layout helps operators understand sorting parameters and performance at a glance.

- Pre-set Programs: The ability to save and load settings for different shrimp types or quality grades streamlines product changeovers.

- Real-time Feedback: Live data on defect rates and machine performance enables immediate process optimization.

- Remote Access: Some systems allow technicians to diagnose issues and adjust settings remotely, reducing downtime.

Note: A complex interface can become a production bottleneck. During a product demonstration, processors should have their own operators test the software to gauge its real-world usability.

Hygiene, Maintenance, and Durability

Shrimp processing environments are harsh. Constant exposure to water, salt, and cleaning agents demands equipment built for durability and sanitation. The design of a shrimp optical sorter directly impacts cleaning efficiency, maintenance downtime, and overall operational lifespan.

Processors should look for machines with:

- Stainless Steel Construction: High-grade stainless steel resists corrosion and is easy to clean.

- IP65 Rating or Higher: This rating ensures the machine is protected against dust and low-pressure water jets from any direction, which is essential for washdown procedures.

- Tool-less Disassembly: Components that can be removed without tools, such as belts and light fixtures, simplify cleaning and routine maintenance.

- Open-Frame Design: An accessible design eliminates hidden areas where product residue and bacteria can accumulate, supporting HACCP compliance.

Regular maintenance is crucial for consistent performance. A well-designed machine facilitates quick and easy access to key components, minimizing downtime and keeping the production line moving.

Calculating Total Cost of Ownership (TCO)

The initial purchase price is just one part of the total investment. The Total Cost of Ownership (TCO) provides a more comprehensive financial picture by accounting for all expenses over the machine's life. A lower initial price can be misleading if the machine has high ongoing costs.

The initial investment for optical sorting systems is high and includes the purchase of the equipment, installation, and training. These factors contribute significantly to the upfront costs. However, a complete TCO calculation must also include recurring expenses.

Key components of TCO include:

- Purchase Price: The upfront cost of the machine.

- Installation and Training: Professional setup and staff education are essential for proper operation.

- Energy Consumption: A typical sorter uses an average of 3–7 kW/h, which contributes to daily operational costs.

- Spare Parts and Maintenance: These costs average 5–8% of the machine's price annually.

- Software Fees: Some systems require annual licensing for content management software.

- Downtime Risks: The potential cost of lost production if the machine fails.

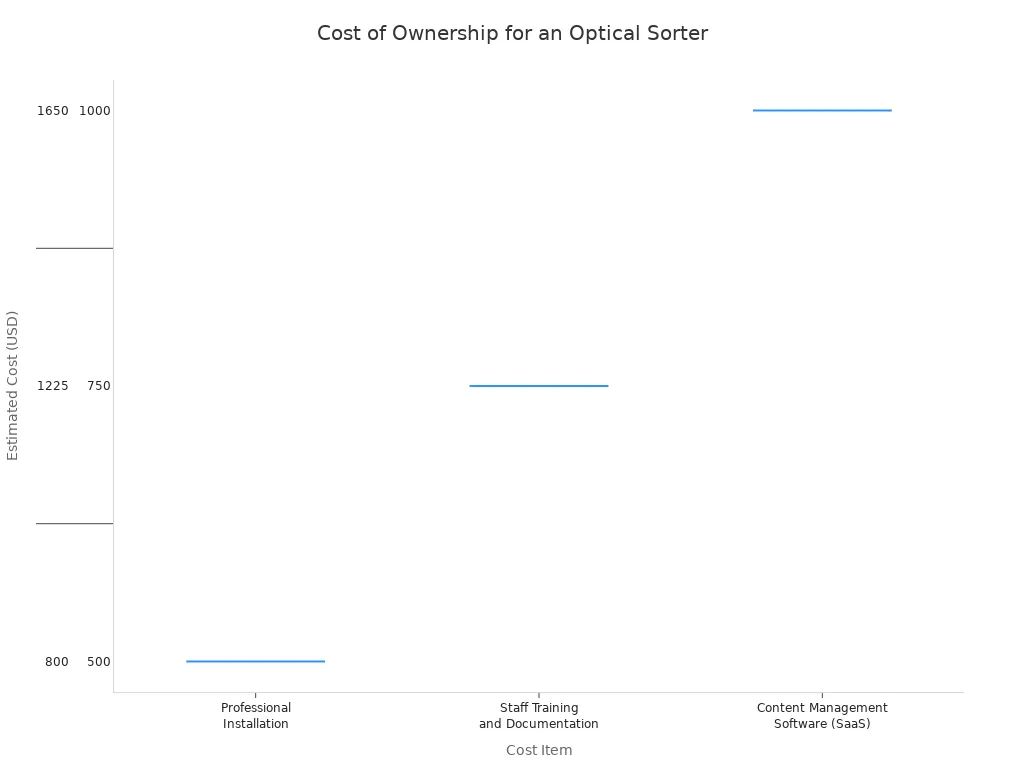

The table below outlines some of the additional costs that processors must factor into their TCO analysis.

| Cost Category | Item | Estimated Range (Extrapolated) |

|---|---|---|

| Initial Costs | Professional Installation | $800 - $2,500 |

| Staff Training and Documentation | $500 - $1,500 | |

| Ongoing Annual Costs | Content Management Software (SaaS) | $1,200 - $3,600 annually |

A thorough TCO calculation helps processors compare different models on a level playing field, revealing the most financially sound option over the long term.

Analyzing Return on Investment (ROI)

Return on Investment (ROI) measures the profitability of the sorter. It calculates how quickly the machine will pay for itself through cost savings and increased revenue. For most processing plants, the ROI for sorting technology is typically realized within 1-3 years, with many achieving payback in 18 to 2.5 months.

Automation is a primary driver of ROI. Optical sorters boost throughput while reducing the need for manual labor. This allows workers to move to more value-added roles and helps mitigate the impact of labor shortages.

Key factors that accelerate ROI include:

- Reduced Labor Costs: Automated systems require fewer operators, leading to significant savings on wages.

- Increased Product Yield: Precise ejection systems minimize the removal of good product, increasing the amount of sellable shrimp from the same input. This higher yield can be significant enough to pay off the initial investment.

- Enhanced Product Quality: Advanced sorters achieve higher material purity rates. This produces a more valuable final product that can command premium prices in the market.

By quantifying these benefits, processors can build a strong business case for investing in an optical sorter and forecast its positive impact on the bottom line.

Making Your Final Decision

Selecting the right equipment requires a structured approach. Processors should move from broad analysis to specific details, ensuring the final choice aligns with both operational needs and financial goals. This final phase involves detailed verification, hands-on testing, and confirming long-term support.

The Essential Buyer's Checklist

A buyer's checklist helps processors systematically compare different models. This tool should list critical technical specifications to ensure an objective evaluation. Key parameters include throughput rate, sorting accuracy, and energy consumption. For example, one model may offer a sorting speed of 170 products per minute with an accuracy of ±1% for larger shrimp. Processors must compare these figures against their own production targets. Comparing a cost-effective base model against a pro model with a 30% higher throughput rate helps clarify which machine best fits the operational scale.

Requesting a Product Demonstration

A product demonstration provides undeniable proof of a sorter's capabilities. Processors should insist on testing the machine with their own product to measure real-world performance. The primary goal is to verify sorting accuracy and product recovery rates, which should exceed 95% for food-grade applications. A successful test reveals how effectively the machine removes defects like shell fragments or discoloration while minimizing the rejection of good shrimp.

One processor noted that a high-performance sorter allowed them to reallocate four workers per shift. They also increased yield by reducing the volume of good product in the reject stream by 35 percent.

Verifying After-Sales Support and Warranty

A sorter is a long-term investment, making after-sales support a critical factor. Processors should confirm the manufacturer's warranty terms, which typically cover critical components for 12 to 24 months. Beyond the warranty, responsive technical support is essential for maximizing uptime. Leading suppliers offer 24/7 technical hotlines for urgent assistance. They also ensure genuine OEM spare parts are readily available, with some guaranteeing same-day or overnight shipping to keep production lines running smoothly.

Selecting the right shrimp optical sorter is a strategic investment in quality, safety, and profitability. A well-chosen machine enhances a brand's reputation by delivering a consistently superior product.

Contact our experts to discuss your specific sorting needs and find the perfect solution for your production line.

FAQ

How does an optical sorter improve shrimp safety?

The sorter identifies and ejects hazardous foreign materials. This process removes contaminants like metal, glass, and stones, ensuring a safer final product for consumers and protecting brand integrity.

Can one sorter handle different shrimp species or sizes?

Yes. Operators can save and load pre-set sorting parameters. This feature allows quick changeovers between different shrimp species, sizes, or quality grades with minimal production downtime.

What technology best detects shell fragments?

Laser sorters excel at this task. They analyze structural properties and can distinguish hard shell fragments from soft shrimp meat, even if the materials share a similar color.

See Also

Capsule Sorters: Essential Devices for Efficient Pharmaceutical Defect Elimination

Tablet Sampling Machines: A Comprehensive Guide for Optimal Laboratory Selection

Top Capsule Checkweighers: Essential Considerations for Buyers in the Coming Year

Sterile Filter Devices: Demystifying Their Functionality and Operational Principles

Plate Heat Exchangers: A Detailed Walkthrough of Their Operational Mechanics